Track Laying Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427799 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Track Laying Equipment Market Size

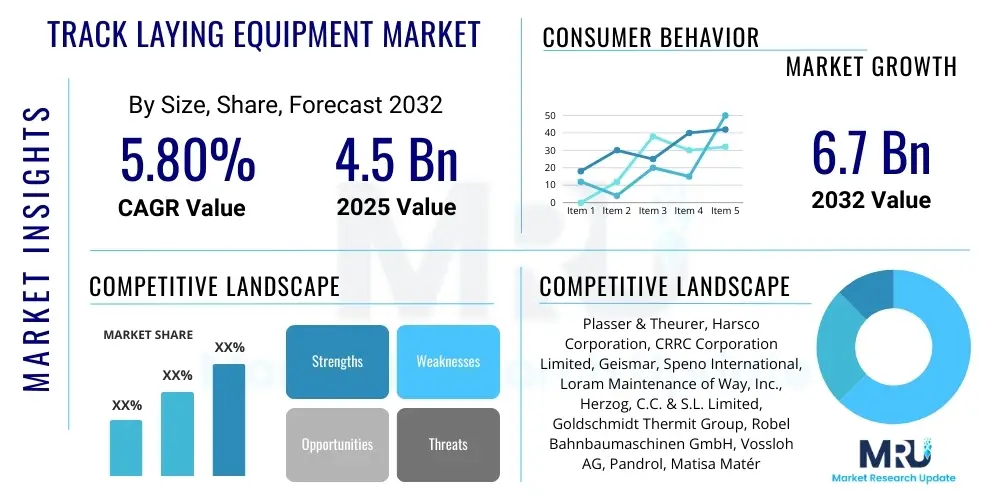

The Track Laying Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.5 billion in 2025 and is projected to reach USD 6.7 billion by the end of the forecast period in 2032. This significant expansion is primarily driven by robust global investments in railway infrastructure development and modernization, including extensive high-speed rail projects across Asia and Europe, coupled with the critical need for maintaining and upgrading existing conventional and urban transit networks. The increasing emphasis on sustainable and efficient transportation solutions, combined with technological advancements in equipment automation and precision, further fuels this market trajectory, ensuring continued demand for sophisticated track laying machinery.

Track Laying Equipment Market introduction

The Track Laying Equipment Market encompasses a broad range of specialized machinery and tools essential for the construction, maintenance, and rehabilitation of railway tracks globally. This includes heavy-duty machinery such as ballast tampers, track renewal trains, rail grinders, rail cranes, and ballast cleaners, alongside smaller, more precise tools. These products are crucial for ensuring the structural integrity, alignment, and operational safety of railway lines, which are fundamental to the efficiency of both passenger and freight transportation systems. The sophisticated engineering involved in these machines allows for precise handling and installation of rails, sleepers, and ballast, thereby significantly reducing manual labor and project timelines.

Major applications of track laying equipment span across new railway line construction, the extensive maintenance and repair of existing tracks, and the modernization of aging infrastructure. This includes high-speed rail networks, urban metro systems, conventional freight and passenger lines, and industrial sidings. The core benefits derived from utilizing specialized track laying equipment include enhanced operational efficiency, improved track quality and longevity, increased safety for both workers and railway operations, and substantial cost reductions through automation and optimized resource utilization. These advantages are particularly vital as global rail networks expand and face escalating demands for faster, safer, and more reliable services.

The market is predominantly driven by several key factors. Foremost among these is the escalating global investment in railway infrastructure, spurred by rapid urbanization, economic growth, and the imperative for sustainable transportation alternatives. Government initiatives and public-private partnerships aimed at developing high-speed rail corridors and expanding urban transit systems, particularly in emerging economies, are significant demand catalysts. Furthermore, the continuous need for routine maintenance, repair, and periodic upgrades of vast existing railway networks worldwide ensures a consistent demand for advanced track laying equipment. The adoption of advanced technologies like automation, IoT, and data analytics to improve operational efficiency and safety also acts as a crucial driving force.

Track Laying Equipment Market Executive Summary

The Track Laying Equipment Market is experiencing dynamic growth, propelled by significant global investments in railway infrastructure and a persistent demand for efficient maintenance solutions. Key business trends indicate a strong shift towards automation and digital integration, with manufacturers focusing on developing intelligent machines capable of enhancing precision, speed, and safety in track construction and maintenance. This technological evolution is leading to more sustainable and cost-effective operational paradigms, allowing railway operators to maximize track uptime and extend asset lifecycles. Moreover, an increasing number of companies are exploring rental and leasing models for equipment, providing greater flexibility for project-based demands and supporting smaller operators.

Regional trends highlight Asia Pacific as the dominant growth region, primarily due to ambitious high-speed rail projects in China, India, and other Southeast Asian nations, coupled with extensive urban metro expansions. Europe also demonstrates robust demand, driven by aging infrastructure modernization initiatives and cross-border rail network enhancements aimed at improving connectivity and reducing carbon emissions. North America, while experiencing steady growth, is focusing on upgrading existing freight rail lines and investing in passenger rail expansion. The Middle East and Africa are emerging as promising markets with new railway development projects supporting economic diversification and resource transportation. Latin America, too, is seeing investments in infrastructure to support mining and agricultural exports.

Segment trends reveal a significant demand for heavy-duty, automatic track laying equipment capable of handling large-scale projects with minimal human intervention. Ballast tampers, track renewal trains, and rail grinders are among the most sought-after categories, reflecting the continuous need for precise track alignment and surface quality. The increasing complexity of urban rail projects also fuels demand for compact, highly maneuverable equipment. Furthermore, the maintenance and repair segment consistently represents the largest share of the market, driven by the lifecycle management of extensive global railway networks. The integration of advanced diagnostics and predictive maintenance capabilities within new equipment offerings is also a notable trend shaping market dynamics across all segments.

AI Impact Analysis on Track Laying Equipment Market

Common user questions regarding AIs impact on the Track Laying Equipment Market frequently revolve around how this technology can enhance operational efficiency, improve safety, and reduce maintenance costs. Users are keen to understand the practical applications of AI in automating complex tasks, optimizing resource allocation, and providing predictive insights for maintenance schedules. Concerns often include the initial investment costs, the need for skilled personnel to manage AI-driven systems, and the reliability of autonomous equipment in varied environmental conditions. Expectations center on AIs ability to revolutionize track inspection, streamline project management, and extend the operational lifespan of railway infrastructure through data-driven precision.

Artificial intelligence is set to profoundly transform the Track Laying Equipment Market by introducing unprecedented levels of automation, precision, and efficiency. Through advanced machine learning algorithms, AI enables equipment to perform tasks with greater accuracy, such as precise track alignment and ballast profiling, significantly reducing the margin for human error. The integration of AI also facilitates real-time data analysis from sensors embedded in machinery, allowing for continuous monitoring of equipment performance and track conditions. This data-driven approach not only optimizes operational workflows but also contributes to substantial cost savings by preventing costly breakdowns and minimizing downtime through proactive maintenance strategies.

The future of track laying operations will increasingly rely on AI to create smarter, more responsive systems. Autonomous track laying equipment, guided by AI and supported by advanced navigation systems, is becoming more prevalent, enabling operations in challenging environments or during non-peak hours with minimal human supervision. Furthermore, AI-powered predictive analytics will move beyond equipment maintenance to encompass comprehensive track health monitoring, identifying potential vulnerabilities before they escalate into major issues. This holistic application of AI promises to enhance the overall safety and reliability of railway networks, positioning AI as a cornerstone technology for the next generation of track laying equipment and infrastructure management.

- Predictive maintenance and fault detection for equipment and track infrastructure.

- Automated track inspection using vision systems and machine learning algorithms.

- Optimized project planning, scheduling, and resource allocation for track construction.

- Enhanced operational safety through real-time hazard detection and autonomous decision-making.

- Real-time data analysis and insights for informed decision-making on site and remotely.

- Autonomous operation of track laying machinery, reducing manual labor requirements.

- Improved precision in track alignment, ballast profiling, and rail welding processes.

- Digital twin technology for simulating and optimizing track laying operations.

- AI-powered quality control and defect identification during and after construction.

DRO & Impact Forces Of Track Laying Equipment Market

The Track Laying Equipment Market is fundamentally shaped by a complex interplay of drivers, restraints, and opportunities, all influenced by various impact forces. A primary driver is the accelerating global investment in railway infrastructure, particularly the development of high-speed rail networks and urban transit systems, which necessitates advanced and efficient track laying solutions. This is further amplified by government initiatives and public-private partnerships focused on improving connectivity, reducing traffic congestion, and promoting sustainable transportation. The inherent benefits of rail transport, such as energy efficiency and lower carbon emissions compared to other modes, contribute to sustained political and economic support for railway expansion and modernization efforts, thereby boosting demand for specialized equipment.

However, the market also faces notable restraints. The high capital expenditure associated with purchasing and maintaining specialized track laying equipment poses a significant barrier, especially for smaller operators or in regions with limited financial resources. This challenge is compounded by the need for highly skilled labor to operate and maintain these complex machines, a shortage of which can impede project execution and increase operational costs. Additionally, stringent environmental regulations governing construction noise, emissions, and waste disposal introduce compliance complexities and can necessitate investments in more eco-friendly, albeit often more expensive, equipment. The cyclical nature of government funding for infrastructure projects can also lead to market volatility, creating uncertainty for manufacturers and service providers.

Opportunities within the market largely stem from technological advancements and the increasing adoption of automation and digitalization. The integration of IoT, AI, and advanced robotics into track laying equipment offers avenues for improved efficiency, precision, and safety, creating new value propositions for end-users. Emerging markets, particularly in Asia Pacific and parts of Africa, present substantial growth potential as these regions embark on ambitious infrastructure development programs to support rapid urbanization and economic expansion. The growing emphasis on predictive maintenance and lifecycle management also opens new service opportunities for equipment manufacturers and specialized contractors. These opportunities, when strategically pursued, can significantly mitigate the impact of existing restraints and propel market growth.

Segmentation Analysis

The Track Laying Equipment Market is meticulously segmented to provide a granular understanding of its diverse components and dynamics. This segmentation helps in identifying specific demand patterns, technological preferences, and operational requirements across various applications and end-user categories. The market is primarily analyzed based on the type of equipment, the level of operation automation, and the application area. Understanding these distinctions is crucial for manufacturers to tailor their product offerings, for service providers to target specific client needs, and for investors to identify high-growth sub-segments within the broader railway infrastructure sector. The continuous evolution of rail technology and operational methodologies further refines these segmentation categories, reflecting the industrys commitment to efficiency and innovation.

Equipment type segmentation typically categorizes machinery based on its primary function in the track laying process. This includes specialized machines for ballast work, rail handling, track assembly, and surface treatment. Each type of equipment is designed for specific tasks, from compacting the ballast bed to grinding rail surfaces for optimal smoothness and safety. The level of operation distinguishes between manual, semi-automatic, and fully automatic systems, reflecting the varying degrees of human intervention and technological sophistication. This differentiation is particularly relevant as the industry moves towards greater automation to enhance precision, reduce labor costs, and improve safety. The application segment then delineates where the equipment is predominantly used, whether for constructing entirely new railway lines, performing routine maintenance on existing tracks, or undertaking extensive rehabilitation and upgrade projects.

Moreover, end-user segmentation further refines market analysis, distinguishing between national railway authorities, private railway operators, urban transit companies, and specialized construction contractors. Each end-user group possesses unique operational scales, budgetary constraints, and project requirements, influencing their equipment procurement strategies. For instance, national railway companies often require heavy-duty, high-capacity equipment for large-scale network maintenance, while urban transit operators might prioritize more compact and versatile machines for metropolitan environments. This comprehensive segmentation framework provides stakeholders with actionable insights to navigate the market effectively, develop targeted strategies, and capitalize on emerging trends across different operational contexts and geographical regions.

- By Type:

- Ballast Tampers

- Track Renewal Trains

- Rail Grinders

- Rail Cranes

- Ballast Cleaners

- Rail-Laying Machines

- Sleeper Laying Machines

- Other Track Equipment (e.g., Track Stabilizers, Ditching Machines)

- By Operation:

- Manual

- Semi-Automatic

- Automatic

- By Application:

- New Track Construction

- Track Maintenance & Repair

- Track Upgrades & Rehabilitation

- By End-User:

- National & Public Railways

- Metro & Urban Transit Systems

- Industrial Railways & Private Operators

- Construction Contractors

Track Laying Equipment Market Value Chain Analysis

The value chain for the Track Laying Equipment Market is a complex network of interconnected activities, commencing from the upstream supply of raw materials and components, moving through manufacturing, and culminating in distribution, sales, and aftermarket services. Upstream activities involve the procurement of specialized steel alloys, hydraulic systems, electronic components, and advanced sensors from a global network of suppliers. These materials and components are critical for ensuring the durability, performance, and technological sophistication of the final machinery. Manufacturers rely heavily on robust supplier relationships to ensure timely delivery, quality assurance, and cost efficiency, forming the foundational layer of the value chain. Research and development also play a significant upstream role, driving innovation in materials and system designs.

Midstream activities are dominated by the equipment manufacturers, who design, assemble, and test the highly specialized track laying machinery. This stage involves intricate engineering processes, quality control, and adherence to international safety and performance standards. Manufacturers often invest heavily in R&D to integrate advanced technologies such as automation, IoT connectivity, and artificial intelligence into their products, differentiating themselves in a competitive market. Furthermore, they are responsible for ensuring the compatibility of various subsystems and the overall reliability of the heavy machinery. The manufacturing process often involves custom-building equipment to meet specific client requirements, reflecting the diverse operational needs within the railway industry.

Downstream activities encompass the distribution, sales, and aftermarket services that connect the manufacturers to the end-users. Distribution channels are typically a mix of direct sales, where manufacturers engage directly with large railway authorities and contractors, and indirect channels involving authorized dealers, distributors, and rental companies. Rental services have gained prominence, offering flexibility to contractors who may not wish to commit to significant capital investments for short-term projects. Aftermarket services, including maintenance, spare parts supply, training, and technical support, are crucial for ensuring the long-term operational efficiency and lifespan of the equipment. These services are vital for customer retention and represent a significant revenue stream for manufacturers, reinforcing their commitment to client satisfaction and operational continuity.

Track Laying Equipment Market Potential Customers

The primary potential customers for track laying equipment are entities responsible for the construction, maintenance, and expansion of railway infrastructure across various scales and operational environments. National and public railway authorities, such as network operators in Europe or national rail corporations in Asia, represent a significant segment. These entities manage vast and complex railway networks, necessitating a constant demand for heavy-duty, high-capacity equipment for both new construction projects and the extensive maintenance of existing lines. Their procurement decisions are often influenced by long-term strategic plans, government funding cycles, and stringent regulatory requirements for safety and efficiency, often leading to large-scale, multi-year contracts.

Urban transit companies, including metro and subway operators, constitute another critical customer segment. With increasing urbanization and the development of new metropolitan areas, there is a continuous global investment in expanding and upgrading urban rail systems. These customers often require specialized, compact, and highly maneuverable equipment capable of operating in confined spaces and during limited operational windows within densely populated areas. Their focus is often on minimizing disruption to public services, optimizing project timelines, and ensuring the highest levels of safety and operational reliability within urban environments, driving demand for technologically advanced and efficient machinery.

Furthermore, specialized construction contractors and private railway operators also represent substantial buyer segments. Construction contractors are typically engaged by public or private entities to execute specific railway projects, ranging from new line construction to track rehabilitation. Their purchasing decisions are driven by project-specific requirements, equipment versatility, and the need for cost-effective solutions that can be deployed across various sites. Private railway operators, particularly those in industrial sectors such as mining, ports, and heavy industry, require track laying equipment for their dedicated rail networks. These operators prioritize equipment durability, robust performance under challenging conditions, and efficient maintenance to ensure uninterrupted operational flows for their core business activities, making them consistent buyers of robust and reliable machinery.

Track Laying Equipment Market Key Technology Landscape

The key technology landscape of the Track Laying Equipment Market is rapidly evolving, driven by the imperative for enhanced precision, efficiency, safety, and automation in railway infrastructure projects. Modern track laying equipment integrates advanced sensor technologies such as GPS/GNSS for centimeter-level positioning and precise track alignment, along with LiDAR and imaging systems for comprehensive track scanning and defect detection. These technologies provide real-time data on track geometry, ballast profiles, and rail conditions, allowing for highly accurate adjustments and informed decision-making during operation. The adoption of these precision instruments significantly reduces the margin for error, ensuring that tracks are laid and maintained to the most stringent international standards for safety and performance.

Automation and robotics are at the forefront of technological innovation in this market. Advanced hydraulic and electric control systems enable sophisticated automation of complex tasks, from precise tamping and leveling to synchronized rail and sleeper placement. Robotic arms are increasingly utilized for repetitive and high-precision tasks like welding and fastening, significantly improving speed and consistency while reducing labor requirements and enhancing worker safety. The development of semi-autonomous and fully autonomous track laying machines, leveraging artificial intelligence and machine learning algorithms, marks a transformative shift, allowing equipment to operate with minimal human intervention, particularly in hazardous or remote environments, optimizing operational efficiency and project timelines.

Furthermore, the integration of IoT (Internet of Things) and digital twin technology is revolutionizing equipment management and operational planning. IoT sensors embedded in track laying equipment facilitate remote monitoring of machine health, performance, and utilization, enabling predictive maintenance and optimizing operational schedules. This connectivity allows for real-time data transmission to central control systems, offering comprehensive insights into project progress and potential issues. Digital twin technology creates virtual replicas of equipment and track sections, allowing operators to simulate various scenarios, optimize work processes, and train personnel in a safe, virtual environment, thereby enhancing efficiency and reducing risks across the entire lifecycle of track laying operations and infrastructure management.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market, primarily fueled by extensive government investments in high-speed rail networks, urban metro expansions in countries like China, India, Japan, and Southeast Asian nations. Rapid urbanization and the need for efficient public transport systems are key drivers.

- Europe: A mature market characterized by significant investments in maintaining and upgrading aging railway infrastructure, alongside the development of new cross-border high-speed rail lines. Germany, France, and the UK are prominent players, emphasizing advanced automation and sustainability.

- North America: The market here is driven by the modernization of existing freight rail lines, which are crucial for economic logistics, and a gradual expansion of passenger rail, including high-speed corridor projects. Focus on efficiency, safety, and digital integration.

- Latin America: Emerging market with increasing investments in railway infrastructure, particularly for resource transportation (mining, agriculture) and urban transit projects in countries like Brazil, Argentina, and Mexico. Growth is project-driven and often reliant on foreign investment.

- Middle East & Africa: This region is witnessing substantial new railway network development to diversify economies and enhance regional connectivity. Large-scale projects in the UAE, Saudi Arabia, and Egypt are driving demand for advanced track laying equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Track Laying Equipment Market.- Plasser & Theurer

- Harsco Corporation

- CRRC Corporation Limited

- Geismar

- Speno International

- Loram Maintenance of Way, Inc.

- Herzog

- C.C. & S.L. Limited

- Goldschmidt Thermit Group

- Robel Bahnbaumaschinen GmbH

- Vossloh AG

- Pandrol (Delachaux Group)

- Matisa Matériel Industriel SA

- Nordco Inc.

- STM S.p.A. (Società Trevi Mantecon)

Frequently Asked Questions

What are the primary factors driving growth in the Track Laying Equipment Market?

The Track Laying Equipment Market is primarily driven by significant global investments in railway infrastructure, including the expansion of high-speed rail networks and urban transit systems, particularly in Asia Pacific. Government initiatives focused on sustainable transportation, coupled with the ongoing need for maintenance and modernization of existing rail lines worldwide, are also crucial growth catalysts. Technological advancements leading to more efficient, automated, and safer equipment further contribute to market expansion.

How is artificial intelligence impacting track laying operations?

Artificial intelligence is profoundly impacting track laying operations by enabling advanced automation, enhancing precision, and improving overall efficiency and safety. AI facilitates predictive maintenance for equipment and infrastructure, automates track inspection through intelligent vision systems, optimizes project planning, and allows for real-time data analysis. This leads to more accurate track alignment, reduced downtime, lower operational costs, and the development of autonomous track laying machinery.

What are the main types of track laying equipment available in the market?

The market offers a diverse range of specialized track laying equipment. Key types include ballast tampers for compacting ballast, track renewal trains for efficient track replacement, rail grinders for maintaining rail surface quality, and rail cranes for heavy lifting. Other essential equipment comprises ballast cleaners, rail-laying machines, and sleeper laying machines, each designed for specific functions in the construction, maintenance, and rehabilitation of railway tracks.

Which geographical regions are experiencing the most significant growth in this market?

Asia Pacific is currently experiencing the most significant growth in the Track Laying Equipment Market, driven by extensive infrastructure development projects in countries like China and India. Europe also maintains robust demand due to continuous modernization and maintenance efforts. Emerging markets in Latin America and the Middle East & Africa are showing substantial potential with new railway network initiatives aimed at economic development and improved connectivity.

What are the key challenges faced by manufacturers and operators in the track laying equipment industry?

Key challenges in the track laying equipment industry include the high initial capital investment required for advanced machinery, making it difficult for some operators to acquire. There is also a notable shortage of skilled labor to operate and maintain increasingly complex and automated equipment. Additionally, stringent environmental regulations impose compliance burdens, while the cyclical nature of government funding for infrastructure projects can lead to market volatility and uncertainty for stakeholders.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager