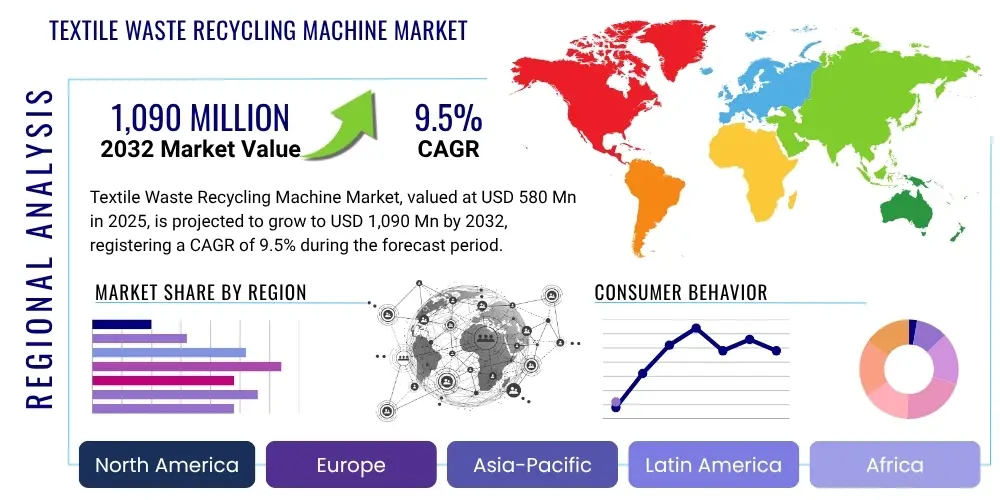

Textile Waste Recycling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430899 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Textile Waste Recycling Machine Market Size

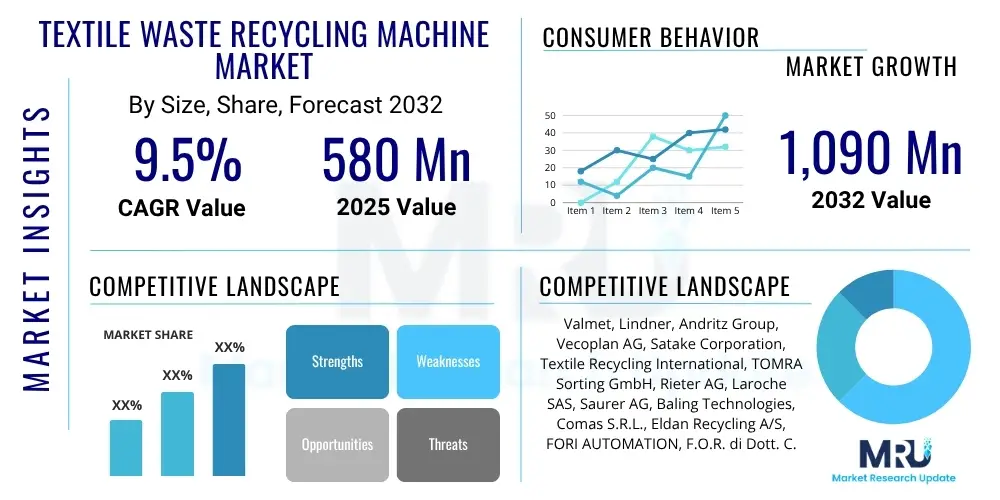

The Textile Waste Recycling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at $580 Million in 2025 and is projected to reach $1,090 Million by the end of the forecast period in 2032.

Textile Waste Recycling Machine Market introduction

The Textile Waste Recycling Machine Market addresses the escalating global issue of textile waste by providing essential equipment for processing discarded textiles into reusable materials. These machines encompass a range of technologies designed to shred, open, clean, and re-spin textile fibers, facilitating their reintegration into the production cycle. Products include mechanical shredders, fiber openers, carding machines, and chemical recycling systems, which transform pre and post-consumer textile waste into secondary raw materials like recycled fibers, yarns, and insulation. The major applications span across the apparel industry, home textiles, automotive sector, and the production of non-woven fabrics.

The primary benefits of these machines are manifold, including significant reductions in landfill waste, conservation of natural resources such as water and energy, and a substantial decrease in the carbon footprint associated with new textile production. They also offer economic advantages by providing a cost-effective alternative to virgin materials, mitigating the impact of raw material price volatility. The market is primarily driven by stringent environmental regulations, growing consumer demand for sustainable and circular products, and corporate sustainability commitments from major fashion and textile brands. Advancements in recycling technologies, coupled with increasing investments in waste management infrastructure, further propel market expansion. The circular economy model, which promotes resource efficiency and waste minimization, forms the foundational thrust for the widespread adoption of textile waste recycling machines.

Textile Waste Recycling Machine Market Executive Summary

The global Textile Waste Recycling Machine Market is experiencing robust growth, propelled by a confluence of environmental pressures, regulatory mandates, and shifting consumer preferences towards sustainable products. Key business trends indicate a strong emphasis on automation, the integration of smart technologies for enhanced sorting and processing, and the formation of strategic partnerships across the textile value chain to create efficient closed-loop systems. Manufacturers are increasingly investing in research and development to improve machine efficiency, versatility, and the quality of recycled outputs, addressing the complexities of diverse textile blends.

From a regional perspective, Asia Pacific continues to dominate the market, largely due to its extensive textile manufacturing base and increasing awareness and investment in sustainable practices. Europe is a significant growth hub, driven by stringent environmental regulations, ambitious circular economy targets, and strong governmental support for recycling initiatives. North America also shows considerable growth, fueled by brand commitments to sustainability and technological advancements in textile recycling. These regions collectively represent the forefront of innovation and adoption in textile waste management.

Segment trends reveal a continued prevalence of mechanical recycling technologies due to their maturity and cost-effectiveness, though chemical recycling is rapidly gaining traction as it offers higher quality outputs suitable for diverse applications. The demand for machinery capable of processing polyester and cotton blends, particularly for apparel and home furnishing applications, is notably high. The market is also seeing increased demand for scalable solutions, from small-capacity machines for localized recycling efforts to large industrial systems for mass processing, reflecting a dynamic and evolving landscape aimed at maximizing resource recovery.

AI Impact Analysis on Textile Waste Recycling Machine Market

User inquiries concerning AI's influence on the Textile Waste Recycling Machine Market frequently revolve around how artificial intelligence can enhance sorting accuracy, optimize operational efficiency, improve the quality of recycled materials, and contribute to overall process automation. The key themes highlight expectations for AI to solve complex challenges such as identifying and separating mixed fiber types, predicting maintenance needs for machinery, and providing real-time data analytics to streamline the recycling workflow. There is a strong interest in AI's potential to elevate the capabilities of existing recycling technologies and unlock new avenues for sustainable textile waste management.

- Enhanced sorting accuracy for mixed textile waste through AI-powered optical recognition and material identification.

- Optimization of machine parameters and operational efficiency via predictive analytics and machine learning algorithms.

- Improved quality control of recycled fibers by continuous monitoring and adjustment based on AI-driven insights.

- Predictive maintenance for recycling machinery, reducing downtime and operational costs.

- Automation of complex tasks, such as untangling and pre-processing, leading to higher throughput and reduced manual labor.

- Better resource allocation and supply chain management through AI-driven forecasting of textile waste streams.

DRO & Impact Forces Of Textile Waste Recycling Machine Market

The Textile Waste Recycling Machine Market is shaped by a multifaceted array of drivers, restraints, and opportunities, all underpinned by significant impact forces. Key drivers include the global push for sustainability, increasing environmental regulations on textile waste disposal, and the growing demand from brands and consumers for products made from recycled content. Resource scarcity and the volatile pricing of virgin raw materials also compel manufacturers to seek alternative, sustainable inputs, thereby boosting the adoption of recycling machinery. These factors collectively create a strong incentive for investment in textile waste management technologies.

However, the market faces several restraints that could impede its growth. High initial capital investment required for advanced recycling machinery and infrastructure represents a significant barrier, particularly for smaller enterprises. Technological limitations, such as the difficulty in efficiently separating complex textile blends or effectively depolymerizing certain synthetic fibers, remain a challenge. Furthermore, the logistical complexities of collecting, sorting, and transporting diverse textile waste streams on a large scale add to operational costs and hinder widespread implementation. The varying quality and consistency of collected textile waste also pose a technical challenge for uniform recycling processes.

Opportunities for market expansion are abundant, particularly in emerging economies where industrialization and consumerism are rapidly increasing textile waste generation, creating a demand for new recycling solutions. Advancements in chemical recycling technologies, which can produce virgin-like fibers from textile waste, present a significant growth avenue. The development of collaborative ecosystems involving waste collectors, recyclers, textile manufacturers, and brands can streamline the entire circular economy process. Moreover, governmental incentives, subsidies, and public-private partnerships focused on circular textile initiatives further amplify market potential and attract investments into the sector. The ongoing innovation in sensor-based sorting and AI-driven process optimization also offers substantial opportunities for improved efficiency and product quality.

Segmentation Analysis

The Textile Waste Recycling Machine Market is broadly segmented based on various attributes, including machine type, technology, application, and capacity. This segmentation helps in understanding the diverse product offerings and the specific needs of different end-users across the textile recycling value chain. Each segment caters to distinct aspects of textile waste processing, from initial preparation to the final conversion into reusable materials, reflecting the complex nature of textile recycling.

Understanding these segments is crucial for market participants to tailor their strategies, develop targeted products, and address specific market demands. The interplay between different machine types and technologies is particularly critical, as the choice often depends on the type of waste, desired output quality, and economic viability. Furthermore, the application and capacity segments define the scale and scope of recycling operations, from small-scale local initiatives to large industrial processing plants.

- By Machine Type:

- Shredding Machines

- Opening Machines

- Carding Machines

- Cutting Machines

- Baling Machines

- Cleaning Machines

- Other Processing Units (e.g., granulators, compactors)

- By Technology:

- Mechanical Recycling

- Chemical Recycling (e.g., solvent-based, enzymatic, pyrolysis)

- Thermal Recycling

- By Application:

- Apparel

- Home Furnishings

- Industrial Textiles (e.g., geotextiles, automotive textiles)

- Automotive

- Non-Wovens

- Building and Construction (e.g., insulation)

- Others (e.g., stuffing materials, composite reinforcement)

- By Capacity:

- Small Capacity Machines (Up to 100 kg/hour)

- Medium Capacity Machines (101 kg/hour to 500 kg/hour)

- Large Capacity Machines (Above 500 kg/hour)

Value Chain Analysis For Textile Waste Recycling Machine Market

The value chain for the Textile Waste Recycling Machine Market begins with upstream activities focused on the procurement of raw materials and components necessary for machine manufacturing. This segment primarily involves suppliers of high-grade steel, advanced motors, hydraulic systems, electronic controls, and specialized sensor technologies. Component manufacturers, often global leaders in industrial machinery parts, play a crucial role in providing reliable and durable elements that ensure the longevity and efficiency of the recycling machines. Additionally, research and development institutions contribute to the innovation and design of new machine functionalities and improved recycling processes.

Midstream activities involve the actual manufacturing, assembly, and testing of the textile waste recycling machines. This stage includes sophisticated engineering, precision fabrication, and quality assurance processes to build robust and efficient equipment. Machine manufacturers leverage their expertise in mechanical engineering, automation, and material science to produce a range of machines tailored for different textile waste types and recycling technologies. The direct interaction with potential clients often informs the customization and modular design of these machines, ensuring they meet specific operational requirements.

Downstream activities encompass the deployment and utilization of these machines by various end-users, leading to the production of recycled fibers and materials. This segment involves textile recycling facilities, garment manufacturers integrating recycled content, fiber producers, and companies specializing in non-woven fabrics or insulation materials. The distribution channels for textile waste recycling machines are typically a mix of direct sales, where manufacturers engage directly with large industrial clients, and indirect channels involving a network of distributors, agents, and local partners. These intermediaries provide sales support, installation services, technical training, and after-sales maintenance, which are critical for the effective operation and longevity of complex recycling machinery.

Textile Waste Recycling Machine Market Potential Customers

The primary purchasers and end-users of Textile Waste Recycling Machines span a diverse range of industries and organizations deeply invested in sustainable practices and resource recovery. These customers are driven by regulatory compliance, corporate social responsibility initiatives, and the economic benefits of reducing waste and sourcing recycled materials. The increasing global focus on circular economy models further broadens the customer base, attracting new entrants seeking to capitalize on sustainable opportunities.

Key potential customers include specialized textile recycling companies that collect, sort, and process various types of textile waste to produce secondary raw materials. Garment manufacturers and apparel brands are also significant buyers, as they increasingly aim to close their own material loops by recycling their pre-consumer waste and incorporating post-consumer recycled content into their products. Furthermore, fiber producers, particularly those involved in synthetic fiber manufacturing, invest in these machines to produce recycled polyester, nylon, and other fibers, reducing their reliance on virgin petrochemicals. Companies manufacturing home furnishings, automotive textiles, and non-woven products also represent a substantial customer segment, seeking recycled inputs for their diverse applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $580 Million |

| Market Forecast in 2032 | $1,090 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Valmet, Lindner, Andritz Group, Vecoplan AG, Satake Corporation, Textile Recycling International, TOMRA Sorting GmbH, Rieter AG, Laroche SAS, Saurer AG, Baling Technologies, Comas S.R.L., Eldan Recycling A/S, FORI AUTOMATION, F.O.R. di Dott. C. Rimondi & C. S.A.S., Huni Maschinenbau, Pallmann Maschinenfabrik GmbH & Co. KG, Picanol Group, Renewcell AB, Worn Again Technologies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Textile Waste Recycling Machine Market Key Technology Landscape

The technological landscape of the Textile Waste Recycling Machine Market is characterized by a continuous drive for innovation aimed at improving efficiency, material recovery rates, and the quality of recycled outputs. Mechanical recycling remains a foundational technology, involving processes such as shredding, cutting, tearing, and carding to break down textile waste into fibers without altering their chemical structure. Advances in mechanical systems focus on precision cutting, optimized fiber opening, and enhanced dust and contaminant removal, allowing for better quality control and broader applicability of mechanically recycled fibers in various products.

Chemical recycling technologies are emerging as a transformative force, capable of depolymerizing textile waste into its constituent monomers or oligomers, which can then be re-polymerized into new, virgin-like fibers. This category includes solvent-based dissolution, enzymatic degradation, and pyrolysis techniques. These advanced methods address the limitations of mechanical recycling, particularly for mixed fiber textiles, and enable a true circularity where textiles can be recycled repeatedly without significant loss of quality. Significant research and development efforts are focused on making these processes more energy-efficient, environmentally friendly, and commercially viable.

Furthermore, automation and digitalization are increasingly integral to modern textile recycling operations. Sensor-based sorting technologies, often powered by artificial intelligence and machine learning, are crucial for accurately identifying and separating different fiber types and colors in mixed textile waste streams. Robotic systems are being deployed for handling and feeding materials, reducing manual labor and improving consistency. Data analytics and IoT integration allow for real-time monitoring of machine performance, predictive maintenance, and process optimization, ensuring maximum operational efficiency and resource utilization across the entire recycling value chain. These technological advancements collectively contribute to making textile recycling more scalable, sustainable, and economically attractive.

Regional Highlights

- Asia Pacific: This region stands as the largest market due to its extensive textile manufacturing base and significant generation of textile waste. Countries like China, India, and Bangladesh are investing heavily in recycling infrastructure, driven by both domestic environmental concerns and the demand for recycled materials from global brands. The presence of a large labor force and evolving regulatory frameworks further support market growth, positioning APAC as a crucial hub for textile recycling machine adoption and innovation.

- Europe: Europe is a pioneering region in circular economy initiatives and boasts some of the most stringent environmental regulations concerning waste management. Countries such as Germany, Sweden, and the Netherlands are at the forefront of adopting advanced chemical recycling technologies and establishing comprehensive textile collection and sorting systems. Strong governmental support, significant investments in R&D, and a high level of consumer awareness regarding sustainability drive the demand for sophisticated textile waste recycling solutions.

- North America: The market in North America is growing steadily, propelled by increasing corporate sustainability commitments from major apparel brands and a rising consumer preference for eco-friendly products. The region is witnessing investments in innovative recycling startups and the integration of automation and AI in waste processing facilities. Focus areas include improving infrastructure for textile collection and developing efficient technologies for complex material separation, particularly in the United States and Canada.

- Latin America: This region presents emerging opportunities as countries like Brazil and Mexico address growing textile waste volumes from their developing economies and textile industries. While the market is still in its nascent stages compared to developed regions, increasing environmental awareness and the potential for economic benefits from resource recovery are expected to drive future investments in textile recycling machinery and infrastructure.

- Middle East and Africa (MEA): The MEA region is gradually increasing its focus on textile waste management, driven by economic diversification efforts and growing environmental consciousness. Countries in the UAE and South Africa are exploring sustainable solutions for industrial and post-consumer textile waste. Investments are primarily in basic mechanical recycling technologies, with a growing interest in more advanced systems as regulatory frameworks and economic incentives develop.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Textile Waste Recycling Machine Market.- Valmet

- Lindner

- Andritz Group

- Vecoplan AG

- Satake Corporation

- Textile Recycling International

- TOMRA Sorting GmbH

- Rieter AG

- Laroche SAS

- Saurer AG

- Baling Technologies

- Comas S.R.L.

- Eldan Recycling A/S

- FORI AUTOMATION

- F.O.R. di Dott. C. Rimondi & C. S.A.S.

- Huni Maschinenbau

- Pallmann Maschinenfabrik GmbH & Co. KG

- Picanol Group

- Renewcell AB

- Worn Again Technologies

Frequently Asked Questions

Common user questions about the Textile Waste Recycling Machine market frequently address its growth trajectory, the underlying drivers, the types of technologies involved, and the key benefits of adopting these systems. Concerns often include investment costs and the challenges associated with recycling diverse textile waste streams effectively.What is the projected growth rate of the Textile Waste Recycling Machine Market?

The Textile Waste Recycling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032, reaching an estimated value of $1,090 Million by 2032.

What are the main drivers for the Textile Waste Recycling Machine Market?

Key drivers include stringent environmental regulations, increasing consumer demand for sustainable products, corporate sustainability commitments, and the need to reduce landfill waste and conserve natural resources.

What types of technologies are used in textile waste recycling machines?

The market primarily utilizes mechanical recycling (shredding, opening, carding) and chemical recycling (solvent-based, enzymatic, pyrolysis) technologies, often augmented by AI-powered sorting and automation.

Who are the primary customers for textile waste recycling machines?

Primary customers include specialized textile recycling companies, garment manufacturers, fiber producers, and industries producing home furnishings, automotive textiles, and non-woven products seeking sustainable inputs.

What are the main challenges faced by the textile waste recycling machine market?

Major challenges include high initial investment costs, technological limitations in separating complex textile blends, logistical complexities in waste collection, and variations in the quality of textile waste inputs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager