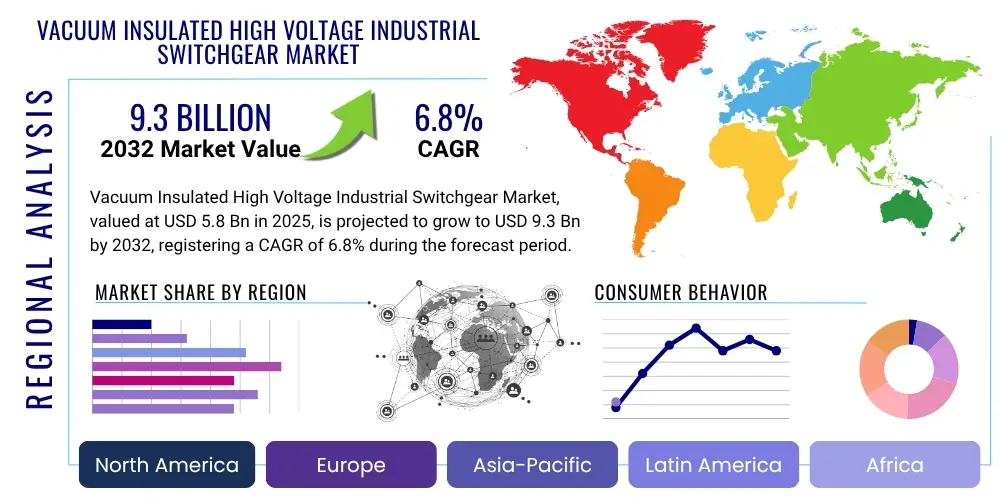

Vacuum Insulated High Voltage Industrial Switchgear Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431179 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Vacuum Insulated High Voltage Industrial Switchgear Market Size

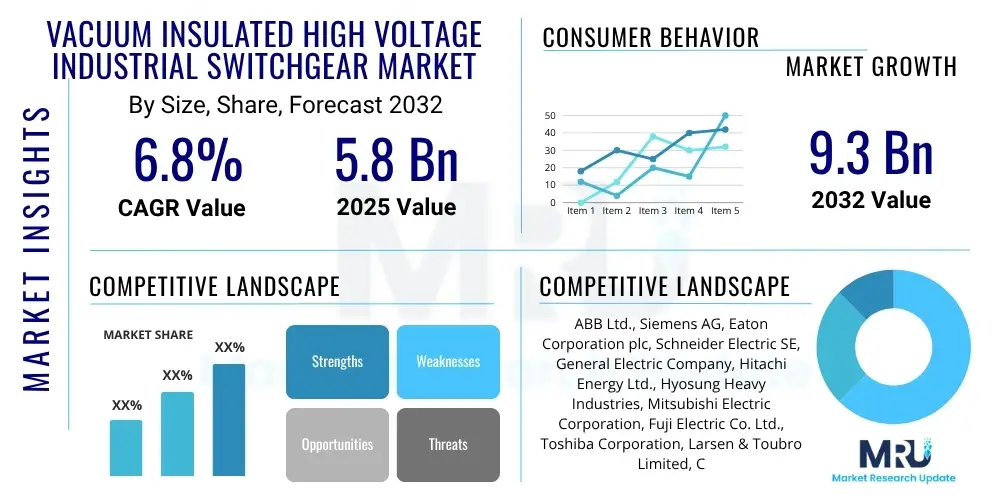

The Vacuum Insulated High Voltage Industrial Switchgear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 5.8 billion in 2025 and is projected to reach USD 9.3 billion by the end of the forecast period in 2032.

Vacuum Insulated High Voltage Industrial Switchgear Market introduction

The Vacuum Insulated High Voltage Industrial Switchgear Market encompasses essential electrical apparatus designed for controlling, protecting, and isolating electrical circuits in high voltage industrial applications. These systems utilize vacuum as the arc quenching and insulating medium, offering significant advantages over traditional SF6 gas or oil insulated switchgear. Their primary purpose is to ensure the safe and reliable operation of power systems by preventing electrical faults, enabling rapid fault clearing, and facilitating maintenance without extensive downtime. This technology is critical for modernizing electrical infrastructure and enhancing grid stability across various demanding industrial environments.

Product description highlights key features such as enhanced safety due to non-flammable and non-toxic insulation, superior reliability through extended operational life, and minimal environmental impact by eliminating harmful greenhouse gases like SF6. Major applications span across power generation plants, including conventional and renewable energy sources, heavy manufacturing industries, mining operations, oil and gas facilities, data centers, and large commercial complexes. These switchgears are vital for managing high voltage loads, protecting valuable equipment, and maintaining continuous power supply in critical industrial processes. The benefits extend to lower total cost of ownership due to reduced maintenance, compact design saving space, and compliance with stringent environmental regulations.

Driving factors for the market include the global push for industrialization, rapid expansion of renewable energy infrastructure requiring robust and reliable switchgear solutions, and ongoing modernization of aging power grids worldwide. Increased demand for electricity, coupled with a focus on energy efficiency and environmental sustainability, further propels the adoption of vacuum insulated technologies. Moreover, stringent safety standards and the inherent operational advantages of vacuum insulation contribute significantly to market growth.

Vacuum Insulated High Voltage Industrial Switchgear Market Executive Summary

The Vacuum Insulated High Voltage Industrial Switchgear Market is currently experiencing robust growth, driven by a confluence of critical business trends, evolving regional demands, and significant advancements across various segmentation types. Key business trends indicate a strong shift towards digitalization, smart grid integration, and a pronounced emphasis on sustainable and eco-friendly solutions. Manufacturers are increasingly incorporating IoT capabilities and advanced monitoring systems into switchgear, enabling predictive maintenance and enhancing operational efficiency for end-users. This technological evolution is pivotal in meeting the complex demands of modern industrial power distribution.

Regionally, the Asia Pacific sector stands out as a primary growth engine, fueled by rapid industrialization, extensive infrastructure development projects, and substantial investments in renewable energy initiatives, particularly in countries like China and India. Europe and North America also demonstrate steady growth, driven by grid modernization efforts, strict environmental regulations phasing out SF6 gas, and the ongoing integration of distributed generation sources. Latin America, the Middle East, and Africa are emerging markets, showing considerable potential with rising industrialization and electrification projects, although growth might be influenced by economic stability and investment cycles.

Segment trends reveal dynamic shifts across different voltage levels and application areas. High voltage applications (above 36 kV) are witnessing increased demand due to large-scale power transmission projects, while medium voltage (12 kV to 36 kV) remains a core segment for industrial and utility distribution networks. Application-wise, the power transmission and distribution sector, alongside renewable energy installations, consistently drives demand, emphasizing the need for reliable and efficient switchgear. The industrial segment, encompassing manufacturing, mining, and oil & gas, also contributes significantly, requiring robust solutions for uninterrupted operations. These trends collectively paint a picture of a market poised for sustained expansion and innovation.

AI Impact Analysis on Vacuum Insulated High Voltage Industrial Switchgear Market

User inquiries regarding AI's impact on Vacuum Insulated High Voltage Industrial Switchgear frequently center on themes of enhanced operational efficiency, predictive maintenance capabilities, and intelligent grid management. Common questions explore how AI algorithms can analyze real-time data from switchgear to detect anomalies, predict potential failures before they occur, and optimize maintenance schedules, thereby reducing downtime and operational costs. There is significant interest in AI's role in improving system reliability, enhancing cybersecurity against grid attacks, and enabling more autonomous power distribution systems. Users also express expectations for AI to facilitate seamless integration with smart grid technologies and to support faster, more accurate fault diagnosis within complex industrial environments, leading to safer and more sustainable power infrastructure. Concerns often revolve around data privacy, the complexity of AI implementation, and the need for skilled personnel to manage these advanced systems.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data (temperature, current, vibration) to forecast equipment failures, allowing proactive maintenance and minimizing unscheduled downtime.

- Optimized Grid Management: AI integrates with smart grid systems to dynamically manage power flow, optimize load balancing, and improve overall grid stability and efficiency.

- Fault Detection and Diagnosis: AI quickly identifies and isolates faults in the electrical system, significantly reducing fault location time and speeding up recovery processes.

- Improved Cybersecurity: AI-driven analytics monitor network traffic and switchgear behavior for anomalies, detecting and mitigating cyber threats to critical infrastructure.

- Energy Efficiency Optimization: AI can analyze power consumption patterns to recommend energy-saving strategies and optimize the operation of connected loads.

- Automated Decision Making: In advanced deployments, AI can enable autonomous operation of certain switchgear functions, responding to grid conditions without human intervention.

- Design and Manufacturing Enhancement: AI tools can optimize switchgear design for performance and manufacturability, streamlining production processes.

- Workforce Augmentation: AI assists human operators by providing intelligent insights and automating routine tasks, freeing up personnel for more complex problem-solving.

DRO & Impact Forces Of Vacuum Insulated High Voltage Industrial Switchgear Market

The Vacuum Insulated High Voltage Industrial Switchgear Market is shaped by a dynamic interplay of driving forces, restraining factors, and promising opportunities, all influenced by various impactful forces. Primary drivers include the global expansion of electricity grids, particularly in developing economies, which necessitates robust and reliable high-voltage equipment. The escalating demand for power from industrial sectors, coupled with significant investments in renewable energy generation such as solar and wind farms, further propels the adoption of these switchgears. Additionally, the inherent benefits of vacuum insulation, such as enhanced safety, environmental friendliness by avoiding SF6 gas, and reduced maintenance, are powerful motivators for end-users to upgrade or implement new systems.

Conversely, the market faces several restraints that could impede its growth trajectory. The relatively high initial capital expenditure associated with vacuum insulated high voltage switchgear, compared to older or less advanced technologies, can be a barrier for some entities, particularly smaller industries or utilities with limited budgets. The complexity of installation and the need for specialized technical expertise for maintenance and operation also present challenges. Furthermore, intense competition from alternative switchgear technologies, including advanced gas-insulated or hybrid solutions, albeit with different environmental footprints, can create market pressures. Stringent regulatory frameworks and compliance requirements, though beneficial for safety and standards, can also add to the cost and complexity for manufacturers.

Despite these restraints, significant opportunities abound for market expansion and innovation. The growing trend of smart grid development and digitalization offers a substantial avenue for integrating advanced monitoring, control, and communication capabilities into switchgear, enhancing their functionality and appeal. Emerging economies undergoing rapid industrialization and urbanization represent vast untapped markets for new infrastructure development. The increasing focus on retrofitting and modernizing aging electrical infrastructure in developed regions provides a continuous demand for advanced, efficient, and environmentally compliant switchgear solutions. Furthermore, advancements in materials science and manufacturing processes could lead to more cost-effective and compact designs, broadening market accessibility. These impact forces collectively define the market landscape, pushing for continuous innovation while demanding strategic navigation of challenges.

Segmentation Analysis

The Vacuum Insulated High Voltage Industrial Switchgear market is comprehensively analyzed through various segmentation categories, offering a granular view of its structure, demand patterns, and growth potential. These segments allow market participants to understand specific niche requirements and tailor their product offerings and strategic approaches accordingly. The primary segmentation considerations revolve around the specific voltage levels the switchgear operates at, the diverse industrial and utility applications it serves, and the physical characteristics or installation environments that define its type. Understanding these distinctions is crucial for identifying key growth areas and competitive advantages within the broader market landscape. Each segment exhibits unique demand drivers and customer profiles, influencing product development and distribution strategies.

- By Voltage Level

- 12 kV to 36 kV (Medium Voltage)

- Above 36 kV (High Voltage)

- By Application

- Power Transmission & Distribution Utilities

- Industrial Manufacturing and Processing Plants

- Mining, Oil, and Gas

- Data Centers

- Railways and Transportation

- Renewable Energy (Solar, Wind)

- Commercial Infrastructure

- By Type

- Primary Switchgear

- Secondary Switchgear

- By Installation

- Indoor Switchgear

- Outdoor Switchgear

Value Chain Analysis For Vacuum Insulated High Voltage Industrial Switchgear Market

The value chain for the Vacuum Insulated High Voltage Industrial Switchgear market commences with a critical upstream segment, involving a diverse range of raw material suppliers and component manufacturers. This includes suppliers of high-grade steel and aluminum for enclosures, copper for conductors, and specialized ceramics or polymers for insulators. A particularly crucial element is the sourcing of vacuum interrupters, which are core to the technology, along with suppliers of control and protection relays, circuit breakers, and other electrical components. These upstream activities are vital for ensuring the quality, reliability, and performance of the final switchgear product, demanding stringent quality control and robust supply chain management from manufacturers.

Moving downstream, the value chain extends through the manufacturing, assembly, and testing phases, where raw materials and components are integrated into complete switchgear units. This stage involves complex engineering, design, and quality assurance processes. Post-manufacturing, the products reach the market through various distribution channels. Direct distribution is common for large, customized projects, where switchgear manufacturers engage directly with major utilities, large industrial clients, and project developers for consultation, sales, and installation support. This approach allows for tailored solutions and direct technical assistance, fostering strong client relationships. These direct interactions are often critical for complex high-voltage installations.

Indirect distribution plays an equally significant role, particularly for standardized products or reaching a broader market. This typically involves leveraging a network of third-party distributors, system integrators, electrical contractors, and engineering, procurement, and construction (EPC) firms. These intermediaries provide localized sales, technical support, installation services, and after-sales maintenance to a wider array of end-users, including smaller industrial plants, commercial establishments, and regional utilities. The efficiency of both direct and indirect channels is paramount for market penetration and ensuring comprehensive customer service throughout the entire product lifecycle, from initial consultation to long-term operational support and eventual decommissioning.

Vacuum Insulated High Voltage Industrial Switchgear Market Potential Customers

The Vacuum Insulated High Voltage Industrial Switchgear market serves a broad and diverse base of potential customers, all of whom require reliable and efficient power distribution and protection within their high voltage electrical infrastructure. At the forefront are power transmission and distribution utilities, which are the primary buyers for integrating new power sources into the grid, expanding their networks, and modernizing aging substations. These utilities depend on high-quality switchgear to maintain grid stability, ensure uninterrupted power supply to residential and commercial users, and protect their extensive assets from electrical faults. Their purchasing decisions are often driven by regulatory compliance, long-term reliability, and overall system efficiency. Additionally, private power generators, including those operating conventional thermal plants or hydropower facilities, as well as an increasingly significant number of renewable energy producers like large-scale solar farms and wind power installations, constitute a major segment of end-users. These entities require robust switchgear to manage the power output from their generation facilities and safely transmit it to the grid.

Beyond the utilities sector, a substantial portion of demand emanates from heavy industrial sectors where uninterrupted power is critical for continuous operations and protecting expensive machinery. This includes industries such as manufacturing and processing plants, particularly in segments like metallurgy, chemicals, automotive, and food & beverage, which operate large motors, furnaces, and production lines that rely on stable high voltage supply. The mining industry, with its extensive electrical infrastructure for excavation and processing, also represents a significant customer base, demanding durable and safe switchgear for harsh operating environments. Similarly, oil and gas facilities, both upstream and downstream, require specialized high voltage switchgear for exploration, extraction, refining, and transportation processes, where safety and reliability are paramount to prevent costly shutdowns and hazardous incidents.

Furthermore, the expanding digital infrastructure globally contributes significantly to the customer base. Data centers, which house critical IT infrastructure, require highly reliable and redundant power systems, making vacuum insulated high voltage switchgear essential for their incoming power distribution and internal protection. Large commercial infrastructure projects, including airports, seaports, and extensive commercial complexes, also utilize these switchgears for their primary electrical distribution. The railway and transportation sector, particularly for high-speed rail networks and electrified public transport systems, also relies on this technology for traction power supply. These diverse end-users are united by their need for high-performance, safe, and environmentally sound electrical protection and control in high voltage environments, driving continuous demand for vacuum insulated switchgear solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 5.8 billion |

| Market Forecast in 2032 | USD 9.3 billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Eaton Corporation plc, Schneider Electric SE, General Electric Company, Hitachi Energy Ltd., Hyosung Heavy Industries, Mitsubishi Electric Corporation, Fuji Electric Co. Ltd., Toshiba Corporation, Larsen & Toubro Limited, CG Power and Industrial Solutions Limited, Lucy Electric, Efacec Power Solutions, Kirloskar Electric Company, Chint Group, Beijing Orient Tantalum Industry Co., Ltd., Shaanxi Jinsha Electric Co., Ltd., Shandong Taikai Power Engineering Co., Ltd., Xian XD Switchgear Electric Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vacuum Insulated High Voltage Industrial Switchgear Market Key Technology Landscape

The technological landscape of the Vacuum Insulated High Voltage Industrial Switchgear market is characterized by continuous innovation aimed at enhancing performance, reliability, safety, and environmental sustainability. At its core, the primary technology remains the vacuum interrupter, which uses a vacuum medium to rapidly quench electrical arcs and interrupt currents, offering superior insulation properties and a longer operational life compared to traditional arc quenching methods. Advancements in vacuum interrupter design, including materials science for contact electrodes and improved manufacturing techniques, are continuously pushing the boundaries of voltage and current ratings, making vacuum technology viable for increasingly higher voltage applications. These innovations are critical for meeting the demanding requirements of modern power grids and heavy industries, ensuring minimal energy loss and maximum fault interruption capability.

Beyond the fundamental vacuum insulation, the market is significantly influenced by the integration of digital and smart technologies. Modern switchgear often incorporates advanced digital control and protection relays, which replace older electromechanical relays, offering higher precision, flexibility, and communication capabilities. These digital relays are capable of complex fault detection, self-diagnosis, and adaptive protection schemes, greatly enhancing the intelligence of the switchgear. The proliferation of smart sensors for monitoring various operational parameters such as temperature, current, voltage, and partial discharges, allows for real-time data collection and analysis. This sensor data, when combined with Internet of Things (IoT) platforms, facilitates remote monitoring, predictive maintenance, and condition-based asset management, shifting away from time-based maintenance schedules. The integration of IoT allows operators to gain unprecedented insights into the health and performance of their switchgear assets, optimizing operational efficiency and reducing downtime.

Further technological advancements include the development of compact and modular designs, which reduce the physical footprint of switchgear installations, an important consideration for urban substations and space-constrained industrial environments. Emphasis is also placed on enhanced insulation materials and improved enclosure designs to ensure robust performance in diverse environmental conditions. There is an ongoing trend towards cybersecurity measures being built directly into switchgear control systems, protecting critical infrastructure from digital threats. While the market is specifically for vacuum-insulated systems, the broader context of switchgear innovation also sees a push for SF6-free alternatives where vacuum technology provides a leading solution, demonstrating commitment to environmental responsibility. These technological strides collectively contribute to a more resilient, intelligent, and sustainable electrical infrastructure, capable of adapting to the evolving demands of industrial and utility applications.

Regional Highlights

- North America:

- Driven by extensive grid modernization initiatives and replacement of aging infrastructure.

- Strong adoption in industrial sectors like manufacturing, oil and gas, and data centers.

- Emphasis on enhanced grid reliability and resilience against extreme weather events.

- Key countries: United States, Canada.

- Europe:

- Robust growth fueled by strict environmental regulations phasing out SF6 gas, promoting vacuum technology.

- Significant investments in renewable energy integration (wind, solar) across the continent.

- Focus on smart grid development and digitalization of energy infrastructure.

- Key countries: Germany, UK, France, Italy, Spain.

- Asia Pacific (APAC):

- Dominant market share driven by rapid industrialization, urbanization, and massive infrastructure development.

- High demand from expanding power transmission and distribution networks, and new power generation projects, especially in renewables.

- Government initiatives to expand access to electricity and strengthen industrial capacity.

- Key countries: China, India, Japan, South Korea, Australia, ASEAN countries.

- Latin America:

- Growing market due to increasing industrial investments, particularly in mining, oil and gas, and manufacturing.

- Investments in grid expansion and modernization to support economic development.

- Political and economic stability can influence the pace of infrastructure projects.

- Key countries: Brazil, Mexico, Argentina, Chile.

- Middle East and Africa (MEA):

- Significant growth potential driven by large-scale infrastructure projects, industrialization, and electrification efforts.

- Demand from the oil and gas sector, which requires robust high-voltage equipment.

- Investments in smart cities and diversifying energy sources are contributing factors.

- Key countries: UAE, Saudi Arabia, Qatar, South Africa, Egypt.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vacuum Insulated High Voltage Industrial Switchgear Market.- ABB Ltd.

- Siemens AG

- Eaton Corporation plc

- Schneider Electric SE

- General Electric Company

- Hitachi Energy Ltd.

- Hyosung Heavy Industries

- Mitsubishi Electric Corporation

- Fuji Electric Co. Ltd.

- Toshiba Corporation

- Larsen & Toubro Limited

- CG Power and Industrial Solutions Limited

- Lucy Electric

- Efacec Power Solutions

- Kirloskar Electric Company

- Chint Group

- Beijing Orient Tantalum Industry Co., Ltd.

- Shaanxi Jinsha Electric Co., Ltd.

- Shandong Taikai Power Engineering Co., Ltd.

- Xian XD Switchgear Electric Co., Ltd.

Frequently Asked Questions

What are the primary benefits of Vacuum Insulated High Voltage Industrial Switchgear?

Vacuum Insulated High Voltage Industrial Switchgear offers superior safety due to non-flammable insulation, enhanced environmental friendliness by eliminating SF6 gas, compact design, reduced maintenance requirements, and higher operational reliability and lifespan.

How is AI impacting the Vacuum Insulated High Voltage Industrial Switchgear market?

AI is enabling predictive maintenance, optimizing grid management, enhancing fault detection and diagnosis, improving cybersecurity, and facilitating remote monitoring, leading to more efficient and reliable switchgear operations.

Which regions are driving the growth of this market?

The Asia Pacific region, particularly China and India, is a major growth driver due to rapid industrialization and infrastructure development. North America and Europe also contribute significantly through grid modernization and renewable energy integration.

What are the main applications for Vacuum Insulated High Voltage Industrial Switchgear?

Key applications include power transmission and distribution utilities, industrial manufacturing plants, mining and oil & gas operations, data centers, renewable energy installations, and railway systems, where high voltage control and protection are critical.

What challenges does the Vacuum Insulated High Voltage Industrial Switchgear market face?

The market faces challenges such as high initial capital expenditure, complex installation procedures, the need for specialized technical expertise, and competition from alternative switchgear technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager