Utility Scale Non Metal Electrical Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429531 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Utility Scale Non Metal Electrical Conduit Market Size

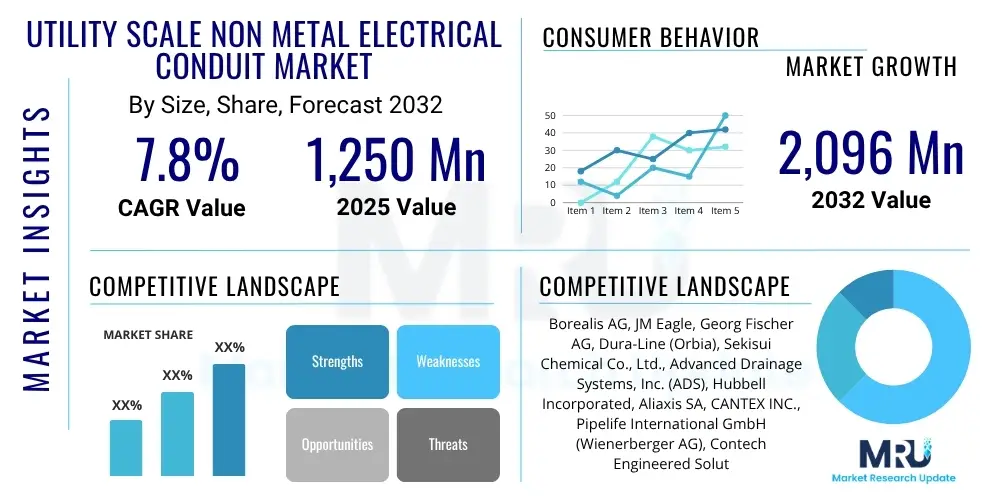

The Utility Scale Non Metal Electrical Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $1,250 Million in 2025 and is projected to reach $2,096 Million by the end of the forecast period in 2032.

Utility Scale Non Metal Electrical Conduit Market introduction

The Utility Scale Non Metal Electrical Conduit Market is a vital segment within the broader electrical infrastructure industry, focusing on the protection and routing of electrical cables in large-scale installations. These conduits, primarily made from materials like High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), fiberglass, and various composites, offer superior benefits such as corrosion resistance, lighter weight, flexibility, and non-conductive properties compared to their metal counterparts. They are specifically designed for applications requiring high durability and protection in challenging environments, ensuring the longevity and reliability of power transmission and distribution systems.

Major applications for non-metal electrical conduits in utility scale settings include vast renewable energy projects like solar farms and wind power installations, expansive data centers, intricate smart grid networks, and critical industrial plants, alongside traditional public utility infrastructure projects. The inherent benefits of these conduits, such as their resistance to chemical degradation, UV radiation, and extreme temperatures, make them ideal for both underground and above-ground utility deployments. Furthermore, their ease of installation significantly reduces labor costs and project timelines, contributing to overall operational efficiency.

The market's growth is predominantly driven by a global surge in infrastructure development, particularly in the renewable energy sector, where non-metal conduits are indispensable for solar and wind farm cabling. Additionally, the increasing focus on modernizing aging electrical grids, coupled with the rapid expansion of smart city initiatives and data center infrastructure, further fuels demand. The shift towards more sustainable and resilient power systems, demanding materials that offer long-term performance and minimal maintenance, positions non-metal electrical conduits as a preferred choice for utility-scale applications worldwide.

Utility Scale Non Metal Electrical Conduit Market Executive Summary

The Utility Scale Non Metal Electrical Conduit Market is experiencing robust growth, driven by an accelerating global transition to renewable energy sources and extensive infrastructure modernization projects. Key business trends indicate a significant investment in sustainable materials and advanced manufacturing processes to enhance conduit performance and reduce environmental impact. Companies are focusing on producing lighter, more durable, and environmentally friendly products that meet stringent utility standards, leading to increased adoption across various large-scale electrical installations. The emphasis on supply chain resilience and localized production is also gaining traction, mitigating risks associated with global raw material price fluctuations and logistical challenges.

Regional trends reveal Asia Pacific as a dominant and rapidly expanding market, propelled by rapid urbanization, massive government-backed infrastructure projects, and a booming renewable energy sector, particularly in countries like China and India. North America and Europe are also demonstrating strong growth, driven by grid modernization efforts, substantial investments in offshore wind and utility-scale solar projects, and the increasing demand for advanced data center infrastructure. Latin America and the Middle East & Africa regions are emerging as significant growth frontiers, fueled by untapped renewable energy potential and ongoing power generation and distribution network expansions.

Segment-wise, the market sees heightened demand for High-Density Polyethylene (HDPE) conduits due to their superior flexibility, chemical resistance, and ease of installation, making them highly suitable for underground and direct burial applications. Fiberglass conduits are also gaining traction, especially in scenarios requiring high strength, elevated temperature resistance, and protection against electromagnetic interference. The application segment is heavily influenced by the exponential growth of solar and wind energy projects, which necessitate extensive cabling infrastructure, further solidifying the position of non-metal conduits as an essential component in the modern utility landscape.

AI Impact Analysis on Utility Scale Non Metal Electrical Conduit Market

User inquiries regarding the impact of Artificial Intelligence on the Utility Scale Non Metal Electrical Conduit Market primarily revolve around how AI can enhance efficiency, reliability, and sustainability across the value chain. Common questions address AI's role in optimizing conduit manufacturing processes, predicting material performance and lifespan, streamlining project logistics and installation, and enabling smart grid integration. There is also significant interest in AI's potential to improve predictive maintenance for electrical infrastructure, thereby extending the lifespan of conduits and reducing operational costs. Users seek understanding on how AI can contribute to the development of next-generation conduit materials and facilitate more intelligent infrastructure planning and management, anticipating benefits like reduced downtime and improved resource allocation.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data from electrical grids, predicting potential conduit failures or degradation, enabling proactive repairs and reducing costly downtime.

- Optimized Manufacturing Processes: AI-driven analytics can fine-tune extrusion or pultrusion processes, improving material consistency, reducing waste, and increasing production efficiency for non-metal conduits.

- Smart Grid Integration: AI contributes to the intelligent management of electrical grids, where advanced non-metal conduits can be integrated with sensors for real-time monitoring of temperature, pressure, and electrical integrity.

- Demand Forecasting and Supply Chain Optimization: AI analyzes market trends, project schedules, and environmental data to accurately forecast demand for specific conduit types, optimizing inventory management and logistics.

- Material Innovation and Design: AI assists in the research and development of new composite and polymer materials for conduits, simulating performance under various conditions to accelerate the creation of more robust and specialized solutions.

- Automated Installation Planning: AI can model optimal conduit routing and installation strategies for large utility projects, considering terrain, environmental factors, and existing infrastructure to minimize costs and time.

DRO & Impact Forces Of Utility Scale Non Metal Electrical Conduit Market

The Utility Scale Non Metal Electrical Conduit Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its trajectory. Key drivers include the aggressive global push for renewable energy expansion, such as the construction of large-scale solar farms and wind energy projects, which necessitate vast networks of durable and corrosion-resistant conduits for cable protection. Additionally, substantial government and private sector investments in modernizing and expanding existing power transmission and distribution grids, particularly with smart grid technologies, are fueling demand for non-metal solutions due to their longevity and operational benefits. The inherent advantages of non-metal materials, such as their lighter weight, flexibility, and resistance to environmental degradation, further accelerate their adoption over traditional metallic options.

However, the market also faces notable restraints. Volatility in the prices of raw materials, primarily polymers like HDPE and PVC, can significantly impact manufacturing costs and profit margins. Intense competition from conventional metal conduits, especially in regions or applications where their robust mechanical protection is still preferred or mandated by older regulations, acts as a limiting factor. Furthermore, the capital-intensive nature of utility-scale projects and potential regulatory complexities or delays in project approvals can hinder market expansion. While non-metal conduits offer long-term cost savings, the initial investment for some advanced composite materials or specialized installation equipment can also be a barrier in certain markets.

Despite these challenges, significant opportunities abound. The increasing global focus on sustainability and green building practices creates a strong incentive for the adoption of environmentally friendly conduit materials and manufacturing processes. The emergence of developing economies, with their rapidly expanding industrialization and urbanization, presents vast untapped markets for utility infrastructure development. Technological advancements leading to the creation of innovative composite materials with enhanced performance characteristics, such as higher temperature resistance or integrated sensing capabilities, will open new application avenues. Moreover, government incentives and supportive policies aimed at promoting renewable energy and smart grid deployment are expected to provide substantial tailwinds for the non-metal conduit market, paving the way for sustained growth and innovation.

Segmentation Analysis

The Utility Scale Non Metal Electrical Conduit Market is comprehensively segmented to provide a detailed understanding of its diverse components and evolving dynamics. This segmentation facilitates targeted market analysis, allowing stakeholders to identify key growth areas and develop tailored strategies. The market is primarily categorized by Material Type, Product Type, Application, and End-User, each reflecting distinct characteristics and market demands. Understanding these segments is crucial for manufacturers, distributors, and utility providers to align their offerings with specific industry requirements and emerging trends.

- By Material Type:

- High-Density Polyethylene (HDPE) Conduit: Known for flexibility, chemical resistance, and ease of installation, ideal for underground and direct burial.

- Polyvinyl Chloride (PVC) Conduit: Cost-effective, good resistance to corrosion and chemicals, widely used in various utility applications.

- Fiberglass Conduit: Offers high strength, temperature resistance, and protection against electromagnetic interference, preferred for demanding environments.

- Composite Conduit: Advanced materials combining properties for enhanced performance, lightweight, and durability.

- Others: Includes other specialized polymers or blends used for niche applications.

- By Product Type:

- Rigid Conduit: Offers structural integrity and robust protection, suitable for exposed or structured installations.

- Flexible Conduit: Provides adaptability for complex routing and vibration resistance, often used in dynamic environments or where tight bends are required.

- By Application:

- Underground Installation: Dominant segment due to protection from environmental factors and aesthetic benefits.

- Above-Ground Installation: Used where conduits are exposed to elements, requiring UV and weather-resistant materials.

- Direct Burial: Specifically designed for direct placement in soil without additional encasement, primarily using robust HDPE.

- By End-User:

- Renewable Energy (Solar, Wind, Hydro): Critical for cabling in vast renewable energy generation facilities.

- Power Utilities: Essential for infrastructure modernization, grid expansion, and maintenance of transmission and distribution networks.

- Data Centers: Used for extensive network cabling, ensuring reliable power and data flow.

- Industrial Plants: For robust protection of electrical systems in harsh industrial environments.

- Telecommunications: Supports fiber optic and communication cabling infrastructure.

- Smart City Infrastructure: For integrated utility and communication networks in urban development projects.

Value Chain Analysis For Utility Scale Non Metal Electrical Conduit Market

The value chain for the Utility Scale Non Metal Electrical Conduit Market begins with the upstream suppliers who provide the essential raw materials. This segment primarily involves petrochemical companies supplying polymers such as polyethylene and polyvinyl chloride resins, as well as manufacturers providing fiberglass, composite materials, and various additives like flame retardants, UV stabilizers, and colorants. These suppliers play a critical role in determining the quality, cost, and availability of the base materials, which directly impacts the final product characteristics and pricing. Relationships with these upstream providers are often long-term and strategic, focusing on consistent supply, material innovation, and cost efficiency to maintain competitive advantage in the market.

Moving downstream, the value chain encompasses the manufacturing, distribution, and eventual installation of the non-metal electrical conduits. Manufacturers process raw materials into finished conduit products through various techniques like extrusion for HDPE and PVC, or pultrusion for fiberglass. These manufacturers also engage in research and development to innovate new material formulations and product designs that meet evolving industry standards and specific application needs. Once manufactured, the conduits are distributed through a network that can include wholesalers, specialized electrical distributors, and direct sales channels, particularly for large-scale utility projects.

The final stage of the value chain involves the end-users and the installation process. Major buyers include utility companies, renewable energy developers, large industrial enterprises, and telecommunication providers. Engineering, Procurement, and Construction (EPC) contractors and specialized electrical contractors are responsible for the installation of these conduits on site, ensuring proper routing, connection, and adherence to safety and operational standards. Direct distribution channels are often preferred for major utility-scale projects to ensure timely delivery and technical support, while indirect channels through distributors serve smaller projects or provide routine supplies. The efficiency and coordination across all these stages are crucial for optimizing costs, enhancing product delivery, and ensuring the successful deployment of utility infrastructure.

Utility Scale Non Metal Electrical Conduit Market Potential Customers

The primary potential customers and end-users of utility-scale non-metal electrical conduits are organizations and entities responsible for developing, managing, and maintaining large-scale electrical and communication infrastructure. These customers require durable, reliable, and often specialized conduit solutions to protect critical cabling across extensive areas and challenging environments. Their purchasing decisions are driven by factors such as project scale, environmental conditions, regulatory compliance, long-term operational costs, and the need for materials that offer superior resistance to corrosion, chemicals, and electrical interference. The growth of these customer segments directly correlates with the expansion of the non-metal conduit market.

Key customers include national and regional power utility companies engaged in modernizing existing power grids and expanding transmission and distribution networks to meet growing energy demands. Additionally, developers and operators of renewable energy projects, such as vast solar farms, onshore and offshore wind farms, and hydroelectric power stations, constitute a significant customer base, as these projects require extensive underground and above-ground cabling infrastructure. Large data center operators and telecommunications companies are also major consumers, utilizing non-metal conduits for their critical power and fiber optic networks, demanding high levels of reliability and protection.

Furthermore, EPC (Engineering, Procurement, and Construction) contractors specializing in large-scale infrastructure projects, industrial plant owners, and government agencies responsible for smart city initiatives and public utility upgrades represent substantial potential customers. These entities are consistently seeking robust, cost-effective, and easy-to-install conduit solutions that can withstand harsh environmental conditions and provide long-term protection for vital electrical and communication assets. Their evolving requirements for sustainability, durability, and performance drive innovation and demand within the Utility Scale Non Metal Electrical Conduit Market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1,250 Million |

| Market Forecast in 2032 | $2,096 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Borealis AG, JM Eagle, Georg Fischer AG, Dura-Line (Orbia), Sekisui Chemical Co., Ltd., Advanced Drainage Systems, Inc. (ADS), Hubbell Incorporated, Aliaxis SA, CANTEX INC., Pipelife International GmbH (Wienerberger AG), Contech Engineered Solutions LLC, Diamond Plastics Corporation, NIBCO Inc., Westlake Pipe & Fittings (Westlake Chemical), Apollo Pipe, CertainTeed (Saint-Gobain), Electri-Flex Company, Ipex Inc. (Aliaxis), Endot Industries Inc., Cresline Plastic Pipe Co., Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Utility Scale Non Metal Electrical Conduit Market Key Technology Landscape

The technology landscape for the Utility Scale Non Metal Electrical Conduit Market is continuously evolving, driven by the demand for enhanced performance, durability, and cost-effectiveness in large-scale electrical infrastructure. Advancements in material science form the bedrock of this evolution, focusing on developing new polymer blends and composite materials that offer superior properties. This includes innovations in High-Density Polyethylene (HDPE) with improved stress crack resistance and UV stability, advanced PVC formulations for greater impact strength and chemical resistance, and novel fiberglass composites that provide exceptional mechanical strength and fire retardancy. These material innovations are critical for extending product lifespan and ensuring reliability in harsh utility environments, from extreme temperatures to corrosive soil conditions.

Beyond material composition, manufacturing technologies play a pivotal role in shaping the market. Advanced extrusion processes for plastic conduits are being refined to achieve tighter tolerances, improved surface finishes, and faster production speeds, thereby reducing manufacturing costs and increasing output. Pultrusion techniques for fiberglass conduits are also seeing innovations, allowing for the creation of complex profiles and integrated features that enhance functionality. Furthermore, the integration of smart manufacturing principles, including automation, real-time quality control, and data analytics, is optimizing production lines, minimizing waste, and ensuring consistent product quality across various material types and conduit sizes.

The adoption of advanced installation technologies is another significant aspect of the market's technological landscape. Techniques such as horizontal directional drilling (HDD) for underground conduit placement have become indispensable for utility-scale projects, minimizing disruption and accelerating deployment. Innovations in conduit joining systems, including advanced fusion welding for HDPE and specialized coupling mechanisms for fiberglass, ensure secure and watertight connections, reducing leakage risks and enhancing overall system integrity. Moreover, the development of smart conduits, embedded with sensors for monitoring parameters like temperature, moisture, and even cable health, represents a future frontier, enabling predictive maintenance and enhancing grid intelligence and resilience for utility operators.

Regional Highlights

- North America: This region is characterized by substantial investments in grid modernization and renewable energy integration, particularly for solar and wind power. The demand for non-metal conduits is robust due to aging infrastructure replacement projects and the expansion of smart grid initiatives.

- Europe: Driven by ambitious green energy targets and the growth of offshore wind farms, Europe exhibits a strong preference for durable and environmentally compliant non-metal conduits. Strict environmental regulations also encourage the adoption of sustainable conduit solutions.

- Asia Pacific (APAC): As the fastest-growing market, APAC benefits from rapid urbanization, massive infrastructure development in emerging economies like China and India, and a booming renewable energy sector. Large-scale utility projects across the region fuel significant demand for diverse non-metal conduit types.

- Latin America: The region presents considerable opportunities due to its vast untapped renewable energy potential, particularly solar and wind, and ongoing efforts to expand and improve national electrical grids. Investments in power generation and distribution infrastructure are steadily increasing.

- Middle East and Africa (MEA): Growth in MEA is largely influenced by large-scale oil and gas infrastructure projects, burgeoning solar power initiatives, and efforts to develop modern urban centers. The need for robust, corrosion-resistant conduits in harsh desert climates is a key driver.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Utility Scale Non Metal Electrical Conduit Market.- Borealis AG

- JM Eagle

- Georg Fischer AG

- Dura-Line (Orbia)

- Sekisui Chemical Co., Ltd.

- Advanced Drainage Systems, Inc. (ADS)

- Hubbell Incorporated

- Aliaxis SA

- CANTEX INC.

- Pipelife International GmbH (Wienerberger AG)

- Contech Engineered Solutions LLC

- Diamond Plastics Corporation

- NIBCO Inc.

- Westlake Pipe & Fittings (Westlake Chemical)

- Apollo Pipe

- CertainTeed (Saint-Gobain)

- Electri-Flex Company

- Ipex Inc. (Aliaxis)

- Endot Industries Inc.

- Cresline Plastic Pipe Co., Inc.

Frequently Asked Questions

What are utility scale non-metal electrical conduits?

Utility scale non-metal electrical conduits are protective pathways, typically made from materials like HDPE, PVC, or fiberglass, designed to house and safeguard electrical cables in large-scale infrastructure projects such as solar farms, wind power plants, data centers, and public utility grids. They offer advantages like corrosion resistance and flexibility over traditional metal conduits.

Why are non-metal conduits preferred over metal in utility scale applications?

Non-metal conduits are favored in utility scale applications due to their superior corrosion resistance, lighter weight, flexibility, and non-conductive properties. They are easier to install, resistant to chemical degradation and UV radiation, and generally more cost-effective over their lifecycle, especially in harsh or underground environments where metal would corrode.

What materials are commonly used for non-metal electrical conduits in utility scale projects?

The most common materials include High-Density Polyethylene (HDPE) for its flexibility and chemical resistance, Polyvinyl Chloride (PVC) for its cost-effectiveness and good insulation properties, and Fiberglass (FRP) for its high strength, temperature resistance, and resistance to electromagnetic interference. Composite materials are also gaining traction for specialized applications.

How does the growth of renewable energy impact the Utility Scale Non Metal Electrical Conduit Market?

The expansion of renewable energy projects, particularly large-scale solar and wind farms, is a major driver for this market. These projects require extensive and durable cabling infrastructure, for which non-metal conduits are ideally suited due to their ability to withstand outdoor elements, ease of installation over vast areas, and long-term reliability.

What are the key installation considerations for utility scale non-metal conduits?

Key installation considerations include proper trenching and backfilling for underground applications, adherence to manufacturer guidelines for bending radius and joining methods (e.g., fusion welding for HDPE), ensuring adequate support for above-ground installations, and compliance with local electrical codes and environmental regulations. Advanced techniques like horizontal directional drilling (HDD) are commonly used to minimize disruption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager