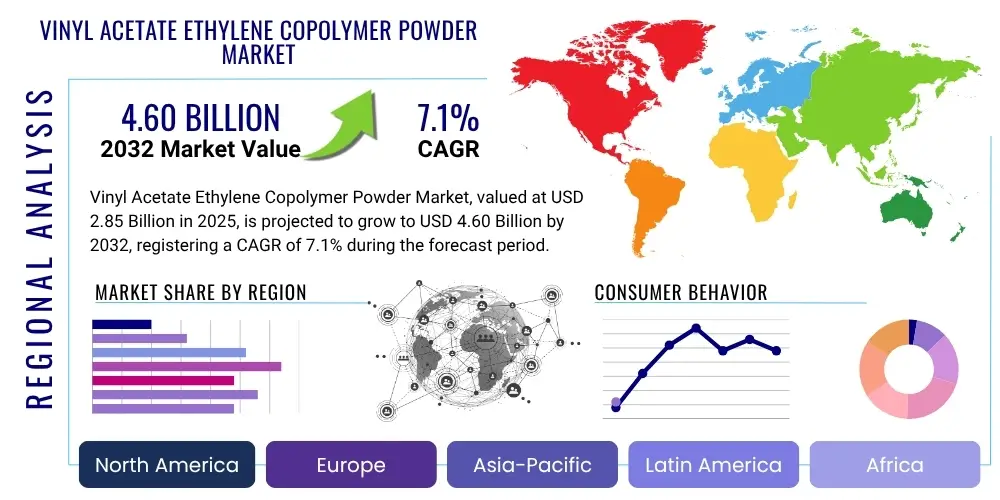

Vinyl Acetate Ethylene Copolymer Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428578 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Vinyl Acetate Ethylene Copolymer Powder Market Size

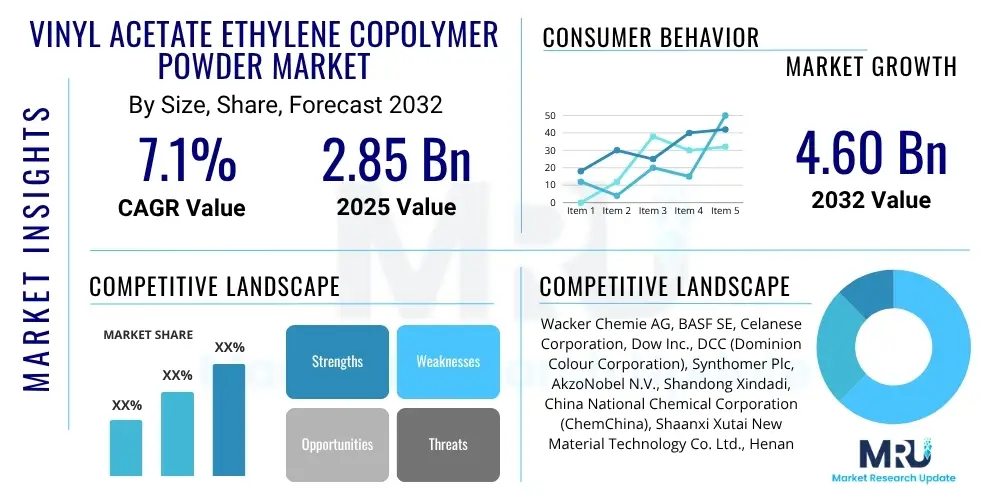

The Vinyl Acetate Ethylene Copolymer Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.1% between 2025 and 2032. The market is estimated at $2.85 Billion in 2025 and is projected to reach $4.60 Billion by the end of the forecast period in 2032.

Vinyl Acetate Ethylene Copolymer Powder Market introduction

The Vinyl Acetate Ethylene Copolymer (VAE) Powder market encompasses the production and distribution of re-dispersible polymer powders, primarily utilized as binders in various dry-mix formulations. These powders are derived from vinyl acetate and ethylene monomers through emulsion polymerization, followed by spray drying, which converts the liquid emulsion into a free-flowing powder. Upon re-dispersion in water, VAE powders form a stable emulsion that imparts crucial performance characteristics to building materials and other industrial products. The core product offering is distinguished by its ability to significantly enhance adhesion, flexibility, cohesion, and water resistance in final applications, making it an indispensable additive in numerous sectors.

Major applications for VAE copolymer powder span a wide array of industries, with construction leading the demand. Within construction, VAE powders are extensively used in dry mix mortars, tile adhesives, self-leveling compounds, wall putties, renders, and exterior insulation finishing systems (EIFS). Beyond building materials, they find applications in paints and coatings to improve film formation and durability, in textile and paper industries as binders for non-wovens and coatings, and in various other adhesive formulations. The versatility of VAE powder allows for tailored solutions across diverse end-use needs, addressing specific requirements for strength, workability, and environmental resilience.

The primary benefits of incorporating VAE powder include improved workability and open time for fresh mortars, enhanced flexural strength and impact resistance in hardened materials, superior adhesion to various substrates, and increased water repellency. These performance enhancements contribute to the longevity and durability of finished products, offering significant value to manufacturers and end-users. Driving factors for market growth include the escalating demand from the global construction industry, particularly in emerging economies experiencing rapid urbanization and infrastructure development. Additionally, a growing emphasis on sustainable and high-performance building materials, coupled with renovation and repair activities, further propels the adoption of VAE copolymer powders due to their efficacy and environmental compatibility in many modern formulations.

Vinyl Acetate Ethylene Copolymer Powder Market Executive Summary

The Vinyl Acetate Ethylene Copolymer Powder market is experiencing robust growth driven by evolving business trends focused on sustainability, high-performance materials, and efficient supply chain management. Manufacturers are increasingly investing in research and development to produce specialized VAE grades that offer enhanced properties such as improved hydrophobicity, crack resistance, and reduced VOC emissions, aligning with stricter environmental regulations and consumer preferences for eco-friendly solutions. Business strategies are shifting towards capacity expansion in key growth regions and strategic collaborations to optimize production processes and expand market reach. Furthermore, the market is witnessing a trend towards consolidation, with larger players acquiring smaller or specialized manufacturers to broaden their product portfolios and strengthen their competitive position, thereby streamlining the overall industry landscape and fostering innovation through economies of scale.

Regional trends are significantly influencing market dynamics, with Asia Pacific emerging as the dominant and fastest-growing region, primarily due to rapid urbanization, extensive infrastructure development, and a booming construction sector in countries like China, India, and Southeast Asian nations. This region’s demand is further fueled by increased disposable incomes and government investments in residential and commercial projects. Europe and North America, while more mature markets, exhibit steady growth driven by renovation activities, demand for advanced green building materials, and the stringent regulatory environment promoting sustainable construction practices. Latin America and the Middle East and Africa are also showing promising growth, characterized by increasing industrialization and construction initiatives, although they currently represent smaller shares of the global market. These regions present significant opportunities for market expansion as their economies continue to develop and industrialize.

Segmentation trends highlight the critical role of the construction sector as the largest application segment for VAE copolymer powders. Within construction, dry mix mortars, tile adhesives, and self-leveling compounds are key areas driving substantial demand, owing to the superior performance benefits VAE powders impart. There is an increasing focus on developing specialized VAE grades tailored for specific end-use applications, such as those requiring extreme weather resistance or superior flexibility for modern architectural designs. Furthermore, the market for high-performance VAE powders, which offer enhanced mechanical properties and durability, is expanding rapidly as industries seek more advanced material solutions. This trend towards customization and specialization across different application segments underscores the evolving needs of various industries for advanced binding and performance-enhancing additives, ensuring sustained market relevance and innovation in VAE powder offerings.

AI Impact Analysis on Vinyl Acetate Ethylene Copolymer Powder Market

User inquiries regarding AI's influence on the Vinyl Acetate Ethylene Copolymer Powder market frequently revolve around its potential to optimize manufacturing processes, enhance product development, and improve supply chain efficiency. Common concerns include how AI can lead to more sustainable production methods, predict market demand fluctuations, and identify novel formulations with superior performance characteristics. Users are keenly interested in whether AI can reduce production costs, minimize waste, and accelerate the time-to-market for innovative VAE products. There is also significant curiosity about AI's role in quality control, ensuring consistency and adherence to stringent industry standards, thereby setting new benchmarks for product excellence and operational efficacy within the specialized chemical sector. The overarching expectation is that AI will introduce unprecedented levels of precision, foresight, and automation, transforming traditional manufacturing and R&D paradigms.

- AI can optimize VAE production parameters, leading to increased yield, reduced energy consumption, and lower operational costs through predictive maintenance and process control.

- Predictive analytics powered by AI can forecast demand for various VAE grades, enabling manufacturers to adjust production schedules and inventory levels more effectively, minimizing waste and improving resource allocation.

- AI-driven material discovery platforms can accelerate the R&D cycle for new VAE formulations, identifying optimal monomer ratios and additive combinations for desired properties like improved adhesion or water resistance.

- Enhanced quality control systems utilizing AI can detect anomalies in VAE powder characteristics during manufacturing, ensuring product consistency and adherence to specifications, reducing batch variations.

- Supply chain optimization through AI can improve logistics, raw material procurement, and distribution networks, mitigating risks associated with supply disruptions and price volatility.

- AI can facilitate the development of more sustainable VAE products by analyzing lifecycle assessment data to identify greener manufacturing routes and bio-based raw material alternatives.

- Real-time data analysis via AI tools can provide actionable insights into market trends, competitive landscapes, and customer preferences, supporting strategic decision-making and product positioning.

DRO & Impact Forces Of Vinyl Acetate Ethylene Copolymer Powder Market

The Vinyl Acetate Ethylene Copolymer Powder market is significantly influenced by a confluence of driving factors, primarily centered around the robust growth of the global construction industry. Rapid urbanization, particularly in emerging economies of Asia Pacific and Latin America, fuels demand for residential, commercial, and infrastructure projects, where VAE powders are essential additives for high-performance building materials like tile adhesives, mortars, and self-leveling compounds. Additionally, the increasing emphasis on energy-efficient and sustainable building practices drives the adoption of VAE in exterior insulation finishing systems (EIFS) and other green construction solutions, leveraging its superior binding and waterproofing properties. The widespread renovation and repair activities in developed regions also contribute substantially, as VAE-modified products offer extended durability and improved aesthetics for aging structures, thus consistently boosting market demand across various construction segments.

Despite strong growth drivers, the market faces notable restraints, most prominently the volatility in raw material prices, particularly for vinyl acetate monomer (VAM) and ethylene. Fluctuations in crude oil prices directly impact the cost of these petrochemical-derived precursors, leading to unpredictable production costs and pressure on profit margins for VAE manufacturers. Stringent environmental regulations, particularly in North America and Europe, regarding VOC emissions and sustainable manufacturing processes, necessitate significant investments in compliant technologies, which can raise operational expenses and pose challenges for smaller players. Furthermore, competition from alternative binders such as redispersible styrene-butadiene rubber (SBR) powders and acrylic polymers, while not directly substitutable in all applications, can present a threat, especially in price-sensitive market segments where cost-effectiveness often dictates material selection.

Opportunities for market expansion are abundant, particularly in the development of specialized VAE grades tailored for niche applications, such as high-performance coatings, advanced adhesives for packaging, and even potential uses in 3D printing for construction materials. The ongoing trend towards sustainable product innovation offers a significant avenue for growth, with manufacturers focusing on developing bio-based VAE polymers and formulations with lower environmental footprints, appealing to environmentally conscious consumers and regulatory bodies. Moreover, untapped potential exists in emerging markets where construction activities are nascent but rapidly expanding, offering new geographical frontiers for market penetration. The continuous evolution of construction techniques and the increasing demand for resilient and durable materials also present opportunities for VAE powders to gain market share by proving their superior performance characteristics against traditional binders.

Segmentation Analysis

The Vinyl Acetate Ethylene Copolymer Powder market is comprehensively segmented to provide a detailed understanding of its diverse applications, product types, and end-user industries. This segmentation aids in identifying key growth areas, understanding competitive landscapes, and formulating effective market strategies. The primary segmentation categories encompass the various applications where VAE powders are utilized, the specific types of VAE products available based on their characteristics, and the broad end-user sectors that consume these materials, reflecting the market's multifaceted nature and wide industrial reach across the globe. Each segment is further broken down to highlight granular market dynamics and opportunities, offering a granular view of demand and supply patterns.

- By Application

- Dry Mix Mortars (Tile Adhesives, Wall Putties, Renders, Skim Coats, Grouts)

- Self-Leveling Compounds

- Exterior Insulation Finishing Systems (EIFS)

- Paints and Coatings (Interior and Exterior Paints, Architectural Coatings)

- Adhesives (Wood Adhesives, Paper Adhesives, Packaging Adhesives, Carpet Adhesives)

- Textiles (Non-woven Binders, Textile Coatings)

- Paper (Paper Coatings, Paper Sizing)

- Other Applications (Gypsum-based Products, Concrete Repair Mortars, Waterproofing Membranes)

- By Type

- General Purpose VAE Powder (Standard Adhesion and Flexibility)

- High Performance VAE Powder (Enhanced Water Resistance, Alkali Resistance, Crack Bridging)

- Specialty VAE Powder (Hydrophobic VAE, UV-Resistant VAE, Low VOC VAE)

- VAE for specific processing characteristics (e.g., improved open time, sag resistance)

- By End-User Industry

- Residential Construction

- Commercial Construction

- Industrial Construction

- Consumer Goods (DIY Home Improvement)

- Automotive (Adhesives for interiors)

- Furniture (Wood Adhesives)

Value Chain Analysis For Vinyl Acetate Ethylene Copolymer Powder Market

The value chain for the Vinyl Acetate Ethylene Copolymer Powder market begins with the upstream segment, which involves the procurement and supply of essential raw materials. Key raw materials include Vinyl Acetate Monomer (VAM) and Ethylene, along with other additives such as protective colloids, initiators, and stabilizers. Major chemical companies specialize in the production of VAM and ethylene, which are then supplied to VAE emulsion manufacturers. The quality and stable supply of these primary raw materials significantly impact the cost and production efficiency of VAE emulsions. Relationships with reliable and cost-effective raw material suppliers are crucial for manufacturers to maintain competitive pricing and ensure consistent production flows, making this initial stage a critical determinant of overall market profitability and stability.

The midstream segment of the value chain is dominated by manufacturers who perform the emulsion polymerization of VAM and ethylene to create VAE emulsions. These emulsions are then subjected to a spray-drying process to convert them into re-dispersible VAE polymer powders. This manufacturing stage requires significant capital investment in specialized equipment, technical expertise, and adherence to stringent quality control standards to produce VAE powders with consistent performance characteristics, such as particle size distribution, re-dispersibility, and glass transition temperature. Innovation at this stage often involves developing specialized VAE grades with enhanced properties tailored for specific applications, differentiating manufacturers in a competitive market. Furthermore, sustainability efforts are increasingly integrated here, focusing on energy efficiency and waste reduction during the polymerization and drying processes to align with global environmental mandates.

The downstream analysis involves the distribution channels and the ultimate reach to end-users. VAE copolymer powders are typically distributed through a combination of direct sales and indirect channels. Large-scale manufacturers often engage in direct sales to major industrial clients, such as multinational dry mix mortar producers or large construction chemical formulators, ensuring technical support and bulk supply. Indirect channels involve a network of distributors, agents, and local traders who serve smaller manufacturers, regional construction companies, and a wider array of industrial clients. These distributors play a crucial role in providing logistical support, localized inventory, and sometimes technical assistance, bridging the gap between VAE producers and a diverse customer base. Effective distribution networks are vital for ensuring timely delivery and broad market penetration, especially in geographically dispersed construction and industrial markets, ultimately linking the product to its final application in various end-use segments.

Vinyl Acetate Ethylene Copolymer Powder Market Potential Customers

Potential customers for Vinyl Acetate Ethylene Copolymer Powder are diverse, primarily spanning the vast global construction sector, where the product is a critical additive for enhancing the performance of various building materials. Dry mix mortar manufacturers constitute a major buyer segment, integrating VAE powders into formulations for tile adhesives, renders, plasters, and self-leveling compounds to improve their workability, adhesion strength, flexibility, and water resistance. Similarly, producers of exterior insulation finishing systems (EIFS) rely on VAE to ensure the durability and thermal efficiency of their facade materials. These end-users are constantly seeking high-performance additives that can meet increasingly stringent building codes and consumer expectations for longevity and structural integrity, making VAE powder an indispensable component in their product development and manufacturing processes.

Beyond construction, other significant end-user industries include manufacturers in the paints and coatings sector, who incorporate VAE powders to improve film formation, adhesion, and overall durability of their products, especially for water-based architectural coatings. The textile industry also represents a key customer base, utilizing VAE as a binder in non-woven fabrics and textile coatings to impart desired stiffness, softness, or strength. Furthermore, the paper industry uses VAE for paper coatings and sizing applications to enhance printability and surface properties. Other niche markets include producers of specialized adhesives for packaging, wood, and carpets, as well as manufacturers of gypsum-based products and concrete repair mortars. These diverse applications underscore the versatility of VAE powder, appealing to a broad spectrum of industrial buyers seeking to enhance the physical and chemical properties of their final products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.85 Billion |

| Market Forecast in 2032 | $4.60 Billion |

| Growth Rate | 7.1% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wacker Chemie AG, BASF SE, Celanese Corporation, Dow Inc., DCC (Dominion Colour Corporation), Synthomer Plc, AkzoNobel N.V., Shandong Xindadi, China National Chemical Corporation (ChemChina), Shaanxi Xutai New Material Technology Co. Ltd., Henan Kaipu Chemical Co. Ltd., VINAVIL S.p.A., Hexion Inc., Reverte, Dairen Chemical Corporation, Organik Kimya, Kuraray Co. Ltd., VAE Resins, Beijing Eastern Petrochemical Co. Ltd., Nippon Gohsei (Mitsubishi Chemical). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vinyl Acetate Ethylene Copolymer Powder Market Key Technology Landscape

The Vinyl Acetate Ethylene Copolymer Powder market is underpinned by sophisticated polymerization and drying technologies that are continuously evolving to meet performance demands and environmental standards. Emulsion polymerization is the core process, where vinyl acetate and ethylene monomers are polymerized in an aqueous medium in the presence of emulsifiers, protective colloids, and initiators to form a stable polymer dispersion. Advancements in this technology focus on optimizing reaction conditions, utilizing novel initiator systems, and employing advanced colloid chemistry to control particle size distribution, morphology, and monomer conversion rates. These innovations are crucial for achieving desired properties such as improved film formation, enhanced water resistance, and superior binding capabilities in the resulting polymer emulsions, which directly impact the final powder characteristics.

Following emulsion polymerization, the next critical technological step is spray drying, which converts the liquid VAE emulsion into a re-dispersible polymer powder. This process involves atomizing the emulsion into a hot drying medium, rapidly evaporating water, and forming fine powder particles. Key technological advancements in spray drying focus on designing more energy-efficient dryers, optimizing nozzle configurations for uniform atomization, and precisely controlling drying temperatures and residence times to prevent polymer degradation and ensure optimal re-dispersibility. The encapsulation technology used during spray drying, often involving inorganic or organic anti-caking agents, is vital for maintaining the free-flowing nature of the powder and preventing agglomeration during storage and handling, ensuring consistent quality and extended shelf life for the VAE powder products.

Further technological innovations in the VAE powder market include the development of specialty grades through chemical modification and additive technologies. This involves incorporating specific functional additives during or after polymerization to impart properties like hydrophobicity, increased alkali resistance, or enhanced flexibility for demanding applications. Research and development efforts are also concentrated on creating low VOC (Volatile Organic Compound) and formaldehyde-free VAE formulations to comply with stricter environmental regulations and address health concerns. Furthermore, advancements in process automation, real-time quality control systems, and data analytics are increasingly being integrated into VAE production to enhance efficiency, reduce manufacturing variability, and accelerate the development of next-generation VAE copolymer powders with improved sustainability profiles and superior performance characteristics, pushing the boundaries of material science in various industries.

Regional Highlights

- Asia Pacific: Dominates the global market, driven by rapid urbanization, extensive infrastructure development, and booming construction activities in countries such as China, India, and Southeast Asian nations. High demand for building materials in residential, commercial, and public infrastructure projects fuels VAE consumption.

- Europe: A mature market with steady growth, primarily influenced by renovation projects, stringent energy efficiency regulations, and a strong emphasis on sustainable and green building materials. Innovation in specialized VAE formulations for high-performance applications is a key characteristic.

- North America: Exhibits consistent demand for VAE powders, propelled by investments in infrastructure upgrades, residential renovation, and increasing adoption of advanced building techniques. Focus on durability, safety, and energy efficiency drives the market for high-quality additives.

- Latin America: Demonstrates significant growth potential due to increasing construction activities, urbanization trends, and rising disposable incomes, particularly in Brazil, Mexico, and Argentina. The region is witnessing a gradual shift towards modern building materials.

- Middle East and Africa (MEA): Emerging as a promising market with substantial investments in construction, driven by economic diversification, population growth, and mega-projects in countries like Saudi Arabia, UAE, and Qatar. Demand for VAE powders is increasing in line with infrastructural expansion.

- China: The largest single country market, fueled by massive construction volume and government initiatives to develop smart cities and affordable housing, leading to unparalleled demand for VAE-modified building products.

- India: Experiencing robust market expansion due to rapid urbanization, significant government spending on infrastructure, and a growing middle class investing in housing and commercial spaces, driving the adoption of high-performance construction chemicals.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vinyl Acetate Ethylene Copolymer Powder Market.- Wacker Chemie AG

- BASF SE

- Celanese Corporation

- Dow Inc.

- DCC (Dominion Colour Corporation)

- Synthomer Plc

- AkzoNobel N.V.

- Shandong Xindadi

- China National Chemical Corporation (ChemChina)

- Shaanxi Xutai New Material Technology Co. Ltd.

- Henan Kaipu Chemical Co. Ltd.

- VINAVIL S.p.A.

- Hexion Inc.

- Reverte

- Dairen Chemical Corporation

- Organik Kimya

- Kuraray Co. Ltd.

- VAE Resins

- Beijing Eastern Petrochemical Co. Ltd.

- Nippon Gohsei (Mitsubishi Chemical)

Frequently Asked Questions

What is Vinyl Acetate Ethylene Copolymer Powder?

Vinyl Acetate Ethylene Copolymer (VAE) Powder is a re-dispersible polymer powder used as a binder in various dry-mix formulations, particularly in the construction industry. It significantly improves the adhesion, flexibility, and water resistance of materials upon re-dispersion in water.

What are the primary applications of VAE powder?

The main applications include dry mix mortars (tile adhesives, renders, self-leveling compounds), exterior insulation finishing systems (EIFS), paints and coatings, textiles (non-woven binders), and paper industries as high-performance binders and modifiers.

What key factors drive the growth of the VAE market?

Market growth is primarily driven by the expanding global construction industry, rapid urbanization in emerging economies, increasing demand for high-performance and sustainable building materials, and rising renovation and repair activities worldwide.

What are the environmental considerations for VAE powder?

Modern VAE powders are often developed with sustainability in mind, focusing on low VOC (Volatile Organic Compound) content and formaldehyde-free formulations. Efforts are also made to optimize production processes for energy efficiency and waste reduction.

How does VAE powder enhance the performance of construction materials?

VAE powder enhances construction materials by improving workability, increasing flexural and impact strength, providing superior adhesion to various substrates, and boosting water repellency, leading to more durable and long-lasting structures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager