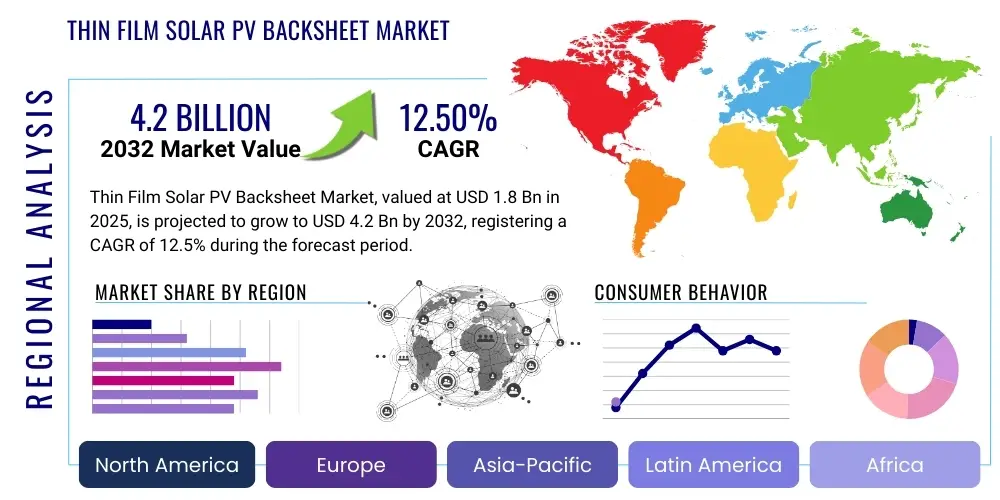

Thin Film Solar PV Backsheet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427673 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Thin Film Solar PV Backsheet Market Size

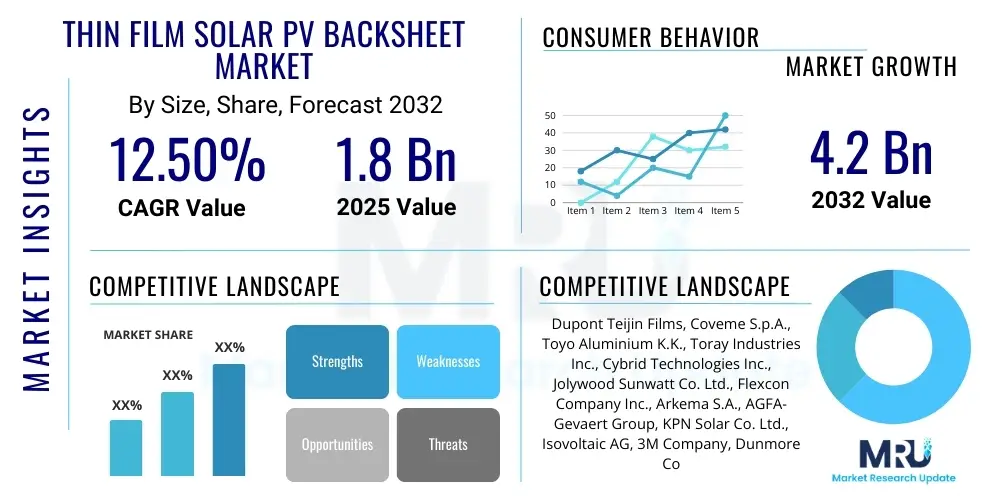

The Thin Film Solar PV Backsheet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2025 and 2032. The market is estimated at USD 1.8 billion in 2025 and is projected to reach USD 4.2 billion by the end of the forecast period in 2032.

Thin Film Solar PV Backsheet Market introduction

The Thin Film Solar PV Backsheet Market is experiencing a period of significant growth, primarily fueled by the accelerating global transition towards renewable energy and the increasing adoption of thin-film solar technologies across diverse applications. Thin film PV backsheets are critical components in solar module manufacturing, designed to provide robust protection to the delicate photovoltaic cells against a myriad of environmental stressors. These stressors include moisture penetration, ultraviolet (UV) radiation, extreme temperatures, and mechanical damage, all of which can severely impact module performance and longevity. The fundamental purpose of a backsheet is to ensure the long-term reliability and operational safety of thin-film solar panels, acting as a crucial barrier that extends the service life of these high-efficiency energy solutions.

Key applications for thin film solar PV backsheets span a broad spectrum of the solar industry. They are extensively used in utility-scale solar farms, commercial and industrial rooftop installations, and increasingly in specialized applications such as building-integrated photovoltaics (BIPV), portable solar devices, and flexible solar arrays. The inherent flexibility, lightweight nature, and enhanced durability offered by these backsheets make them particularly suitable for thin-film modules, which themselves are often chosen for their superior performance in diffuse light conditions, aesthetic integration, and suitability for non-traditional surfaces. The major benefits derived from high-quality thin film backsheets include improved module efficiency by preventing degradation, enhanced electrical insulation for safety, and significant resistance to delamination, which collectively contribute to a lower levelized cost of energy (LCOE) over the modules lifecycle. Driving factors for this markets expansion include supportive government policies and incentives for solar energy, continuous technological advancements in thin-film materials, and a growing consumer and industrial demand for sustainable and efficient energy solutions.

Thin Film Solar PV Backsheet Market Executive Summary

The Thin Film Solar PV Backsheet Market is characterized by dynamic business trends driven by global sustainability agendas and technological innovation. Key business trends include an increasing focus on developing advanced fluoropolymer-free backsheets to address environmental concerns and reduce manufacturing costs, alongside the rising adoption of multi-layer co-extruded backsheets for enhanced performance and durability. Strategic partnerships and collaborations between backsheet manufacturers and thin-film module producers are becoming more prevalent, aimed at optimizing material integration and accelerating product development cycles. Furthermore, the market is witnessing a shift towards localized manufacturing in key solar hubs to mitigate supply chain risks and cater to regional demands more effectively. Regional trends indicate robust growth in the Asia-Pacific region, particularly in China, India, and Southeast Asian countries, owing to extensive governmental support for solar energy projects and massive investments in renewable infrastructure. Europe and North America also exhibit significant market potential, driven by stringent environmental regulations, advanced technological adoption, and a strong emphasis on energy independence. Segment trends highlight a predominant share for PET-based backsheets due to their cost-effectiveness and proven performance, while innovative materials like PVDF and Tedlar continue to gain traction for their superior weatherability and longevity in harsh environments. The increasing demand for flexible and lightweight solar modules is also boosting the market for highly adaptable backsheet solutions, signaling a clear trajectory towards more specialized and high-performance product offerings across the value chain.

AI Impact Analysis on Thin Film Solar PV Backsheet Market

Artificial intelligence (AI) is poised to exert a transformative influence on the Thin Film Solar PV Backsheet Market, addressing user concerns related to material optimization, production efficiency, and predictive maintenance. Users frequently inquire about AIs capacity to enhance the durability and lifespan of backsheets, reduce manufacturing defects, and predict potential failures before they occur. There is significant interest in how AI can be leveraged for advanced material science, particularly in identifying novel polymer combinations or enhancing existing formulations to resist harsh environmental conditions more effectively, thereby extending module longevity and improving energy yield. Furthermore, users are keen to understand AIs role in optimizing the production process, from raw material inspection and quality control to the precise lamination and cutting of backsheets, ultimately leading to reduced waste and improved cost-efficiency. The expectation is that AI will enable a more data-driven approach to backsheet development and deployment, making solar modules more reliable and cost-effective over their entire operational lifespan, thereby accelerating global solar adoption.

The integration of AI in the thin film solar PV backsheet sector promises to revolutionize various stages of the product lifecycle, from initial design and material selection to manufacturing and post-installation monitoring. AI algorithms can analyze vast datasets pertaining to material properties, weather patterns, and module performance to predict optimal backsheet compositions that offer superior resistance to UV degradation, moisture ingress, and thermal stress. This data-driven material innovation can significantly reduce the traditional trial-and-error approach, leading to faster development cycles and the introduction of more robust, tailor-made backsheet solutions for specific climatic conditions. Moreover, AI-powered systems can enhance quality control throughout the manufacturing process, employing computer vision and machine learning to detect microscopic flaws or irregularities that human inspection might miss, ensuring that only high-quality backsheets proceed to module assembly. This proactive quality assurance minimizes defects, reduces scrap rates, and ensures consistent product performance, which is critical for long-term module reliability.

Beyond manufacturing, AI is also anticipated to play a crucial role in the operational phase of thin-film solar modules equipped with advanced backsheets. Predictive maintenance, powered by AI, can analyze data from installed solar arrays—including temperature, humidity, and irradiance—to monitor the health of backsheets in real-time. By identifying subtle changes or degradation patterns, AI can alert operators to potential issues such as delamination or cracking before they escalate, allowing for timely interventions that prevent costly failures and extend the operational life of the entire solar farm. This proactive approach not only optimizes energy generation but also reduces maintenance costs and improves the overall return on investment for solar projects. The ability of AI to provide deeper insights into backsheet performance under various field conditions will foster continuous improvement in product design and application, ultimately strengthening the resilience and efficiency of thin film solar technology.

- AI-driven material innovation accelerates the development of advanced backsheet formulations with enhanced durability and environmental resistance.

- Predictive analytics optimize manufacturing processes, reducing defects and waste through real-time quality control and process parameter adjustments.

- Machine learning algorithms enable sophisticated fault detection, identifying potential backsheet degradation or delamination early in the product lifecycle.

- AI-powered simulation tools allow for virtual testing of backsheet performance under various stress conditions, minimizing physical prototyping.

- Automated inspection systems using computer vision improve the accuracy and speed of quality checks for manufactured backsheets.

- Data analytics from deployed solar modules provide feedback for continuous improvement of backsheet design and material properties.

- Optimization of supply chain logistics for backsheet materials through AI-driven forecasting and inventory management.

DRO & Impact Forces Of Thin Film Solar PV Backsheet Market

The Thin Film Solar PV Backsheet Market is shaped by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the escalating global demand for renewable energy, particularly solar photovoltaics, propelled by international climate change agreements and national energy independence initiatives. The continuous reduction in the overall cost of thin-film solar module manufacturing, making them more competitive, further stimulates backsheet demand. Moreover, the increasing adoption of flexible and lightweight thin-film modules in niche applications like BIPV, portable electronics, and space-constrained installations significantly contributes to market growth. However, the market faces restraints such as the volatility of raw material prices, particularly for advanced polymers, which can impact manufacturing costs and product affordability. The relatively higher initial cost of high-performance backsheets compared to standard options, alongside the challenge of ensuring long-term durability in extremely harsh environments, also poses hurdles. Opportunities abound in the development of innovative, eco-friendly, and more durable backsheet materials, such as fluoropolymer-free and bio-based options, which can cater to growing environmental concerns and regulatory pressures. Furthermore, advancements in manufacturing technologies, including automation and economies of scale, offer avenues for cost reduction and enhanced production efficiency. The market is influenced by impact forces such as stringent environmental regulations promoting sustainable materials, technological advancements in polymer science, and competitive pricing pressures from traditional crystalline silicon PV backsheets. The ongoing research and development into new backsheet compositions that offer superior protection against module degradation and extended module lifetimes are paramount to sustaining market momentum.

Segmentation Analysis

The Thin Film Solar PV Backsheet Market is meticulously segmented based on various critical parameters, including material type, application, and end-use, to provide a comprehensive understanding of its intricate dynamics and evolving landscape. This segmentation allows for a granular analysis of market trends, consumer preferences, and technological advancements across different product categories and operational environments. The choice of backsheet material is pivotal, as it directly influences the durability, performance, and cost-effectiveness of thin-film solar modules, leading to distinct market segments based on the chemical composition and structural integrity of the backsheet layers. Similarly, the diverse applications of thin-film solar technology, ranging from large-scale utility projects to specialized flexible electronics, necessitate a clear segmentation to address the varied requirements and specifications of each segment. Understanding these segmentations is essential for stakeholders to identify lucrative opportunities, tailor product offerings, and devise effective market entry strategies that align with specific demands within the rapidly expanding solar energy sector.

The primary material types utilized for thin film solar PV backsheets include various polymers and their combinations, each offering distinct advantages in terms of mechanical strength, UV resistance, moisture barrier properties, and cost. The dominant materials include polyethylene terephthalate (PET), polyvinyl fluoride (PVF, commonly known as Tedlar), polyvinylidene fluoride (PVDF), and various multi-layer co-extruded films. The performance characteristics of these materials directly impact the lifespan and efficiency of thin-film modules, driving innovation towards materials that offer superior protection against environmental degradation while maintaining flexibility and cost-efficiency. This material-based segmentation is crucial for manufacturers to optimize their product portfolios and for purchasers to select the most appropriate backsheet for their specific project requirements and environmental conditions, ensuring long-term module reliability.

- By Material Type:

- Polyethylene Terephthalate (PET) Backsheets: Cost-effective, good electrical insulation, widely used for general-purpose applications.

- Polyvinyl Fluoride (PVF / Tedlar) Backsheets: Excellent UV resistance, long-term weatherability, superior moisture barrier, preferred for high-performance and harsh environments.

- Polyvinylidene Fluoride (PVDF) Backsheets: High chemical resistance, good UV stability, suitable for demanding applications requiring robust protection.

- Multi-Layer Co-Extruded Backsheets: Customized layers offering combined benefits like enhanced adhesion, flexibility, and barrier properties.

- Other Advanced Polymer Backsheets (e.g., PP, EVA-free): Emerging materials focusing on specific properties like fluorine-free solutions, improved thermal performance, or enhanced adhesion.

- By Application:

- Utility-Scale Solar Farms: Large-scale ground-mounted installations requiring high durability and long-term performance.

- Commercial & Industrial Rooftop Installations: Modules for commercial buildings, often requiring lightweight and flexible solutions.

- Building-Integrated Photovoltaics (BIPV): Aesthetically integrated solar elements in building materials, emphasizing flexibility and design compatibility.

- Flexible & Portable Solar Devices: Used in consumer electronics, automotive, and off-grid applications where lightweight and bendable characteristics are critical.

- Specialty Applications: Includes aerospace, marine, and other niche uses demanding specific environmental resistances.

- By End-Use:

- On-Grid Solar Installations: Connected to the national power grid, focusing on large-scale energy generation.

- Off-Grid Solar Installations: Independent systems for remote areas or specific power needs, prioritizing reliability and efficiency.

Thin Film Solar PV Backsheet Market Value Chain Analysis

The Thin Film Solar PV Backsheet Markets value chain encompasses a sophisticated sequence of activities, beginning with the sourcing of raw materials and extending to the final distribution channels for the finished product. Upstream analysis reveals the critical role of polymer resin manufacturers and chemical suppliers who provide the foundational materials such as PET, PVF, PVDF, and various additives. These suppliers are crucial for ensuring the quality, consistency, and cost-effectiveness of the primary materials used in backsheet production. The manufacturing stage involves intricate processes including film extrusion, lamination, and coating, where these raw materials are transformed into multi-layered backsheets with specific protective properties. The efficiency and technological sophistication of backsheet manufacturers are vital in this phase, as they influence the final products performance and cost structure. Downstream analysis focuses on the integration of these backsheets into thin-film solar modules by module assemblers and PV manufacturers. These entities are the primary direct customers, requiring backsheets that meet stringent performance and reliability standards for their final products. The distribution channel is multifaceted, comprising direct sales channels where backsheet manufacturers supply directly to large-scale module producers, and indirect channels involving distributors and agents who serve smaller manufacturers or specific regional markets. Both direct and indirect channels play a significant role in market penetration and ensuring timely delivery of specialized backsheet solutions to a diverse customer base globally.

Thin Film Solar PV Backsheet Market Potential Customers

The primary potential customers and end-users of thin film solar PV backsheets are diverse, reflecting the broad application spectrum of thin-film solar technology. At the forefront are large-scale thin-film solar module manufacturers, who procure backsheets as a critical component for their production lines. These manufacturers require high volumes of consistently high-quality backsheets that meet specific technical specifications for various module designs, including those for cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si) technologies. Beyond direct module manufacturers, companies specializing in building-integrated photovoltaics (BIPV) represent a growing customer segment. These BIPV firms integrate solar cells into building materials like roofing tiles, facades, and windows, requiring flexible, durable, and often aesthetically adaptable backsheets. Furthermore, manufacturers of flexible electronics and portable solar devices, such as solar chargers for consumer goods or solar-powered outdoor gear, are also significant buyers, prioritizing lightweight and bendable backsheet solutions. Research and development institutions, pilot project developers, and niche application providers in sectors like automotive, aerospace, and marine also constitute potential customers, seeking custom backsheet solutions for specialized and demanding environments, driving innovation and demand for advanced materials.

Thin Film Solar PV Backsheet Market Key Technology Landscape

The Thin Film Solar PV Backsheet Markets technological landscape is characterized by continuous innovation aimed at enhancing durability, improving performance, and reducing costs. A core technological focus is on advanced polymer science, involving the development of new fluorine-containing and fluorine-free polymer compositions that offer superior resistance to UV radiation, moisture, and thermal stress. Technologies such as multi-layer co-extrusion are paramount, allowing manufacturers to combine different polymer layers with distinct properties (e.g., UV-resistant outer layer, adhesive inner layer, barrier core) into a single, highly functional backsheet. Surface modification technologies, including plasma treatment and specialized coatings, are also crucial for improving adhesion between backsheet layers and enhancing resistance to environmental degradation. Furthermore, advancements in lamination techniques ensure defect-free bonding of backsheets to thin-film encapsulants, preventing delamination and moisture ingress over the modules lifespan. Research into novel conductive backsheets for specific module designs, as well as bio-degradable or recyclable backsheet materials, represents emerging technological frontiers. The integration of advanced manufacturing processes, including high-speed extrusion lines and automated quality control systems, further contributes to the technological sophistication, driving efficiency and precision in backsheet production to meet the rigorous demands of the solar industry.

Regional Highlights

- Asia-Pacific: Dominates the global market for thin film solar PV backsheets, driven by massive investments in solar energy infrastructure, particularly in China, India, Japan, and South Korea. China stands as the largest producer and consumer of solar modules, benefiting from strong government support and declining manufacturing costs. The regions expanding manufacturing base for thin-film solar cells and modules, coupled with a robust supply chain, fuels significant demand for backsheets, making it a pivotal growth area.

- Europe: Exhibits steady growth fueled by ambitious renewable energy targets, stringent environmental regulations, and a focus on high-efficiency, long-lasting solar installations. Countries like Germany, France, and Italy are significant markets due to established solar industries and a strong emphasis on product quality and sustainable materials. The adoption of advanced backsheet technologies for flexible and BIPV applications is also noteworthy in this region.

- North America: A substantial market characterized by technological innovation, increasing utility-scale solar projects, and a growing residential solar sector. The United States and Canada are key contributors, driven by federal and state incentives, a focus on energy independence, and a demand for durable products suitable for diverse climatic conditions. Research and development into next-generation backsheet materials are prominent here.

- Latin America: Emerging as a high-growth region for thin film solar PV backsheets, with countries like Brazil, Mexico, and Chile leading the adoption of solar energy due to abundant solar resources and favorable government policies. The demand is primarily for large-scale solar projects, necessitating robust and cost-effective backsheet solutions that can withstand varying environmental challenges across the continent.

- Middle East & Africa: Represents a burgeoning market with immense potential, spurred by ambitious renewable energy goals and abundant solar irradiation. The UAE, Saudi Arabia, and South Africa are investing heavily in solar power, requiring high-performance backsheets capable of withstanding extreme temperatures, sand abrasion, and high UV levels characteristic of desert environments. Local manufacturing initiatives are also slowly gaining traction.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thin Film Solar PV Backsheet Market.- Dupont Teijin Films

- Coveme S.p.A.

- Toyo Aluminium K.K.

- Toray Industries Inc.

- Cybrid Technologies Inc.

- Jolywood (Suzhou) Sunwatt Co. Ltd.

- Flexcon Company Inc.

- Arkema S.A.

- AGFA-Gevaert Group

- KPN Solar Co. Ltd.

- Isovoltaic AG

- 3M Company

- Dunmore Corporation

- Hangzhou First Applied Material Co., Ltd.

- Taiflex Scientific Co., Ltd.

Frequently Asked Questions

What is a thin film solar PV backsheet and why is it important?

A thin film solar PV backsheet is a critical multi-layered polymer sheet that forms the outermost protective layer on the non-illuminated side of a thin-film solar module. Its primary function is to shield the delicate photovoltaic cells from environmental degradation, including moisture ingress, UV radiation, thermal stress, and mechanical damage. This protection is vital for ensuring the long-term durability, operational safety, and sustained energy output of the solar panel, directly impacting its lifespan and overall efficiency in energy generation. Without a robust backsheet, thin-film modules would be highly susceptible to premature failure, leading to significant reductions in performance and increased maintenance costs, underscoring its indispensable role in solar energy systems.

What are the primary materials used in thin film solar PV backsheets and their key advantages?

The primary materials used in thin film solar PV backsheets typically include Polyethylene Terephthalate (PET), Polyvinyl Fluoride (PVF, commonly known as Tedlar), and Polyvinylidene Fluoride (PVDF), often in multi-layered constructions. PET backsheets are prized for their cost-effectiveness, good electrical insulation, and widespread applicability in general solar projects. PVF (Tedlar) backsheets offer exceptional UV resistance, superior moisture barrier properties, and long-term weatherability, making them ideal for high-performance modules in harsh environments. PVDF backsheets provide high chemical resistance and good UV stability, suitable for demanding applications. Multi-layer co-extruded backsheets combine these materials to leverage their individual strengths, creating custom solutions with enhanced adhesion, flexibility, and barrier properties tailored to specific performance requirements and environmental conditions.

How do thin film backsheets differ from those used in crystalline silicon solar panels?

While both thin film and crystalline silicon (c-Si) solar panels utilize backsheets for protection, there are subtle differences often driven by the inherent characteristics of the module technology. Thin film modules, generally more flexible and lighter, often require backsheets that emphasize flexibility and enhanced barrier properties against moisture due to the inherent sensitivity of thin-film materials to moisture. Their lighter weight also permits thinner backsheet constructions. C-Si modules, being more rigid and thicker, may prioritize mechanical strength and robust UV resistance, though moisture barrier is equally important. The specific chemical compatibility between the backsheet and the encapsulant (e.g., EVA or POE) can also vary depending on the cell technology, influencing material selection. Overall, thin-film backsheets are often engineered to complement the unique advantages and sensitivities of their respective thin-film cell technologies, focusing on optimized flexibility, lower weight, and targeted barrier performance.

What are the key drivers for growth in the Thin Film Solar PV Backsheet Market?

The Thin Film Solar PV Backsheet Markets growth is primarily propelled by several interconnected factors. Firstly, the accelerating global demand for renewable energy, driven by climate change concerns and governmental mandates for clean energy adoption, significantly boosts solar panel production. Secondly, continuous technological advancements in thin-film solar cells, leading to improved efficiency and cost reductions, make them increasingly competitive, thereby increasing the demand for their protective backsheets. Thirdly, the expanding applications of thin-film modules in specialized areas such as building-integrated photovoltaics (BIPV), flexible electronics, and portable solar devices, where their unique properties are highly valued, creates new market segments for backsheets. Lastly, supportive government policies, incentives, and investment in solar infrastructure across developing and developed economies provide a robust framework for market expansion. The emphasis on long-term module reliability and performance also drives demand for high-quality, durable backsheets.

What are the environmental and sustainability considerations impacting backsheet development?

Environmental and sustainability considerations are increasingly impacting backsheet development, driving innovation towards greener solutions. A major concern is the use of fluoropolymers (like PVF and PVDF), which, while offering excellent performance, are sometimes under scrutiny due to their environmental persistence during manufacturing and disposal. This has spurred significant research into developing high-performance, fluorine-free backsheets that maintain durability and protection without these chemicals. Manufacturers are also exploring bio-based or recyclable polymer alternatives to reduce the carbon footprint of solar modules. Additionally, efforts are focused on minimizing material waste during production and enhancing the overall recyclability of solar panels at the end of their lifecycle, contributing to a more circular economy in the solar industry. These considerations are becoming crucial for market acceptance and regulatory compliance, shaping the future trajectory of backsheet material science and manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager