Ultra-high Performance Concrete Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430457 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Ultra-high Performance Concrete Market Size

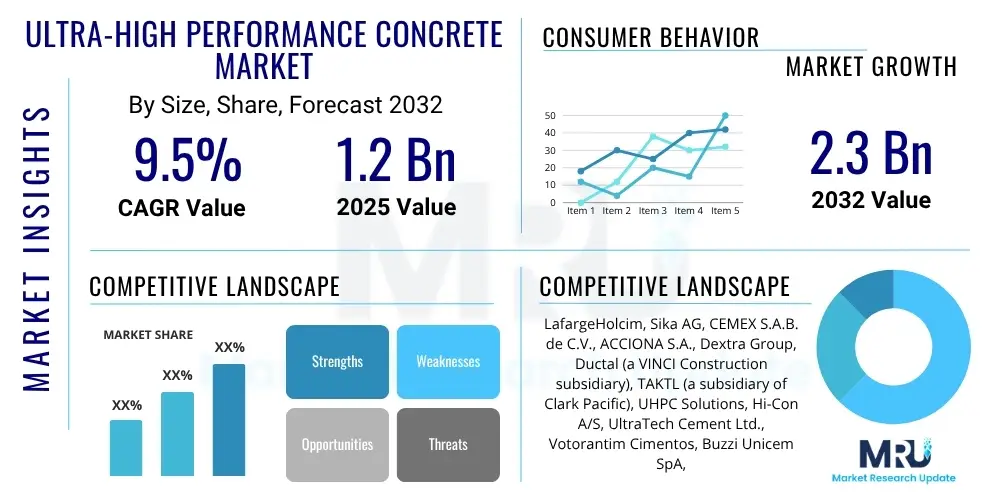

The Ultra-high Performance Concrete Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at $1.2 Billion in 2025 and is projected to reach $2.3 Billion by the end of the forecast period in 2032.

Ultra-high Performance Concrete Market introduction

Ultra-high Performance Concrete (UHPC) represents a revolutionary class of concrete characterized by its exceptional strength, durability, and ductility, far exceeding conventional concrete. This advanced composite material is typically formulated with a low water-to-binder ratio, fine reactive powders, and steel or synthetic fibers, contributing to its dense microstructure and superior mechanical properties. Major applications span critical infrastructure projects such as bridges, high-rise buildings, long-span structures, and protective constructions, where its enhanced performance is invaluable. The inherent benefits of UHPC include significantly extended service life, reduced maintenance costs, the ability to create slender and innovative architectural designs, and improved resilience against extreme environmental conditions and seismic events.

The market for UHPC is primarily driven by the escalating global demand for sustainable and resilient infrastructure, fueled by rapid urbanization and the need for modern construction solutions. Its superior mechanical properties enable designers to achieve thinner, lighter, and more durable structures, offering substantial economic and environmental advantages. Furthermore, the increasing focus on repairing and rehabilitating aging infrastructure worldwide presents a significant impetus for UHPC adoption, as it offers a robust and long-lasting solution for structural enhancements. The material's aesthetic versatility also drives its use in architectural facades and decorative elements, expanding its application scope beyond purely structural contexts.

Ultra-high Performance Concrete Market Executive Summary

The Ultra-high Performance Concrete market is experiencing robust growth, propelled by several key business, regional, and segmental trends. Globally, the construction industry is witnessing a paradigm shift towards high-performance and sustainable materials, with UHPC emerging as a preferred choice due to its superior durability, strength, and reduced lifecycle costs. Business trends indicate a surge in strategic collaborations, mergers, and acquisitions aimed at expanding production capacities and geographical reach, alongside significant investments in research and development to optimize mix designs and application techniques. Companies are increasingly focusing on integrating digital solutions and automation into UHPC production to enhance efficiency and consistency.

From a regional perspective, Asia Pacific leads the market, driven by massive infrastructure development projects, particularly in countries like China and India, which are rapidly urbanizing and investing heavily in transportation networks and urban complexes. North America and Europe are also significant markets, primarily focusing on the rehabilitation and upgrading of aging infrastructure, where UHPC offers unparalleled longevity and resistance to degradation. The Middle East and Africa regions are showing promising growth, attributed to ambitious construction programs and mega-projects. Segment trends highlight the dominance of precast UHPC elements due to their quality control and speed of construction, while ready-mix UHPC is gaining traction for on-site applications requiring flexibility and large volumes.

AI Impact Analysis on Ultra-high Performance Concrete Market

User inquiries concerning AI's influence on the Ultra-high Performance Concrete market often revolve around optimizing material properties, enhancing production efficiency, and improving structural design. Common questions address how AI can refine UHPC mix designs to achieve specific performance characteristics, its role in quality control during manufacturing and curing, and its potential for predicting the long-term behavior and durability of UHPC structures. There is also significant interest in AI's contribution to sustainable UHPC production, by minimizing waste and optimizing resource utilization, and in leveraging AI for automated inspection and maintenance of UHPC infrastructure. Users express expectations for AI to unlock new levels of precision, cost-effectiveness, and environmental responsibility within the UHPC domain, while also recognizing the challenges related to data acquisition and model validation.

- AI optimizes UHPC mix designs by predicting optimal material combinations for desired mechanical and durability properties.

- Enhanced quality control through AI-driven sensor monitoring during mixing, casting, and curing processes.

- Predictive analytics powered by AI for assessing long-term performance and lifespan of UHPC structures under varying conditions.

- Automated defect detection and structural health monitoring in UHPC components using AI-driven image recognition.

- Improved sustainability by AI-guided reduction of cement content and optimization of supplementary cementitious materials.

- AI-enabled robotic fabrication and 3D printing of complex UHPC geometries, reducing labor costs and construction time.

- Advanced simulation and modeling using AI for complex structural analysis and design with UHPC.

DRO & Impact Forces Of Ultra-high Performance Concrete Market

The Ultra-high Performance Concrete market is shaped by a complex interplay of drivers, restraints, opportunities, and competitive impact forces. Key drivers include the escalating global demand for robust and sustainable infrastructure, particularly in rapidly urbanizing regions, and the increasing investment in civil engineering projects worldwide. The superior mechanical properties of UHPC, such as ultra-high compressive strength, enhanced durability, and ductility, make it an attractive alternative to traditional concrete for demanding applications, leading to greater adoption. Furthermore, a growing emphasis on lifecycle cost reduction and a lower carbon footprint in construction also favors UHPC, as its extended service life significantly reduces maintenance and replacement needs. The flexibility in architectural design offered by UHPC also expands its application possibilities.

However, the market faces significant restraints, primarily the high initial material cost compared to conventional concrete, which can deter adoption for budget-sensitive projects. The requirement for specialized mixing, casting, and curing techniques, along with a lack of widespread awareness and standardized practices in some regions, also poses challenges. Opportunities for market growth are abundant, particularly in emerging economies where infrastructure development is booming, and in the retrofitting and rehabilitation of existing structures. Advancements in material science, leading to the development of more cost-effective fibers and admixtures, along with increased prefabrication and modular construction methods, present lucrative avenues for expansion. Moreover, stringent environmental regulations pushing for sustainable building materials offer a clear pathway for UHPC market penetration.

The impact forces influencing the UHPC market include the bargaining power of buyers, which is moderate due to the specialized nature of the product and its high performance value, but can increase with greater market competition. The bargaining power of suppliers of raw materials like high-strength cement, steel fibers, and specialized admixtures is relatively high due to the concentrated nature of some of these industries. The threat of new entrants is low due to the significant capital investment, specialized knowledge, and technological expertise required for UHPC production. However, the threat of substitutes, such as conventional high-performance concrete or advanced steel composites, remains a moderate factor. Competitive rivalry among existing players is intensifying as companies vie for market share, driving innovation and efficiency.

Segmentation Analysis

The Ultra-high Performance Concrete market is meticulously segmented to provide a comprehensive understanding of its various components and growth trajectories. These segmentations allow for detailed analysis of market dynamics, identifying key areas of demand and supply across different product types, applications, and regional landscapes. The primary goal of this segmentation is to offer granular insights into market opportunities, competitive positioning, and strategic investment decisions for stakeholders involved in the UHPC industry. Each segment is influenced by unique drivers and restraints, contributing to a diverse and evolving market structure.

- By Type

- Fiber Reinforced UHPC

- Non-Fiber Reinforced UHPC

- By Application

- Bridges and Roadways

- Buildings (High-rise, Commercial, Residential)

- Architectural Elements

- Security and Protection Structures

- Water and Marine Infrastructure

- Repair and Rehabilitation

- By End-Use Industry

- Construction

- Military and Defense

- Oil and Gas

- Industrial

- By Form

- Precast UHPC

- Cast-in-Place / Ready-Mix UHPC

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Ultra-high Performance Concrete Market

The value chain for the Ultra-high Performance Concrete market encompasses a sequence of activities from raw material sourcing to end-user consumption, involving various stakeholders and processes. The upstream segment primarily involves the procurement and supply of specialized raw materials critical for UHPC production. This includes high-strength cements, finely graded silica fume, ground granulated blast furnace slag, high-performance superplasticizers, and various types of fibers such as steel, PVA, or carbon fibers. Key suppliers in this stage are chemical companies, cement manufacturers, and fiber producers, whose quality and consistency directly impact the final UHPC product performance.

Moving downstream, these raw materials are processed by UHPC manufacturers, who often employ advanced mixing technologies and stringent quality control protocols to produce either precast UHPC elements or ready-mix UHPC for on-site applications. This stage involves significant research and development to optimize mix designs for specific project requirements. The distribution channel for UHPC products can be direct, particularly for large-scale infrastructure projects where manufacturers supply directly to major construction companies or government entities. Indirect channels involve specialized distributors or concrete suppliers who then sell to smaller contractors, architectural firms, or precast concrete plants for further fabrication. The choice of distribution channel often depends on the project size, geographical location, and the manufacturer's operational strategy.

Finally, the market reaches its end-users, which include general contractors, civil engineering firms, government agencies responsible for public infrastructure, and architectural design studios. These entities integrate UHPC into various applications such as bridges, buildings, coastal defenses, and specialized architectural facades. The effectiveness of the value chain is highly dependent on efficient logistics, technical support, and robust quality assurance mechanisms at every stage. Collaboration between material suppliers, manufacturers, and end-users is crucial for fostering innovation, ensuring product quality, and promoting broader adoption of UHPC solutions in the construction industry.

Ultra-high Performance Concrete Market Potential Customers

Potential customers for Ultra-high Performance Concrete are diverse, spanning various sectors that prioritize durability, high strength, and long-term performance in their construction and infrastructure projects. A primary segment includes government agencies and public works departments responsible for developing and maintaining critical national infrastructure. These entities frequently invest in UHPC for bridges, highways, tunnels, dams, and marine structures, where resistance to extreme loads, environmental degradation, and seismic activity is paramount. The long lifespan and reduced maintenance requirements of UHPC offer significant lifecycle cost savings, making it an attractive option for public sector investments.

Another significant customer base comprises commercial and residential developers, particularly those involved in constructing high-rise buildings, large-span structures, and architecturally demanding projects. UHPC allows for more slender designs, increased usable space, and enhanced aesthetic appeal, fulfilling both structural and design objectives. Industrial sector players, including those in oil and gas, energy, and heavy manufacturing, also constitute potential customers for specialized applications requiring extreme durability and resistance to harsh chemical or physical environments. Furthermore, military and defense organizations utilize UHPC for protective structures, fortifications, and critical infrastructure due to its superior blast and impact resistance.

Beyond new construction, a growing segment of potential customers includes repair and rehabilitation contractors and engineering firms specializing in retrofitting existing structures. UHPC is an ideal material for strengthening and extending the life of aging infrastructure, offering solutions for bridge deck overlays, structural repairs, and seismic upgrades. Architectural firms and precast concrete manufacturers also serve as intermediaries, procuring UHPC for bespoke structural and facade elements, showcasing the material's versatility and design flexibility. The increasing awareness of UHPC's advantages in terms of resilience, sustainability, and longevity continues to expand its potential customer base across both public and private sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.2 Billion |

| Market Forecast in 2032 | $2.3 Billion |

| Growth Rate | CAGR 9.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LafargeHolcim, Sika AG, CEMEX S.A.B. de C.V., ACCIONA S.A., Dextra Group, Ductal (a VINCI Construction subsidiary), TAKTL (a subsidiary of Clark Pacific), UHPC Solutions, Hi-Con A/S, UltraTech Cement Ltd., Votorantim Cimentos, Buzzi Unicem SpA, HeidelbergCement AG, Holcim Group, GCP Applied Technologies, BASF SE, Fosroc International Ltd., W. R. Grace & Co., Chryso S.A.S. (Saint-Gobain), Italcementi (HeidelbergCement Group) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ultra-high Performance Concrete Market Key Technology Landscape

The Ultra-high Performance Concrete market is continuously evolving, driven by significant advancements in material science, manufacturing processes, and digital integration. A fundamental aspect of the technology landscape involves sophisticated mix design methodologies, leveraging advanced computational tools and material characterization techniques to precisely tailor UHPC properties for specific applications. This includes optimizing particle packing densities, selecting ideal cementitious binders, and incorporating novel admixtures and fiber types to achieve desired strength, ductility, and durability. The development of self-consolidating UHPC formulations has also streamlined casting processes, reducing labor and improving finish quality.

In terms of manufacturing, automation and robotics are playing an increasingly pivotal role, particularly in the production of precast UHPC elements. Robotic systems enable precise mixing, casting, and finishing, ensuring consistency and high quality, while also facilitating the creation of complex geometries not achievable with traditional methods. Additive manufacturing, specifically 3D printing of UHPC, represents a cutting-edge technology allowing for highly customized and intricate structural components or architectural facades, significantly reducing waste and construction time. Furthermore, the integration of smart sensors and IoT devices into UHPC structures is enabling real-time monitoring of structural health, performance, and environmental conditions, moving towards intelligent infrastructure systems.

Beyond production, new technologies are also focusing on extending the lifecycle and enhancing the sustainability of UHPC. This includes the development of self-healing UHPC, where microcapsules or vascular networks within the concrete can autonomously repair cracks, further extending durability and reducing maintenance. Innovations in sustainable raw materials, such as supplementary cementitious materials (SCMs) from industrial by-products, are also a key focus, aiming to reduce the carbon footprint associated with cement production. These technological advancements collectively contribute to making UHPC a more versatile, cost-effective, and environmentally responsible material for modern construction.

Regional Highlights

- North America: This region is a mature market driven by extensive infrastructure rehabilitation and upgrading projects, particularly in the United States and Canada. There is a strong emphasis on extending the lifespan of existing bridges and roadways, as well as constructing resilient structures capable of withstanding extreme weather events. Innovation in mix designs and prefabrication techniques are key trends.

- Europe: European countries are at the forefront of sustainable construction and architectural innovation, contributing significantly to UHPC adoption. The market is propelled by stringent environmental regulations, a focus on aesthetically pleasing architectural designs, and the need for durable solutions for historical preservation and modern urban development. Germany, France, and the Nordic countries are key contributors.

- Asia Pacific (APAC): The APAC region represents the largest and fastest-growing market for UHPC, primarily fueled by rapid urbanization, massive infrastructure development initiatives, and increasing investments in commercial and residential construction, especially in China, India, and Southeast Asian nations. The demand for resilient and efficient construction materials for new mega-projects is a major driver.

- Latin America: This region is an emerging market for UHPC, with increasing investments in public infrastructure projects and a growing awareness of high-performance construction materials. Countries like Brazil and Mexico are witnessing gradual adoption, driven by the need to upgrade transportation networks and develop resilient buildings.

- Middle East and Africa (MEA): The MEA region is characterized by ambitious construction programs, particularly in the UAE, Saudi Arabia, and Qatar, focusing on mega-projects, futuristic cities, and diversified economic development. This creates significant demand for advanced construction materials like UHPC, especially for iconic architectural structures and robust infrastructure designed for harsh climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ultra-high Performance Concrete Market.- LafargeHolcim

- Sika AG

- CEMEX S.A.B. de C.V.

- ACCIONA S.A.

- Dextra Group

- Ductal (a VINCI Construction subsidiary)

- TAKTL (a subsidiary of Clark Pacific)

- UHPC Solutions

- Hi-Con A/S

- UltraTech Cement Ltd.

- Votorantim Cimentos

- Buzzi Unicem SpA

- HeidelbergCement AG

- Holcim Group

- GCP Applied Technologies

- BASF SE

- Fosroc International Ltd.

- W. R. Grace & Co.

- Chryso S.A.S. (Saint-Gobain)

- Italcementi (HeidelbergCement Group)

Frequently Asked Questions

What is Ultra-high Performance Concrete (UHPC)?

Ultra-high Performance Concrete (UHPC) is an advanced cementitious composite material characterized by extremely high compressive strength (typically over 150 MPa), exceptional durability, and enhanced ductility. It achieves these properties through a dense, optimized matrix, low water-to-binder ratio, fine reactive powders, and often incorporates steel or synthetic fibers.

What are the primary applications of UHPC?

UHPC is primarily used in critical infrastructure such as bridges, roadways, high-rise buildings, and marine structures due to its superior strength and durability. It is also favored for architectural elements, security barriers, and for the repair and rehabilitation of existing concrete structures where long-term performance and minimal maintenance are crucial.

How does UHPC contribute to sustainable construction?

UHPC contributes to sustainable construction by significantly extending the service life of structures, thereby reducing the need for frequent repairs or replacements and minimizing material consumption over time. Its high strength allows for thinner sections, reducing overall material volume and dead load, and its enhanced durability lessens environmental impact from maintenance and repairs.

What are the main advantages of using UHPC over traditional concrete?

The main advantages of UHPC include significantly higher compressive and tensile strength, superior durability against abrasion, freeze-thaw cycles, and chemical attack, and enhanced ductility due to fiber reinforcement. This leads to longer service life, reduced maintenance costs, more slender structural designs, and improved resilience against extreme events compared to traditional concrete.

What are the key challenges in the Ultra-high Performance Concrete market?

Key challenges in the UHPC market include its higher initial material cost compared to conventional concrete, which can be a barrier for some projects. Additionally, specialized mixing and curing procedures are often required, and there is a need for greater awareness, standardized specifications, and skilled labor for widespread adoption across all regions and project types.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager