Tinplate Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429669 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Tinplate Packaging Market Size

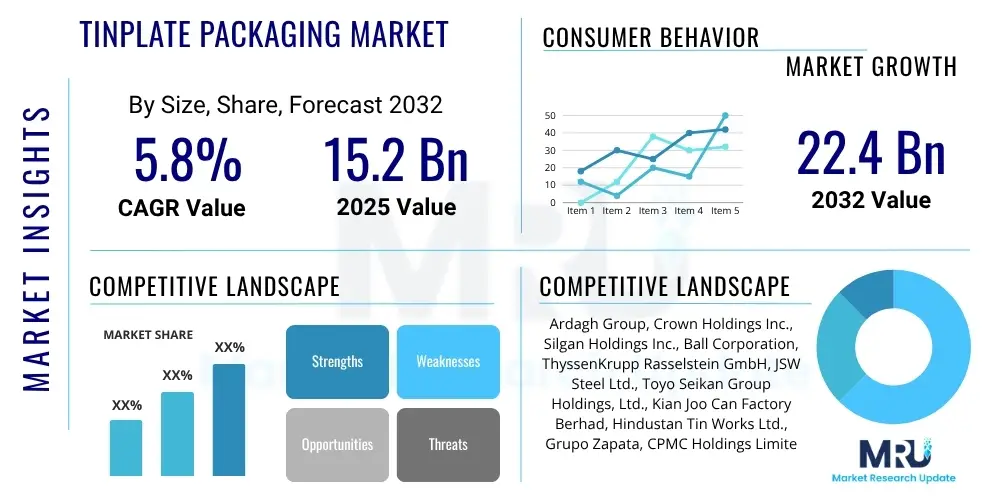

The Tinplate Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 15.2 billion in 2025 and is projected to reach USD 22.4 billion by the end of the forecast period in 2032.

Tinplate Packaging Market introduction

The Tinplate Packaging Market encompasses a vital segment of the global packaging industry, characterized by its robust, versatile, and highly recyclable nature. Tinplate, essentially steel sheet coated with a thin layer of tin, offers exceptional barrier properties against light, oxygen, and moisture, thereby preserving product integrity and extending shelf life significantly. Its applications are broad and diverse, primarily concentrated in the food and beverage sectors for canning fruits, vegetables, processed meats, and various beverages, including soft drinks, beers, and energy drinks. Beyond consumables, tinplate is extensively utilized for aerosols (such as deodorants, paints, and insecticides), general line containers for paints, chemicals, oils, and even high-end cosmetic and pharmaceutical products, reflecting its adaptability across numerous industries. The inherent benefits of tinplate packaging, including its excellent formability, printability for brand differentiation, and unmatched sustainability credentials through high recycling rates, render it a preferred choice for manufacturers worldwide. Furthermore, its ability to withstand high temperatures and pressures makes it ideal for sterilization processes, crucial for food safety and preservation. The market's growth is predominantly driven by the increasing global demand for packaged and processed foods, fueled by urbanization, changing consumer lifestyles, and the imperative for sustainable packaging solutions that align with environmental conservation efforts. Continuous innovation in lightweighting, advanced coatings, and digital printing technologies further bolsters its appeal and competitive edge in the dynamic packaging landscape. The robust demand for extended shelf life, coupled with the rising focus on food security and waste reduction, positions tinplate packaging as a cornerstone of modern industrial and consumer product distribution. Its intrinsic strength protects contents from damage during transport and storage, minimizing spoilage and ensuring product quality from factory to consumer. This combination of protective qualities, aesthetic versatility, and environmental responsibility underpins its enduring relevance and projected growth.

Tinplate Packaging Market Executive Summary

The tinplate packaging market is currently experiencing significant transformative shifts driven by evolving consumer preferences, stringent environmental regulations, and continuous technological advancements across business, regional, and segment levels. From a business trend perspective, the industry is heavily invested in developing innovative coating technologies, such as BPA-non-intent (BPA-NI) and other advanced organic coatings, to address growing health concerns and comply with global food safety standards. There is a strong emphasis on lightweighting initiatives to reduce material usage, lower transportation costs, and enhance the environmental profile of tinplate products, contributing to a circular economy. Furthermore, market players are focusing on improving the aesthetics and functionality of tinplate packaging through sophisticated printing techniques, ergonomic designs, and easy-open features, aiming to capture consumer attention and enhance convenience. The integration of smart packaging solutions, such as QR codes and NFC tags, is also emerging, enabling better traceability, consumer engagement, and anti-counterfeiting measures. Regionally, the Asia Pacific market is demonstrating robust growth, primarily fueled by rapid industrialization, increasing urbanization, rising disposable incomes, and the burgeoning demand for packaged food and beverages in countries like China, India, and Southeast Asian nations. Europe and North America, while mature markets, continue to exhibit stable demand, largely driven by strong recycling infrastructures and a persistent consumer and regulatory push towards sustainable and recyclable packaging alternatives. Latin America and the Middle East & Africa regions are also witnessing gradual expansion due to improving economic conditions, expanding retail networks, and a growing consumer base adopting modern packaged goods. In terms of segment trends, the food and beverage sector remains the dominant application area for tinplate packaging, particularly for processed foods, canned fruits and vegetables, and various alcoholic and non-alcoholic beverages, owing to its superior barrier properties and extended shelf-life capabilities. The aerosol segment is projected to show steady growth, benefiting from expanding applications in personal care, home care, and industrial products. The general line cans segment, used for paints, chemicals, and industrial oils, is also a stable contributor, driven by ongoing industrial activity. The pharmaceutical and cosmetic segments, while smaller, are showing incremental growth due to the premium perception and protective attributes offered by tinplate, reflecting a diversified demand base that underpins the market's resilience and future prospects. These multifaceted trends collectively indicate a market poised for sustained expansion, adapting to contemporary demands for safety, sustainability, and aesthetic appeal.

AI Impact Analysis on Tinplate Packaging Market

User inquiries regarding AI's impact on the tinplate packaging market frequently center on how artificial intelligence can optimize manufacturing processes, enhance supply chain efficiency, improve quality control, and contribute to sustainable practices. Users are keen to understand AI's role in predictive maintenance for machinery, automated inspection systems for defect detection, and intelligent inventory management. There is also considerable interest in AI-driven insights for demand forecasting and product design optimization, which can lead to reduced waste and improved material utilization. Essentially, the overarching themes involve leveraging AI to drive operational efficiencies, reduce costs, boost product quality, and bolster environmental responsibility across the entire tinplate packaging value chain, making processes smarter, faster, and more sustainable. Stakeholders are particularly interested in how AI can offer a competitive advantage through data-driven decision making and automation.

- AI-powered predictive maintenance: Minimizing downtime and optimizing operational efficiency of production lines by forecasting equipment failures.

- Automated quality inspection: Utilizing computer vision and machine learning for real-time defect detection, ensuring consistent product quality and reducing waste.

- Supply chain optimization: AI algorithms enhancing logistics, inventory management, and raw material procurement, leading to cost savings and improved delivery times.

- Demand forecasting: Advanced analytical models providing accurate predictions of market needs, optimizing production schedules and reducing overstocking or shortages.

- Generative design for packaging: AI assisting in creating lightweight yet robust packaging designs, optimizing material usage and structural integrity.

- Energy efficiency management: AI systems monitoring and adjusting energy consumption in manufacturing processes, contributing to lower operational costs and reduced carbon footprint.

- Waste reduction and recycling optimization: AI aiding in sorting and identifying materials in recycling facilities, improving the efficiency and purity of recycled tinplate.

DRO & Impact Forces Of Tinplate Packaging Market

The tinplate packaging market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and various impact forces that collectively dictate its growth trajectory and competitive landscape. Key drivers propelling market expansion include the consistently increasing global demand for packaged and processed food and beverages, driven by urbanization, changing consumer lifestyles, and the need for convenient, shelf-stable products, especially in emerging economies. The exceptional barrier properties of tinplate, which extend product shelf life and ensure food safety, further solidify its position. Additionally, tinplate's strong sustainability credentials, specifically its 100% recyclability without loss of quality, align well with growing environmental awareness and corporate social responsibility initiatives, making it an attractive option for eco-conscious consumers and brands. However, the market faces notable restraints, primarily intense competition from alternative packaging materials such as plastics, aluminum, and glass, each offering distinct advantages in terms of cost, weight, or aesthetic flexibility. Fluctuations in raw material prices, particularly for steel and tin, introduce significant cost volatility for manufacturers, impacting profit margins and investment decisions. Stringent environmental regulations concerning metal mining, processing, and waste disposal also pose challenges, requiring continuous investment in compliance and cleaner production technologies. The relatively high initial capital expenditure required for setting up tinplate manufacturing and filling lines can also be a deterrent for new entrants or smaller players. Despite these challenges, substantial opportunities exist for market players. These include the development and adoption of advanced, BPA-non-intent coatings that cater to evolving health and safety standards, expanding into niche applications such as premium pet food or specialized industrial chemicals, and exploring lightweighting innovations to enhance cost-effectiveness and reduce environmental impact. Growth in emerging markets, characterized by expanding middle classes and increasing purchasing power, presents fertile ground for market penetration. The integration of smart packaging technologies, offering enhanced traceability and consumer engagement through digital features, represents a futuristic growth avenue. The market is also influenced by external impact forces such as technological advancements in manufacturing processes and material science, shifting consumer preferences towards sustainable and convenient packaging, evolving regulatory frameworks globally, and geopolitical factors affecting raw material supply chains. The interplay of these forces necessitates continuous innovation, strategic partnerships, and adaptive business models to ensure sustained growth and resilience in the tinplate packaging market.

Segmentation Analysis

The tinplate packaging market is comprehensively segmented to provide a granular understanding of its diverse applications, product types, and end-use industries. This segmentation allows for precise market analysis, identifying key growth areas and competitive dynamics within specific niches. The market is primarily segmented by product type, which delineates the various forms tinplate takes in its final packaging application, each serving distinct functional and aesthetic purposes. Further segmentation by application or end-use industry highlights the primary sectors that consume tinplate packaging, reflecting the broad utility of this material across both consumer and industrial goods. Understanding these segments is crucial for manufacturers to tailor their product offerings, develop targeted marketing strategies, and allocate resources effectively, capitalizing on specific market demands and trends. Each segment's growth is influenced by unique drivers, consumer behaviors, and regulatory environments, necessitating a detailed approach to market assessment.

- By Product Type:

- 2-Piece Cans

- 3-Piece Cans

- Aerosol Cans

- Closures and Lids

- General Line Cans

- Battery Casings

- Others (e.g., promotional tins, specialty containers)

- By Application/End-Use Industry:

- Food & Beverages

- Fruits and Vegetables

- Processed Meat and Seafood

- Dairy Products

- Soups and Ready Meals

- Beverages (Carbonated Soft Drinks, Beer, Juices)

- Confectionery

- Pet Food

- Oils and Fats

- Paints & Coatings

- Chemical & Industrial

- Solvents

- Adhesives

- Lubricants

- Pharmaceuticals (limited applications for specific products)

- Cosmetics & Personal Care (Aerosols for hairspray, deodorants)

- Household Products (Cleaning aerosols, polishes)

- Others (e.g., automotive products, gifts, stationery)

Value Chain Analysis For Tinplate Packaging Market

The value chain for the tinplate packaging market is a complex ecosystem involving multiple stages, from raw material extraction and processing to the final distribution of packaged goods, each adding value and incurring costs. The upstream segment of the value chain is dominated by raw material suppliers, primarily large steel manufacturers responsible for producing cold-rolled steel sheets, which form the base material for tinplate. These steel producers, in turn, rely on iron ore miners and coking coal suppliers. Tin suppliers, sourcing from various global mining operations, provide the essential coating material. Specialty chemical companies also play a role by supplying coatings, lacquers, and inks crucial for product protection and branding. Downstream activities involve the tinplate manufacturers who transform the raw steel sheets into tinplate coils or sheets through the electrolytic tinning process, followed by packaging converters who shape and print the tinplate into various packaging forms like cans, lids, and containers. Further down the chain, fillers and brand owners, such as large food and beverage companies, chemical manufacturers, and pharmaceutical firms, utilize these tinplate packages for their products. The distribution channel is multifaceted, encompassing direct sales, where large tinplate manufacturers or converters sell directly to major brand owners, and indirect sales, involving a network of distributors and wholesalers who supply packaging to smaller and medium-sized enterprises (SMEs). E-commerce platforms are increasingly becoming a supplementary channel for smaller volume orders and specialized packaging. The efficiency and collaboration across these stages are critical for optimizing costs, ensuring product quality, and meeting market demands. Innovations in material science at the upstream level can significantly impact downstream processing, while demands from brand owners for sustainable or customized solutions drive changes across the entire chain. The interdependencies highlight the importance of strategic partnerships and integrated supply chain management to maintain competitiveness and responsiveness within the tinplate packaging industry.

Tinplate Packaging Market Potential Customers

The tinplate packaging market serves a vast and diverse customer base, primarily comprising various end-use industries that require robust, protective, and sustainable packaging solutions for their products. The largest segment of potential customers includes food processing companies and beverage manufacturers, ranging from global multinational corporations to regional producers, who rely on tinplate cans for preserving fruits, vegetables, processed meats, seafood, dairy products, soups, ready meals, carbonated soft drinks, beers, and fruit juices. These companies value tinplate for its excellent barrier properties, extended shelf life capabilities, and ability to withstand thermal processing. Another significant customer group consists of companies in the paints and coatings industry, utilizing tinplate for durable and secure containers that prevent product degradation and leakage. Chemical and industrial product manufacturers, including producers of solvents, adhesives, lubricants, and various industrial oils, also represent a substantial customer segment due to tinplate's strength and chemical resistance. The cosmetic and personal care sector, particularly for aerosol products like hairsprays, deodorants, and shaving foams, alongside household product manufacturers for cleaning agents and polishes, are growing customer categories. Pet food manufacturers are also key buyers, seeking reliable packaging that maintains nutritional integrity and freshness. Furthermore, there's a niche market among pharmaceutical companies for specific products requiring high barrier protection, and for promotional or specialty packaging for gifts and confectionery where the premium aesthetic of tinplate adds value. These end-users are not merely purchasing a container but investing in a solution that safeguards their product, enhances brand perception, and contributes to their sustainability objectives, making them critical stakeholders in the tinplate packaging value chain. Understanding the specific needs and regulatory environments of each customer segment is paramount for suppliers to develop tailored packaging solutions and maintain strong market penetration.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.2 Billion |

| Market Forecast in 2032 | USD 22.4 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ardagh Group, Crown Holdings Inc., Silgan Holdings Inc., Ball Corporation, ThyssenKrupp Rasselstein GmbH, JSW Steel Ltd., Toyo Seikan Group Holdings, Ltd., Kian Joo Can Factory Berhad, Hindustan Tin Works Ltd., Grupo Zapata, CPMC Holdings Limited, Envases Universales, Berlin Packaging, Can-Pack S.A., Metal Container Corporation, Pacific Can, Daiwa Can Company, Emballator Group, Tata Steel Packaging, Massilly Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tinplate Packaging Market Key Technology Landscape

The tinplate packaging market is continuously evolving through significant technological advancements aimed at enhancing product performance, sustainability, and manufacturing efficiency. A primary focus lies in the development of advanced coatings, particularly those that are BPA-non-intent (BPA-NI) or entirely BPA-free, in response to growing consumer and regulatory concerns regarding food contact safety. These new organic coatings offer comparable or superior protection against corrosion and chemical interactions without the potential health risks associated with traditional epoxy resins. Lightweighting technologies are also paramount, involving innovations in steel composition and can-making processes to reduce material thickness while maintaining structural integrity, thereby lowering raw material costs, transportation expenses, and environmental footprints. High-speed manufacturing lines, integrated with automation and robotics, are becoming standard to increase production throughput, improve precision, and reduce labor costs, allowing manufacturers to meet surging global demand more efficiently. Digital printing technologies are transforming branding and customization capabilities, enabling shorter print runs, rapid design changes, and personalized packaging options that were previously unattainable with traditional offset printing, offering brands greater flexibility and market responsiveness. Furthermore, innovations in material science are exploring new alloy compositions for tinplate that offer enhanced strength-to-weight ratios and improved corrosion resistance, expanding the material's application possibilities. The integration of smart packaging features, such as QR codes, NFC tags, and augmented reality elements, allows for enhanced product traceability, consumer engagement, and anti-counterfeiting measures, ushering in an era of interactive and data-rich packaging solutions. These technological shifts are not only driving operational improvements but also positioning tinplate packaging as a highly adaptable and sustainable choice for a diverse array of industries in a competitive market environment, ensuring its continued relevance and growth by meeting contemporary demands for safety, efficiency, and environmental responsibility.

Regional Highlights

- North America: This region represents a mature yet stable market for tinplate packaging, characterized by established food and beverage industries, a strong emphasis on convenience packaging, and high consumer awareness regarding product safety and recyclability. Innovations in advanced coatings and lightweighting are prominent here, driven by stringent regulatory standards and the demand for sustainable options. The extensive recycling infrastructure also supports a robust circular economy for tinplate, maintaining consistent demand.

- Europe: Europe stands as a significant market, with a strong focus on sustainability, high recycling rates, and strict environmental regulations. Countries like Germany, France, and the UK are leading in the adoption of advanced tinplate solutions for food preservation and aerosols. The demand is stable, influenced by a mature packaged food sector and a consumer base that increasingly prioritizes eco-friendly packaging materials. Research and development in lightweight designs and innovative coatings are continually driven by both consumer preference and legislative mandates.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for tinplate packaging, propelled by rapid urbanization, increasing disposable incomes, and the booming packaged food and beverage industries in countries such as China, India, Japan, and Southeast Asian nations. The region benefits from expanding manufacturing capabilities and a vast consumer base, driving significant demand for both traditional and innovative tinplate solutions. Investment in new production capacities and technological upgrades is commonplace to meet the escalating regional consumption patterns.

- Latin America: This region is witnessing steady growth in the tinplate packaging market, influenced by improving economic conditions, expanding modern retail formats, and a gradual shift towards packaged food consumption. Countries like Brazil and Mexico are key markets, with increasing demand from the beverage and processed food sectors. While still developing in terms of recycling infrastructure compared to more mature markets, the potential for growth remains substantial as urbanization and consumer awareness continue to rise.

- Middle East and Africa (MEA): The MEA region represents an emerging market with considerable growth potential. Infrastructure development, rising population, and increasing per capita income are driving the demand for packaged goods, thereby boosting the tinplate packaging sector. While smaller in market size compared to other regions, investments in food processing and manufacturing facilities, particularly in Gulf Cooperation Council (GCC) countries and parts of Africa, are expected to fuel future growth. Local production capabilities are expanding, reducing reliance on imports.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tinplate Packaging Market.- Ardagh Group

- Crown Holdings Inc.

- Silgan Holdings Inc.

- Ball Corporation

- ThyssenKrupp Rasselstein GmbH

- JSW Steel Ltd.

- Toyo Seikan Group Holdings, Ltd.

- Kian Joo Can Factory Berhad

- Hindustan Tin Works Ltd.

- Grupo Zapata

- CPMC Holdings Limited

- Envases Universales

- Berlin Packaging

- Can-Pack S.A.

- Metal Container Corporation

- Pacific Can

- Daiwa Can Company

- Emballator Group

- Tata Steel Packaging

- Massilly Group

Frequently Asked Questions

What are the primary advantages of utilizing tinplate packaging for products?

Tinplate packaging offers numerous key advantages including exceptional barrier protection against light, oxygen, and moisture, which significantly extends product shelf life and preserves freshness. It is highly durable and resistant to impact, ensuring product integrity during transport and storage. Furthermore, tinplate is 100% recyclable, contributing to a circular economy and aligning with sustainability goals. Its excellent printability allows for vivid branding and aesthetic appeal, making it a versatile choice for various consumer and industrial goods.

How does tinplate packaging contribute to environmental sustainability?

Tinplate packaging is a highly sustainable choice due to its infinite recyclability without loss of material quality. It is a permanent material that can be recycled repeatedly, reducing the need for virgin resources and minimizing waste. The steel industry, including tinplate production, has made significant strides in reducing its environmental footprint through energy-efficient processes and increased use of recycled content. Its robust nature also helps prevent product spoilage, further reducing overall waste.

What are the main applications of tinplate packaging across industries?

The main applications for tinplate packaging span a wide range of industries. It is predominantly used in the food and beverage sector for canning processed fruits, vegetables, meats, seafood, dairy products, and various beverages like soft drinks, beer, and juices. Beyond consumables, tinplate is crucial for aerosol cans used in personal care, home care, and industrial products, as well as for general line containers for paints, chemicals, and oils. Its versatility also extends to specialty and promotional packaging.

What technological innovations are currently influencing the tinplate packaging market?

Key technological innovations impacting the tinplate packaging market include the development of advanced BPA-non-intent (BPA-NI) and BPA-free coatings for enhanced food safety, and lightweighting techniques to reduce material usage and costs while maintaining strength. Digital printing technologies are enabling greater customization and faster turnaround times for branding. Additionally, automation and smart packaging features, such as QR codes and NFC tags, are improving manufacturing efficiency, traceability, and consumer engagement.

What challenges does the tinplate packaging market face and how are they being addressed?

The tinplate packaging market faces challenges such as intense competition from alternative materials (plastics, aluminum, glass), volatility in raw material prices (steel, tin), and stringent environmental regulations. These challenges are being addressed through continuous innovation in product design (e.g., lightweighting), development of sustainable coatings (e.g., BPA-NI), investment in advanced manufacturing technologies for cost efficiency, and strategic collaborations across the value chain to ensure stable raw material supply and adherence to regulatory standards. Focusing on tinplate's superior recyclability is a key competitive advantage.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager