Virtual PLC & Soft PLC Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429796 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Virtual PLC & Soft PLC Market Size

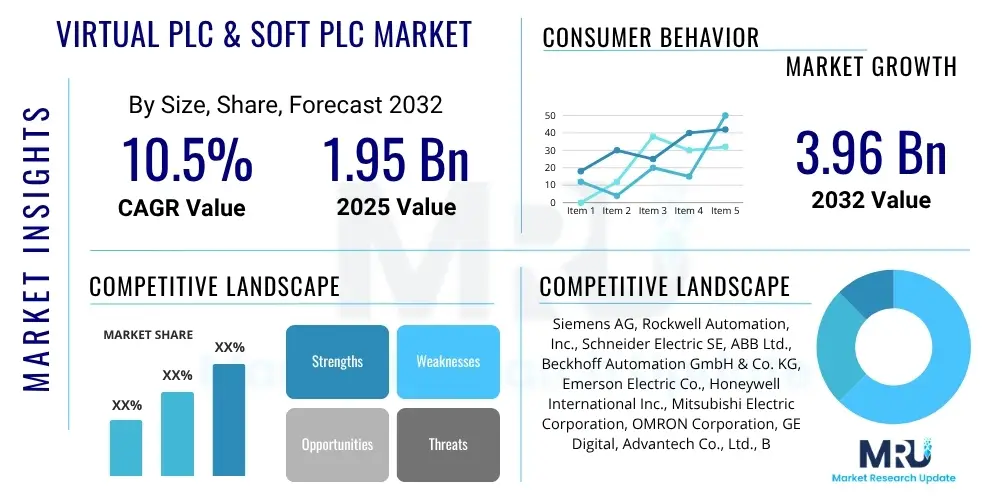

The Virtual PLC & Soft PLC Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at USD 1.95 billion in 2025 and is projected to reach USD 3.96 billion by the end of the forecast period in 2032.

Virtual PLC & Soft PLC Market introduction

The Virtual PLC & Soft PLC Market represents a significant paradigm shift in industrial automation, moving away from traditional hardware-centric programmable logic controllers towards software-defined solutions. Virtual PLCs leverage virtualization technologies to run PLC functionalities on standard industrial computers or servers, offering enhanced flexibility and resource optimization. Soft PLCs, on the other hand, are software programs that provide PLC functionalities without dedicated hardware, running on general-purpose industrial PCs and offering greater adaptability and integration capabilities within existing IT infrastructures. This evolution is driven by the increasing demand for agile, scalable, and cost-effective automation solutions across various industries.

The product scope of Virtual and Soft PLCs encompasses a wide range of software applications and platforms designed to replicate, enhance, and extend the control capabilities traditionally provided by hardware PLCs. These solutions enable complex control logic, real-time data processing, and seamless integration with higher-level systems such as SCADA, MES, and ERP. Key benefits include reduced hardware costs, simplified maintenance, enhanced diagnostics, and the ability to implement rapid changes to control logic without physical rewiring. Their ability to integrate with cloud and edge computing paradigms further extends their utility in modern industrial environments, facilitating remote management and distributed control architectures.

Major applications for Virtual PLC and Soft PLC technologies span discrete manufacturing, process industries, building automation, energy management, and infrastructure. They are crucial in sectors like automotive for assembly line control, food and beverage for precise process orchestration, and oil and gas for pipeline monitoring and safety systems. The primary driving factors for market growth include the accelerating pace of Industry 4.0 adoption, the pervasive integration of the Industrial Internet of Things (IIoT), the growing emphasis on operational efficiency and predictive maintenance, and the imperative for flexible, scalable automation solutions that can adapt to evolving production demands and market conditions. The ongoing digital transformation across industrial sectors is a fundamental catalyst for this market's expansion.

Virtual PLC & Soft PLC Market Executive Summary

The Virtual PLC & Soft PLC market is experiencing robust growth, primarily fueled by the accelerating digital transformation initiatives across global industries and the continuous drive towards more integrated and flexible automation systems. Key business trends indicate a strong move towards software-centric architectures, enabling enterprises to reduce capital expenditure on proprietary hardware and achieve greater operational agility. There is a noticeable shift in investment towards solutions that offer enhanced connectivity, real-time data processing capabilities, and seamless integration with broader enterprise systems, reflecting a strategic imperative for comprehensive operational visibility and control. The increasing sophistication of cybersecurity threats also drives demand for more secure and easily updateable software-based control systems, influencing purchasing decisions and product development.

Regionally, the market exhibits diverse growth dynamics. Asia Pacific stands out as a high-growth region, propelled by rapid industrialization, extensive government support for manufacturing advancements, and significant investments in smart factories, particularly in countries like China, India, and South Korea. North America and Europe, characterized by mature industrial bases, are focusing on adopting advanced automation solutions for optimization, modernization of existing infrastructure, and leveraging the benefits of Industry 4.0. These regions are seeing increased adoption driven by labor cost optimization, enhancing manufacturing output quality, and a strong emphasis on integrating IT and OT landscapes. Latin America and the Middle East and Africa are emerging as promising markets, driven by infrastructure development projects, diversification of economies, and initial stages of industrial automation adoption, albeit at a slower pace due to varying economic conditions and technological readiness.

Segment trends within the Virtual PLC & Soft PLC market highlight a pronounced shift towards cloud-based and edge-based deployment models, offering unprecedented scalability and accessibility. The software component segment continues to dominate, evolving with advanced functionalities such as artificial intelligence integration for predictive control and enhanced diagnostics. End-user industries like automotive and discrete manufacturing remain pivotal, but significant growth is also observed in sectors such as packaging, pharmaceuticals, and utilities, driven by stringent regulatory requirements, the need for precision control, and continuous process optimization. The increasing complexity of industrial processes and the demand for personalized production further underscore the value proposition of flexible, software-defined control systems, fostering innovation in market offerings and encouraging broader adoption across a diversified industrial landscape.

AI Impact Analysis on Virtual PLC & Soft PLC Market

Users frequently inquire about how artificial intelligence can transform the capabilities of Virtual PLC and Soft PLC systems, specifically concerning enhanced operational efficiency, predictive maintenance, and decision-making. There is significant interest in understanding AI's role in optimizing real-time control, improving system diagnostics, and providing adaptive process adjustments. Concerns often revolve around the complexity of integrating AI algorithms, ensuring data privacy and security within AI-driven control systems, and the potential for increased system vulnerability or unforeseen operational risks. Expectations include more autonomous control systems, better fault detection, and the ability to learn from operational data to continuously improve performance, driving a new era of intelligent automation that surpasses traditional rule-based control logic.

- AI enhances predictive maintenance by analyzing operational data from Virtual PLCs to forecast equipment failures, minimizing downtime.

- Optimizes industrial processes through machine learning algorithms, leading to improved energy efficiency and resource utilization.

- Enables adaptive control systems that can learn and adjust to dynamic production environments, improving flexibility and responsiveness.

- Strengthens cybersecurity by detecting anomalous patterns in network traffic and control logic, identifying potential threats.

- Facilitates advanced diagnostics and troubleshooting by rapidly pinpointing root causes of operational issues.

- Supports automated quality control through computer vision and pattern recognition, reducing defects.

- Drives greater autonomy in industrial operations, allowing for self-optimizing and self-healing automation systems.

- Improves human-machine collaboration by providing intelligent insights and simplified interfaces for operators.

DRO & Impact Forces Of Virtual PLC & Soft PLC Market

The Virtual PLC & Soft PLC Market is significantly shaped by a confluence of powerful drivers, challenging restraints, and compelling opportunities that dictate its trajectory and influence competitive dynamics. Key drivers include the relentless pursuit of Industry 4.0 and smart manufacturing initiatives, which necessitate flexible, interconnected, and software-defined control architectures. The inherent cost-effectiveness, scalability, and ease of integration offered by virtual and soft PLCs compared to their hardware counterparts further propel their adoption. Moreover, the increasing demand for real-time data analytics, remote monitoring, and predictive maintenance capabilities across industrial operations consistently reinforces the market's growth, as these systems provide the necessary computational backbone for such advanced functionalities. The pervasive trend of digital transformation across global enterprises is arguably the most significant overarching driver, pushing industries to modernize their control systems.

However, several restraints temper the market's explosive potential. The significant installed base of legacy hardware PLCs in various industries poses a substantial barrier to entry for virtualized solutions, requiring considerable investment and complex migration strategies. Concerns regarding cybersecurity vulnerabilities associated with software-defined systems, especially given their increased connectivity, remain a critical challenge for end-users and manufacturers alike. A shortage of skilled personnel proficient in both industrial automation and IT technologies to implement, manage, and maintain these sophisticated systems also limits widespread adoption. Additionally, regulatory complexities and standardization issues across different industrial sectors can create hurdles for seamless integration and interoperability, leading to slower uptake in certain regions or industries.

Despite these challenges, the market is rich with opportunities that promise sustained future growth. The convergence of IT and operational technology (OT) environments is creating new avenues for integrated solutions that leverage cloud and edge computing, enhancing data processing at the source and improving response times. The ongoing development of artificial intelligence and machine learning algorithms offers profound opportunities for embedding advanced intelligence into virtual and soft PLCs, enabling more autonomous control, adaptive processes, and superior predictive capabilities. Furthermore, expansion into new industrial verticals, such as smart cities, agriculture, and healthcare, where flexible and distributed control is increasingly vital, presents significant untapped market potential. The continuous innovation in open-source platforms and virtualization technologies will also reduce development costs and foster a more collaborative ecosystem, accelerating market evolution.

Segmentation Analysis

The Virtual PLC & Soft PLC Market is extensively segmented to reflect the diverse technological offerings, application areas, and deployment models that define its landscape. These segmentations provide a granular view of market dynamics, enabling a deeper understanding of specific growth drivers and emerging trends across different product types, components, industries, and geographical regions. Analyzing these segments is crucial for stakeholders to identify key growth areas, formulate targeted strategies, and understand competitive positioning within the evolving industrial automation ecosystem.

- By Type

- Software-based PLC

- Hardware-agnostic PLC

- Cloud-based PLC

- By Component

- Software (e.g., Runtime engines, Development environments)

- Services (e.g., Consulting, Integration, Maintenance & Support)

- By Industry Vertical

- Automotive

- Manufacturing (Discrete & Process)

- Food & Beverage

- Oil & Gas

- Power & Energy

- Water & Wastewater

- Pharmaceuticals & Life Sciences

- Chemicals & Petrochemicals

- Packaging

- Aerospace & Defense

- Utilities

- Building Automation

- By Deployment Model

- On-premise

- Cloud-based

- Edge-based

- By Application

- Process Control

- Discrete Control

- Motion Control

- Safety Control

- Batch Control

Value Chain Analysis For Virtual PLC & Soft PLC Market

The value chain for the Virtual PLC & Soft PLC Market is characterized by a series of interconnected stages, from initial software development and underlying hardware provisioning to final integration and end-user adoption. At the upstream end, key activities involve intense research and development by software vendors to create robust and efficient PLC emulation software, operating systems, and development environments. This stage also includes the provision of high-performance industrial PCs, servers, and virtualization technologies by hardware manufacturers, which form the foundational infrastructure upon which virtual and soft PLCs operate. Cloud service providers are increasingly integral upstream partners, offering scalable and resilient platforms for cloud-based PLC solutions, alongside cybersecurity solution providers who ensure the integrity and protection of these software-defined control systems.

Moving downstream, the value chain encompasses system integrators and automation solution providers who play a critical role in customizing, configuring, and deploying Virtual PLC and Soft PLC systems to meet specific industrial requirements. These integrators bridge the gap between complex software capabilities and diverse operational needs, providing expertise in network setup, data acquisition, and interfacing with existing machinery and enterprise systems. Distribution channels are primarily bifurcated into direct and indirect models. Direct sales involve vendors engaging directly with large industrial clients, offering tailored solutions and long-term support. Indirect channels, on the other hand, leverage a network of value-added resellers (VARs), distributors, and regional partners who provide localized sales, technical support, and implementation services, especially for small and medium-sized enterprises (SMEs) or in geographically dispersed markets. This dual approach ensures comprehensive market reach and customer support, catering to a broad spectrum of industrial clients with varying technical expertise and project scales.

The interplay between upstream providers of core technologies and downstream integrators and distributors is crucial for market penetration and customer satisfaction. Collaboration across this value chain ensures that cutting-edge software innovations are effectively translated into deployable, functional, and scalable solutions for diverse end-users. The continuous feedback loop from end-users to integrators and then back to software developers is vital for product improvement and the evolution of Virtual PLC and Soft PLC technologies to address emerging industrial challenges and opportunities. The efficiency and responsiveness of this value chain are key determinants of market growth and the successful adoption of these advanced automation solutions, particularly as the demand for highly customized and intelligent control systems intensifies in the era of Industry 4.0.

Virtual PLC & Soft PLC Market Potential Customers

The potential customers for Virtual PLC & Soft PLC solutions span a broad spectrum of industrial and commercial sectors, primarily encompassing entities focused on optimizing their operational efficiency, enhancing automation flexibility, and driving digital transformation. Key end-user segments include discrete manufacturing industries such as automotive, electronics, and general machinery, where precise control over assembly lines, robotic operations, and quality inspection is paramount. Process industries, including chemicals, oil & gas, pharmaceuticals, and food & beverage, also represent significant buyers, seeking advanced control for continuous processes, batch production, and stringent regulatory compliance. These sectors benefit from the improved scalability, reduced hardware footprint, and enhanced data integration capabilities offered by software-defined PLCs, enabling more agile and responsive production environments.

Beyond traditional manufacturing, the market extends to infrastructure and utilities sectors, such as power generation, water and wastewater treatment, and building automation. In these areas, Virtual PLCs and Soft PLCs facilitate intelligent monitoring, energy management, and distributed control of critical assets and systems. The inherent benefits of remote management, simplified maintenance, and reduced total cost of ownership make these solutions highly attractive for managing geographically dispersed operations or complex building ecosystems. Emerging applications in smart cities, agriculture (e.g., precision farming automation), and logistics also highlight expanding customer bases, as these sectors increasingly require sophisticated, adaptable, and cost-effective automation to manage complex operations and enhance resource efficiency. The growing adoption of Industrial IoT (IIoT) across all these verticals further drives the demand for flexible, software-centric control systems capable of integrating vast amounts of sensor data and acting upon real-time insights.

Small and Medium-sized Enterprises (SMEs) are also becoming increasingly significant potential customers, driven by the desire to implement advanced automation without the prohibitive upfront costs associated with traditional hardware PLCs. Virtual and Soft PLCs offer a more accessible entry point into sophisticated industrial control, allowing SMEs to compete more effectively through improved efficiency and quality. Furthermore, original equipment manufacturers (OEMs) who integrate control systems into their machinery represent another vital customer segment, benefiting from the ability to standardize control platforms across different machine models, simplify commissioning, and offer enhanced remote diagnostic and update capabilities to their own customers. The versatility and adaptability of these technologies position them as central to the modernization efforts across a wide array of industrial purchasers, seeking to future-proof their operations in an increasingly competitive and technologically driven landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.95 billion |

| Market Forecast in 2032 | USD 3.96 billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation, Inc., Schneider Electric SE, ABB Ltd., Beckhoff Automation GmbH & Co. KG, Emerson Electric Co., Honeywell International Inc., Mitsubishi Electric Corporation, OMRON Corporation, GE Digital, Advantech Co., Ltd., B&R Automation, Phoenix Contact GmbH & Co. KG, Bosch Rexroth AG, Kontron S&T AG, National Instruments Corporation, CODESYS Group, WAGO Kontakttechnik GmbH & Co. KG, Eaton Corporation plc, Hitachi, Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Virtual PLC & Soft PLC Market Key Technology Landscape

The Virtual PLC & Soft PLC market's technological landscape is rapidly evolving, driven by advancements in several critical areas that enhance functionality, connectivity, and scalability. Central to this evolution is the pervasive adoption of virtualization technologies, which enable PLC functionalities to run efficiently on standard industrial computers or virtual machines, abstracting control logic from proprietary hardware. This foundation is further bolstered by the increasing integration of cloud computing and edge computing paradigms, allowing for centralized management and data processing in the cloud while maintaining real-time control and low latency at the edge. These distributed computing models facilitate greater flexibility, scalability, and resilience for industrial control systems, enabling operations to leverage the benefits of both centralized intelligence and localized responsiveness.

Another pivotal aspect of the technology landscape is the development and refinement of Industrial Internet of Things (IIoT) platforms and protocols. Virtual and Soft PLCs are increasingly designed to seamlessly integrate with IIoT ecosystems, facilitating extensive data collection from sensors and devices, and enabling bidirectional communication with enterprise-level applications. This integration is vital for predictive maintenance, operational optimization, and advanced analytics. Furthermore, the emphasis on robust cybersecurity protocols and solutions is paramount, with technologies like encryption, secure boot, intrusion detection systems, and network segmentation becoming standard features to protect these interconnected, software-defined control systems from escalating cyber threats, ensuring operational integrity and data privacy in increasingly open architectures.

Open-source software platforms and standardized communication protocols such as OPC UA, MQTT, and EtherCAT are also profoundly influencing the market by fostering greater interoperability, reducing vendor lock-in, and accelerating innovation. These technologies enable Virtual and Soft PLCs to communicate effectively with a wide array of devices and systems from different manufacturers, facilitating the creation of highly integrated and flexible automation environments. The convergence of Information Technology (IT) and Operational Technology (OT) is a fundamental technological shift, with Virtual and Soft PLCs serving as key enablers. This convergence allows industrial control systems to leverage IT best practices, tools, and infrastructure, leading to more efficient development, deployment, and management of automation solutions. As industries continue to embrace digital transformation, the continuous evolution of these core technologies will define the future capabilities and widespread adoption of Virtual PLC and Soft PLC solutions.

Regional Highlights

- North America: A leader in advanced manufacturing and industrial automation, North America demonstrates strong adoption of Virtual PLC & Soft PLC solutions, driven by substantial investments in smart factories and a focus on operational efficiency and digital transformation across industries like automotive, aerospace, and pharmaceuticals. The presence of key technology developers and early adopters fuels innovation.

- Europe: Characterized by a robust manufacturing base, particularly in Germany and Italy, Europe is a significant market for Virtual PLC & Soft PLC, propelled by initiatives like Industry 4.0 and the emphasis on modernizing existing infrastructure. Demand is high for solutions that offer flexibility, scalability, and adherence to stringent regulatory standards, especially in process industries and machine building.

- Asia Pacific (APAC): This region is projected to be the fastest-growing market, primarily due to rapid industrialization, extensive government support for manufacturing sectors, and significant investments in smart city projects and factory automation in countries like China, India, Japan, and South Korea. The large manufacturing output and growing demand for cost-effective automation solutions are key drivers.

- Latin America: An emerging market, Latin America is experiencing gradual adoption of Virtual PLC & Soft PLC technologies, driven by infrastructure development and the modernization of industries such as mining, oil & gas, and food & beverage. Economic growth and the increasing need for operational optimization are contributing to market expansion.

- Middle East and Africa (MEA): This region shows nascent but growing potential, fueled by diversification efforts from oil-dependent economies, significant infrastructure projects, and increasing industrialization. Investments in manufacturing, utilities, and logistics are creating demand for advanced automation solutions to enhance efficiency and competitiveness.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Virtual PLC & Soft PLC Market.- Siemens AG

- Rockwell Automation, Inc.

- Schneider Electric SE

- ABB Ltd.

- Beckhoff Automation GmbH & Co. KG

- Emerson Electric Co.

- Honeywell International Inc.

- Mitsubishi Electric Corporation

- OMRON Corporation

- GE Digital

- Advantech Co., Ltd.

- B&R Automation

- Phoenix Contact GmbH & Co. KG

- Bosch Rexroth AG

- Kontron S&T AG

- National Instruments Corporation

- CODESYS Group

- WAGO Kontakttechnik GmbH & Co. KG

- Eaton Corporation plc

- Hitachi, Ltd.

Frequently Asked Questions

What is a Virtual PLC?

A Virtual PLC is a software-based programmable logic controller that runs on standard industrial computers or servers, utilizing virtualization technology to perform control functions typically handled by dedicated hardware PLCs. It offers greater flexibility and scalability.

How do Soft PLCs differ from traditional PLCs?

Soft PLCs are software applications that emulate PLC functionalities on general-purpose industrial PCs, whereas traditional PLCs are hardware-based. Soft PLCs offer lower hardware costs, easier maintenance, and seamless integration with IT systems, unlike traditional, proprietary hardware PLCs.

What are the main benefits of Virtual PLCs?

The primary benefits include reduced hardware costs, enhanced flexibility and scalability, easier integration with IT infrastructure, simplified maintenance and diagnostics, and improved capabilities for remote management and software updates, all contributing to lower total cost of ownership.

Which industries benefit most from Soft PLCs?

Industries such as automotive, food & beverage, pharmaceuticals, discrete manufacturing, and utilities benefit significantly from Soft PLCs due to their need for agile production, complex process control, regulatory compliance, and demand for real-time data integration and operational efficiency.

What are the cybersecurity concerns for Virtual PLCs?

Key cybersecurity concerns include potential vulnerabilities in software, network attack surfaces due to increased connectivity, and risks associated with data privacy and integrity. Robust security measures like encryption, secure network architectures, and regular software updates are crucial to mitigate these risks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager