Ultrasonic Sensors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430627 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Ultrasonic Sensors Market Size

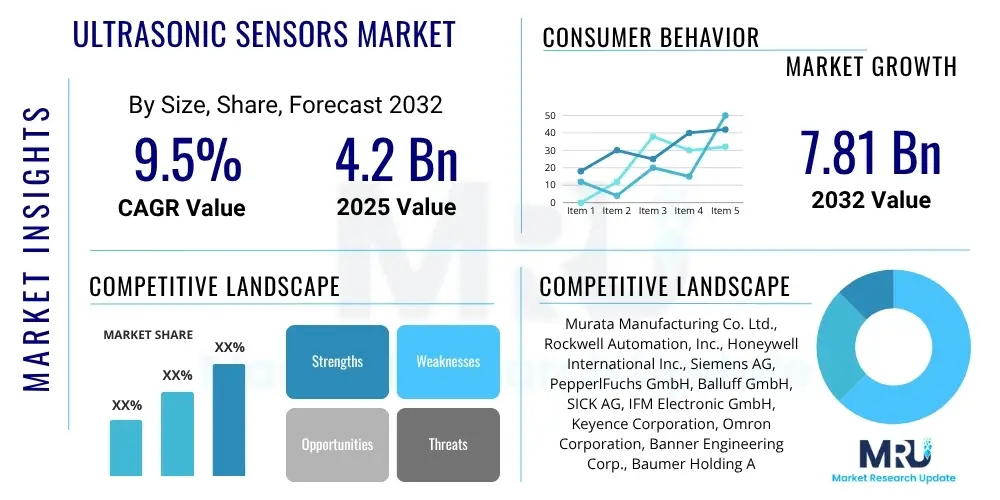

The Ultrasonic Sensors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 4.2 Billion in 2025 and is projected to reach USD 7.81 Billion by the end of the forecast period in 2032.

Ultrasonic Sensors Market introduction

Ultrasonic sensors are sophisticated electronic devices designed to measure distances or detect the presence of objects without physical contact, leveraging the principles of sound wave propagation. They emit high-frequency sound waves, typically in the range of 20 kHz to 500 kHz, which are beyond the human hearing threshold, and then measure the time it takes for these waves to bounce off a target object and return to the sensor. This "time-of-flight" measurement is then translated into a distance value with remarkable precision and reliability. The core component is often a piezoelectric transducer, which efficiently converts electrical energy into mechanical vibrations (sound) and vice-versa, acting as both an emitter and a receiver. Their non-contact nature is a significant advantage, as it prevents wear and tear, allows for detection of fragile or delicate objects, and ensures operational longevity in demanding environments.

The versatility of ultrasonic sensors drives their extensive adoption across a multitude of industries. In industrial automation, they are indispensable for tasks such as accurate liquid level monitoring in chemical and food processing plants, precise object positioning on conveyor belts, and collision avoidance for automated guided vehicles (AGVs) and robotics. The automotive sector integrates them for critical safety and convenience features, including sophisticated parking assistance systems, blind spot detection, and an integral part of advanced driver-assistance systems (ADAS) that enhance vehicle safety and move towards autonomous driving capabilities. Furthermore, their application extends to medical diagnostics, particularly in ultrasound imaging for prenatal care and internal organ examination, offering non-invasive insights.

Beyond these major segments, ultrasonic sensors find utility in consumer electronics for proximity sensing in smart home devices, gesture recognition, and even drone altitude control. Their inherent benefits, such as robust performance in challenging environmental conditions (e.g., dusty, smoky, or dark areas where optical sensors might fail), the ability to detect transparent objects, and relatively low cost, make them a preferred sensing solution. The market is propelled by a confluence of factors including the global imperative for enhanced automation, stringent safety regulations mandating advanced sensing in vehicles and industrial machinery, and the continuous innovation in sensor miniaturization and integration capabilities, paving the way for new and more intelligent applications across the industrial and consumer landscapes.

Ultrasonic Sensors Market Executive Summary

The global Ultrasonic Sensors Market is poised for substantial expansion, demonstrating dynamic growth fueled by an escalating emphasis on automation and intelligent systems across various sectors. Current business trends highlight a significant push towards the development of smarter, more robust, and highly integrated sensor solutions. Manufacturers are increasingly investing in miniaturization technologies to embed ultrasonic sensors into compact devices and demanding environments, while simultaneously enhancing their data processing capabilities through onboard microcontrollers. The industry is also witnessing a surge in strategic collaborations, mergers, and acquisitions aimed at consolidating market position, expanding product portfolios, and leveraging synergistic technologies to create more comprehensive sensing platforms. This competitive landscape is characterized by continuous innovation, with a focus on improving sensor accuracy, range, and resistance to environmental interference, crucial for high-reliability applications.

Regionally, the market exhibits varied growth trajectories and significant strategic importance across key geographical areas. Asia Pacific (APAC) currently stands as the leading market, driven by its expansive manufacturing base, rapid industrialization, and booming automotive sector, particularly in economies such as China, Japan, South Korea, and India. The region's proactive adoption of Industry 4.0 initiatives and smart factory concepts further accelerates the deployment of ultrasonic sensors in diverse industrial applications. North America and Europe, while being mature markets, continue to demonstrate robust growth, primarily propelled by sustained technological innovation, stringent safety and environmental regulations, and a high demand for advanced automation in automotive, aerospace, and healthcare sectors. These regions are also at the forefront of R&D, contributing to next-generation ultrasonic sensing technologies.

Segmentation analysis reveals prominent trends influencing market dynamics. The automotive segment remains a cornerstone, with the increasing integration of ultrasonic sensors into advanced driver-assistance systems (ADAS), parking assist, and autonomous driving solutions representing a significant demand driver. In the industrial sector, the relentless pursuit of operational efficiency, precision manufacturing, and worker safety fuels the adoption of these sensors for object detection, liquid level monitoring, and robotic navigation within automated production lines. The medical and healthcare segment is witnessing steady growth due to the non-invasive diagnostic capabilities of ultrasound technology, alongside emerging applications in therapeutic devices. Furthermore, the consumer electronics industry is integrating ultrasonic sensors into smart home devices and gesture control systems, expanding their market reach and utility. These diverse segment-specific demands collectively contribute to the sustained upward trajectory of the ultrasonic sensors market.

AI Impact Analysis on Ultrasonic Sensors Market

Users frequently inquire about how Artificial Intelligence (AI) can significantly enhance the performance and application scope of ultrasonic sensors, moving beyond traditional capabilities. Key themes that emerge from these questions revolve around improving the interpretation of raw sensor data, enabling more sophisticated decision-making in complex autonomous systems, facilitating proactive predictive maintenance, and greatly expanding the operational capabilities of robotic navigation and industrial automation. There are high expectations for AI to effectively overcome current limitations of ultrasonic sensors, such as susceptibility to acoustic noise interference, difficulties in distinguishing between multiple objects, or challenges in mapping complex, dynamic environments. By leveraging AI, sensors can achieve sophisticated pattern recognition, adapt in real-time to changing conditions, and provide more accurate and context-aware outputs. Users are also concerned with the practical aspects, including the computational demands for AI processing, the need for extensive training data, and potential issues related to data privacy and ethical implications, especially in critical applications like autonomous vehicles. Despite these concerns, the prevailing sentiment is that AI will be a transformative force, unlocking unprecedented levels of precision, reliability, and autonomy for ultrasonic sensing technology.

- Enhanced data interpretation and signal processing to effectively reduce noise and improve the clarity of readings.

- Superior object classification, differentiation, and advanced environmental mapping capabilities for robust robotics and autonomous vehicle navigation.

- Implementation of predictive maintenance through the analysis of historical sensor data patterns to accurately anticipate and prevent equipment failures.

- Dynamic and adaptive sensor calibration and performance optimization, allowing sensors to function optimally in diverse and challenging environmental conditions.

- Facilitation of complex gesture recognition, human-machine interaction, and user interface enhancements in sophisticated consumer electronics.

- Integral integration into advanced driver-assistance systems (ADAS) for more reliable, nuanced collision avoidance and precise parking assistance.

- Development of intelligent, self-learning inspection systems for superior quality control and anomaly detection in manufacturing processes.

- Enabling more precise, consistent, and nuanced liquid level, flow, and volume measurements in industrial and process control applications.

- Augmenting medical imaging by significantly improving image resolution, clarity, and diagnostic accuracy for better patient outcomes.

- Facilitating the creation of more intelligent, responsive, and energy-efficient smart home devices capable of sophisticated presence and activity detection.

DRO & Impact Forces Of Ultrasonic Sensors Market

The Ultrasonic Sensors Market is significantly influenced by a confluence of powerful driving forces, inherent restraints, and compelling opportunities that collectively shape its growth trajectory. Key drivers include the pervasive global push for industrial automation and the widespread adoption of Industry 4.0 paradigms, which necessitate highly precise, reliable, and non-contact sensing solutions for an array of applications such as process control, robotics, and sophisticated material handling systems. The automotive sector's relentless evolution towards fully autonomous vehicles and increasingly advanced driver-assistance systems (ADAS) heavily relies on ultrasonic sensors for robust proximity detection, efficient parking assistance, and effective low-speed collision avoidance, thereby acting as a powerful accelerator for market expansion. Moreover, the growing demand for non-invasive medical diagnostics, coupled with increasing regulatory focus on safety standards across various industrial and consumer applications, further reinforces the critical role of ultrasonic sensors. Their ability to operate effectively in harsh industrial environments, where optical or other sensor types may fail due to dust, smoke, or light variations, also significantly contributes to their rising adoption.

However, the market faces certain inherent restraints that could potentially impede its otherwise robust growth. These include the comparatively limited effective range and resolution of some ultrasonic sensors when directly compared to alternative advanced technologies like lidar or radar, particularly for long-distance detection and high-resolution mapping requirements. Environmental factors such as extreme temperature fluctuations, high humidity levels, significant air turbulence, or variations in air composition can critically affect sound wave propagation, thereby impacting sensor performance, accuracy, and overall reliability, posing considerable challenges for deployment in uncontrolled or rapidly changing settings. Furthermore, the initial cost associated with implementing advanced ultrasonic sensor arrays and the inherent complexity of seamlessly integrating them into highly sophisticated, multi-sensor systems can sometimes act as a barrier for smaller enterprises or for applications where cost-effectiveness is a paramount concern. Moreover, the phenomenon of acoustic interference from multiple ultrasonic sources operating in densely populated sensor environments can lead to erroneous readings or ghosting, necessitating the development and deployment of advanced signal processing techniques and intelligent communication protocols to mitigate these challenges effectively.

Opportunities for substantial market growth are abundant and continuously expanding, particularly with the ongoing integration of ultrasonic sensors with advanced Internet of Things (IoT) platforms and sophisticated Artificial Intelligence (AI) algorithms. This powerful synergy promises unprecedented enhancements in data analytics, predictive capabilities, and smarter, more autonomous decision-making processes, thereby opening entirely new avenues for innovative applications in smart cities, precision agriculture, advanced environmental monitoring, and intelligent infrastructure management. Concurrently, significant advancements in miniaturization technologies and novel material science are enabling the development of considerably smaller, more energy-efficient, and highly versatile ultrasonic sensors that can be seamlessly embedded into an even broader range of compact devices and innovative product designs. The strategic expansion into emerging economies with rapidly developing industrial infrastructures, coupled with increasing disposable incomes and a rising awareness of automation benefits, also presents substantial untapped market potential. The continuous innovation in transducer design, advanced signal processing algorithms, and sensor fusion techniques is expected to systematically overcome many existing limitations, further expanding the addressable market and creating a plethora of novel and highly impactful use cases for ultrasonic technology across global industries.

Segmentation Analysis

The Ultrasonic Sensors Market is extensively segmented based on a multitude of critical factors including product type, the specific end-user industry, application domain, and the underlying operating principle. This comprehensive segmentation provides a highly granular and insightful view into the intricate market dynamics, enabling a detailed understanding of growth opportunities and challenges across diverse categories within the ultrasonic sensor ecosystem. Such a detailed breakdown is crucial for stakeholders to accurately identify prevalent market trends, discern evolving consumer preferences, and recognize specific technological advancements pertinent to each segment. This understanding empowers businesses to craft highly targeted and effective strategies, optimize product development, and allocate resources efficiently to capitalize on the most promising areas of growth. Each segment possesses unique characteristics and demand drivers, necessitating a tailored approach to market penetration and expansion. Furthermore, the segmentation aids in competitive analysis, allowing companies to benchmark their performance and innovate strategically within their chosen niches.

- By Type

- Proximity Sensors: Used for short-range detection of objects without physical contact, common in industrial automation and robotics.

- Level Sensors: Specifically designed for continuous or point level measurement of liquids and solids in tanks and bins.

- Distance Measurement Sensors: Offer precise distance calculation over a range, crucial for positioning and navigation applications.

- Flow Sensors: Employed to measure the flow rate of liquids or gases in pipes, often in non-invasive setups.

- Through-beam Sensors: Consist of separate transmitter and receiver units, detecting objects that break the ultrasonic beam.

- Retro-reflective Sensors: Combine transmitter and receiver in one housing, detecting objects by reflection off a specific reflector.

- Diffuse Sensors: Integrate transmitter and receiver, detecting objects by their own reflection, providing simple and flexible detection.

- By End-User Industry

- Automotive: For parking assist, blind spot detection, and advanced driver-assistance systems (ADAS).

- Industrial Automation: Object detection, presence sensing, liquid level monitoring, robotic control, material handling.

- Medical & Healthcare: Ultrasound imaging, diagnostic tools, therapeutic applications, patient monitoring.

- Consumer Electronics: Smart home devices, gesture control, presence detection, drone altitude sensing.

- Aerospace & Defense: Drone navigation, obstacle detection, altitude measurement for UAVs, ground support equipment.

- Food & Beverage: Liquid level control in tanks, packaging detection, quality control.

- Chemical & Petrochemical: Non-contact level measurement in harsh or corrosive environments, flow measurement.

- Packaging: Object detection, sorting, and positioning in automated packaging lines.

- Agriculture: Precision farming applications, autonomous vehicle navigation, crop monitoring.

- Marine: Depth sounding, underwater object detection, navigation, anti-collision systems.

- By Application

- Object Detection: Sensing the presence or absence of objects.

- Distance Measurement: Calculating precise distances between the sensor and a target.

- Liquid Level Control: Monitoring and controlling liquid levels in containers.

- Collision Avoidance: Preventing impacts in vehicles, robots, and industrial machinery.

- Material Handling: Guiding automated systems for picking, placing, and conveying materials.

- Robotics: Navigation, obstacle avoidance, and precise positioning of robotic arms.

- Parking Assistance: Guiding vehicles into parking spaces safely.

- Blind Spot Detection: Alerting drivers to vehicles in blind spots.

- Process Control: Monitoring and regulating various parameters in industrial processes.

- Medical Imaging: Generating images of internal body structures.

- Security Systems: Perimeter protection and presence detection.

- Drone Navigation: Altitude hold and obstacle avoidance for unmanned aerial vehicles.

- By Operating Principle

- Pulse-Echo Sensors: Emit a pulse and measure the time for the echo to return, commonly used for distance.

- Through-Beam Sensors: Utilize separate transmitter and receiver, detecting interruptions in the continuous beam.

- Retro-Reflective Sensors: Sensor detects reflection from a specific target reflector.

- Diffuse Sensors: Sensor detects reflection from the target object itself.

- By Frequency Range

- Low-Frequency Ultrasonic Sensors: Typically below 100 kHz, offer longer range but lower resolution, suitable for liquid level.

- High-Frequency Ultrasonic Sensors: Typically above 100 kHz, offer higher resolution and accuracy for shorter distances, ideal for object detection and thin material measurement.

Value Chain Analysis For Ultrasonic Sensors Market

The value chain for the Ultrasonic Sensors Market represents a comprehensive series of interconnected activities that collectively contribute to the creation and delivery of ultrasonic sensing solutions, starting from the foundational raw materials and extending to the ultimate end-user adoption. The upstream segment of this value chain is primarily concerned with the meticulous sourcing and initial processing of critical raw materials. This includes specialized piezoelectric ceramics, most notably Lead Zirconate Titanate (PZT), which are essential for transducer functionality. Additionally, it involves the procurement of high-grade plastics and metals for robust sensor housing, alongside a diverse array of advanced electronic components such as microcontrollers, sophisticated amplifiers, signal processors, and communication interfaces. Manufacturers specializing in these core components and materials form the fundamental bedrock of the supply chain, meticulously ensuring the consistent quality, reliable availability, and precise specifications of all necessary inputs for the subsequent sensor production phases. Furthermore, significant research and development activities, encompassing innovative transducer design, advanced acoustic modeling, and sophisticated algorithm development, are integral to this upstream phase, focusing relentlessly on enhancing performance, reliability, and miniaturization capabilities.

In the midstream segment, dedicated sensor manufacturers meticulously design, precisely assemble, rigorously test, and integrate various components to fabricate fully functional and robust ultrasonic devices. This highly technical stage involves cutting-edge precision engineering, streamlined assembly line operations, and stringent multi-stage quality control measures designed to guarantee that the final sensors consistently meet or exceed demanding industry standards and specific performance specifications. Manufacturers often specialize in particular types of ultrasonic sensors or strategically target specific end-user industries, allowing them to develop highly customized and optimized sensing solutions. The manufacturing process often incorporates advanced automation itself, utilizing robotics for assembly and AI-driven vision systems for quality checks, ensuring consistency and efficiency. Innovation in packaging, environmental sealing, and electromagnetic compatibility (EMC) also occurs at this stage, adapting sensors for diverse and challenging operational environments.

The downstream segment of the value chain is primarily focused on effective market access and efficient product distribution, ensuring that the finished ultrasonic sensors reach a diverse and extensive customer base. This segment relies heavily on a robust and well-established network of distributors, highly specialized value-added resellers, and expert system integrators who bridge the gap between manufacturers and end-users. These intermediaries frequently provide crucial additional services such as comprehensive technical support, professional installation, bespoke customization, and seamless integration of ultrasonic sensors into larger, more complex industrial or automotive systems, thereby adding significant value to the overall solution package. Distribution channels for ultrasonic sensors are typically bifurcated into direct and indirect methods. Direct distribution often involves manufacturers engaging in direct sales to large original equipment manufacturers (OEMs) or key industrial clients, fostering deep, long-term relationships and offering highly tailored solutions. Conversely, indirect distribution, which accounts for a substantial portion of the market, leverages a broad network of third-party distributors, wholesalers, and specialized online marketplaces. The efficiency and reliability of these diverse distribution networks are absolutely critical for ensuring timely product delivery, maintaining competitive pricing, and providing effective post-sales technical support, all of which directly impact customer satisfaction, market penetration, and ultimately, the sustainable growth of the ultrasonic sensors market.

Ultrasonic Sensors Market Potential Customers

Potential customers for ultrasonic sensors encompass an extraordinarily wide array of industries and applications, a testament to the versatility, reliability, and increasingly indispensable nature of this technology within modern operational systems. In the critically important automotive sector, key buyers primarily include major automotive original equipment manufacturers (OEMs) such as BMW, Daimler, Ford, General Motors, Toyota, and Volkswagen, alongside their crucial Tier 1 suppliers like Bosch, Continental, and ZF. These entities meticulously integrate ultrasonic sensors into sophisticated parking assistance systems, advanced blind spot monitoring, and an ever-expanding suite of advanced driver-assistance systems (ADAS) to significantly enhance vehicle safety, driver convenience, and pave the way for increasingly autonomous driving capabilities. Furthermore, the burgeoning electric vehicle (EV) market presents an accelerating customer segment, as these vehicles inherently adopt and expand upon sophisticated sensor arrays for enhanced navigation, perimeter safety, and advanced environmental perception. Beyond new vehicle production, automotive aftermarket suppliers also procure these sensors for vehicle upgrades, repairs, and direct replacements, indicating a continuous demand stream.

Within the expansive industrial automation landscape, a vast number of manufacturers across diverse sectors such as precision machinery, advanced robotics, efficient packaging, and intricate material handling are primary and consistent customers for ultrasonic sensors. Leading industrial automation companies like Rockwell Automation, Siemens, ABB, and Fanuc, along with countless smaller enterprises engaged in process control, smart factory automation, and intelligent logistics, rely heavily on ultrasonic sensors for highly accurate object detection, precise distance measurement, critical liquid level sensing in a myriad of tanks and vessels, and exact robotic arm positioning to consistently optimize operational efficiency, enhance productivity, and ensure robust worker safety across their facilities. The global proliferation of Industry 4.0 initiatives and the widespread adoption of smart factory concepts further intensify demand from forward-thinking operators seeking to implement highly advanced automation, real-time monitoring, and predictive maintenance solutions to gain a competitive edge. The inherent robustness of ultrasonic sensors makes them ideal for demanding factory environments.

Beyond these core industrial and automotive giants, potential customers also extend to prominent consumer electronics brands like Samsung, LG, and various smart home technology developers creating innovative devices that utilize ultrasonic sensors for subtle proximity sensing, intuitive gesture control, and efficient presence detection. Robotics companies, ranging from those developing industrial robots for manufacturing to service robots for healthcare and hospitality, are significant buyers, leveraging ultrasonic technology for navigation, obstacle avoidance, and human-robot interaction. The aerospace and defense sector employs these sensors for applications such such as precise drone navigation, obstacle detection for unmanned aerial vehicles (UAVs), and ground support equipment. Even the rapidly modernizing agricultural sector is emerging as a critical customer, with growing applications in precision farming, autonomous agricultural machinery for crop monitoring, and livestock management. Essentially, any industry or application requiring reliable, non-contact, and often robust measurement of distance, presence, or level, particularly in challenging environmental conditions, represents a viable and often high-value potential customer for ultrasonic sensor manufacturers and specialized solution providers globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 Billion |

| Market Forecast in 2032 | USD 7.81 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Murata Manufacturing Co. Ltd., Rockwell Automation, Inc., Honeywell International Inc., Siemens AG, PepperlFuchs GmbH, Balluff GmbH, SICK AG, IFM Electronic GmbH, Keyence Corporation, Omron Corporation, Banner Engineering Corp., Baumer Holding AG, Microsonic GmbH, Migatron Corporation, MaxBotix Inc., Cognex Corporation, Prowave Electronic Co. Ltd., Gems Sensors & Controls, Contrinex AG, Eaton Corporation plc., TE Connectivity, TDK Corporation, Sensata Technologies, Panasonic Corporation, Analog Devices Inc., Texas Instruments Incorporated. |

| Regions Covered | North America (United States, Canada, Mexico), Europe (Germany, United Kingdom, France, Italy, Spain, Russia, Rest of Europe), Asia Pacific (China, Japan, India, South Korea, ASEAN, Australia, Rest of APAC), Latin America (Brazil, Argentina, Rest of Latin America), Middle East, and Africa (MEA) (GCC Countries, South Africa, Rest of MEA). |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ultrasonic Sensors Market Key Technology Landscape

The technological landscape of the Ultrasonic Sensors Market is currently experiencing a period of intense innovation, primarily aimed at substantially enhancing performance, improving reliability in demanding conditions, and expanding the overall versatility of these sensing devices across a multitude of applications. At its fundamental core, the technology continues to rely on advanced piezoelectric transducers, which are remarkable materials capable of efficiently converting electrical energy into mechanical vibrations (sound waves) and, conversely, converting mechanical vibrations back into electrical signals. Recent advancements are heavily focused on developing novel material compositions, exploring new manufacturing processes, and optimizing transducer designs to significantly improve sensitivity, broaden frequency response, and increase the overall efficiency of these transducers. This relentless pursuit of innovation is directly leading to the development of more compact, energy-efficient, and exceptionally robust sensor designs that can withstand increasingly harsh environmental and operational conditions.

The integration of powerful microcontrollers and specialized digital signal processing (DSP) units plays an absolutely pivotal role in modern ultrasonic sensor technology. These integrated components enable the execution of highly sophisticated signal processing algorithms that are crucial for effectively filtering out acoustic noise, precisely compensating for complex environmental variations such as temperature and humidity, and dramatically improving the accuracy and repeatability of distance and presence measurements. The evolution of DSP techniques allows for real-time data analysis and significantly more precise interpretation of reflected sound waves, which is indispensable for highly complex and dynamic applications like robotic navigation and advanced process control. Furthermore, significant trends in miniaturization are driving the capability to seamlessly embed ultrasonic sensors into increasingly smaller devices and highly confined spaces without any compromise on performance, which is a critical factor for sectors such as consumer electronics, compact robotics, and certain specialized medical devices where space is a premium commodity.

The convergence of ultrasonic technology with the power of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is fundamentally transforming the capabilities and potential applications of ultrasonic sensors. AI can be strategically employed for advanced pattern recognition, allowing sensors to differentiate between various object types, material properties, or complex environmental conditions with significantly greater accuracy and intelligence than traditional rule-based methods. This paradigm shift enables groundbreaking applications such as highly accurate predictive maintenance by detecting subtle acoustic signatures of impending equipment failure, intelligent object classification in sophisticated industrial settings, and remarkably precise and adaptive navigation for fully autonomous systems. Moreover, the emergence of edge computing, where AI processing occurs directly on the sensor device itself, dramatically reduces data latency, minimizes bandwidth requirements, and enhances data privacy, making intelligent ultrasonic sensors considerably more efficient, responsive, and secure for mission-critical real-time applications. These profound technological advancements, collectively, are instrumental in driving the continuous expansion of ultrasonic sensor applications and accelerating their widespread adoption across diverse and evolving global industries.

Regional Highlights

- North America: This region is a global frontrunner in technological innovation and exhibits a high rate of early adoption of advanced automation solutions. Its robust automotive industry, particularly in the United States and Canada, drives significant demand for high-performance ultrasonic sensors in advanced driver-assistance systems (ADAS), parking assistance, and emerging autonomous vehicle technologies. Furthermore, the region's strong healthcare sector and substantial investment in R&D contribute to the widespread application of ultrasonic sensors in medical diagnostics and advanced robotics. The presence of numerous major technology players and dynamic startups fosters a highly competitive and continuously innovative market environment.

- Europe: Characterized by a highly mature and sophisticated industrial base, coupled with stringent safety regulations and a strong emphasis on environmental protection, Europe exhibits a consistently robust demand for ultrasonic sensors. This demand is particularly pronounced in factory automation, advanced process control, and efficient logistics within key industrial nations such as Germany, the United Kingdom, and France. Countries within the European Union are at the forefront of Industry 4.0 adoption, actively pushing for the implementation of intelligent and highly integrated sensor solutions. The region also sees substantial and growing use of ultrasonic technology in precision agriculture, specialized medical applications, and renewable energy sectors.

- Asia Pacific (APAC): Positioned as the largest and most rapidly growing market globally for ultrasonic sensors, APAC is primarily driven by its expansive and continuously expanding manufacturing sectors in countries like China, India, South Korea, and Japan. These nations are experiencing booming automotive production, rapid industrialization, and significant investments in smart city infrastructure. As a global hub for consumer electronics manufacturing, APAC further boosts sensor demand for a wide array of smart devices. Proactive government initiatives supporting industrial automation, smart manufacturing, and technological upgrading across various industries also contribute significantly to the region's accelerated market growth.

- Latin America: This region represents an emerging market characterized by increasing industrialization and ongoing infrastructure development. Growth in Latin America is primarily propelled by substantial investments in automotive manufacturing, particularly in Brazil and Mexico, alongside expanding mining and oil & gas industries, all of which necessitate reliable and robust sensing solutions for optimized operational efficiency and enhanced safety. The growing manufacturing base, coupled with efforts towards modernizing industrial processes, continues to drive the adoption of ultrasonic sensors in various segments, including agriculture and food processing.

- Middle East and Africa (MEA): This region is experiencing considerable growth in the ultrasonic sensors market, largely attributed to strategic diversification efforts away from traditional oil economies. This diversification is leading to significant investments in ambitious smart city projects, broader industrial automation initiatives, and critical infrastructure development across the region. The burgeoning construction sector, coupled with a rising demand for efficient resource management solutions in areas such as water and wastewater treatment, plays a crucial role in driving the increased adoption of ultrasonic sensors for various monitoring and control applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ultrasonic Sensors Market.- Murata Manufacturing Co. Ltd.

- Rockwell Automation, Inc.

- Honeywell International Inc.

- Siemens AG

- PepperlFuchs GmbH

- Balluff GmbH

- SICK AG

- IFM Electronic GmbH

- Keyence Corporation

- Omron Corporation

- Banner Engineering Corp.

- Baumer Holding AG

- Microsonic GmbH

- Migatron Corporation

- MaxBotix Inc.

- Cognex Corporation

- Prowave Electronic Co. Ltd.

- Gems Sensors & Controls

- Contrinex AG

- Eaton Corporation plc.

- TE Connectivity Ltd.

- TDK Corporation

- Sensata Technologies Holding plc

- Panasonic Corporation

- Analog Devices Inc.

- Texas Instruments Incorporated

Frequently Asked Questions

What are the primary applications of ultrasonic sensors?

Ultrasonic sensors are widely utilized across various industries for essential applications such as precise object detection and presence sensing, accurate distance measurement, reliable liquid level control in tanks, critical collision avoidance in automotive systems and industrial robotics, and non-invasive diagnostic imaging in medical ultrasound scans.

How do ultrasonic sensors differ from other proximity sensors?

Ultrasonic sensors distinguish themselves from other proximity sensors, like optical or inductive types, by employing high-frequency sound waves rather than light or magnetic fields to detect objects and measure distances. This makes them highly effective and reliable in challenging environments characterized by dirt, dust, smoke, or darkness, and uniquely capable of detecting transparent or translucent materials that optical sensors often struggle with.

What are the main advantages of using ultrasonic sensors?

The primary advantages of integrating ultrasonic sensors include their capability for non-contact measurement, which extends sensor lifespan and protects delicate objects, their high accuracy and repeatability in distance sensing, reliable operation across diverse environmental conditions (e.g., fog, smoke, varying light), the unique ability to detect transparent objects, and a generally favorable cost-effectiveness for a wide range of industrial and consumer applications.

What factors restrain the growth of the ultrasonic sensors market?

Several factors can restrain the growth of the ultrasonic sensors market, including limitations in their maximum operating range and resolution compared to competing technologies like lidar, their sensitivity to extreme temperature fluctuations and significant air turbulence, the potential for acoustic interference in multi-sensor deployments, and the often higher initial cost associated with implementing advanced sensor arrays or customized solutions.

How is AI impacting the ultrasonic sensors market?

Artificial Intelligence (AI) is profoundly impacting the ultrasonic sensors market by significantly enhancing their capabilities, including improved data interpretation and noise reduction for clearer signals, enabling advanced object classification and sophisticated environmental mapping for autonomous systems, facilitating proactive predictive maintenance, and optimizing sensor performance and responsiveness in complex, dynamic operational scenarios.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager