Vibration Monitoring Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429912 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Vibration Monitoring Market Size

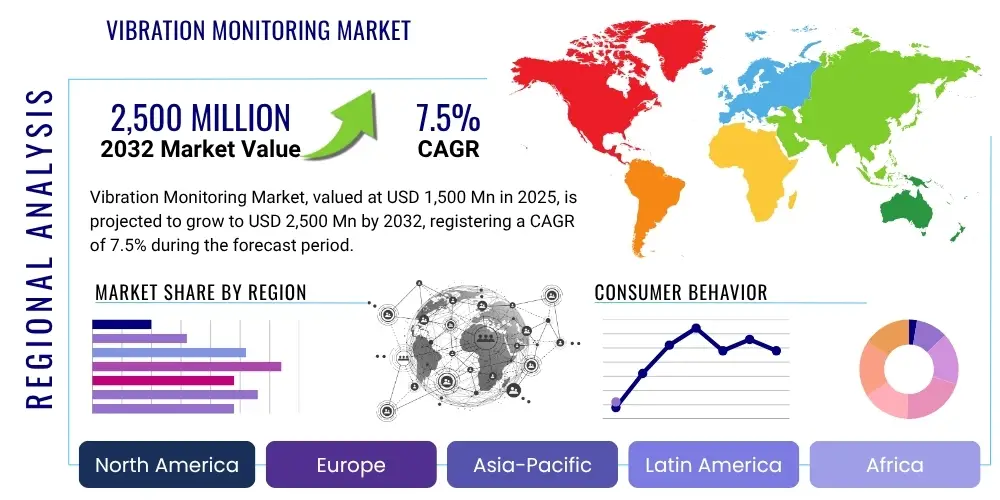

The Vibration Monitoring Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 1,500 Million in 2025 and is projected to reach USD 2,500 Million by the end of the forecast period in 2032.

Vibration Monitoring Market introduction

The Vibration Monitoring Market encompasses the technologies and services designed to measure, analyze, and interpret vibration signals from rotating and reciprocating machinery. These systems are crucial for ensuring the operational health, safety, and efficiency of industrial assets across various sectors. The primary product offering includes sophisticated sensors like accelerometers, proximity probes, and velocity transducers, coupled with data acquisition units, signal conditioners, and analytical software. These components work in synergy to detect early signs of mechanical faults, such as bearing wear, imbalance, misalignment, and looseness, preventing catastrophic failures and optimizing maintenance schedules.

Major applications of vibration monitoring span critical industries including oil and gas, power generation, manufacturing, metals and mining, and aerospace, where machinery downtime can lead to significant financial losses and safety hazards. The benefits derived from implementing vibration monitoring systems are substantial; they enable proactive and predictive maintenance strategies, drastically reducing unplanned downtime, extending asset lifespan, enhancing operational safety, and lowering overall maintenance costs. This proactive approach ensures continuous operation, improves production output, and helps organizations comply with stringent industrial safety and environmental regulations.

The market's growth is primarily driven by the escalating demand for predictive maintenance solutions, the widespread adoption of Industry 4.0 and industrial IoT (IIoT) technologies, and a growing emphasis on operational efficiency and asset integrity. As industries seek to maximize asset utilization and minimize unforeseen failures, vibration monitoring emerges as a cornerstone technology for smart manufacturing and intelligent asset management, transforming traditional reactive maintenance paradigms into data-driven, preventive approaches. The continuous technological advancements in sensor capabilities, data analytics, and wireless communication are further fueling its expansion and integration into more complex industrial environments.

Vibration Monitoring Market Executive Summary

The Vibration Monitoring Market is experiencing robust expansion, driven by a global shift towards predictive maintenance and the increasing digitalization of industrial operations. Key business trends include the proliferation of wireless vibration sensors, the integration of cloud-based analytics for remote monitoring, and the development of comprehensive software platforms that offer advanced diagnostic capabilities. Companies are focusing on providing integrated solutions that combine hardware, software, and services, moving away from standalone product offerings to deliver greater value through actionable insights. Strategic partnerships and acquisitions are also prominent, as market players seek to broaden their technological portfolios and extend their geographical reach, especially in emerging industrial economies.

Regionally, North America and Europe continue to be significant markets, characterized by mature industrial infrastructures, stringent regulatory frameworks, and early adoption of advanced monitoring technologies. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth, fueled by rapid industrialization, expanding manufacturing sectors, and increasing investments in automation and smart factories in countries like China, India, and Southeast Asia. Latin America and the Middle East and Africa (MEA) are also showing promising growth, driven by investments in oil and gas, mining, and power generation sectors, where asset integrity and operational uptime are paramount. These regions present substantial opportunities for companies offering cost-effective and scalable vibration monitoring solutions.

In terms of segmentation, the market is witnessing a notable trend towards portable and wireless vibration monitoring systems due to their flexibility, ease of deployment, and reduced installation costs. The software segment, particularly cloud-based solutions offering real-time data analysis and remote accessibility, is also gaining significant traction. End-user industries such as oil and gas, energy and power, and manufacturing remain dominant, but there is an increasing penetration in sectors like food and beverage, pulp and paper, and marine, driven by the universal need for equipment reliability. The demand for services, including installation, calibration, training, and consulting, is also growing as organizations seek expertise to effectively implement and manage these sophisticated systems, ensuring optimal performance and data utilization.

AI Impact Analysis on Vibration Monitoring Market

User inquiries about the impact of Artificial Intelligence (AI) on the Vibration Monitoring Market frequently revolve around how AI can enhance predictive accuracy, automate diagnostics, and handle vast quantities of data more efficiently than traditional methods. Common questions express a desire to understand if AI can make vibration analysis more accessible to non-experts, reduce false positives, and ultimately deliver more precise prescriptive maintenance recommendations. There is also significant interest in the cost implications of AI integration, potential challenges in data labeling and model training, and the future role of human analysts alongside AI-powered systems. Users seek clarity on how AI can transform raw vibration data into truly actionable intelligence, addressing concerns about data volume management and the reliability of automated insights.

The integration of AI and Machine Learning (ML) algorithms is fundamentally transforming the Vibration Monitoring Market by introducing unprecedented levels of analytical depth and automation. AI-driven solutions are capable of processing and interpreting complex vibration data patterns that might be imperceptible to human analysts or traditional rule-based systems. This capability significantly improves the accuracy of fault detection, allowing for earlier identification of anomalies and more precise diagnoses of equipment health issues. By learning from historical data and operational parameters, AI models can predict potential failures with higher confidence, moving beyond reactive and even basic predictive maintenance towards truly prescriptive maintenance strategies where specific actions are recommended based on predicted degradation.

Furthermore, AI algorithms are instrumental in automating the diagnostic process, reducing the need for extensive human intervention and specialized expertise for routine analyses. This automation enables continuous, real-time monitoring of numerous assets simultaneously, scaling the benefits of vibration analysis across entire industrial ecosystems. AI systems can identify subtle changes in vibration signatures that indicate incipient faults, filter out noise, and even adapt to changing operating conditions, thereby minimizing false alarms and improving the overall reliability of monitoring systems. This not only optimizes maintenance scheduling but also enhances operational safety by preemptively addressing potential equipment malfunctions before they escalate into critical failures, leading to significant cost savings and improved asset availability.

- Enhanced predictive accuracy: AI algorithms can analyze complex vibration patterns to predict equipment failures with higher precision and earlier detection.

- Automated anomaly detection: AI systems can continuously monitor data, automatically identifying deviations from normal operating conditions.

- Prescriptive maintenance recommendations: Beyond predicting failures, AI can suggest specific maintenance actions to prevent or mitigate issues.

- Reduced false positives: AI improves the reliability of alerts by filtering out noise and irrelevant data, leading to more trustworthy diagnostics.

- Optimized resource allocation: Better predictions allow maintenance teams to allocate resources more efficiently, reducing unplanned downtime.

- Improved data interpretation: AI simplifies the interpretation of large datasets, making advanced vibration analysis accessible to a broader user base.

- Self-learning capabilities: AI models can continuously learn from new data, improving their performance and adaptability over time.

DRO & Impact Forces Of Vibration Monitoring Market

The Vibration Monitoring Market is significantly shaped by a confluence of drivers, restraints, opportunities, and pervasive impact forces that dictate its growth trajectory and competitive landscape. A primary driver is the accelerating demand for predictive maintenance solutions across diverse industrial sectors, fueled by the imperative to minimize downtime, extend asset lifespans, and reduce operational costs. The global embrace of Industry 4.0 principles, coupled with the pervasive integration of the Industrial Internet of Things (IIoT), is further propelling market expansion, as interconnected smart sensors and advanced analytics become central to modern industrial operations. Moreover, stringent industrial safety regulations and environmental compliance standards, particularly in hazardous environments like oil and gas, necessitate reliable equipment health monitoring, thereby bolstering the adoption of vibration monitoring systems. Technological advancements, including the miniaturization of sensors, improved data processing capabilities, and the development of user-friendly analytical software, continuously enhance the efficacy and accessibility of these systems, making them indispensable tools for asset management.

Despite these strong growth drivers, the market faces several notable restraints. The initial capital investment required for implementing comprehensive vibration monitoring systems can be substantial, posing a barrier for small and medium-sized enterprises (SMEs) with limited budgets. The complexity involved in integrating these advanced systems into existing legacy infrastructure, along with the need for specialized technical expertise for installation, calibration, and data interpretation, also presents a challenge. A pervasive shortage of skilled professionals capable of effectively managing and leveraging these sophisticated technologies can hinder widespread adoption and optimal utilization. Furthermore, concerns regarding data security and privacy, especially with the increasing reliance on cloud-based solutions and remote monitoring, necessitate robust cybersecurity measures, which can add to the overall implementation cost and complexity, potentially slowing down market penetration in some sectors.

Opportunities within the Vibration Monitoring Market are abundant, driven by ongoing innovation and untapped market potential. The rapid development of wireless and portable vibration monitoring solutions offers enhanced flexibility, ease of deployment, and reduced installation costs, making them attractive for a wider range of applications and industries. Emerging economies, particularly in the Asia Pacific region, present significant growth avenues due to their rapid industrialization and increasing investments in manufacturing and infrastructure development. The continuous integration of Artificial Intelligence (AI) and Machine Learning (ML) for advanced analytics, predictive modeling, and automated diagnostics is creating new possibilities for more precise and proactive maintenance strategies. Additionally, the growing trend towards remote monitoring, driven by the need for continuous oversight and exacerbated by global events requiring reduced on-site personnel, offers substantial growth potential for cloud-enabled and IIoT-integrated solutions, allowing for critical asset surveillance from anywhere in the world.

Segmentation Analysis

The Vibration Monitoring Market is meticulously segmented to provide a granular view of its diverse components, applications, and end-user industries, offering stakeholders comprehensive insights into market dynamics and growth opportunities. This segmentation enables a detailed understanding of how different technologies, systems, and services are adopted across various industrial landscapes, reflecting specific operational needs and regulatory requirements. The primary segmentation criteria typically include components (hardware, software, services), system types (online, portable), end-user industries (oil and gas, power generation, manufacturing, etc.), application areas (machine condition monitoring, quality control), and deployment models (on-premise, cloud-based). Each segment exhibits unique growth patterns and market demands, influenced by technological advancements, economic conditions, and regional industrial development.

- Component

- Hardware

- Sensors

- Accelerometers

- Proximity Probes

- Velocity Transducers

- Displacement Sensors

- Data Collectors

- Signal Conditioners

- Analyzers

- Cables and Connectors

- Sensors

- Software

- On-Premise

- Cloud-Based

- Diagnostic Software

- Data Management Software

- Services

- Installation

- Maintenance and Support

- Training

- Consulting and Data Analysis

- Calibration

- Hardware

- System

- Online Vibration Monitoring Systems

- Portable Vibration Monitoring Systems

- Wireless Vibration Monitoring Systems

- End User Industry

- Oil and Gas

- Energy and Power (including Wind Energy)

- Metals and Mining

- Cement

- Automotive

- Aerospace and Defense

- Food and Beverage

- Pulp and Paper

- Chemicals

- Marine

- Water and Wastewater

- Pharmaceuticals

- Others (e.g., HVAC, Textiles)

- Application

- Machine Condition Monitoring

- Quality Control

- Structural Health Monitoring

- Process Monitoring

- Predictive Maintenance

- Deployment

- On-Premise

- Cloud-Based

Value Chain Analysis For Vibration Monitoring Market

The value chain for the Vibration Monitoring Market commences with upstream activities involving the sourcing of raw materials and the manufacturing of intricate components essential for these systems. This stage includes suppliers of specialized metals, ceramics, and electronic components required for sensors, data acquisition units, and signal processors. Manufacturers of microcontrollers, communication modules, and power management integrated circuits also form a critical part of the upstream segment, providing the foundational technologies. Key players at this stage focus on innovation in sensor technology, material science, and electronic design to produce high-performance, durable, and reliable components that can withstand harsh industrial environments and provide accurate data for vibration analysis. Efficiency and quality control at this stage are paramount, as they directly impact the performance and longevity of the final vibration monitoring solutions.

Moving downstream, the value chain encompasses the assembly of these components into complete vibration monitoring systems, their integration into broader industrial control systems, and ultimately, their deployment at end-user facilities. System integrators play a crucial role here, customizing solutions to meet specific client requirements, ensuring seamless interoperability with existing machinery and IT infrastructure. The distribution channel involves a combination of direct sales from manufacturers to large industrial clients, and indirect sales through a network of distributors, value-added resellers (VARs), and channel partners who often provide localized support and expertise. Post-sales services, including installation, calibration, maintenance, training, and ongoing data analysis support, form a significant part of the downstream value proposition, ensuring optimal system performance and customer satisfaction. The direct sales approach often caters to highly specialized or large-scale projects where direct manufacturer engagement is preferred, while indirect channels broaden market reach and provide regional accessibility.

The distribution landscape is characterized by both direct and indirect models. Direct sales channels typically involve manufacturers engaging directly with large industrial enterprises, offering customized solutions, technical support, and long-term service contracts. This approach allows for closer client relationships, tailored product development, and better control over the customer experience. Indirect channels, on the other hand, leverage a network of third-party distributors, system integrators, and resellers to reach a broader customer base, particularly small and medium-sized enterprises (SMEs). These partners often bring local market knowledge, additional service capabilities, and provide regional sales and technical support, which is vital for market penetration. The balance between direct and indirect distribution strategies is crucial for maximizing market coverage while maintaining brand reputation and service quality. The emergence of e-commerce platforms also provides an additional, albeit less prevalent, channel for standard components and simpler systems.

Vibration Monitoring Market Potential Customers

The primary potential customers for vibration monitoring solutions are organizations across a wide array of industrial sectors that rely heavily on the continuous and efficient operation of rotating and reciprocating machinery. These end-users are driven by the need to minimize unplanned downtime, reduce maintenance costs, enhance operational safety, and extend the lifespan of critical assets. Industries such as oil and gas, power generation (including conventional, nuclear, and renewable energy), and manufacturing (automotive, chemicals, metals and mining, pulp and paper, food and beverage) represent the core demand base, as machinery failures in these sectors can lead to severe financial penalties, environmental damage, and risks to personnel. These industries often operate complex, capital-intensive equipment where even minor mechanical faults can escalate into significant operational disruptions, making predictive maintenance capabilities highly valuable.

Beyond these traditional heavy industries, there is a growing pool of potential customers in sectors that are increasingly recognizing the benefits of proactive asset management. This includes the marine industry, where engine and propulsion system integrity is paramount for safety and schedule adherence, and the water and wastewater treatment sector, which operates numerous pumps and motors critical for public infrastructure. The pharmaceutical and biotechnology industries also represent significant potential, as the reliability of manufacturing equipment directly impacts product quality and regulatory compliance. Furthermore, commercial buildings and facilities management are exploring vibration monitoring for HVAC systems and other essential utilities to optimize energy consumption and prevent costly repairs. Any enterprise with a substantial investment in machinery that requires continuous operation and high reliability can be considered a potential buyer.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1,500 Million |

| Market Forecast in 2032 | USD 2,500 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, Emerson Electric Co., General Electric, Honeywell International Inc., Rockwell Automation, National Instruments, Siemens AG, Bruel & Kjaer, Meggitt PLC, Parker Hannifin Corporation, AZIMA DLI, Pruftechnik Dieter Busch AG, SPM Instrument AB, Banner Engineering, Fluke Corporation, Baker Hughes (GE Oil & Gas), Bosch Rexroth AG, PCB Piezotronics, Inc., Spectris plc, Teledyne FLIR LLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vibration Monitoring Market Key Technology Landscape

The technology landscape of the Vibration Monitoring Market is characterized by continuous innovation aimed at improving data accuracy, system reliability, ease of use, and integration capabilities. At its core, the market relies on sophisticated sensor technologies, primarily accelerometers for measuring absolute vibration, proximity probes for relative shaft vibration, and velocity transducers. These sensors are increasingly becoming smaller, more robust, and capable of operating in extreme industrial environments, often incorporating wireless capabilities for easier deployment and reduced cabling costs. Advancements in Micro-Electro-Mechanical Systems (MEMS) technology are enabling the production of highly sensitive and compact sensors that can be embedded directly into machinery or utilized in portable devices, enhancing accessibility and widespread adoption.

Beyond sensor technology, data acquisition systems (DAS) and signal conditioning units are critical for converting raw analog vibration signals into digital data suitable for analysis. Modern DAS units are becoming more intelligent, offering higher sampling rates, improved resolution, and on-board processing capabilities to filter noise and extract relevant features before transmitting data. The evolution of industrial communication protocols, including Ethernet/IP, PROFINET, and particularly wireless standards like Wi-Fi, Bluetooth Low Energy (BLE), and cellular IoT (e.g., NB-IoT, LTE-M), is transforming how vibration data is collected and transmitted from remote or inaccessible locations. This shift towards wireless data transmission significantly reduces installation complexity and cost, making continuous monitoring more feasible across extensive industrial facilities.

The analytical backbone of vibration monitoring is provided by advanced software platforms and computational intelligence. Specialized software for vibration analysis offers powerful tools for spectral analysis, time waveform analysis, and advanced diagnostics, enabling maintenance professionals to pinpoint specific machinery faults. The integration of IoT platforms and cloud computing is enabling remote monitoring and centralized data management, allowing for asset health assessment from anywhere in the world and facilitating data sharing across enterprise systems. Furthermore, the burgeoning application of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is revolutionizing predictive capabilities, automating anomaly detection, and providing prescriptive maintenance recommendations based on vast historical and real-time data, thus elevating vibration monitoring from merely diagnostic to truly intelligent and proactive asset management.

Regional Highlights

- North America: A mature market characterized by early adoption of advanced industrial technologies, stringent regulatory frameworks for industrial safety, and significant investments in research and development. The region, particularly the United States and Canada, benefits from a robust manufacturing base, extensive oil and gas operations, and a strong focus on digital transformation and Industry 4.0 initiatives.

- Europe: Another key region with a strong emphasis on industrial automation, environmental protection, and occupational safety standards. Countries such as Germany, the UK, and France are leaders in industrial machinery manufacturing and have a high adoption rate of predictive maintenance technologies. Government initiatives supporting smart factories and sustainable industrial practices further drive market growth.

- Asia Pacific (APAC): Expected to be the fastest-growing region, driven by rapid industrialization, expanding manufacturing sectors, and increasing infrastructure development in economies like China, India, Japan, and South Korea. Growing investments in smart cities, renewable energy, and automated production facilities are creating substantial demand for vibration monitoring solutions, often favoring cost-effective and scalable wireless technologies.

- Latin America: An emerging market showing steady growth, primarily fueled by investments in the oil and gas, mining, and power generation industries. Countries like Brazil and Mexico are witnessing increased adoption as industries strive to improve operational efficiency and reduce maintenance costs. Economic stability and foreign investments are key factors influencing market expansion.

- Middle East and Africa (MEA): This region is experiencing considerable growth, largely due to significant investments in its vast oil and gas sector, as well as developing infrastructure projects and diversification efforts away from oil dependence. The need for enhanced asset integrity, operational safety, and reduced downtime in critical energy and industrial facilities is driving the demand for advanced vibration monitoring systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vibration Monitoring Market.- SKF

- Emerson Electric Co.

- General Electric

- Honeywell International Inc.

- Rockwell Automation

- National Instruments

- Siemens AG

- Bruel & Kjaer

- Meggitt PLC

- Parker Hannifin Corporation

- AZIMA DLI

- Pruftechnik Dieter Busch AG

- SPM Instrument AB

- Banner Engineering

- Fluke Corporation

- Baker Hughes (GE Oil & Gas)

- Bosch Rexroth AG

- PCB Piezotronics, Inc.

- Spectris plc

- Teledyne FLIR LLC

Frequently Asked Questions

What is vibration monitoring and why is it important?

Vibration monitoring involves measuring and analyzing mechanical vibrations in machinery to assess its operational health. It is crucial for predictive maintenance, helping to detect early signs of equipment faults, prevent unexpected downtime, reduce maintenance costs, and enhance operational safety by allowing for proactive repairs.

How does AI impact the accuracy of vibration monitoring?

AI significantly enhances vibration monitoring accuracy by processing complex data patterns, identifying subtle anomalies, and learning from historical data to predict failures with higher precision than traditional methods. This leads to fewer false positives and more reliable diagnostic insights.

What are the main types of vibration monitoring systems?

The main types include online vibration monitoring systems, which provide continuous, real-time data for critical assets; portable vibration monitoring systems, used for routine inspections of multiple assets; and wireless vibration monitoring systems, which offer flexible deployment and remote data collection.

Which industries are the primary end-users of vibration monitoring solutions?

Key end-user industries include oil and gas, power generation, manufacturing (automotive, chemicals, metals and mining), pulp and paper, and aerospace and defense. These sectors rely on machinery uptime and safety, making vibration monitoring indispensable.

What are the key drivers for the growth of the Vibration Monitoring Market?

The market is driven by increasing demand for predictive maintenance, the widespread adoption of Industry 4.0 and IIoT, stringent industrial safety regulations, and continuous technological advancements in sensor and analytical software.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Engine Vibration Monitoring Market Statistics 2025 Analysis By Application (Vehicle, Aircraft, Others), By Type (Integrator filters (velocity mode), Dual-integrator filters (displacement mode)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Vibration Monitoring Equipment Market Statistics 2025 Analysis By Application (Machinery Manufacturing, Chemical Industry, Vehicle, Electric Power), By Type (Offline Vibration Monitoring Equipment, Online Vibration Monitoring Equipment), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager