Vacuum Insulated Low Voltage Industrial Switchgear Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429523 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Vacuum Insulated Low Voltage Industrial Switchgear Market Size

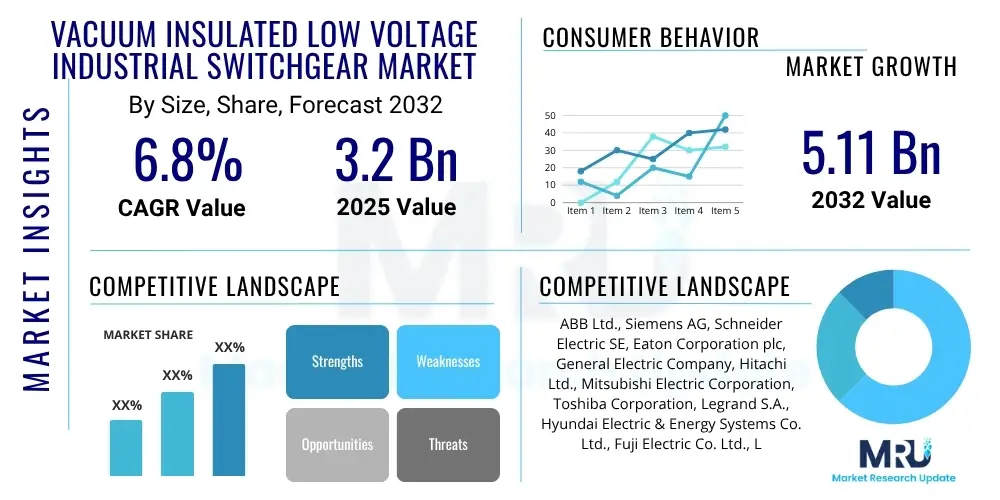

The Vacuum Insulated Low Voltage Industrial Switchgear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.2 Billion in 2025 and is projected to reach USD 5.11 Billion by the end of the forecast period in 2032.

Vacuum Insulated Low Voltage Industrial Switchgear Market introduction

The Vacuum Insulated Low Voltage Industrial Switchgear market is experiencing robust expansion driven by increasing industrialization, stringent safety regulations, and a growing demand for reliable and efficient power distribution solutions across diverse sectors. This specialized switchgear employs vacuum technology for arc quenching, providing superior operational safety, enhanced reliability, and a compact design compared to traditional air or oil insulated counterparts. Key benefits include extended operational lifespan, reduced maintenance requirements, improved environmental compatibility due to the absence of harmful insulating gases, and enhanced safety features for personnel operating industrial electrical systems. Its primary applications span manufacturing facilities, process industries such as chemical and petrochemical, critical infrastructure like data centers, and advanced commercial buildings where uninterrupted and safe power supply is paramount.

The core product, vacuum insulated low voltage industrial switchgear, is an electrical apparatus designed for controlling, protecting, and isolating electrical equipment in low voltage circuits, typically below 1000V. Its distinctive feature is the utilization of vacuum interrupters, which are sealed devices where switching contacts operate within a vacuum chamber, preventing arcing and enhancing fault interruption capabilities. This design contributes to its compact footprint and suitability for space-constrained industrial environments. The inherent benefits of this technology, such as fire resistance, explosion proof characteristics, and minimized environmental impact, align with modern industrial standards and sustainability goals.

Driving factors for market growth include the global push for smart grid integration, modernization of aging electrical infrastructure, and the expansion of renewable energy generation facilities requiring robust and efficient power management systems. Furthermore, increasing investments in industrial automation and digitalization across various manufacturing sectors are propelling the demand for advanced switchgear solutions that can integrate seamlessly with smart control systems. Regulatory bodies worldwide are also imposing stricter safety and environmental compliance standards, further accelerating the adoption of vacuum insulated switchgear as a preferred choice for industrial power distribution and protection.

Vacuum Insulated Low Voltage Industrial Switchgear Market Executive Summary

The global Vacuum Insulated Low Voltage Industrial Switchgear Market is poised for significant growth, influenced by dynamic business trends centered on sustainability, digitalization, and operational efficiency. Industries are increasingly investing in smart switchgear solutions that integrate IoT capabilities, remote monitoring, and advanced analytics for predictive maintenance and enhanced operational control. The shift towards modular and customizable switchgear designs is also a key business trend, allowing for greater flexibility and scalability in industrial applications. Additionally, the market sees a growing emphasis on lifecycle cost reduction, where the initial investment in premium vacuum insulated switchgear is justified by long-term savings in maintenance, energy efficiency, and minimized downtime.

Regionally, the market exhibits varied growth trajectories and adoption rates. The Asia Pacific region is anticipated to be a dominant force, driven by rapid industrialization, infrastructure development, and significant investments in smart city projects, particularly in countries like China and India. North America and Europe are characterized by mature markets focused on upgrading and modernizing existing industrial infrastructure to meet new efficiency and safety standards, along with increasing adoption in renewable energy projects. Latin America and the Middle East & Africa regions are emerging as high-growth markets due to burgeoning industrial sectors, urbanization, and energy infrastructure expansion, albeit with specific challenges related to local manufacturing capabilities and regulatory frameworks.

Segment-wise, the market is primarily segmented by type (fixed and withdrawable), voltage range, application, and end-user industry. The withdrawable type segment is gaining traction due to its advantages in maintenance and quick replacement, minimizing operational downtime in critical industrial processes. Application segments such as manufacturing, process industries, and data centers are expected to hold substantial market shares, driven by continuous expansion and the critical need for reliable power systems. The increasing integration of smart features and digital components across all segments is a consistent trend, enhancing the functionality and appeal of vacuum insulated low voltage switchgear solutions to a broader industrial clientele.

AI Impact Analysis on Vacuum Insulated Low Voltage Industrial Switchgear Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Vacuum Insulated Low Voltage Industrial Switchgear Market often revolve around how AI can enhance reliability, optimize maintenance schedules, detect faults more efficiently, and integrate with existing industrial control systems. Users are concerned about the cybersecurity implications of connecting switchgear to AI-driven networks and the level of technical expertise required for implementation and management. There is also significant interest in AI's potential to reduce operational costs and improve energy management within industrial settings. The overarching expectation is that AI will transform switchgear from passive protection devices into intelligent, proactive components of a broader smart industrial ecosystem, offering unprecedented levels of operational insight and control.

- Predictive maintenance optimization: AI algorithms analyze operational data from switchgear to predict potential failures, enabling proactive maintenance and minimizing unscheduled downtime.

- Enhanced fault detection and diagnostics: AI systems can quickly identify and localize faults, distinguishing between transient and permanent issues, thereby accelerating troubleshooting and recovery.

- Optimized power flow and load management: AI can dynamically adjust switchgear operations to balance loads, optimize energy distribution, and improve overall system efficiency, reducing electricity consumption.

- Remote monitoring and control: AI-powered platforms facilitate real-time remote monitoring of switchgear health and performance, allowing for centralized control and rapid response to alerts.

- Cybersecurity enhancements: AI can detect anomalous patterns in network traffic and operational data, identifying potential cyber threats or unauthorized access attempts to smart switchgear systems.

- Automated configuration and self-healing capabilities: Future applications may include AI-driven self-configuration based on operational needs and automated rerouting of power in the event of localized failures.

- Integration with industrial IoT and smart factory ecosystems: AI serves as the intelligence layer that processes data from various sensors and devices within the switchgear and wider industrial environment, enabling holistic system optimization.

- Extended asset lifespan: By ensuring optimal operation and timely maintenance, AI contributes to prolonging the service life of switchgear components and the entire system.

DRO & Impact Forces Of Vacuum Insulated Low Voltage Industrial Switchgear Market

The Vacuum Insulated Low Voltage Industrial Switchgear Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the impact forces influencing its trajectory. Key drivers include the global trend towards industrial automation and digitalization, which necessitates advanced and reliable power distribution systems. Stringent safety regulations and environmental standards imposed by various governments and international bodies are compelling industries to adopt safer, more eco-friendly switchgear technologies like vacuum insulated options, moving away from older, less sustainable solutions. Additionally, the rapid growth of renewable energy infrastructure and smart grid initiatives globally are creating substantial demand for efficient and robust low voltage switchgear to integrate diverse energy sources and manage complex power networks. The increasing need for energy efficiency in industrial operations also plays a significant role, as modern switchgear helps in minimizing power losses and optimizing energy consumption.

Despite these strong drivers, the market faces several restraints that could impede its growth. The high initial capital investment required for vacuum insulated switchgear compared to conventional air-insulated alternatives can be a deterrent for small and medium-sized enterprises (SMEs) with limited budgets. Furthermore, the complexity of integrating advanced switchgear with existing legacy systems in older industrial plants poses technical challenges and requires specialized expertise. A lack of skilled personnel capable of installing, operating, and maintaining these sophisticated systems in certain developing regions also presents a significant hurdle. Competition from well-established conventional switchgear technologies, which often come with lower price points and familiar operational characteristics, continues to be a factor affecting market penetration.

Opportunities for market expansion are abundant, particularly in the realm of technological advancements and untapped geographical markets. The ongoing integration of IoT, AI, and cloud-based analytics into switchgear systems presents a significant opportunity for developing 'smart' switchgear with enhanced monitoring, diagnostic, and predictive maintenance capabilities. Expanding industrial sectors in emerging economies across Asia Pacific, Latin America, and Africa offer fertile ground for new installations and infrastructure development projects. Moreover, the global push for the modernization of aging electrical infrastructure in developed economies creates a continuous demand for advanced switchgear upgrades. The increasing adoption of electric vehicles and the associated charging infrastructure, along with the proliferation of data centers, are also opening new avenues for specialized vacuum insulated low voltage switchgear applications, further solidifying its market position and potential for innovation.

Segmentation Analysis

The Vacuum Insulated Low Voltage Industrial Switchgear Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth opportunities. This segmentation helps in identifying key market dynamics, customer preferences, and technological trends across various applications and end-user industries. The market is primarily categorized based on factors such as product type, voltage range, application sector, and the specific end-user industry, reflecting the varied requirements and deployment scenarios for this critical electrical equipment. Each segment offers unique insights into demand patterns, competitive landscapes, and potential areas for innovation and market penetration, allowing stakeholders to tailor strategies effectively.

- By Type

- Fixed Type

- Withdrawable Type

- By Voltage

- Below 400V

- 400V to 1000V

- By Application

- Power Generation & Distribution

- Manufacturing Industry

- Process Industry (e.g., Oil & Gas, Chemical, Metals & Mining)

- Commercial Buildings & Infrastructure

- Data Centers

- Renewable Energy Integration

- By End-User Industry

- Oil & Gas

- Mining

- Chemical & Petrochemical

- Food & Beverage

- Automotive

- Pharmaceutical

- Cement & Construction

- Utilities

- Textile

Value Chain Analysis For Vacuum Insulated Low Voltage Industrial Switchgear Market

The value chain for the Vacuum Insulated Low Voltage Industrial Switchgear Market encompasses a series of interconnected activities, beginning from raw material procurement and extending to the end-users and post-sales services. Upstream activities involve the sourcing and manufacturing of essential components and raw materials. These include high-purity metals for conductors and structural components, advanced insulation materials such as epoxy resins and ceramics, vacuum interrupters, circuit breakers, protective relays, current and voltage transformers, and various control and monitoring devices. Key suppliers in this stage specialize in these specific electrical and mechanical components, ensuring their quality and performance directly impact the final product's reliability and efficiency. This phase often involves specialized manufacturers for vacuum interrupters, which are core to the product's functionality.

Midstream activities primarily focus on the design, assembly, and testing of the complete vacuum insulated low voltage industrial switchgear units. Manufacturers integrate the procured components, engineer the switchgear panels according to specific voltage ratings and application requirements, and conduct rigorous quality control and performance testing. This stage involves significant engineering expertise to ensure compliance with international safety standards, electrical codes, and environmental regulations. Customization for specific industrial projects, including integration with smart grid technologies and automation systems, is also a crucial part of the manufacturing process, allowing switchgear to meet diverse operational demands and client specifications.

Downstream activities involve the distribution, installation, commissioning, and subsequent maintenance and servicing of the switchgear. Distribution channels can be direct, where major manufacturers sell directly to large industrial clients or utilities, often for large-scale infrastructure projects. Indirect channels involve a network of authorized distributors, system integrators, and electrical contractors who reach a broader base of small and medium-sized industrial customers. Post-sales support, including warranty services, preventive maintenance, spare parts supply, and technical assistance, forms an integral part of the downstream value chain, ensuring the long-term operational efficiency and safety of the installed switchgear. The effectiveness of these channels significantly influences market reach and customer satisfaction.

Vacuum Insulated Low Voltage Industrial Switchgear Market Potential Customers

Potential customers for Vacuum Insulated Low Voltage Industrial Switchgear are primarily entities requiring robust, safe, and efficient power distribution and protection solutions for their critical operations. These include a broad spectrum of industrial enterprises, commercial establishments, and infrastructure developers that rely on continuous and reliable electrical supply to power their machinery, processes, and facilities. The superior safety features, compact design, and reduced maintenance requirements of vacuum insulated switchgear make it particularly attractive to industries where operational uptime, personnel safety, and environmental compliance are paramount. The growing complexity of industrial electrical networks, coupled with the integration of renewable energy sources, further expands the base of potential buyers seeking advanced switchgear solutions.

Specific end-user industries represent a significant segment of potential customers. Manufacturing plants, including automotive assembly, food and beverage processing, pharmaceuticals, and heavy machinery, consistently invest in modern switchgear to ensure seamless production lines and protect expensive equipment. Process industries such as oil and gas, chemical and petrochemical, and metals and mining require extremely rugged and reliable switchgear to operate in harsh and potentially hazardous environments. Additionally, data centers, which demand absolute power reliability and efficient cooling, are increasingly adopting vacuum insulated low voltage switchgear due to its compact footprint and enhanced safety features that minimize fire risks. The utilities sector, encompassing power generation, transmission, and distribution companies, also represents a core customer segment, particularly for grid modernization and integration of distributed energy resources.

Beyond traditional industrial sectors, emerging applications and infrastructure projects are expanding the customer base. Large commercial complexes, hospitals, and high-rise buildings are adopting these systems for enhanced safety and power management. Urban development projects, smart cities initiatives, and public transportation infrastructure (like metro systems and railway electrification) also represent growing opportunities. Furthermore, the increasing global investment in renewable energy projects, including solar farms and wind power installations, requires sophisticated low voltage switchgear for efficient power collection and grid integration. Any organization that prioritizes electrical safety, operational continuity, energy efficiency, and a reduced environmental footprint in their electrical infrastructure is a strong potential customer for vacuum insulated low voltage industrial switchgear.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 5.11 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Schneider Electric SE, Eaton Corporation plc, General Electric Company, Hitachi Ltd., Mitsubishi Electric Corporation, Toshiba Corporation, Legrand S.A., Hyundai Electric & Energy Systems Co. Ltd., Fuji Electric Co. Ltd., Lucy Electric, Larsen & Toubro Limited, CG Power and Industrial Solutions Limited, Hyosung Heavy Industries, Powell Industries Inc., Chint Group, Zhejiang Kete Electrical Co. Ltd., Shandong Taikai Power Engineering Co. Ltd., Meidensha Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vacuum Insulated Low Voltage Industrial Switchgear Market Key Technology Landscape

The Vacuum Insulated Low Voltage Industrial Switchgear Market is characterized by a rapidly evolving technological landscape, driven by the continuous pursuit of enhanced safety, operational efficiency, and integration capabilities. At its core, the primary technology is the vacuum interrupter, which uses a vacuum as the arc quenching medium, offering superior performance in terms of rapid arc extinction, minimal contact erosion, and extended lifespan compared to air or oil-based systems. This core technology is continuously refined to improve dielectric strength, reduce size, and enhance reliability under various operating conditions. Advances in materials science contribute to the development of more durable and environmentally friendly insulation materials, such as advanced epoxy resins and specialized ceramics, which further contribute to the compact design and safety profile of the switchgear.

Beyond the fundamental insulation and interruption technologies, the market is increasingly adopting digital and smart technologies. The integration of advanced sensors for monitoring parameters like temperature, current, voltage, and partial discharges is becoming standard. These sensors feed data to integrated digital control units and intelligent electronic devices (IEDs), which process the information to provide real-time operational insights and facilitate proactive maintenance. The development of modular designs is another key technological trend, allowing for greater flexibility in system configuration, easier installation, and quicker expansion or modification to meet evolving industrial requirements. This modularity also simplifies maintenance procedures and reduces overall downtime.

The convergence of Information Technology (IT) and Operational Technology (OT) is profoundly impacting the switchgear market. This involves the incorporation of Industrial IoT (IIoT) capabilities, enabling remote monitoring, control, and data analytics via cloud-based platforms. Predictive analytics, powered by machine learning algorithms, is a critical innovation, allowing operators to forecast potential equipment failures and schedule maintenance activities efficiently, thereby preventing costly outages. Furthermore, communication protocols like IEC 61850 are being increasingly adopted to ensure seamless interoperability between different components of the switchgear and with broader grid management or industrial automation systems. These technological advancements collectively contribute to making vacuum insulated low voltage industrial switchgear more intelligent, resilient, and an integral part of modern smart industrial and utility infrastructure.

Regional Highlights

- North America: This region represents a mature market with significant demand driven by the modernization of aging industrial and utility infrastructure, coupled with stringent safety regulations. The United States and Canada are leading adopters, focusing on enhancing grid reliability, integrating renewable energy sources, and expanding data center capabilities.

- Europe: Europe is a key market characterized by strong emphasis on energy efficiency, environmental sustainability, and smart grid initiatives. Countries like Germany, the UK, and France are heavily investing in industrial automation and upgrading existing facilities, propelling the demand for advanced vacuum insulated switchgear solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to rapid industrialization, extensive infrastructure development, and increasing investments in manufacturing and power generation, particularly in China, India, and Southeast Asian countries. The region's expanding smart city projects and rural electrification efforts also contribute significantly to market expansion.

- Latin America: This region is experiencing steady growth, fueled by investments in industrial sectors, mining, and oil & gas, alongside efforts to improve electrical infrastructure. Countries like Brazil and Mexico are emerging as significant contributors to market demand as they focus on industrial expansion and modernization.

- Middle East and Africa (MEA): The MEA market is witnessing considerable growth driven by burgeoning industrialization, urbanization, and large-scale infrastructure projects, especially in the GCC countries. Investments in industrial parks, oil & gas facilities, and power generation capacity are key factors accelerating the adoption of vacuum insulated low voltage switchgear.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vacuum Insulated Low Voltage Industrial Switchgear Market.- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Eaton Corporation plc

- General Electric Company

- Hitachi Ltd.

- Mitsubishi Electric Corporation

- Toshiba Corporation

- Legrand S.A.

- Hyundai Electric & Energy Systems Co. Ltd.

- Fuji Electric Co. Ltd.

- Lucy Electric

- Larsen & Toubro Limited

- CG Power and Industrial Solutions Limited

- Hyosung Heavy Industries

- Powell Industries Inc.

- Chint Group

- Zhejiang Kete Electrical Co. Ltd.

- Shandong Taikai Power Engineering Co. Ltd.

- Meidensha Corporation

Frequently Asked Questions

What are the primary benefits of vacuum insulated low voltage switchgear?

Vacuum insulated low voltage switchgear offers superior safety due to effective arc quenching in a vacuum, preventing fire and explosion risks. It provides high reliability and an extended operational lifespan with minimal maintenance, thanks to its robust design and sealed interrupters. Its compact footprint also allows for efficient use of space in industrial environments, and it is environmentally friendly, as it does not use harmful insulating gases.

How does vacuum insulation enhance safety in industrial environments?

Vacuum insulation significantly enhances safety by containing and extinguishing electrical arcs within a sealed vacuum chamber, preventing them from spreading and causing explosions or fires. This design drastically reduces the risk of electrical accidents, enhances personnel protection, and minimizes damage to surrounding equipment, making industrial operations safer and more secure.

What industries are the main adopters of this technology?

The main adopters of vacuum insulated low voltage switchgear include manufacturing (automotive, food & beverage, pharmaceuticals), process industries (oil & gas, chemical, mining), data centers requiring critical power reliability, power generation and distribution utilities, and large commercial and infrastructure projects. These sectors prioritize safety, reliability, and efficiency in their electrical systems.

What are the future trends impacting the market?

Future trends impacting the market include the increasing integration of Artificial Intelligence (AI) and Industrial IoT for predictive maintenance and smart grid capabilities. There is also a growing focus on modular and customizable designs, further advancements in materials for enhanced sustainability, and expanded applications in renewable energy integration and electric vehicle charging infrastructure.

How does this technology contribute to energy efficiency?

Vacuum insulated low voltage switchgear contributes to energy efficiency through its advanced design that minimizes power losses during operation. Its precise control and protection capabilities prevent system overloads and faults, which can lead to inefficient energy consumption. When integrated with smart monitoring and AI, it can optimize power distribution and load management, leading to overall reduced energy waste in industrial facilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager