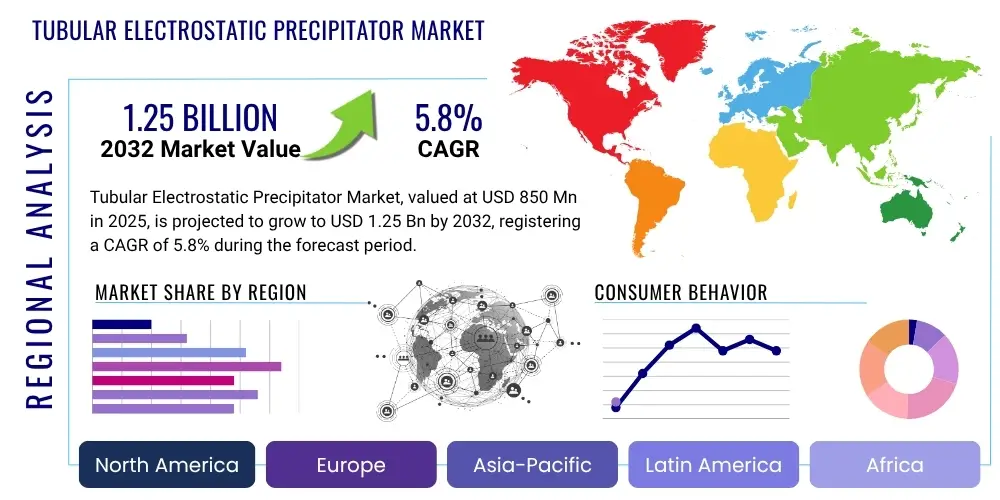

Tubular Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430101 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Tubular Electrostatic Precipitator Market Size

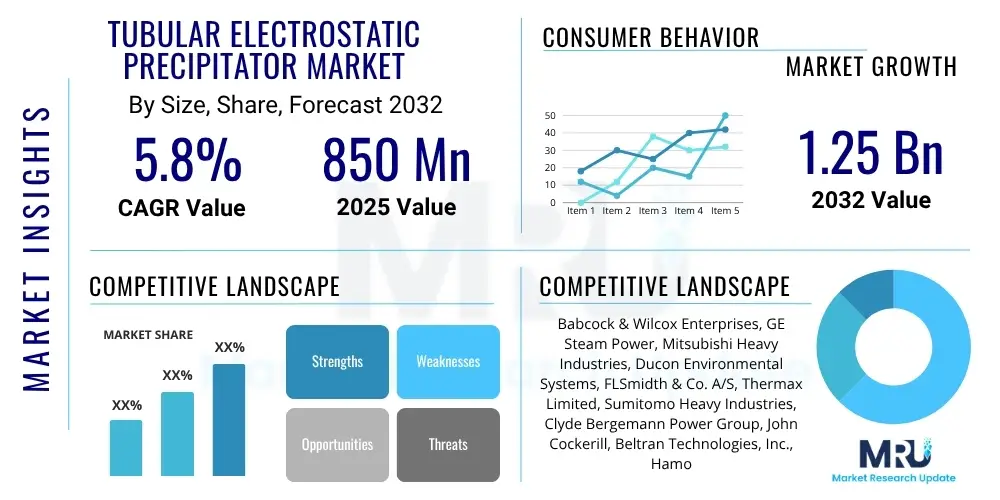

The Tubular Electrostatic Precipitator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 850 Million in 2025 and is projected to reach USD 1.25 Billion by the end of the forecast period in 2032.

Tubular Electrostatic Precipitator Market introduction

The Tubular Electrostatic Precipitator (TEP) market focuses on advanced air pollution control systems designed to remove particulate matter from industrial gas streams. TEPs are highly efficient devices that utilize electrostatic forces to separate dust particles and aerosols from flue gases. The product, a specialized type of electrostatic precipitator, consists of a series of cylindrical collection electrodes, often referred to as tubes, through which the contaminated gas flows. Inside these tubes, discharge electrodes generate a strong electric field, charging the particulate matter, which then migrates to and collects on the inner surface of the tubes.

Major applications for Tubular Electrostatic Precipitators span a diverse range of heavy industries including power generation, cement manufacturing, metallurgical processes, chemical production, and waste incineration. Their robust design and operational flexibility make them particularly well-suited for applications involving sticky, corrosive, or high-resistivity dusts, as well as for handling wet gas streams. The key benefits of TEPs include their exceptional particulate removal efficiency, particularly for sub-micron particles, low pressure drop contributing to energy savings, and their ability to operate effectively in harsh environments with varying temperatures and moisture content.

Driving factors propelling the growth of the Tubular Electrostatic Precipitator market primarily include the global tightening of environmental regulations governing industrial emissions, increasing public and governmental emphasis on air quality improvement, and the ongoing industrialization and urbanization in developing economies. The demand for sustainable and highly efficient pollution control technologies is also a significant driver, as industries seek solutions that offer both regulatory compliance and operational cost-effectiveness. The inherent advantages of TEPs in handling specific types of particulate matter that challenge other technologies further cement their market position.

Tubular Electrostatic Precipitator Market Executive Summary

The Tubular Electrostatic Precipitator market is experiencing robust growth driven by a confluence of stringent global environmental regulations and increasing industrial activity, particularly in emerging economies. Key business trends indicate a strong focus on technological advancements aimed at enhancing collection efficiency, reducing energy consumption, and improving the operational lifespan of TEP systems. Manufacturers are increasingly investing in modular designs, smart control systems, and integration capabilities to offer customized solutions that meet specific industry requirements and challenging flue gas conditions. Furthermore, strategic collaborations and mergers among leading players are observed, aimed at expanding geographic reach and strengthening product portfolios, reflecting a dynamic competitive landscape focused on innovation and market consolidation.

Regional trends highlight the Asia Pacific as the dominant and fastest-growing market, primarily fueled by rapid industrial expansion in countries like China, India, and Southeast Asian nations. This growth is accompanied by escalating concerns over air pollution and the subsequent implementation of stricter emission standards, compelling industries to adopt advanced pollution control technologies. North America and Europe, while mature markets, demonstrate consistent demand driven by ongoing retrofitting projects, stringent regulatory compliance, and a strong emphasis on maintaining existing air quality standards. Latin America and the Middle East and Africa are also showing promising growth as new industrial projects come online and environmental awareness gains traction, though at a comparatively slower pace.

Segment trends reveal a sustained demand for wet TEPs, particularly in applications involving corrosive or sticky particulate matter, offering superior collection efficiency and simultaneous gas cooling and pollutant absorption. Dry TEPs continue to be favored for high-temperature applications and larger particle removal. By application, the power generation and cement industries remain significant contributors to market revenue, with increasing demand also observed from metallurgical and chemical processing sectors due to their inherent challenges in managing diverse emission profiles. The market is also seeing a shift towards higher capacity TEP units, reflecting the scale of modern industrial operations and the need for more comprehensive pollution control solutions.

AI Impact Analysis on Tubular Electrostatic Precipitator Market

Common user questions regarding AI's impact on the Tubular Electrostatic Precipitator market often revolve around optimizing operational efficiency, enhancing predictive maintenance capabilities, and improving the overall lifespan and performance of TEP systems. Users are keen to understand how artificial intelligence can move beyond traditional control systems to offer smarter, more autonomous pollution control. Key themes include the potential for AI to adapt to varying operational conditions in real-time, diagnose complex faults before they lead to downtime, and contribute to significant energy savings. There is a clear expectation that AI will transform TEPs into more intelligent and self-optimizing assets within industrial plants, leading to reduced operational costs and improved environmental compliance.

- Predictive Maintenance: AI algorithms analyze sensor data from TEPs to forecast potential equipment failures, optimizing maintenance schedules and reducing unscheduled downtime.

- Real-time Performance Optimization: AI systems dynamically adjust TEP operational parameters, such as voltage and rapping intensity, in response to varying gas flow, dust load, and particle characteristics, maximizing collection efficiency and minimizing energy consumption.

- Fault Diagnosis and Anomaly Detection: Machine learning models can quickly identify subtle anomalies in TEP operation, pinpointing issues like electrode degradation or insulator fouling, enabling prompt corrective actions.

- Energy Efficiency Improvement: AI-driven control strategies optimize power consumption by ensuring the TEP operates only at the necessary intensity for given pollution levels, leading to significant energy savings.

- Process Automation and Remote Monitoring: AI facilitates advanced automation of TEP operations and enables comprehensive remote monitoring and control, reducing the need for manual intervention and enhancing operational safety.

- Improved Lifespan and Reliability: By ensuring optimal operating conditions and proactive maintenance, AI contributes to extending the operational life of TEP components and increasing overall system reliability.

DRO & Impact Forces Of Tubular Electrostatic Precipitator Market

The Tubular Electrostatic Precipitator market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces. The primary drivers are the escalating global concerns over air quality and the subsequent implementation of increasingly stringent emission regulations by environmental agencies worldwide. Industrial expansion, particularly in rapidly developing economies, concurrently generates a greater volume of particulate emissions, necessitating robust and efficient pollution control technologies like TEPs. Furthermore, the inherent advantages of TEPs in handling fine and challenging particulate matter, coupled with their long operational life and relatively low operating costs over time, position them favorably against alternative solutions, driving their adoption across diverse industrial applications. The growing awareness among industries about their environmental responsibilities and the pursuit of corporate social responsibility initiatives also contribute significantly to market expansion.

Despite these strong drivers, the market faces notable restraints. The initial capital expenditure for installing Tubular Electrostatic Precipitator systems can be substantial, representing a significant investment for industries, especially small and medium-sized enterprises. The complexity of TEP design, installation, and specialized maintenance requirements often necessitates skilled personnel and regular upkeep, which can add to the total cost of ownership. Moreover, competition from other established and emerging particulate control technologies, such as bag filters and wet scrubbers, poses a challenge, particularly in applications where TEPs may not offer a distinct cost or performance advantage. Space constraints in existing industrial facilities for TEP installation can also present a practical limitation.

Significant opportunities for market growth lie in the retrofitting of older industrial plants with modern TEP systems to meet updated emission standards, particularly in North America and Europe. Emerging economies in Asia Pacific, Latin America, and the Middle East and Africa offer substantial greenfield project opportunities as industrial infrastructure continues to develop. Technological advancements, including the integration of smart sensors, IoT, and AI for predictive maintenance and operational optimization, present avenues for product innovation and differentiation. Furthermore, the increasing focus on resource recovery from collected particulate matter and the potential for TEPs to be integrated into broader carbon capture, utilization, and storage (CCUS) strategies could unlock new market segments and applications, expanding the overall scope and value proposition of these vital pollution control systems.

Segmentation Analysis

The Tubular Electrostatic Precipitator market is comprehensively segmented to provide a detailed understanding of its various facets, enabling tailored market strategies and focused product development. These segments delineate the market based on intrinsic product characteristics, the nature of the industries served, and the capacity of the systems, reflecting the diverse requirements of end-users. Such a breakdown is crucial for identifying specific growth pockets and addressing unique challenges within each category. The segmentation analysis reveals distinct trends in demand and adoption rates across different types, applications, and capacities, highlighting areas of high potential and competitive intensity. Understanding these distinctions is paramount for stakeholders aiming to optimize their market positioning and maximize their penetration in this critical environmental technology sector.

- By Type:

- Dry Tubular Electrostatic Precipitators

- Wet Tubular Electrostatic Precipitators

- By Application:

- Power Generation (Coal-fired power plants, Biomass power plants)

- Cement Industry

- Metallurgical Industry (Steel plants, Foundries, Non-ferrous metals)

- Chemical Industry

- Waste Incineration Plants

- Pulp and Paper Industry

- Glass Industry

- Other Industrial Applications

- By Capacity:

- Small Capacity (Below 50,000 Am3/hr)

- Medium Capacity (50,000 - 200,000 Am3/hr)

- Large Capacity (Above 200,000 Am3/hr)

- By End-Use Industry:

- Industrial

- Commercial

Value Chain Analysis For Tubular Electrostatic Precipitator Market

The value chain for the Tubular Electrostatic Precipitator market begins with upstream activities involving the sourcing and manufacturing of essential raw materials and components. This stage includes suppliers of specialized metals like high-grade steel for structural components, ceramics for insulators, and electrical components such as high-voltage power supplies, transformers, and control systems. Key players in this segment are material producers and component fabricators who ensure the quality and specific technical requirements are met for the robust operation of TEP units in harsh industrial environments. Research and development activities also form a crucial part of the upstream, focusing on improving collection efficiency, reducing energy consumption, and enhancing the durability of TEP designs and materials. This foundational stage dictates the overall quality, performance, and cost-effectiveness of the final TEP system.

Moving downstream, the value chain encompasses the manufacturing, assembly, and integration of the TEP systems, often followed by installation, commissioning, and ongoing maintenance services. Major TEP manufacturers typically manage the design, fabrication, and assembly in-house, ensuring adherence to strict engineering standards. The distribution channel plays a vital role in connecting these manufacturers with end-users. Direct sales are common for large-scale industrial projects where manufacturers engage directly with clients, offering customized solutions, technical support, and project management services. This direct approach ensures a deep understanding of client needs and facilitates complex system integration. Indirect channels involve collaboration with engineering, procurement, and construction (EPC) contractors, system integrators, and regional distributors or agents who provide local market access, installation expertise, and post-sales support, particularly for smaller projects or in geographically dispersed markets.

Post-sales activities, which include operation, maintenance, and periodic upgrades, are critical for the long-term performance and efficiency of TEPs, thus forming an integral part of the downstream segment. Service providers specializing in maintenance, spare parts supply, performance monitoring, and efficiency optimization contribute significantly to the lifecycle value of TEP installations. The collaboration between direct sales teams and indirect partners ensures comprehensive market coverage and service delivery, allowing TEP solutions to reach a broad spectrum of industrial clients globally. The efficiency of this value chain, from raw material procurement to after-sales support, directly impacts customer satisfaction, market reputation, and the sustained growth of the Tubular Electrostatic Precipitator market.

Tubular Electrostatic Precipitator Market Potential Customers

Potential customers for Tubular Electrostatic Precipitators are predominantly found across heavy industrial sectors that generate significant volumes of particulate matter emissions during their operational processes. These end-users are driven by the imperative to comply with increasingly stringent environmental regulations and to improve air quality, as well as by the desire to optimize their operational efficiency and enhance their corporate image. The primary buyers of TEP systems are entities involved in large-scale manufacturing and energy production, where effective particulate control is not just a regulatory requirement but also a critical component of sustainable operations. These industries often require robust, high-efficiency, and reliable solutions that can handle diverse and challenging gas stream compositions, temperatures, and dust characteristics, making TEPs an ideal choice for specific applications.

Key end-user segments include the power generation industry, particularly coal-fired and biomass power plants, which are major sources of fly ash and other particulates. The cement industry represents another significant customer base, requiring TEPs for capturing dust from kilns and clinker coolers. Metallurgical facilities, such as steel mills, foundries, and non-ferrous metal processing plants, rely on TEPs to manage emissions from smelting, refining, and casting operations. The chemical industry also presents substantial demand for TEPs, especially for processes involving acid mists, sticky aerosols, or fine chemical powders. Furthermore, waste incineration plants utilize TEPs to clean flue gases generated from the combustion of municipal, industrial, and hazardous waste, ensuring compliance with strict air pollution standards and protecting public health from harmful emissions.

Beyond these traditional heavy industries, the pulp and paper, glass manufacturing, and certain specialized mining operations also represent important customer segments, each with unique challenges in particulate emission control that TEPs are well-equipped to address. The growing trend of retrofitting older industrial facilities to meet modern environmental standards also expands the customer base, as existing plants seek to upgrade their pollution control infrastructure without complete overhauls. Overall, any industrial entity facing significant particulate matter emission challenges, particularly those with complex gas streams or stringent efficiency requirements, is a potential buyer of Tubular Electrostatic Precipitator technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 850 Million |

| Market Forecast in 2032 | USD 1.25 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises, GE Steam Power, Mitsubishi Heavy Industries, Ducon Environmental Systems, FLSmidth & Co. A/S, Thermax Limited, Sumitomo Heavy Industries, Clyde Bergemann Power Group, John Cockerill, Beltran Technologies, Inc., Hamon Group, Fujian Longking Co. Ltd., AAF International (Daikin Industries), Dustex, Alstom Power, KC Cottrell, CTP, Anrui, Feida, Howden Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tubular Electrostatic Precipitator Market Key Technology Landscape

The Tubular Electrostatic Precipitator market is characterized by a dynamic technology landscape continually evolving to meet more stringent emission standards and operational demands. At its core, the technology relies on high-voltage power supplies and robust electrode designs. Modern TEPs incorporate advanced high-frequency transformer-rectifier sets that provide precise control over voltage and current, thereby optimizing the charging and collection efficiency of particulate matter while minimizing energy consumption. Innovations in discharge electrode geometry and materials, such as spiked or barbed designs, enhance corona discharge and particle charging, contributing to superior performance even with difficult-to-collect dusts. Furthermore, the development of sophisticated rapping systems for dry TEPs, employing pneumatic or electromagnetic actuators, ensures effective dust removal from collection electrodes without re-entrainment into the gas stream. For wet TEPs, continuous liquid film systems are critical for washing away collected particles and preventing re-emission.

Control systems are another pivotal aspect of the TEP technology landscape. The transition from analog to digital control systems has enabled more precise management of operating parameters, offering real-time monitoring, fault detection, and automated optimization. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) are commonly integrated to manage power levels, rapping cycles, and gas flow, ensuring stable and efficient operation under varying load conditions. The advent of computational fluid dynamics (CFD) modeling has revolutionized TEP design, allowing engineers to simulate gas flow patterns and particle trajectories within the precipitator. This enables optimized internal geometries, improved gas distribution, and enhanced collection efficiency, reducing the need for extensive physical prototyping and accelerating development cycles. CFD also helps in predicting pressure drops and ensuring uniform velocity profiles, which are crucial for performance.

The latest advancements are heavily influenced by the integration of smart technologies, IoT, and artificial intelligence. Smart sensors are being deployed to collect granular data on gas temperature, humidity, particulate concentration, and electrode conditions in real-time. This data feeds into IoT platforms, enabling remote monitoring and predictive analytics. AI and machine learning algorithms are increasingly being used to analyze this vast dataset, providing insights for predictive maintenance, optimizing operational parameters dynamically, and diagnosing potential issues before they lead to downtime. This intelligent automation not only enhances the reliability and lifespan of TEP systems but also significantly improves their energy efficiency and overall environmental performance, marking a significant shift towards more autonomous and adaptive air pollution control solutions. The focus remains on developing TEPs that are not only highly effective but also cost-efficient, energy-saving, and capable of operating with minimal human intervention.

Regional Highlights

- North America: This region represents a mature market with stringent environmental regulations enforced by agencies like the EPA. Demand is primarily driven by retrofitting existing industrial facilities to meet updated emission standards and the continuous need for high-efficiency pollution control in sectors such as power generation and metallurgy. Innovation in smart TEP technologies and digital integration for predictive maintenance are key trends.

- Europe: Similar to North America, Europe is characterized by strict environmental directives from the European Union, fostering a strong demand for advanced TEP systems. The focus here is on sustainability, energy efficiency, and adherence to Best Available Techniques (BAT) for industrial emissions. Countries like Germany, the UK, and France are significant contributors, with a strong emphasis on reducing industrial carbon footprints.

- Asia Pacific (APAC): The APAC region is the largest and fastest-growing market for Tubular Electrostatic Precipitators, driven by rapid industrialization, urbanization, and a burgeoning manufacturing sector in countries like China, India, and Southeast Asian nations. Increasing awareness of air pollution issues and the implementation of stricter environmental laws are compelling industries to adopt advanced pollution control solutions at an unprecedented rate. Greenfield investments in power, cement, and steel sectors are major demand catalysts.

- Latin America: This region is experiencing steady growth in the TEP market, propelled by developing industrial infrastructure and increasing environmental awareness. Countries like Brazil and Mexico are leading the adoption of modern pollution control technologies, particularly in mining, cement, and power generation sectors, as regulatory frameworks become more defined and enforced.

- Middle East and Africa (MEA): The MEA market for TEPs is nascent but holds significant potential due to ongoing investments in industrial and infrastructure projects, particularly in the oil and gas, petrochemical, and power generation sectors. While environmental regulations are still evolving in some parts, a growing emphasis on industrial sustainability and the diversification of economies are expected to drive future demand for air pollution control solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tubular Electrostatic Precipitator Market.- Babcock & Wilcox Enterprises

- GE Steam Power

- Mitsubishi Heavy Industries

- Ducon Environmental Systems

- FLSmidth & Co. A/S

- Thermax Limited

- Sumitomo Heavy Industries

- Clyde Bergemann Power Group

- John Cockerill

- Beltran Technologies, Inc.

- Hamon Group

- Fujian Longking Co. Ltd.

- AAF International (Daikin Industries)

- Dustex

- Alstom Power

- KC Cottrell

- CTP

- Anrui

- Feida

- Howden Group

Frequently Asked Questions

Analyze common user questions about the Tubular Electrostatic Precipitator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Tubular Electrostatic Precipitator (TEP) and how does it work?

A Tubular Electrostatic Precipitator is an air pollution control device that removes fine particulate matter from industrial gas streams. It functions by passing gas through a series of tubes where high voltage electrodes charge particles, causing them to migrate to and collect on the inner surfaces of the tubes. Collected dust is then periodically removed.

What are the primary applications of Tubular Electrostatic Precipitators?

TEPs are primarily used in heavy industries such as power generation (coal-fired and biomass plants), cement manufacturing, metallurgical processes (steel, foundries), chemical production, and waste incineration. They are particularly effective for challenging applications involving sticky, corrosive, or high-resistivity dusts and wet gas streams.

What are the key benefits of utilizing TEPs for industrial emission control?

Key benefits include very high particulate removal efficiency, especially for sub-micron particles, low pressure drop leading to reduced energy consumption, robust operation in harsh industrial environments (high temperature, high moisture), and a long operational lifespan with proper maintenance.

How do TEPs contribute to environmental compliance and sustainability?

TEPs significantly reduce the emission of harmful particulate matter, helping industries comply with stringent air quality regulations. By efficiently cleaning exhaust gases, they contribute to improved public health, reduced environmental impact, and support corporate sustainability goals through effective pollution control and, in some cases, resource recovery.

What factors are driving the growth of the Tubular Electrostatic Precipitator market?

Market growth is primarily driven by escalating global environmental concerns, increasingly stringent air emission regulations worldwide, rapid industrialization in developing economies, and the inherent technical advantages of TEPs in handling complex particulate challenges, coupled with technological advancements like AI integration.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager