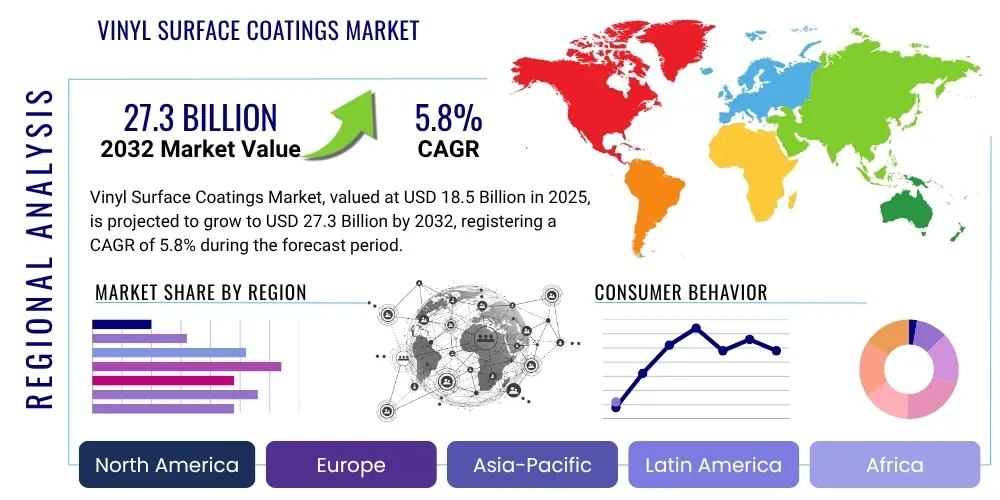

Vinyl Surface Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429310 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Vinyl Surface Coatings Market Size

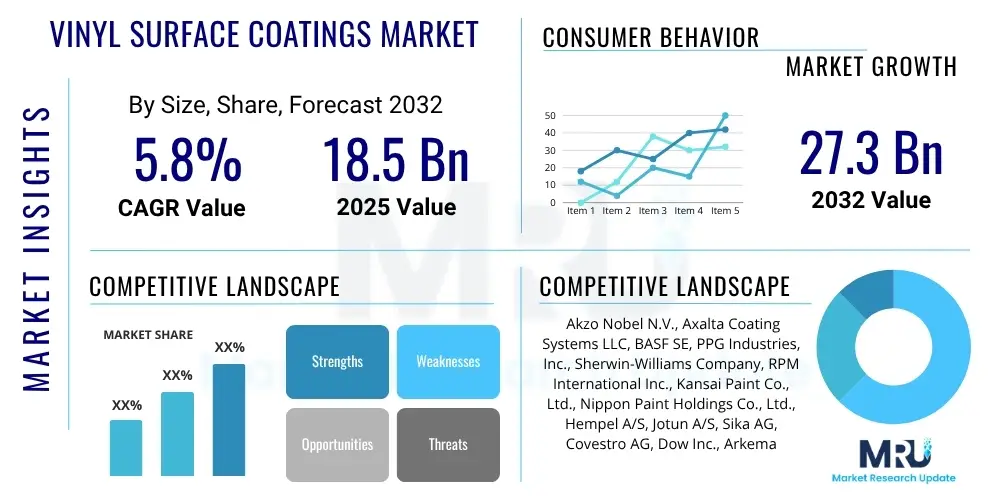

The Vinyl Surface Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 18.5 billion in 2025 and is projected to reach USD 27.3 billion by the end of the forecast period in 2032.

Vinyl Surface Coatings Market introduction

The Vinyl Surface Coatings Market encompasses a diverse range of products designed to protect, enhance, and decorate various substrates, leveraging the exceptional properties of vinyl polymers. These coatings, primarily based on polyvinyl chloride (PVC), polyvinylidene chloride (PVDC), and vinyl acetate copolymers, offer superior durability, chemical resistance, aesthetic versatility, and cost-effectiveness, making them indispensable across numerous industrial and consumer applications. Their ability to form robust films that resist abrasion, moisture, and common corrosive agents has solidified their position as a preferred choice in demanding environments. The market's growth is inherently tied to the expansion of key end-use industries, which increasingly seek high-performance surface protection solutions that also meet evolving environmental and regulatory standards.

Vinyl surface coatings find extensive application in critical sectors such as building and construction, where they are used for flooring, wall coverings, roofing, and window profiles, providing long-lasting protection and aesthetic appeal to structures. In the automotive industry, these coatings contribute to interior and exterior finishes, offering enhanced durability and UV resistance, crucial for vehicle longevity and appearance. Furthermore, they are widely adopted in packaging for food, pharmaceuticals, and consumer goods, where they serve as protective barriers and decorative elements, extending shelf life and improving product presentation. The versatility of vinyl coatings allows for various formulations, including solvent-borne, water-borne, and powder coatings, each tailored to specific application requirements and environmental considerations, thus broadening their market penetration.

The primary benefits driving the adoption of vinyl surface coatings include their exceptional resilience against environmental degradation, ease of application, and broad spectrum of finishes, from high-gloss to matte. These advantages, coupled with a favorable cost-to-performance ratio, underscore their market appeal. Key driving factors propelling market expansion include rapid urbanization, leading to increased construction activities globally, particularly in emerging economies. The rising demand for durable and low-maintenance materials in residential, commercial, and industrial infrastructure further stimulates market growth. Additionally, advancements in coating technology, such as the development of low-VOC and bio-based vinyl formulations, are addressing environmental concerns and expanding market opportunities, ensuring sustained growth in an increasingly sustainability-focused landscape.

Vinyl Surface Coatings Market Executive Summary

The Vinyl Surface Coatings Market is experiencing robust growth, primarily driven by accelerated urbanization and infrastructure development worldwide, coupled with a consistent demand for high-performance and aesthetically versatile surface protection solutions across multiple industries. Emerging business trends highlight a significant shift towards sustainable formulations, including water-borne and low-volatile organic compound (VOC) vinyl coatings, in response to stringent environmental regulations and growing consumer preference for eco-friendly products. Companies are strategically investing in research and development to innovate bio-based vinyl resins and advanced curing technologies that enhance durability and reduce environmental impact. Furthermore, there is a discernible trend towards market consolidation through mergers and acquisitions, as key players aim to expand their product portfolios, technological capabilities, and geographical reach, thus strengthening their competitive positions in a dynamic market landscape.

Regionally, the Asia Pacific (APAC) market continues to dominate the vinyl surface coatings landscape, fueled by rapid industrialization, burgeoning construction sectors, and increasing automotive production, particularly in economies such as China, India, and Southeast Asian nations. This region benefits from a large consumer base and significant government investments in infrastructure projects, creating a high demand for durable and cost-effective coating solutions. North America and Europe, while representing mature markets, are characterized by a strong emphasis on regulatory compliance and technological advancements, driving the adoption of specialized and sustainable vinyl coating formulations. Growth in these regions is also propelled by renovation activities and the demand for advanced materials in sectors like aerospace and automotive refinishing, where high-performance coatings are critical for safety and longevity. Emerging markets in Latin America, the Middle East, and Africa are showing promising growth trajectories, supported by industrial expansion and increasing disposable incomes, which are driving residential and commercial construction.

Segmentation trends reveal significant traction across various application and end-use industry segments. The building and construction sector remains the largest consumer of vinyl surface coatings, leveraging their use in flooring, wall coverings, and external cladding due to their durability, water resistance, and aesthetic appeal. Within this sector, the demand for vinyl flooring, known for its longevity and ease of maintenance, is particularly strong. The automotive industry is another pivotal segment, where vinyl coatings are utilized for interior components, protective films, and underbody protection, offering resistance against corrosion and abrasion. The packaging industry is also witnessing increased adoption of vinyl coatings for protective and decorative purposes on metal cans, flexible packaging, and rigid containers, ensuring product integrity and enhancing brand presentation. Innovations in polymer science are further allowing for the development of highly specialized vinyl coatings tailored to specific segment needs, fostering growth across niche applications such as marine and industrial machinery.

AI Impact Analysis on Vinyl Surface Coatings Market

User questions related to the impact of AI on the Vinyl Surface Coatings Market frequently center on how artificial intelligence can optimize formulation processes, improve production efficiency, enhance quality control, and predict market trends. There is considerable interest in AI's role in accelerating the discovery of novel materials, particularly sustainable and bio-based vinyl resins, and its potential to personalize product development based on specific customer requirements. Concerns often revolve around the initial investment costs for AI implementation, the need for skilled personnel to manage AI systems, and the implications for job displacement within the manufacturing sector. Users also frequently inquire about AI's ability to minimize waste, reduce energy consumption in production, and improve supply chain visibility and resilience. The overarching expectation is that AI will drive significant advancements in product performance, manufacturing sustainability, and operational agility, ultimately leading to more competitive and environmentally responsible coating solutions.

- AI-driven predictive analytics optimize raw material procurement by forecasting demand and supply fluctuations, minimizing inventory costs and reducing waste.

- AI algorithms accelerate the development of new vinyl coating formulations by simulating molecular interactions and predicting material properties, significantly cutting R&D cycles.

- Machine learning enhances quality control processes by analyzing production data in real-time, detecting anomalies, and predicting potential defects before they occur.

- Robotics and AI-powered automation improve manufacturing efficiency and consistency, leading to higher throughput and reduced human error in coating application.

- AI facilitates hyper-personalization of vinyl coating products, allowing manufacturers to tailor specific properties like color, texture, and durability to individual customer needs.

- Predictive maintenance for production equipment, powered by AI, reduces downtime and extends the lifespan of machinery, ensuring continuous operational flow.

- AI models analyze vast datasets to identify emerging market trends, consumer preferences, and competitive landscapes, informing strategic business decisions.

- Supply chain optimization through AI improves logistics, warehousing, and distribution networks, leading to faster delivery and lower transportation costs.

- AI supports sustainability initiatives by optimizing energy consumption in production facilities and identifying opportunities for waste reduction and recycling of vinyl materials.

- Data-driven insights from AI help manufacturers comply with complex environmental regulations by monitoring emissions and material compositions more effectively.

- AI can aid in developing smart coatings by integrating sensors and data analysis for real-time monitoring of surface conditions, predicting maintenance needs.

- Enhanced customer service and technical support through AI-powered chatbots and virtual assistants providing instant solutions and product recommendations.

- Optimization of coating application processes, such as spray patterns and drying times, through AI, leading to superior finish quality and material savings.

- AI supports risk assessment and management by analyzing potential hazards in production or product use, improving safety protocols.

- Facilitates the development of bio-based and recyclable vinyl formulations by screening and optimizing sustainable raw materials.

DRO & Impact Forces Of Vinyl Surface Coatings Market

The Vinyl Surface Coatings Market is significantly influenced by a confluence of driving forces that propel its expansion and restraining factors that impede growth, alongside emerging opportunities that shape its future trajectory. A primary driver is the accelerating pace of global urbanization and the subsequent surge in construction and infrastructure development, particularly in developing economies, which necessitates vast quantities of durable and aesthetic surface protection. The inherent properties of vinyl coatings, such as exceptional weatherability, chemical resistance, and abrasion durability, make them ideal for a myriad of applications in building exteriors, interiors, and industrial settings. Furthermore, the sustained growth in the automotive sector, driven by increasing vehicle production and the demand for enhanced durability and aesthetic appeal in automotive finishes and interior components, contributes substantially to market momentum. The cost-effectiveness of vinyl coatings compared to alternative materials also positions them favorably in price-sensitive markets, ensuring their continued adoption.

Conversely, the market faces notable restraints, most prominently the volatility of raw material prices, including monomers like vinyl chloride monomer (VCM) and plasticizers, which are derived from petrochemicals. Fluctuations in crude oil prices directly impact production costs, leading to unpredictable pricing pressures on manufacturers and potentially affecting profit margins. Another significant challenge is the increasingly stringent environmental regulations globally, particularly concerning volatile organic compound (VOC) emissions from solvent-based coatings. These regulations compel manufacturers to invest heavily in research and development for eco-friendlier formulations, such as water-borne and high-solids coatings, which, while beneficial long-term, impose immediate compliance costs and technological hurdles. Intense competition from alternative coating technologies, including acrylics, polyurethanes, and epoxies, which offer distinct performance advantages for specific applications, also constrains market share expansion for vinyl-based solutions.

Despite these challenges, the Vinyl Surface Coatings Market is replete with opportunities for innovation and growth. The rising demand for sustainable and green building materials presents a substantial opportunity for manufacturers to develop and commercialize low-VOC, non-toxic, and bio-based vinyl coating solutions that meet stringent environmental standards and appeal to environmentally conscious consumers. Technological advancements in nanotechnology and smart coatings offer avenues for developing enhanced vinyl coatings with self-healing properties, anti-microbial functions, and temperature-regulating capabilities, opening up new high-value applications. Moreover, the expanding application scope in emerging markets, driven by industrialization and improving living standards, provides untapped potential for market penetration. Strategic collaborations and partnerships between coating manufacturers, raw material suppliers, and end-use industries can further facilitate the development of customized and high-performance solutions, thereby mitigating restraints and capitalizing on these burgeoning opportunities, fostering long-term market sustainability and growth.

Segmentation Analysis

The Vinyl Surface Coatings Market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, consumer preferences, and growth opportunities across various product types, applications, and end-use industries. This segmentation is crucial for strategic planning, product development, and market penetration, as it highlights the specific areas of demand and the unique performance requirements inherent to each category. The classifications by resin type differentiate between the primary chemical compositions that define the coating's core properties and performance characteristics. Application-based segmentation provides clarity on where these coatings are predominantly used, reflecting their versatility, while end-use industry segmentation identifies the major sectors driving consumption, thus illustrating the broad economic impact and interdependencies within the market landscape. This multi-dimensional approach to segmentation enables stakeholders to pinpoint specific market niches and develop targeted strategies for growth and innovation within the vinyl surface coatings domain.

- By Resin Type:

- Polyvinyl Chloride (PVC): Widely used for its durability, chemical resistance, and cost-effectiveness in construction and industrial applications.

- Polyvinylidene Chloride (PVDC): Valued for its exceptional barrier properties against moisture, oxygen, and chemicals, particularly in packaging.

- Vinyl Acetate Copolymers: Utilized in water-borne formulations, offering good adhesion and flexibility for diverse applications including paints and adhesives.

- Other Vinyl Resins: Includes vinylidene fluoride polymers (PVDF) and other specialty vinyls used for high-performance and niche applications requiring superior weatherability and chemical inertness.

- By Application:

- Flooring: Dominant application, including vinyl tiles, sheets, and luxury vinyl planks, favored for durability, water resistance, and aesthetic variety.

- Wall Coverings: Used in residential, commercial, and healthcare settings for protective and decorative purposes.

- Furniture: Applied to wood and composite furniture for protection, aesthetics, and ease of cleaning.

- Automotive Components: Interior trim, dashboards, and underbody coatings for protection against wear, corrosion, and UV radiation.

- Packaging Materials: Coatings for metal cans, flexible packaging, and films to enhance barrier properties, printability, and protection.

- Building & Construction (Exteriors, Interiors): Roofing membranes, window profiles, and architectural coatings for weather protection and longevity.

- Textiles: Used for coating fabrics to impart waterproofing, durability, and fire resistance.

- Adhesives & Sealants: Vinyl resins are critical components in formulating various types of adhesives and sealants.

- Other Industrial Applications: Marine coatings, agricultural equipment, appliances, and general industrial protective coatings.

- By End-Use Industry:

- Building & Construction: Largest segment, driven by residential, commercial, and infrastructure projects globally.

- Automotive: Encompasses original equipment manufacturing (OEM) and automotive refinish for various vehicle types.

- Packaging: Food & beverage, pharmaceutical, and consumer goods packaging.

- Textile: Apparel, technical textiles, and industrial fabrics.

- Consumer Goods: Appliances, electronics, and household items.

- Industrial: Machinery, equipment, marine, and other heavy industries requiring robust protection.

Value Chain Analysis For Vinyl Surface Coatings Market

The value chain for the Vinyl Surface Coatings Market is a complex, multi-stage process that begins with the extraction and processing of raw materials, moves through various manufacturing and formulation stages, and culminates in distribution and end-use application. Upstream analysis involves the procurement of essential raw materials, primarily petrochemical derivatives, which are crucial for synthesizing vinyl monomers such as vinyl chloride monomer (VCM) and vinyl acetate monomer. Key suppliers in this segment include chemical and petrochemical companies that produce these monomers, along with plasticizers, stabilizers, pigments, and various additives like fillers, flow modifiers, and rheology modifiers. The quality and cost-effectiveness of these initial inputs significantly impact the final product's performance and pricing, making strong supplier relationships and efficient procurement strategies vital for coating manufacturers. Innovations in bio-based raw materials are also becoming increasingly important in this upstream segment, driving sustainability efforts throughout the chain.

Midstream activities involve the intricate process of coating manufacturing and formulation. This stage is dominated by specialized coating companies that convert raw vinyl resins and other additives into finished liquid or powder coating products. This involves polymerization processes, dispersion, grinding, and mixing to achieve the desired viscosity, color, curing characteristics, and application properties. Significant research and development efforts are concentrated at this stage to enhance coating performance, introduce new functionalities like anti-microbial or self-cleaning properties, and ensure compliance with environmental regulations through the development of low-VOC or water-borne formulations. Quality control and testing are paramount to ensure that the coatings meet industry standards and customer specifications, adding significant value through specialized technical expertise and advanced manufacturing capabilities. The efficiency of these manufacturing processes directly influences production costs and market competitiveness, necessitating continuous optimization.

Downstream analysis focuses on the distribution channels and the end-users who apply the vinyl surface coatings. Distribution channels are varied and include direct sales to large industrial clients (e.g., automotive OEMs, large construction firms), indirect sales through a network of distributors, wholesalers, retailers, and increasingly, e-commerce platforms for smaller batches and specialty products. These channels are crucial for market reach and customer accessibility, requiring robust logistics and supply chain management. The end-users span a wide array of industries, including building and construction, automotive, packaging, textile, and consumer goods manufacturing. Technical support, application training, and after-sales service provided by manufacturers and distributors add considerable value at this stage, ensuring optimal product performance and customer satisfaction. The direct interaction with end-users provides valuable feedback for product improvement and innovation, completing the value chain loop and driving future market developments through a symbiotic relationship between manufacturers and their client base.

Vinyl Surface Coatings Market Potential Customers

The potential customers for the Vinyl Surface Coatings Market are incredibly diverse, spanning numerous industries that require durable, protective, and aesthetically pleasing surface solutions for their products and infrastructure. At the forefront are businesses within the building and construction sector, including residential and commercial developers, contractors, architects, and interior designers. These entities utilize vinyl coatings for a wide array of applications such as flooring (vinyl tiles, luxury vinyl planks), wall coverings, roofing membranes, window and door profiles, and exterior cladding. The demand here is driven by the need for materials that offer longevity, ease of maintenance, moisture resistance, and a broad spectrum of design options, making vinyl coatings a staple in modern construction projects and renovation initiatives, particularly in high-traffic or moisture-prone environments.

Another significant customer segment is the automotive industry, encompassing original equipment manufacturers (OEMs) and automotive aftermarket suppliers. Car manufacturers extensively use vinyl coatings for interior components like dashboards, door panels, and seating materials, where flexibility, durability, UV resistance, and aesthetic appeal are crucial. Additionally, protective vinyl films and underbody coatings provide essential resistance against corrosion, stone chips, and environmental elements, extending the lifespan and maintaining the appearance of vehicles. The increasing global vehicle production, coupled with a rising consumer demand for higher quality and more durable car interiors, positions automotive companies as key off-takers for specialized vinyl coating solutions that meet stringent industry standards for performance and safety, driving innovation in this segment.

Beyond these major sectors, the packaging industry represents a substantial and growing customer base for vinyl surface coatings. Food and beverage manufacturers, pharmaceutical companies, and consumer goods brands employ these coatings for protective and decorative purposes on metal cans, flexible packaging films, and rigid containers. Vinyl coatings enhance barrier properties, protecting contents from moisture, oxygen, and chemicals, thereby extending shelf life and ensuring product integrity. They also provide excellent adhesion for printing, allowing for vibrant graphics and branding. Furthermore, other industrial sectors such as textiles (for coated fabrics), marine (for protective boat coatings), and various manufacturing industries (for appliance finishes and industrial equipment protection) consistently seek out vinyl coating solutions. These diverse applications underscore the broad utility and enduring market relevance of vinyl surface coatings across a wide spectrum of industrial and consumer-focused end-users.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 Billion |

| Market Forecast in 2032 | USD 27.3 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Akzo Nobel N.V., Axalta Coating Systems LLC, BASF SE, PPG Industries, Inc., Sherwin-Williams Company, RPM International Inc., Kansai Paint Co., Ltd., Nippon Paint Holdings Co., Ltd., Hempel A/S, Jotun A/S, Sika AG, Covestro AG, Dow Inc., Arkema S.A., Solvay S.A., DIC Corporation, Lonza Group AG, Synthomer plc, Michelman, Inc., Wacker Chemie AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vinyl Surface Coatings Market Key Technology Landscape

The Vinyl Surface Coatings Market is continuously evolving, driven by significant advancements in material science and processing technologies aimed at enhancing performance, sustainability, and application efficiency. A pivotal technological trend involves the development of low-volatile organic compound (VOC) and zero-VOC formulations, primarily water-borne and high-solids vinyl coatings. This shift is a direct response to increasing environmental regulations and a growing industry demand for greener solutions that minimize air pollution and improve worker safety. Innovations in emulsion polymerization techniques enable the creation of highly stable and film-forming latexes that deliver comparable or superior performance to traditional solvent-borne systems, including excellent adhesion, flexibility, and chemical resistance, thereby expanding their applicability across sensitive environments and diverse substrates without compromising on quality or durability.

Another critical area of technological advancement is the integration of nanotechnology into vinyl coating formulations. Nanoparticles, such as nano-silica, titanium dioxide, and various metal oxides, are being incorporated to impart novel properties like enhanced scratch resistance, improved UV stability, self-cleaning capabilities, and anti-microbial functions. These intelligent or 'smart' coatings offer extended durability, reduced maintenance requirements, and contribute to healthier environments, making them particularly attractive for high-traffic public spaces, healthcare facilities, and demanding industrial applications. Furthermore, advancements in UV/EB (ultraviolet/electron beam) curable vinyl coatings are gaining traction due to their rapid curing speeds, reduced energy consumption, and superior physical properties, leading to higher production efficiencies and lower environmental footprints compared to conventional thermal curing methods, especially in flooring and furniture industries.

The development of advanced polymerization techniques and novel vinyl resin architectures also plays a crucial role in shaping the market's technological landscape. This includes the creation of specialized vinyl copolymers with tailored properties to meet specific performance criteria, such as enhanced flame retardancy, improved adhesion to challenging substrates, or increased flexibility for various bending and forming operations. Bio-based vinyl resins, derived from renewable resources, are emerging as a sustainable alternative to traditional petrochemical-based polymers, signaling a future direction for the industry aimed at reducing its carbon footprint. Coupled with automated application systems, including robotic spraying and precision coating technologies, these innovations are not only improving the consistency and quality of vinyl surface coatings but also broadening their functional scope and fostering a more sustainable and efficient manufacturing ecosystem that is responsive to dynamic market needs and stringent regulatory demands.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations, driving demand for low-VOC and sustainable vinyl coating solutions. Significant consumption occurs in the renovation and remodeling sector, as well as the automotive and aerospace industries. Innovation in advanced materials and specialized coatings is a key trend, with the United States and Canada leading in technological adoption and high-performance applications. The region exhibits a strong focus on durable, long-lasting coatings for both residential and commercial infrastructure.

- Europe: Marked by a strong emphasis on sustainability, circular economy principles, and high-quality standards. Western European countries like Germany, France, and the UK are prominent consumers, particularly in the construction, automotive, and industrial sectors. Regulatory pressures, such as REACH, encourage the development and adoption of environmentally friendly formulations, including water-borne and solvent-free vinyl coatings. The region also boasts a robust research and development ecosystem, fostering innovation in smart coatings and bio-based alternatives.

- Asia Pacific (APAC): The largest and fastest-growing market for vinyl surface coatings, primarily driven by rapid urbanization, industrialization, and infrastructure development in countries such as China, India, Japan, and Southeast Asian nations. High demand from the booming construction, automotive manufacturing, and packaging industries fuels market expansion. Economic growth, increasing disposable incomes, and a large consumer base contribute to the widespread adoption of vinyl coatings, with a growing focus on cost-effectiveness and product versatility.

- Latin America: An emerging market demonstrating significant growth potential, propelled by increasing investments in infrastructure projects, expanding automotive production, and a rising middle class driving residential and commercial construction. Countries like Brazil, Mexico, and Argentina are key contributors. While cost remains a significant factor, there is a growing awareness and adoption of higher-performance and more durable coating solutions for various applications, especially in urban development and industrial expansion initiatives.

- Middle East and Africa (MEA): This region is experiencing considerable growth due to substantial investments in construction, hospitality, and energy sectors, particularly in the GCC countries (Saudi Arabia, UAE) and parts of Africa. Rapid population growth and government-led diversification efforts are driving the demand for protective and decorative coatings for new buildings, industrial facilities, and infrastructure. The market is also influenced by specific climatic challenges, necessitating coatings with superior UV resistance and weatherability, thus creating opportunities for specialized vinyl formulations that can withstand harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vinyl Surface Coatings Market.- Akzo Nobel N.V.

- Axalta Coating Systems LLC

- BASF SE

- PPG Industries, Inc.

- Sherwin-Williams Company

- RPM International Inc.

- Kansai Paint Co., Ltd.

- Nippon Paint Holdings Co., Ltd.

- Hempel A/S

- Jotun A/S

- Sika AG

- Covestro AG

- Dow Inc.

- Arkema S.A.

- Solvay S.A.

- DIC Corporation

- Lonza Group AG

- Synthomer plc

- Michelman, Inc.

- Wacker Chemie AG

Frequently Asked Questions

What are vinyl surface coatings and their primary applications?

Vinyl surface coatings are protective and decorative layers derived from vinyl polymers like PVC, PVDC, and vinyl acetate copolymers. They are renowned for their exceptional durability, chemical resistance, aesthetic versatility, and cost-effectiveness. Their primary applications span numerous industries, including building and construction for flooring, wall coverings, and roofing; automotive for interior components and protective films; and packaging for enhanced barrier properties and product presentation. These coatings also find widespread use in textiles, furniture, and various industrial applications where robust surface protection and aesthetic enhancement are critical, contributing significantly to the longevity and appearance of finished products across diverse sectors globally.

What key factors are driving the growth of the Vinyl Surface Coatings Market?

The Vinyl Surface Coatings Market is primarily driven by several interconnected factors. Rapid global urbanization and significant investments in infrastructure development, particularly in emerging economies, are fueling demand for durable and aesthetic building materials. The expanding automotive industry, with increasing vehicle production and a focus on enhanced interior and exterior finishes, also contributes significantly. Furthermore, the inherent benefits of vinyl coatings, such as their superior weatherability, chemical resistance, abrasion durability, and favorable cost-to-performance ratio compared to alternative materials, make them highly attractive across a broad spectrum of industrial and consumer applications. Continuous innovation in product formulation, including sustainable options, further propels market expansion.

What are the main challenges faced by manufacturers in the Vinyl Surface Coatings Market?

Manufacturers in the Vinyl Surface Coatings Market encounter several significant challenges that impact their operations and profitability. One major hurdle is the volatility of raw material prices, particularly petrochemical derivatives used in vinyl monomer production, which can lead to unpredictable manufacturing costs and pressure on profit margins. Another critical challenge is the increasingly stringent global environmental regulations concerning volatile organic compound (VOC) emissions from coatings. Compliance necessitates substantial investments in research and development for eco-friendlier, low-VOC, or water-borne formulations. Additionally, intense competition from alternative coating technologies, such as acrylics and polyurethanes, which may offer specialized performance advantages for certain applications, continuously demands innovation and differentiation to maintain market share and competitiveness.

How is sustainability impacting the development of vinyl surface coatings?

Sustainability is profoundly impacting the development of vinyl surface coatings, driving a significant paradigm shift towards greener and more environmentally responsible products. Manufacturers are increasingly focused on developing low-volatile organic compound (VOC) and zero-VOC formulations, primarily through water-borne and high-solids technologies, to reduce air pollution and meet stringent environmental regulations. There is a growing emphasis on incorporating bio-based raw materials derived from renewable resources, moving away from petrochemical dependence and reducing the carbon footprint of products. Additionally, efforts are being made to enhance the recyclability of vinyl-coated products and explore circular economy principles, aiming to minimize waste and promote resource efficiency throughout the product lifecycle, thereby aligning with global environmental objectives and consumer demand for eco-conscious materials.

Which regions are key contributors to the Vinyl Surface Coatings Market, and why?

The Asia Pacific (APAC) region is the largest and most dynamic contributor to the Vinyl Surface Coatings Market, primarily due to rapid industrialization, extensive urbanization, and booming construction activities in countries like China, India, and Southeast Asia. These factors drive immense demand for durable and cost-effective coatings. North America and Europe are also significant contributors, representing mature markets characterized by a strong focus on regulatory compliance, technological advancements, and the adoption of specialized, high-performance, and sustainable vinyl formulations, particularly in renovation, automotive, and industrial sectors. Emerging markets in Latin America and the Middle East & Africa are showing promising growth, fueled by infrastructure development and increasing industrial output, further solidifying the global reach and diverse regional influences on the vinyl surface coatings industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager