Utility Scale Oil Insulated Switchgear Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428795 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Utility Scale Oil Insulated Switchgear Market Size

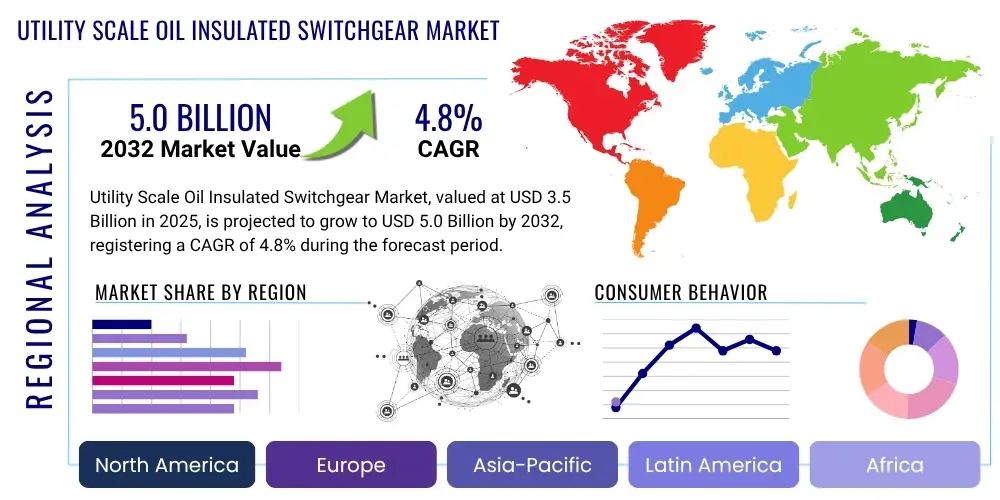

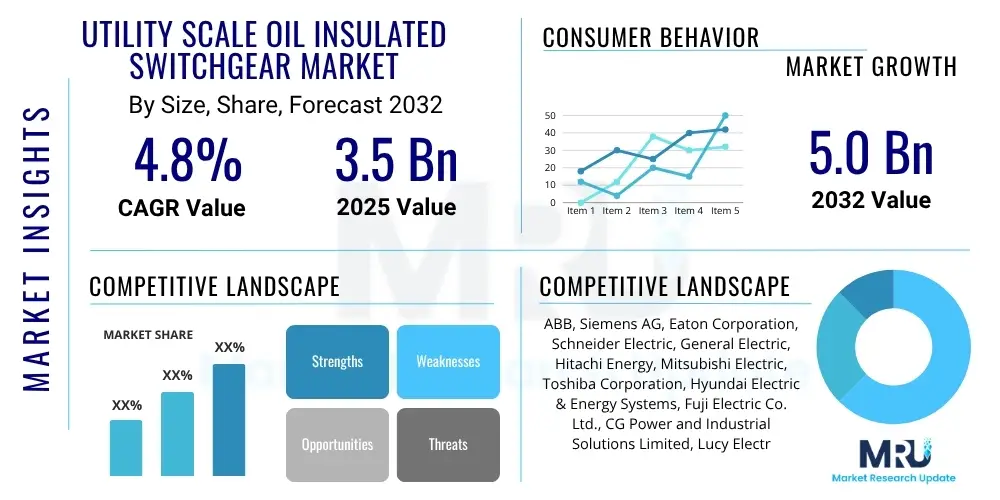

The Utility Scale Oil Insulated Switchgear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at $3.5 Billion in 2025 and is projected to reach $5.0 Billion by the end of the forecast period in 2032.

Utility Scale Oil Insulated Switchgear Market introduction

The Utility Scale Oil Insulated Switchgear Market encompasses electrical switching apparatus that utilize insulating oil as a dielectric medium for arc quenching and insulation. These systems are crucial components in large-scale power infrastructure, providing protection, control, and isolation of electrical circuits in utility environments. This established technology ensures the safe and efficient operation of power grids, handling high voltages and currents associated with utility applications.

Product description includes a variety of devices such as circuit breakers, disconnectors, load break switches, and earthing switches, all designed to interrupt fault currents, isolate sections of the grid for maintenance, or switch power flows. Their primary function is to enhance grid reliability and safety by managing power distribution effectively. Major applications span across power generation plants, electricity transmission networks, and distribution substations, where they are integral to maintaining stable power supply and protecting critical equipment from electrical disturbances.

The benefits of oil insulated switchgear include proven reliability, cost-effectiveness for certain applications, and extensive operational history. Driving factors for this market are the ongoing expansion and modernization of global power grids, the increasing integration of renewable energy sources that require robust grid infrastructure, and rising electricity demand from industrialization and urbanization across developing economies. While newer technologies exist, oil insulated switchgear continues to hold a significant market share due to its established performance and economic viability.

Utility Scale Oil Insulated Switchgear Market Executive Summary

The Utility Scale Oil Insulated Switchgear Market is experiencing steady growth driven by global infrastructure development and the imperative to modernize aging power grids. Key business trends indicate a shift towards enhanced digitalization and smart grid integration, even for conventional switchgear types, focusing on predictive maintenance and remote monitoring capabilities. Manufacturers are increasingly offering hybrid solutions that combine the proven reliability of oil insulation with advanced control systems, aiming to extend the operational life and efficiency of existing installations. Strategic partnerships and acquisitions are also notable, as companies seek to consolidate market position and expand their technological offerings in a competitive landscape.

Regional trends reveal significant activity in Asia Pacific, propelled by rapid industrialization, urbanization, and substantial investments in new power generation and transmission projects, particularly in countries like China and India. North America and Europe, while having mature grids, are primarily focused on replacing aging infrastructure, upgrading existing substations, and integrating a higher proportion of renewable energy sources, which necessitates robust and reliable switchgear. Latin America, the Middle East, and Africa are also showing steady growth, driven by electrification initiatives and the development of new utility infrastructure to meet growing energy demands. Each region presents unique opportunities and challenges influenced by regulatory frameworks, economic development, and environmental policies.

In terms of segment trends, the high voltage and extra high voltage categories continue to dominate due to their essential role in long-distance power transmission and large-scale substations. While new installations might favor gas-insulated switchgear (GIS) or air-insulated switchgear (AIS) in certain contexts, the vast installed base of oil insulated switchgear ensures a continuous demand for maintenance, upgrades, and replacements. There is also a growing emphasis on more environmentally friendly insulating oils and improved sealing technologies to mitigate potential environmental impacts, addressing some of the traditional concerns associated with this technology. The market is also seeing innovation in monitoring and diagnostic tools that can be integrated with existing oil-insulated assets, enhancing their operational intelligence.

AI Impact Analysis on Utility Scale Oil Insulated Switchgear Market

Common user questions regarding AI's impact on the Utility Scale Oil Insulated Switchgear Market frequently revolve around how artificial intelligence can enhance the operational efficiency, reliability, and lifespan of these critical assets. Users are keen to understand AI's role in predictive maintenance, fault detection, and optimizing grid performance, seeking solutions to reduce downtime and operational costs. There is also considerable interest in how AI can integrate with existing, often older, oil insulated systems without requiring complete overhauls, and concerns about data security, the complexity of implementation, and the need for skilled personnel to manage AI-driven systems within traditional utility infrastructures are prominent. Expectations are high for AI to provide actionable insights from operational data, transforming reactive maintenance into a proactive strategy, and enabling more intelligent management of power flow across the grid.

- AI-driven predictive maintenance can forecast equipment failures by analyzing operational data, significantly reducing unplanned outages and extending switchgear lifespan.

- Enhanced fault detection and isolation through AI algorithms can pinpoint issues faster, minimizing the impact of faults on the wider grid.

- Optimization of switchgear operation, including switching sequences and load balancing, leading to improved grid efficiency and reduced energy losses.

- Real-time monitoring and anomaly detection, allowing for immediate intervention and preventing minor issues from escalating into major system failures.

- Integration of AI with existing SCADA systems to provide comprehensive insights and automate routine decision-making processes, augmenting human operators.

- Improved asset management by leveraging AI to track switchgear health, performance, and maintenance history, optimizing capital expenditure and operational budgets.

- Forecasting of energy demand and supply fluctuations, enabling more strategic deployment and operation of switchgear within dynamic grid environments.

DRO & Impact Forces Of Utility Scale Oil Insulated Switchgear Market

The Utility Scale Oil Insulated Switchgear Market is primarily driven by the escalating demand for electricity worldwide, fueled by rapid industrialization and urbanization in emerging economies. Significant investments in grid modernization and expansion projects, particularly in Asia Pacific and other developing regions, are creating substantial opportunities for new installations and upgrades. The need to replace aging infrastructure in mature markets like North America and Europe also contributes significantly to market growth, as utility companies seek to enhance the reliability and efficiency of their existing power networks. Furthermore, the integration of diverse and often intermittent renewable energy sources into the grid necessitates robust and dependable switchgear solutions to manage power fluctuations and ensure grid stability, thereby bolstering demand for traditional insulation technologies.

However, the market faces several restraints, most notably the environmental concerns associated with mineral insulating oil, including potential leakages and disposal challenges. The emergence and increasing adoption of alternative technologies, such as gas-insulated switchgear (GIS) and air-insulated switchgear (AIS), which offer advantages in terms of compactness, reduced maintenance, and environmental impact, pose a significant competitive threat. High capital investment required for installation and maintenance of oil-insulated systems, along with stringent environmental regulations, can deter new investments. Additionally, the inherent flammability of mineral oil and the need for specific safety precautions can be a limiting factor in certain applications and densely populated areas, pushing some operators towards less volatile alternatives.

Opportunities for market players lie in the development of more environmentally friendly dielectric fluids, such as natural esters, which can offer improved performance characteristics and reduced ecological footprint. The expansion of smart grid initiatives presents an avenue for integrating advanced monitoring and control systems with oil insulated switchgear, extending their operational intelligence and prolonging their useful life. Developing economies offer considerable growth potential as they continue to build out their electrical infrastructure. Impact forces on the market include technological advancements driving efficiency and reducing environmental impact, evolving regulatory landscapes pushing for greener alternatives, and geopolitical factors affecting global energy policies and infrastructure investments. The push for digitalization and the rise of the Internet of Things (IoT) in grid management are also transforming the competitive dynamics.

Segmentation Analysis

The Utility Scale Oil Insulated Switchgear Market is comprehensively segmented across various parameters including type, voltage level, application, and installation type, providing a granular view of market dynamics. This segmentation allows for a detailed understanding of consumer preferences, technological adaptations, and regional demand patterns within the broader utility sector. Each segment reflects specific operational needs and regulatory requirements, influencing product development and market strategies. Understanding these segments is crucial for stakeholders to identify key growth areas and tailor their offerings to diverse market demands, from generation plants to distribution networks.

- By Type:

- Circuit Breaker

- Disconnector

- Load Break Switch

- Earthing Switch

- Others (e.g., Fuse-switch combinations)

- By Voltage Level:

- High Voltage (HV) (66 kV to 220 kV)

- Extra High Voltage (EHV) (220 kV to 765 kV)

- Ultra High Voltage (UHV) (>765 kV)

- By Application:

- Power Generation

- Transmission Utilities

- Industrial Applications

- Railways

- Others (e.g., data centers)

- By Installation:

- Indoor

- Outdoor

Value Chain Analysis For Utility Scale Oil Insulated Switchgear Market

The value chain for the Utility Scale Oil Insulated Switchgear Market begins with upstream activities involving the sourcing of critical raw materials and components. This includes suppliers of high-grade steel and aluminum for enclosures, copper for conductors, specialized insulating oils (mineral or natural ester-based), ceramics and polymers for insulators, and various electronic components for control and protection mechanisms. The quality and availability of these materials directly impact the manufacturing process and the final product's performance and cost-effectiveness. Key players in this stage focus on ensuring a stable supply chain and cost efficiency, often through long-term contracts and strategic partnerships with raw material providers.

Midstream activities involve the manufacturing, assembly, and testing of the switchgear units. Leading manufacturers invest heavily in research and development to enhance product design, improve insulation properties, optimize arc quenching capabilities, and integrate smart grid functionalities. This stage also includes rigorous quality control and adherence to international standards to ensure the reliability, safety, and longevity of the switchgear. Production facilities are often specialized, requiring advanced machinery and skilled labor for intricate assembly processes, including precise oil filling and sealing techniques to prevent leaks and ensure optimal insulation performance.

Downstream analysis focuses on the distribution, installation, and post-sales services. Distribution channels are predominantly direct, especially for large utility-scale projects where manufacturers work closely with end-users such as national grid operators, private utility companies, and independent power producers. Indirect channels may involve system integrators or authorized distributors for smaller projects or specific component sales. Installation requires specialized expertise, often provided by the manufacturer or certified contractors, to ensure proper commissioning and integration into the existing grid infrastructure. Post-sales services, including maintenance, repairs, upgrades, and technical support, are crucial for customer satisfaction and extending the operational life of the switchgear, contributing significantly to the overall value proposition throughout the product lifecycle.

Utility Scale Oil Insulated Switchgear Market Potential Customers

The primary potential customers and end-users of Utility Scale Oil Insulated Switchgear are entities involved in the generation, transmission, and distribution of electricity on a large scale. This includes national and regional electricity grid operators responsible for managing power flow across vast networks, ensuring grid stability, and preventing blackouts. These operators require robust and reliable switchgear to handle high voltages and currents, facilitating the safe isolation of equipment for maintenance and the protection of critical assets from fault conditions. Their purchasing decisions are often influenced by long-term reliability, compliance with national grid standards, and total cost of ownership, including maintenance and operational expenses over decades.

Another significant customer segment comprises private utility companies and independent power producers (IPPs) who own and operate power generation facilities, including conventional thermal plants, hydroelectric dams, and large-scale renewable energy installations such as solar farms and wind power plants. For these customers, oil insulated switchgear is essential for connecting their generation assets to the main transmission grid, managing power output, and protecting their expensive generating equipment. Their buying criteria often include equipment efficiency, integration capabilities with plant control systems, and the ability to withstand harsh environmental conditions specific to power plant operations.

Furthermore, large industrial complexes, such as heavy manufacturing plants, metallurgical facilities, and petrochemical refineries, often operate their own high-voltage substations and distribution networks, making them key consumers of utility-scale switchgear. These industries require reliable power supply to maintain continuous operations and protect sensitive machinery from electrical faults. While their power requirements might not always reach the ultra-high voltages of national grids, their need for robust and dependable switchgear for significant power loads ensures they remain a vital customer base. Railways and other large infrastructure projects also represent potential customers requiring specialized switchgear for their electrification needs and power distribution systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.5 Billion |

| Market Forecast in 2032 | $5.0 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Siemens AG, Eaton Corporation, Schneider Electric, General Electric, Hitachi Energy, Mitsubishi Electric, Toshiba Corporation, Hyundai Electric & Energy Systems, Fuji Electric Co. Ltd., CG Power and Industrial Solutions Limited, Lucy Electric, L&T Electrical & Automation, Weg S.A., Alstom Grid, Bharat Heavy Electricals Limited (BHEL), Xiamen Huadian Switchgear, TIEFENBACH GmbH, Qualitrol Corporation, Tavrida Electric AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Utility Scale Oil Insulated Switchgear Market Key Technology Landscape

The technology landscape for Utility Scale Oil Insulated Switchgear is characterized by a blend of long-established principles and ongoing evolutionary enhancements aimed at improving reliability, safety, and environmental performance. At its core, the technology relies on the excellent dielectric properties of insulating oil, typically mineral oil, which effectively quenches arcs during current interruption and provides robust electrical insulation between live parts and ground. The design of circuit breakers, including mechanisms for contact separation and oil flow dynamics, is crucial for achieving rapid and efficient arc extinction, thereby minimizing wear and ensuring operational longevity. Disconnectors and load break switches also utilize oil insulation for safe isolation and switching under specific load conditions, reflecting a mature and proven engineering approach.

While the fundamental principles remain consistent, continuous advancements focus on several key areas. Materials science plays a vital role in developing improved contact materials for enhanced arc resistance and reduced maintenance, as well as more robust sealing technologies to prevent oil leaks and extend the operational life of the switchgear. The development of alternative dielectric fluids, such as natural ester oils, is gaining traction. These bio-degradable and less flammable options offer a more environmentally friendly alternative to mineral oil, addressing some of the traditional concerns associated with oil-insulated equipment without compromising performance. These advancements contribute to the overall sustainability profile of the technology, aligning with global environmental objectives.

Furthermore, the integration of advanced monitoring, control, and protection systems is a significant technological trend. Modern oil insulated switchgear incorporates sophisticated sensors for real-time measurement of operational parameters such as oil temperature, pressure, and dissolved gas analysis, enabling predictive maintenance and early fault detection. Digital protection relays, remote control capabilities, and communication protocols (e.g., IEC 61850) facilitate seamless integration into smart grid infrastructures and substation automation systems. These digital enhancements transform traditional switchgear into intelligent assets, capable of providing valuable data for grid management, improving operational efficiency, and enhancing overall grid resilience. The evolution emphasizes making reliable, existing technology smarter and more adaptable to future grid requirements.

Regional Highlights

- North America: Characterized by an urgent need to upgrade and replace aging power infrastructure. Investments in grid modernization and resilience, coupled with the integration of renewable energy sources, drive demand. Strict regulatory frameworks also influence technology choices.

- Europe: Focuses on renewable energy integration and achieving carbon neutrality goals. The region exhibits a strong emphasis on eco-friendly solutions and advanced smart grid technologies, leading to demand for both replacement and technologically enhanced oil insulated switchgear.

- Asia Pacific (APAC): The dominant region due to rapid economic growth, industrialization, and urbanization, particularly in China, India, and Southeast Asian countries. Massive investments in new power generation and transmission projects, along with grid expansion, fuel substantial market growth.

- Latin America: Experiencing consistent growth driven by electrification initiatives, expanding industrial sectors, and investments in new energy infrastructure. The demand is primarily from utility companies seeking to extend power access and improve grid reliability across diverse geographies.

- Middle East and Africa (MEA): Growth is propelled by significant investments in energy infrastructure, driven by increasing electricity demand from population growth, industrial development, and large-scale urban projects. Oil and gas sector expansion also contributes to the need for robust power distribution systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Utility Scale Oil Insulated Switchgear Market.- ABB

- Siemens AG

- Eaton Corporation

- Schneider Electric

- General Electric

- Hitachi Energy

- Mitsubishi Electric

- Toshiba Corporation

- Hyundai Electric & Energy Systems

- Fuji Electric Co. Ltd.

- CG Power and Industrial Solutions Limited

- Lucy Electric

- L&T Electrical & Automation

- Weg S.A.

- Alstom Grid

- Bharat Heavy Electricals Limited (BHEL)

- Xiamen Huadian Switchgear

- TIEFENBACH GmbH

- Qualitrol Corporation

- Tavrida Electric AG

Frequently Asked Questions

What is utility scale oil insulated switchgear?

Utility scale oil insulated switchgear refers to electrical switching equipment that uses insulating oil as a dielectric medium for arc quenching and insulation in high voltage power applications, crucial for grid protection, control, and isolation.

Why is oil used as an insulator in switchgear?

Oil is used due to its excellent dielectric strength, high thermal conductivity for cooling, and effective arc-quenching properties, which are vital for safely interrupting high currents in utility-scale electrical systems.

What are the primary applications of this switchgear?

Its primary applications are in power generation plants, electricity transmission networks, and distribution substations, where it is used to manage and protect high-voltage electrical circuits.

What are the main drivers for the oil insulated switchgear market?

Key drivers include global grid modernization, increasing integration of renewable energy sources, industrialization and urbanization in emerging economies, and the replacement of aging power infrastructure.

How does oil insulated switchgear compare to gas insulated switchgear (GIS)?

Oil insulated switchgear is typically less expensive and has a proven track record, while GIS offers a more compact design, lower maintenance, and superior environmental performance due to SF6 gas insulation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager