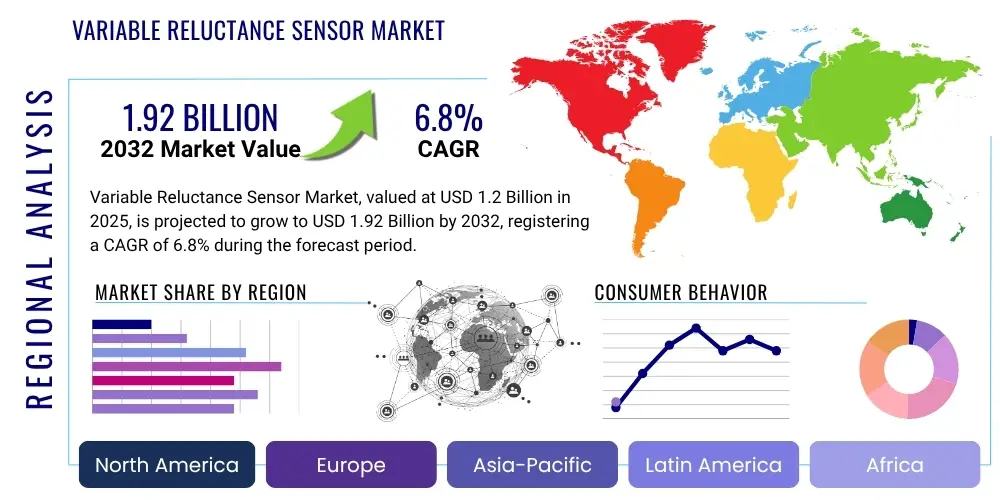

Variable Reluctance Sensor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428837 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Variable Reluctance Sensor Market Size

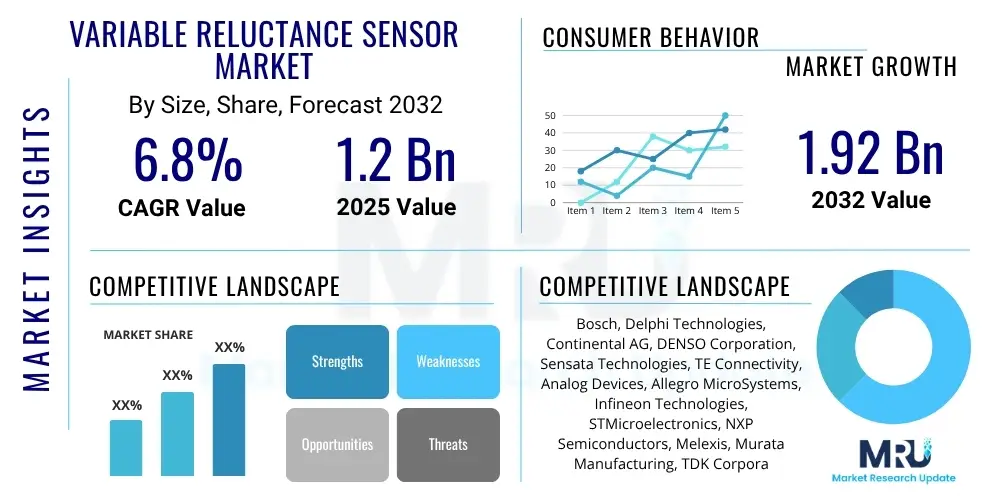

The Variable Reluctance Sensor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.92 Billion by the end of the forecast period in 2032.

Variable Reluctance Sensor Market introduction

The Variable Reluctance Sensor market is deeply integrated into various modern industrial and automotive systems, serving as a foundational technology for motion and speed detection. Operating on the principle of magnetic induction, these sensors transform the physical movement of a ferromagnetic target into an electrical signal. This process involves a coil of wire wrapped around a permanent magnet, generating a magnetic field. When a ferrous material, such as a gear tooth or a metal disc with discontinuities, passes through this field, it alters the magnetic flux, inducing a voltage in the coil. This mechanism, requiring no external power for passive variants, contributes to their inherent robustness and reliability, making them indispensable in environments where active power sources might be impractical or introduce vulnerabilities.

The inherent simplicity and durability of Variable Reluctance Sensors make them highly desirable for a wide range of critical applications. In the automotive sector, they are the backbone of engine timing, crankshaft position, camshaft position, and anti-lock braking systems (ABS), providing crucial data for engine control units (ECUs) and vehicle stability systems. Industrially, they are deployed extensively in motor speed feedback, turbine monitoring, flow metering, and conveyor belt speed control, ensuring operational efficiency and safety. The core benefits of these sensors include their ability to withstand extreme temperatures, vibrations, and contaminants without compromising performance, their cost-effectiveness due to minimal component count, and their long operational lifespan. The primary driving forces behind the market's anticipated growth are the escalating global demand for advanced automotive safety features, the rapid expansion of industrial automation and smart factory paradigms, and the profound shift towards electric and hybrid vehicle technologies, all of which heavily depend on precise and reliable motion sensing.

Variable Reluctance Sensor Market Executive Summary

The Variable Reluctance Sensor market is currently undergoing a period of significant evolution, influenced by a confluence of technological advancements, shifting economic landscapes, and an increasing demand for precision sensing. Key business trends point towards an intensified focus on enhancing the capabilities of VR sensors, particularly through miniaturization, improved signal-to-noise ratios, and seamless integration with advanced digital signal processing (DSP) units. This evolution is enabling VR sensors to overcome traditional limitations such as performance at very low speeds, expanding their utility into more demanding and nuanced applications. Furthermore, there is a growing trend towards incorporating diagnostic capabilities directly into the sensor module, facilitating predictive maintenance and overall system health monitoring in complex machinery.

Regionally, the market exhibits diverse growth patterns. Asia Pacific stands out as the primary growth engine, driven by its robust and expanding manufacturing sector, widespread industrialization, and the rapid adoption and production of electric vehicles across countries like China, India, and South Korea. North America and Europe, while more mature, maintain strong market positions due to continuous innovation in automotive R&D, a high degree of industrial automation, and stringent safety regulations that necessitate sophisticated and reliable sensing technologies. In terms of segmentation, the automotive sector continues to dominate the market as the largest end-user, with an unceasing demand for accurate speed and position sensors for various vehicle systems. However, the industrial segment is witnessing the most dynamic growth, fueled by the global push towards smart factories, Industry 4.0 initiatives, and the critical need for precise monitoring and control in diverse industrial processes. The increasing sophistication of active VR sensors, which incorporate integrated electronics for superior performance, is also a notable trend driving overall market expansion.

AI Impact Analysis on Variable Reluctance Sensor Market

Users frequently inquire about how Artificial Intelligence can enhance Variable Reluctance Sensor capabilities, whether AI can compensate for their inherent limitations like low-speed performance, and if AI-powered sensing technologies might eventually render traditional VR sensors obsolete. The overarching theme suggests an expectation that AI will primarily augment VR sensors, transforming raw data into actionable insights for predictive maintenance and advanced diagnostics, rather than replacing the fundamental sensing mechanism. There is significant interest in AI's role in improving the interpretation of VR sensor signals, especially in complex, noisy environments, and in enabling more sophisticated control systems.

- AI-driven signal processing improves accuracy and reduces noise from VR sensor outputs, particularly at very low speeds.

- Predictive analytics powered by AI utilizes VR sensor data to anticipate equipment failures, enabling proactive maintenance.

- AI algorithms enhance diagnostic capabilities by interpreting complex patterns in VR sensor data, identifying anomalies in engine or machinery performance.

- Integration with AI-enabled control systems allows for real-time adjustments and optimization based on VR sensor feedback.

- AI contributes to the development of 'smart' VR sensor systems that can self-calibrate or adapt to changing operational conditions.

DRO & Impact Forces Of Variable Reluctance Sensor Market

The Variable Reluctance Sensor market is significantly propelled by a robust set of driving factors. A primary driver is the burgeoning global automotive industry, which continues to rely heavily on VR sensors for critical functionalities. The accelerating transition towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) further intensifies this demand, as precise speed and position sensing are indispensable for efficient motor control, regenerative braking systems, and overall powertrain management in these advanced vehicles. Manufacturers are constantly seeking reliable, durable, and cost-effective sensors capable of operating under the demanding conditions of modern vehicle powertrains, a niche perfectly filled by VR sensors due to their inherent ruggedness and immunity to high temperatures.

Furthermore, the relentless expansion of industrial automation and the widespread adoption of Industry 4.0 paradigms across manufacturing sectors globally constitute another powerful driver. Smart factories and automated production lines require numerous sensors to monitor machine operation, control motor speeds, manage conveyor systems, and ensure precise timing in various processes. Variable Reluctance Sensors are highly valued in these environments for their ability to deliver consistent performance amidst industrial noise, vibration, and contaminants, making them ideal for mission-critical applications where uptime and reliability are paramount. Their low maintenance requirements and long operational life further enhance their appeal for industrial customers striving for operational efficiency and reduced downtime.

Despite these strong drivers, the Variable Reluctance Sensor market faces distinct restraints that can impede its growth and widespread adoption in certain applications. A key limitation for traditional passive VR sensors is their significantly reduced accuracy and signal output at very low rotational speeds. As the target speed decreases, the induced voltage in the coil diminishes, making it challenging for control systems to obtain precise and reliable data, which can be critical for applications requiring fine-grained control or static position detection. This often necessitates complex signal conditioning or the use of alternative sensor technologies in low-speed scenarios, adding to system complexity and cost.

Another significant restraint is the susceptibility of VR sensors to electromagnetic interference (EMI) in electrically noisy environments. While robust, the inductive nature of these sensors can make them vulnerable to external magnetic fields and electrical noise generated by motors, power lines, or other high-current devices, potentially leading to signal distortion or erroneous readings. Moreover, VR sensors primarily provide incremental speed or relative position information based on passing targets, rather than absolute position. For applications demanding continuous, absolute positional data, VR sensors typically need to be integrated with other components or sophisticated algorithms, which can increase system complexity and limit their standalone utility in certain advanced robotic or positioning systems.

Amidst these challenges, the Variable Reluctance Sensor market is presented with numerous strategic opportunities for growth and innovation. The ongoing advancements in integrated electronics and digital signal processing (DSP) represent a significant opportunity. By integrating advanced ASICs and signal conditioning circuits directly into active VR sensors, manufacturers can effectively mitigate traditional limitations, such as low-speed performance and EMI susceptibility. These integrated solutions offer enhanced signal-to-noise ratios, improved accuracy across a wider speed range, and direct digital output, making VR sensors more compatible with modern digital control systems and expanding their addressable market into higher-precision applications.

Furthermore, the expansion into new and niche application sectors offers considerable growth potential. Beyond traditional automotive and industrial uses, VR sensors are finding increasing utility in areas like specialized medical devices requiring precise motion sensing, critical monitoring systems within the oil and gas industry operating in harsh environments, and renewable energy systems such as wind turbines, where robust speed sensing is vital for efficiency and safety. The increasing global emphasis on predictive maintenance and condition monitoring also presents an opportunity, as VR sensors can provide crucial real-time data for anomaly detection and proactive equipment servicing, leveraging AI and data analytics to transform raw sensor data into actionable insights, thereby adding significant value beyond mere speed detection.

The Variable Reluctance Sensor market is also profoundly influenced by several broader impact forces that shape its development and competitive landscape. Technological advancements are perhaps the most significant, encompassing breakthroughs in material science, such as new ferromagnetic alloys that enhance magnetic properties and temperature stability, as well as innovations in manufacturing processes that allow for greater miniaturization and improved sensor robustness. These advancements enable the creation of more compact, efficient, and durable sensors capable of performing in even more extreme conditions, thus expanding their utility and market appeal across diverse industries. The continuous drive for higher performance sensors at lower costs forces manufacturers to innovate constantly.

Moreover, the evolving regulatory landscape, particularly within the automotive sector, plays a crucial role. Stricter global emissions standards and heightened safety regulations (e.g., for engine efficiency, braking systems, and vehicle stability control) mandate the integration of increasingly precise and reliable sensing technologies, directly boosting the demand for high-quality VR sensors. Economic conditions, including global industrial output, capital expenditures in manufacturing, and consumer spending on new vehicles, directly correlate with the demand for VR sensors as integral components. Lastly, the competitive dynamics within the sensor industry, characterized by the emergence and refinement of alternative sensing technologies like Hall effect, magnetoresistive, and optical sensors, exerts constant pressure on VR sensor manufacturers to innovate, differentiate their products, and offer superior performance-to-cost ratios to maintain market share and relevance.

- Drivers:

- Surging global automotive production, notably in Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs), where VR sensors are vital for drivetrain and wheel speed monitoring.

- Rapid proliferation of industrial automation, smart factories, and Industry 4.0 initiatives, demanding robust sensors for process control and machinery monitoring.

- Increasing imperative for reliable and durable speed and position sensing solutions in harsh operating environments, characterized by high temperatures, vibrations, and contaminants.

- Inherent cost-effectiveness and proven durability of Variable Reluctance Sensors compared to several alternative sensor technologies, making them economically viable for mass production.

- Restraints:

- Significant limitations in accuracy and signal output at very low rotational speeds for passive Variable Reluctance Sensors, posing challenges for precise measurements in certain applications.

- Susceptibility to electromagnetic interference (EMI) from surrounding electrical components or power lines, which can degrade signal integrity and reliability in noisy environments.

- Inability to provide absolute position sensing directly; these sensors primarily offer incremental speed or relative position, requiring additional components for full positional data.

- Complex signal conditioning often required to process the raw analog output, particularly for passive variants, adding to system design complexity and cost.

- Opportunities:

- Integration with advanced digital signal processing (DSP) and specialized ASICs to significantly enhance low-speed performance, improve signal-to-noise ratio, and bolster EMI immunity.

- Expansion into emerging application sectors such as advanced robotics, specialized medical equipment, renewable energy systems (e.g., wind turbines), and critical infrastructure monitoring.

- Ongoing technological advancements focusing on miniaturization, enhanced material science for improved magnetic properties, and multi-functional sensor integration for compact designs.

- Growing adoption of predictive maintenance systems that leverage real-time sensor data, including from VR sensors, for condition monitoring and anomaly detection, preventing costly downtime.

- Impact Forces:

- Technological Advancements: Continuous innovations in sensor design, material science, and integrated electronics directly influence sensor performance, cost, and applicability.

- Regulatory Landscape: Evolving safety and environmental regulations in the automotive and industrial sectors often mandate the use of specific, high-reliability sensing technologies.

- Economic Conditions: Global economic growth rates, industrial output, and capital expenditures significantly impact demand for new machinery and vehicles incorporating VR sensors.

- Competitive Dynamics: The presence and development of alternative sensing technologies (e.g., Hall effect, optical, magnetoresistive) drive innovation and competitive pricing within the VR sensor market.

Segmentation Analysis

The Variable Reluctance Sensor market is segmented across various parameters, providing a granular view of its structure and dynamics. These segments help in understanding specific application areas, technological preferences, and end-user industries that drive market demand and innovation. The segmentation by type differentiates between passive and active sensors, each catering to distinct operational requirements regarding power supply and signal quality. Passive sensors, while simpler and requiring no external power, are limited in low-speed applications. Active sensors, conversely, incorporate integrated electronics that enhance signal quality and allow for better performance at lower speeds, making them suitable for more complex control systems. This evolution addresses critical performance gaps and broadens the utility of VR sensor technology.

Application-wise, the market is primarily driven by the fundamental need for precise speed and position detection, crucial for accurate mechanical system monitoring and control across diverse industrial and automotive contexts. Whether it is monitoring the rotation of an engine crankshaft or the speed of a conveyor belt, VR sensors provide vital feedback for optimal operation. Furthermore, the segmentation by end-user industry highlights the diverse sectors that rely on the robustness and reliability of VR sensors for critical operations. The automotive industry, for example, constitutes the largest segment, using these sensors extensively in engine management, transmission systems, and wheel speed detection for vehicle safety. Industrial applications are also rapidly expanding, reflecting the global push towards automation and efficient process control.

- By Type:

- Passive Variable Reluctance Sensors

- Active Variable Reluctance Sensors

- By Application:

- Speed Sensing

- Position Sensing

- Timing Sensing

- By End-User Industry:

- Automotive

- Industrial

- Aerospace and Defense

- Medical Devices

- Oil and Gas

- Heavy Machinery

Value Chain Analysis For Variable Reluctance Sensor Market

The value chain for the Variable Reluctance Sensor market encompasses several distinct stages, from the procurement of fundamental raw materials to the final distribution and integration of the sensors into complex systems, each step adding critical value. Upstream activities are concentrated on the meticulous sourcing and processing of specialized raw materials that are indispensable for the sensor's functionality. This includes high-grade ferromagnetic metals for the pole piece and target material, ensuring optimal magnetic properties; precisely drawn copper wire for the inductive coil, which determines signal strength; and robust permanent magnets that establish the base magnetic field. Additionally, advanced plastics, epoxies, and encapsulants are crucial for housing and protecting the sensor from environmental stressors. Suppliers in this segment must adhere to strict quality controls, as the integrity and consistency of these materials directly dictate the VR sensor's performance characteristics, durability, and operational lifespan.

Downstream activities are largely driven by system integrators and original equipment manufacturers (OEMs) who embed VR sensors as essential components within their larger products, such as sophisticated automotive engines, industrial control systems, or complex aerospace machinery. These partners frequently require customized sensor designs, tailored specifications, and rigorous testing protocols to ensure seamless integration and compliance with stringent application-specific performance and safety standards. The distribution channels for VR sensors are multifaceted. Direct sales channels are typically employed for large-volume orders and strategic partnerships with major automotive and industrial OEMs, where personalized technical support, co-development efforts, and direct logistical coordination are paramount. Conversely, indirect channels, comprising an extensive network of distributors, resellers, and online platforms, cater to a broader market, including smaller manufacturers, aftermarket service providers, and a wider array of industrial applications. This hybrid distribution model ensures comprehensive market reach, allowing for both specialized, high-touch relationships and efficient, broad-market penetration based on client size, technical requirements, and geographic spread.

Variable Reluctance Sensor Market Potential Customers

The Variable Reluctance Sensor market caters to a broad and diverse spectrum of potential customers spanning multiple industrial sectors, primarily those with a critical need for reliable and robust speed, position, or timing detection in mechanical systems. These customers are predominantly large-scale manufacturers and intricate system integrators who strategically incorporate VR sensors as fundamental components within their end products. The automotive industry represents the largest and most consistent customer segment, with major vehicle manufacturers and their extensive network of Tier 1 suppliers continually demanding high-performance VR sensors. These sensors are vital for indispensable functions such as precise engine management, efficient transmission control, and the accurate monitoring of wheel speeds for anti-lock braking (ABS) and traction control systems, all of which rely on the proven durability and operational integrity of VR sensors in harsh under-hood conditions.

Beyond the dominant automotive sector, industrial machinery manufacturers constitute another substantial customer base. These companies integrate VR sensors into a wide array of equipment, ranging from precision motor control systems and automated conveyor belts to critical turbine speed monitoring and heavy construction machinery. Organizations focused on industrial automation, advanced robotics, and sophisticated process control systems also form a significant customer segment, actively seeking sensors that can withstand demanding operational environments characterized by high temperatures, significant vibrations, and exposure to various contaminants, while consistently providing accurate feedback. Furthermore, the aerospace and defense sector values VR sensors for their exceptional resilience in extreme conditions, deploying them in critical applications such as aircraft engine monitoring and control systems. Emerging customer segments include manufacturers of specialized medical devices, where precise motion sensing is paramount for device functionality, and the demanding oil and gas industry, which requires exceedingly robust sensing solutions for drilling operations, pipeline monitoring, and equipment diagnostics in challenging remote or hazardous locations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.92 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch, Delphi Technologies, Continental AG, DENSO Corporation, Sensata Technologies, TE Connectivity, Analog Devices, Allegro MicroSystems, Infineon Technologies, STMicroelectronics, NXP Semiconductors, Melexis, Murata Manufacturing, TDK Corporation, Amphenol Corporation, Honeywell International, ZF Friedrichshafen, Omron Corporation, Rockwell Automation, Eaton Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Variable Reluctance Sensor Market Key Technology Landscape

The technological landscape of the Variable Reluctance Sensor market is continuously evolving, driven by an imperative to enhance performance, expand application versatility, and ensure unwavering reliability in increasingly demanding operational environments. At the heart of these advancements lies the meticulous precision engineering of the sensor's fundamental components. This encompasses the development of advanced coil winding techniques, which are crucial for maximizing signal generation efficiency while simultaneously minimizing unwanted electrical noise, thereby significantly improving the sensor's signal-to-noise ratio and overall measurement accuracy. Equally critical is the sophisticated magnetic circuit design, meticulously engineered to ensure a consistent and powerful magnetic field throughout the sensing area, which is paramount for accurate and repeatable detection of ferromagnetic targets across varying speeds. Ongoing research into novel ferromagnetic materials for the core and pole piece, exploring advanced alloys that offer superior magnetic permeability, enhanced temperature stability, and robust corrosion resistance, remains a key area of technological focus, directly impacting the sensor's sensitivity and operational lifespan under extreme conditions.

Beyond the basic inductive element, significant technological strides are being made in the realm of signal conditioning and processing electronics, particularly for active Variable Reluctance Sensors. These integrated circuits are ingeniously designed to amplify the often weak analog signals generated at very low target speeds, effectively filter out common electromagnetic interference (EMI) that can plague electrically noisy industrial environments, and convert the purified analog signal into a precise digital output compatible with modern microcontrollers and advanced control systems. The miniaturization of these sophisticated electronics, frequently achieved through the integration of Application-Specific Integrated Circuits (ASICs) directly embedded within the compact sensor package, enables the development of highly integrated, compact sensor solutions that offer advanced functionalities. These include sophisticated self-diagnostics for predictive maintenance, automatic temperature compensation to maintain accuracy across wide thermal ranges, and even rudimentary predictive analysis capabilities that can monitor sensor health and anticipate potential failures, significantly reducing system downtime.

Furthermore, the development of robust encapsulation materials and advanced assembly techniques is absolutely vital to ensuring the VR sensor's exceptional resilience against severe environmental factors. This includes enduring intense vibrations common in automotive engines and heavy machinery, extreme temperature fluctuations ranging from sub-zero to high heat, and prolonged exposure to aggressive fluids or corrosive contaminants prevalent in industrial and oil and gas applications. These engineering efforts directly guarantee the prolonged operational reliability and extended service life of VR sensors in critical automotive, industrial, and aerospace applications, cementing their position as a preferred sensing technology where durability and consistent performance are non-negotiable.

Regional Highlights

- North America: This region is characterized by a high rate of technological adoption and innovation, particularly within the automotive and aerospace sectors, leading to significant and sustained demand for advanced VR sensors. The formidable presence of major automotive Original Equipment Manufacturers (OEMs) and a robust focus on advanced industrial automation, coupled with substantial defense sp

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager