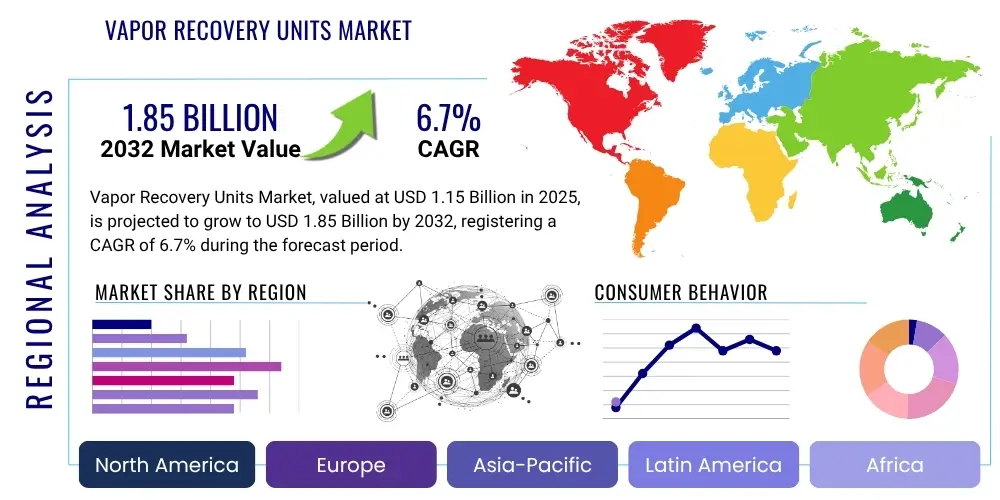

Vapor Recovery Units Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429106 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Vapor Recovery Units Market Size

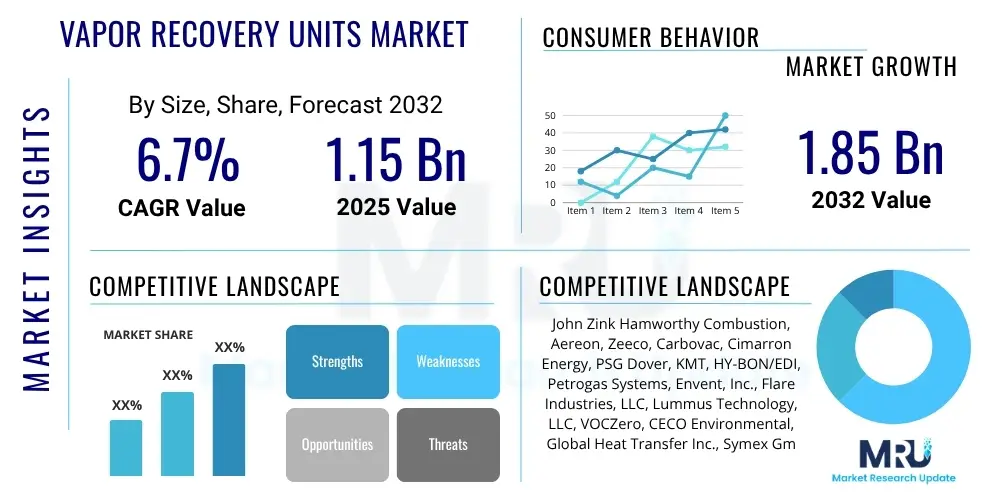

The Vapor Recovery Units Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at $1.15 Billion in 2025 and is projected to reach $1.85 Billion by the end of the forecast period in 2032.

Vapor Recovery Units Market introduction

Vapor Recovery Units (VRUs) are essential industrial systems designed to capture and recover Volatile Organic Compounds (VOCs) that evaporate during the storage, transfer, and processing of crude oil, natural gas, gasoline, and various chemicals. These units play a critical role in environmental protection by reducing atmospheric emissions and in economic efficiency by recovering valuable hydrocarbons or other chemical products that would otherwise be lost. The technology typically involves processes such as adsorption, condensation, absorption, or membrane separation to efficiently separate and reclaim vapors from gas streams, preventing their release into the atmosphere.

The primary applications for VRUs span across numerous industrial sectors, notably the oil and gas industry, including upstream exploration and production, midstream transportation and storage, and downstream refining and petrochemical operations. They are also widely employed in chemical manufacturing plants, bulk liquid storage terminals, and even in some pharmaceutical and food processing facilities that handle volatile substances. The immediate benefits include significant reductions in air pollution, compliance with stringent environmental regulations, and the economic advantage of recovering saleable products, which contributes directly to a company's bottom line.

Driving factors for the Vapor Recovery Units market primarily stem from the increasing global emphasis on environmental stewardship and regulatory compliance. Governments and international bodies are continually tightening emissions standards for VOCs, pushing industries to adopt more effective vapor recovery solutions. Furthermore, the rising awareness of the economic benefits associated with product recovery, coupled with advancements in VRU technology that enhance efficiency and reduce operational costs, are propelling market growth. The expansion of oil and gas infrastructure and the increasing demand for energy also contribute to the heightened need for effective vapor management systems.

Vapor Recovery Units Market Executive Summary

The Vapor Recovery Units market is experiencing robust growth driven by evolving global environmental regulations, a heightened focus on corporate sustainability, and the economic imperative to recover valuable hydrocarbons. Key business trends indicate a shift towards more advanced, integrated, and automated VRU systems that offer higher recovery efficiencies and lower operational footprints. Companies are increasingly investing in modular and scalable solutions to meet diverse operational needs and adapt to varying regulatory landscapes across different regions. The competitive landscape is characterized by innovation in adsorption materials, condensation techniques, and sensor technologies to optimize performance and reduce emissions to near-zero levels.

Regional trends highlight North America and Europe as mature markets with established regulatory frameworks and significant demand for VRUs, largely due to stringent environmental protection policies and a well-developed oil and gas infrastructure. The Asia Pacific region is emerging as a high-growth market, propelled by rapid industrialization, increasing energy consumption, and a growing recognition of environmental concerns, particularly in countries like China and India. Latin America and the Middle East and Africa are also expected to demonstrate substantial growth, driven by new oil and gas discoveries and expanding refining capacities, coupled with developing regulatory standards for emissions control.

Segment trends within the VRU market indicate strong performance across various technologies and applications. The carbon adsorption segment remains dominant due to its proven effectiveness and versatility, though condensation technologies, particularly refrigerated and cryogenic systems, are gaining traction for higher efficiency in specific applications. From an application perspective, the oil and gas sector continues to be the largest end-user, with increasing demand from storage tanks, loading terminals, and processing plants. The market is also seeing demand for VRUs in the chemical and pharmaceutical industries, underscoring the broader applicability and necessity of these systems for emissions control and product recovery.

AI Impact Analysis on Vapor Recovery Units Market

User inquiries concerning the impact of Artificial Intelligence on the Vapor Recovery Units market primarily center on the potential for enhanced operational efficiency, predictive maintenance capabilities, and improved compliance monitoring. Users are keen to understand how AI can optimize VRU performance by analyzing real-time data, predict equipment failures before they occur, and automate complex operational adjustments. There is also significant interest in AI's role in integrating VRU operations within broader industrial control systems and leveraging data analytics for better environmental reporting and strategic decision-making. The overarching expectation is that AI will transform VRUs from reactive systems into proactive, intelligent assets.

- AI-powered predictive maintenance reduces downtime and extends equipment lifespan by analyzing operational data for early anomaly detection.

- Optimized performance through AI algorithms that adjust operating parameters in real-time based on fluctuating vapor loads and environmental conditions.

- Real-time monitoring and reporting capabilities are significantly enhanced, ensuring continuous compliance with regulatory standards and immediate identification of potential issues.

- Improved safety protocols are implemented via AI-driven analytics that identify hazardous conditions or potential leaks more accurately and rapidly than traditional methods.

- Data-driven decision making is facilitated by AI, providing actionable insights into efficiency improvements, resource allocation, and long-term investment strategies for VRU systems.

- Enhanced integration with existing SCADA and DCS systems for a unified and intelligent control environment across industrial operations.

DRO & Impact Forces Of Vapor Recovery Units Market

The Vapor Recovery Units market is significantly influenced by a dynamic interplay of driving forces, inherent restraints, and emerging opportunities, all of which contribute to its overall market trajectory. A primary driver is the global escalation of environmental protection mandates and regulations aimed at reducing Volatile Organic Compound (VOC) emissions. These stringent rules compel industries, particularly oil and gas, chemical, and petrochemical sectors, to invest in effective vapor recovery solutions to avoid heavy penalties and maintain operational licenses. Alongside regulatory pressures, the economic incentive of recovering valuable lost product, such as hydrocarbons, provides a substantial impetus for VRU adoption, directly impacting profitability and resource conservation.

However, the market also faces notable restraints. The initial capital investment required for purchasing and installing VRU systems can be substantial, posing a barrier to entry for smaller companies or those operating on tight budgets. Additionally, the operational complexities associated with VRU maintenance, the need for specialized technical expertise, and the integration challenges with existing infrastructure can deter some potential adopters. Furthermore, a lack of comprehensive awareness regarding the long-term economic and environmental benefits in certain developing regions also acts as a constraint, slowing market penetration despite the clear advantages.

Opportunities within the VRU market are abundant and promising. The rapid industrialization and growing energy demand in emerging economies, particularly in Asia Pacific and Latin America, present significant untapped markets for VRU deployment. Technological advancements, including the development of more efficient, compact, and automated VRU systems, offer avenues for market expansion and improved performance. Moreover, the increasing integration of digital technologies such as IoT, AI, and advanced analytics into VRUs promises enhanced efficiency, predictive maintenance, and optimized operations, further broadening their appeal and application across a wider range of industrial processes. The global push towards sustainability and circular economy principles further solidifies the long-term growth prospects for the Vapor Recovery Units market, driven by both environmental and economic impact forces.

Segmentation Analysis

The Vapor Recovery Units market is comprehensively segmented to provide a detailed understanding of its diverse landscape and growth dynamics. This segmentation allows for precise analysis of market trends, identifying key areas of opportunity and potential challenges across different technologies, applications, end-use industries, and capacities. Each segment is critical in defining the specific needs and drivers of various market participants, from raw material suppliers to end-users.

- By Technology

- Carbon Adsorption

- Condensation (Refrigerated, Cryogenic)

- Membrane Separation

- Absorption

- By Application

- Storage Tanks

- Loading Terminals (Rail, Truck, Marine)

- Processing Plants (Gas Processing, Chemical Manufacturing)

- Other Industrial Vents

- By End-Use Industry

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Pharmaceutical

- Food & Beverage

- Other Manufacturing Industries

- By Capacity

- Small Capacity (Up to 100 CFM)

- Medium Capacity (101-500 CFM)

- Large Capacity (Above 500 CFM)

Value Chain Analysis For Vapor Recovery Units Market

The value chain for the Vapor Recovery Units market encompasses a series of interconnected activities, beginning from the sourcing of raw materials to the ultimate delivery and post-sales support of VRU systems. The upstream segment involves the procurement of critical components such as compressors, vacuum pumps, absorbent materials (e.g., activated carbon), membranes, heat exchangers, instrumentation, and control systems from specialized suppliers. These raw material and component providers play a vital role in ensuring the quality, efficiency, and reliability of the final VRU product, often requiring specialized engineering and material science expertise.

Midstream activities primarily involve the design, engineering, and manufacturing of the VRU systems by specialized equipment manufacturers. These companies assemble various components, integrate proprietary technologies, and customize units to meet specific client requirements regarding vapor composition, flow rates, and regulatory compliance. This stage also includes rigorous testing and quality assurance to ensure the systems perform effectively under diverse operational conditions. Innovation in this segment often focuses on enhancing energy efficiency, reducing footprint, and improving recovery rates through advanced process design and material selection.

The downstream segment of the value chain focuses on the distribution, installation, commissioning, and ongoing maintenance and service of VRUs. Distribution channels can be direct, where manufacturers sell directly to large industrial end-users, particularly for custom or large-scale projects. Indirect channels involve a network of specialized distributors, value-added resellers, and Engineering, Procurement, and Construction (EPC) firms who integrate VRUs into larger industrial projects. Post-sales support, including spare parts, technical assistance, and routine maintenance, is crucial for ensuring the long-term operational efficiency and compliance of these units, forming a significant part of the market’s ongoing revenue streams and customer satisfaction.

Vapor Recovery Units Market Potential Customers

The potential customers for Vapor Recovery Units primarily consist of industrial entities that handle volatile organic compounds (VOCs) during their operational processes, making them subject to environmental regulations and keen on product recovery. These end-users span a wide array of sectors, each with unique requirements for vapor management and emissions control. The core customer base is driven by the need to comply with increasingly stringent environmental standards, minimize product losses, and enhance operational safety.

Key end-user segments include oil and gas exploration and production companies, which deploy VRUs at well sites, tank batteries, and gas gathering facilities to capture flash gas and tank vapors. Midstream operators, such as pipeline companies and storage terminal operators, utilize VRUs at loading and unloading racks for trucks, railcars, and marine vessels, as well as at storage tank farms. Downstream customers, including refineries and petrochemical plants, integrate VRUs into various processing units to control emissions from distillation columns, reactor vents, and wastewater treatment facilities, ensuring continuous regulatory compliance and maximum product yield.

Beyond the traditional oil and gas sector, the chemical manufacturing industry represents a significant customer base, using VRUs to recover valuable solvents and reduce emissions from processing volatile chemicals. Pharmaceutical companies also employ VRUs to recover solvents in manufacturing processes and to comply with air quality standards. Furthermore, bulk liquid storage terminals for various industrial chemicals, food processing plants handling volatile flavor compounds, and even wastewater treatment plants with high VOC concentrations are increasingly adopting VRU technology. The diverse application spectrum underscores the broad appeal and essential nature of VRUs across any industry managing volatile organic compounds.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.15 Billion |

| Market Forecast in 2032 | $1.85 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | John Zink Hamworthy Combustion, Aereon, Zeeco, Carbovac, Cimarron Energy, PSG Dover, KMT, HY-BON/EDI, Petrogas Systems, Envent, Inc., Flare Industries, LLC, Lummus Technology, LLC, VOCZero, CECO Environmental, Global Heat Transfer Inc., Symex GmbH & Co. KG, SVR Global, Sichuan Rongteng Energy Technology Co., Ltd., Green Conversion Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vapor Recovery Units Market Key Technology Landscape

The Vapor Recovery Units market is characterized by a diverse and evolving technology landscape, primarily driven by the need for higher recovery efficiencies, lower operational costs, and enhanced environmental compliance. The most widely adopted technologies include activated carbon adsorption, which utilizes beds of activated carbon to adsorb VOCs from vapor streams, followed by a desorption cycle to recover the captured product. This method is favored for its robustness and effectiveness across a wide range of vapor compositions and flow rates, continuously undergoing improvements in absorbent materials and regeneration processes to maximize lifespan and performance.

Condensation technologies, particularly refrigerated and cryogenic systems, represent another significant segment. Refrigerated condensation units cool vapor streams to temperatures that cause VOCs to condense back into liquid form, offering high recovery rates for specific applications. Cryogenic systems operate at much lower temperatures, often using liquid nitrogen, for nearly complete recovery of even lighter hydrocarbons, making them ideal for high-value product recovery or very stringent emission limits. Membrane separation technology, while less prevalent, is gaining traction for its compact design and continuous operation, selectively permeating VOCs through specialized membranes.

Further advancements in the VRU technology landscape include the integration of absorption methods, where VOCs are absorbed into a liquid solvent, followed by separation and recovery of the valuable components. Beyond these core processes, the market is increasingly adopting smart technologies such as IoT sensors for real-time monitoring of performance metrics, advanced analytics for predictive maintenance, and automation systems for optimized operational control. These digital integrations are enhancing the reliability, efficiency, and remote management capabilities of VRUs, allowing for more proactive adjustments and minimizing human intervention, thereby contributing significantly to operational excellence and long-term sustainability.

Regional Highlights

- North America: This region holds a significant share of the global Vapor Recovery Units market, primarily driven by stringent environmental regulations imposed by agencies such as the EPA, especially concerning emissions from oil and gas operations. The mature oil and gas infrastructure across the United States and Canada, coupled with a proactive approach towards sustainability and technological adoption, fuels consistent demand for advanced VRU solutions. High investments in environmental compliance and product recovery initiatives further solidify its market position.

- Europe: Europe represents a robust market for VRUs, influenced by strong environmental policies and a collective commitment to reducing greenhouse gas emissions across the European Union. Countries like Germany, the UK, and the Netherlands emphasize sustainable industrial practices and robust regulatory enforcement, pushing industries to implement efficient vapor recovery systems. The region's focus on decarbonization and circular economy principles drives innovation and adoption of advanced VRU technologies.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as a high-growth market for Vapor Recovery Units. This growth is propelled by rapid industrialization, expanding energy demand, and increasing awareness regarding environmental pollution, particularly in major economies such as China, India, and Southeast Asian countries. Developing environmental regulations and significant investments in oil and gas and chemical sectors are creating substantial opportunities for VRU manufacturers, albeit with varying degrees of regulatory enforcement across nations.

- Latin America: This region is experiencing considerable growth in the VRU market, largely due to an expanding oil and gas sector and evolving environmental legislations. Countries like Brazil, Mexico, and Argentina are investing in new exploration and production projects, alongside infrastructure development, which necessitate effective vapor management. While regulatory frameworks are still maturing in some areas, the increasing focus on sustainable operations and compliance is driving VRU adoption.

- Middle East and Africa (MEA): The MEA region, particularly the Gulf Cooperation Council (GCC) countries, represents a significant market given its vast oil and gas reserves and extensive refining capacities. With increasing global scrutiny on environmental footprints, there is a growing impetus for adopting VRU technologies to meet international standards and enhance operational efficiency. Investments in new petrochemical complexes and expansions of existing facilities are key drivers, balancing resource recovery with environmental stewardship.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vapor Recovery Units Market.- John Zink Hamworthy Combustion

- Aereon

- Zeeco

- Carbovac

- Cimarron Energy

- PSG Dover

- KMT

- HY-BON/EDI

- Petrogas Systems

- Envent, Inc.

- Flare Industries, LLC

- Lummus Technology, LLC

- VOCZero

- CECO Environmental

- Global Heat Transfer Inc.

- Symex GmbH & Co. KG

- SVR Global

- Sichuan Rongteng Energy Technology Co., Ltd.

- Green Conversion Systems Inc.

Frequently Asked Questions

What are Vapor Recovery Units (VRUs)?

Vapor Recovery Units (VRUs) are industrial systems designed to capture and recover volatile organic compounds (VOCs) that evaporate during the handling, storage, or processing of liquid hydrocarbons and chemicals, preventing their release into the atmosphere.

Why are VRUs considered essential in modern industrial operations?

VRUs are essential because they ensure compliance with stringent environmental regulations by reducing harmful VOC emissions and offer significant economic benefits by recovering valuable products that would otherwise be lost, thus improving operational efficiency and profitability.

Which industries are the primary users of Vapor Recovery Units?

The primary industries utilizing VRUs include the oil and gas sector (upstream, midstream, downstream), chemical and petrochemical manufacturing, bulk liquid storage terminals, and in some specialized cases, pharmaceutical and food processing facilities that handle volatile substances.

What are the main technologies employed in Vapor Recovery Units?

Key technologies in VRUs include carbon adsorption, which uses activated carbon to capture vapors; condensation systems (refrigerated or cryogenic) that cool vapors to liquefy them; membrane separation; and absorption, where vapors are absorbed into a liquid solvent for recovery.

How do Vapor Recovery Units contribute to sustainability initiatives?

VRUs contribute significantly to sustainability by drastically reducing air pollution through VOC emission control, conserving valuable natural resources by recovering lost product, and helping industries meet environmental compliance targets, aligning with global efforts towards a greener economy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager