Visual surface inspection Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430173 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Visual surface inspection Market Size

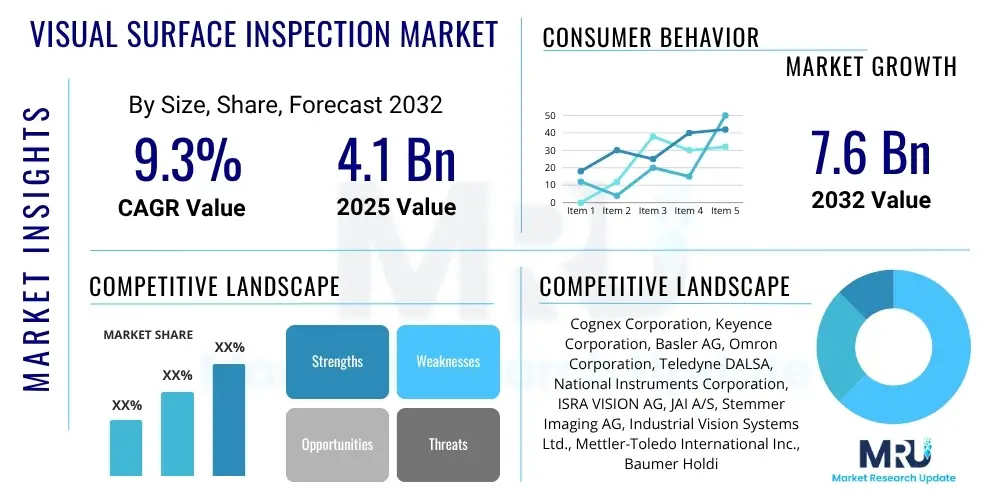

The Visual surface inspection Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.3% between 2025 and 2032. The market is estimated at USD 4.1 Billion in 2025 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2032.

Visual surface inspection Market introduction

The Visual surface inspection Market encompasses technologies and systems designed to automatically detect and analyze defects, irregularities, or characteristics on the surface of products. This critical process ensures quality control across various manufacturing sectors by employing cameras, sensors, and advanced software to identify deviations from specified standards. These systems are indispensable for maintaining high product integrity, reducing waste, and enhancing operational efficiency in modern production lines.

Visual surface inspection products typically include sophisticated machine vision cameras, high-resolution optical sensors, specialized lighting solutions, and powerful image processing software that can be integrated into existing manufacturing workflows or deployed as standalone units. Major applications span a wide array of industries, including automotive, electronics, medical devices, food and beverage, pharmaceuticals, and aerospace, where precision and reliability are paramount. The benefits derived from implementing these systems are substantial, ranging from improved product quality and consistency to significant reductions in manufacturing costs associated with defects, reworks, and manual inspection errors. Furthermore, these systems contribute to faster throughput and better compliance with increasingly stringent industry regulations and customer expectations.

Driving factors for the market's growth include the surging demand for automation in manufacturing processes, the global emphasis on stringent quality control standards, and the escalating adoption of Industry 4.0 initiatives that necessitate intelligent, interconnected inspection solutions. As industries worldwide strive for higher efficiency and flawless production, the role of visual surface inspection systems becomes increasingly central, fostering innovation and expansion within the market.

Visual surface inspection Market Executive Summary

The Visual surface inspection market is experiencing robust growth driven by a confluence of technological advancements and evolving industrial requirements. Key business trends indicate a strong shift towards more integrated and intelligent inspection systems, particularly those leveraging artificial intelligence and deep learning for enhanced accuracy and reduced false positives. Regional trends highlight significant expansion in Asia Pacific due to rapid industrialization and manufacturing growth, while North America and Europe maintain their dominance through continuous innovation and adoption of advanced solutions in high-value manufacturing sectors. These regions are actively investing in R&D to further refine inspection capabilities and integrate them into smart factory ecosystems.

Segment trends reveal an increasing demand for sophisticated software solutions that offer advanced analytics, predictive maintenance capabilities, and seamless integration with existing enterprise resource planning (ERP) systems. The hardware segment continues to evolve with higher resolution cameras, more versatile lighting techniques, and faster processing units. Furthermore, the market is witnessing diversification in application areas, moving beyond traditional manufacturing into emerging fields such as renewable energy components and advanced materials, thereby expanding the potential customer base and fostering new revenue streams for market players. This dynamic environment necessitates continuous adaptation and innovation from market participants to capitalize on emerging opportunities and address evolving challenges.

Overall, the market is characterized by intense competition among established players and emerging innovators, all striving to deliver solutions that meet the increasing demand for precision, speed, and automation in quality assurance. Strategic partnerships, mergers, and acquisitions are common as companies seek to expand their technological portfolios and market reach, further consolidating the industry landscape and accelerating the pace of innovation within visual surface inspection technologies.

AI Impact Analysis on Visual surface inspection Market

Users frequently inquire about how Artificial Intelligence (AI) fundamentally transforms visual surface inspection, focusing on its ability to enhance defect detection, minimize human error, and improve operational efficiency. There is keen interest in AI's capacity to learn from complex visual data, differentiate between critical and non-critical anomalies, and adapt to varying production conditions without extensive reprogramming. Key themes revolve around achieving higher levels of accuracy, reducing false positives and negatives, speeding up inspection processes, and the long-term cost benefits associated with AI integration. Concerns often center on the initial investment, data requirements for training AI models, and the expertise needed for successful deployment and maintenance of these advanced systems. Users also seek clarity on how AI can integrate with existing machine vision infrastructure and the extent of automation it can bring to quality control, ranging from simple defect classification to predictive quality analytics.

- Improved Defect Detection Accuracy: AI algorithms, particularly deep learning, can identify subtle and complex defects that might be missed by traditional rule-based systems or human inspectors, leading to higher precision.

- Reduced False Positives and Negatives: AI models are trained on vast datasets, enabling them to distinguish between actual defects and acceptable variations or noise, significantly decreasing erroneous alerts and missed defects.

- Faster Throughput and Efficiency: Automated AI-powered inspection systems can process images and make decisions at much higher speeds than human inspectors, thereby accelerating production lines and increasing overall efficiency.

- Adaptive Learning and Flexibility: AI systems can continuously learn and improve their inspection capabilities from new data, allowing them to adapt to product variations, new defect types, and changing manufacturing environments without extensive manual recalibration.

- Predictive Quality Analytics: Beyond simple defect detection, AI can analyze patterns in defects to predict potential production issues, enabling proactive adjustments in manufacturing processes and preventing future quality problems.

- Automation of Complex Inspections: AI allows for the automation of highly subjective and complex inspection tasks, such as surface finish quality, aesthetic defects, or intricate assembly verification, where traditional machine vision struggles.

- Cost Reduction through Waste Minimization: By accurately identifying defects early in the production process, AI-driven inspection helps reduce material waste, rework, and the financial impact of product recalls, leading to significant cost savings.

DRO & Impact Forces Of Visual surface inspection Market

The Visual surface inspection market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by various impact forces. The primary drivers include the escalating demand for stringent quality control and defect-free products across industries, propelled by rising consumer expectations and regulatory compliance requirements. Furthermore, the relentless pursuit of manufacturing automation and the widespread adoption of Industry 4.0 paradigms are compelling businesses to integrate advanced inspection technologies for enhanced operational efficiency and reduced manual labor. The imperative to minimize production costs, reduce waste, and improve overall yield also acts as a powerful catalyst for market growth, encouraging investments in sophisticated visual inspection solutions.

However, the market faces notable restraints, predominantly the high initial capital investment required for implementing advanced visual surface inspection systems, which can be a barrier for small and medium-sized enterprises (SMEs). The technical complexity associated with integrating these systems into existing production lines, along with the need for specialized technical expertise for installation, calibration, and maintenance, also poses significant challenges. Moreover, the lack of standardized inspection protocols across diverse industries and the inherent variability in surface characteristics can sometimes limit the widespread adoption of off-the-shelf solutions, necessitating costly customization.

Despite these challenges, substantial opportunities exist, particularly in the integration of Artificial Intelligence (AI) and Machine Learning (ML) with visual inspection systems, which promises to enhance accuracy, reduce false positives, and enable predictive analytics. The expansion into emerging economies, characterized by rapid industrialization and growing manufacturing sectors, presents new avenues for market penetration. Furthermore, the development of more affordable, user-friendly, and versatile inspection solutions tailored for specific niche applications or SMEs could unlock significant untapped market potential. The continuous innovation in sensor technology, camera resolution, and image processing algorithms also creates ongoing opportunities for market expansion and competitive differentiation.

Impact forces on the market include the rapid pace of technological advancements, particularly in machine vision, AI, and computing power, which constantly reshape product capabilities and market expectations. Regulatory pressures, especially in sectors like automotive, aerospace, and medical devices, necessitate robust inspection processes, thereby driving demand. The competitive landscape, characterized by both established industry giants and agile startups, fosters innovation and price competition. Lastly, global economic conditions and supply chain dynamics can influence investment decisions in automation technologies, impacting market growth trajectories.

Segmentation Analysis

The Visual surface inspection market is comprehensively segmented to provide a granular view of its diverse components, technologies, applications, and regional dynamics. This segmentation helps in understanding the various facets driving market growth and identifying specific opportunities and challenges within each category. The market is typically broken down by components, inspection types, end-user industries, and geographical regions, allowing for a detailed analysis of market trends and competitive landscapes. Each segment plays a crucial role in shaping the overall market trajectory, reflecting different levels of technological maturity, adoption rates, and investment priorities across various sectors.

- By Component

- Hardware (Cameras, Lighting, Optics, Processors, Frame Grabbers)

- Software (Image Processing, AI/ML Algorithms, Control Software)

- Services (Installation, Maintenance, Customization, Training)

- By Type

- Automated Optical Inspection (AOI)

- Automated X-ray Inspection (AXI)

- Automated Visual Inspection (AVI)

- Other Inspection Technologies (e.g., Thermal Inspection, Ultrasonic Inspection)

- By Application

- Defect Detection

- Dimension Measurement

- Assembly Verification

- Character Recognition (OCR/OCV)

- Surface Finish Analysis

- By End-User Industry

- Electronics (Printed Circuit Boards, Semiconductors, Displays)

- Automotive (Engine Components, Body Panels, Interior Parts)

- Medical & Pharmaceutical (Syringes, Pills, Packaging, Devices)

- Food & Beverage (Packaging Integrity, Product Quality, Contaminant Detection)

- Aerospace & Defense (Turbine Blades, Structural Components)

- Packaging (Labeling, Sealing, Fill Level)

- Metals & Machinery (Sheet Metal, Castings, Welds)

- Plastics & Rubber

- Textiles

- Others (Glass, Wood, etc.)

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Visual surface inspection Market

The value chain for the Visual surface inspection market begins with upstream activities focused on the development and manufacturing of core components. This includes the production of high-resolution cameras, advanced optical lenses, specialized lighting solutions (such as LED and laser lighting), powerful processors, and frame grabbers. Crucially, the upstream segment also encompasses the development of sophisticated image processing software, artificial intelligence algorithms, and machine learning models that form the intelligence layer of these inspection systems. Key players in this stage are often technology providers specializing in optics, sensors, and software development, whose innovations directly influence the capabilities and performance of the final inspection systems.

Moving downstream, the value chain involves system integrators and original equipment manufacturers (OEMs) who assemble these components into complete, functional visual surface inspection systems. These integrators play a vital role in customizing solutions to meet specific industry requirements, ensuring seamless integration into existing manufacturing lines, and providing the necessary technical support and maintenance. The final stage of the value chain involves the end-user industries, such as automotive, electronics, medical, and food and beverage, which deploy these systems for quality control, defect detection, and process optimization. Their feedback and evolving needs drive further innovation upstream, creating a continuous cycle of development and application.

Distribution channels for visual surface inspection systems are typically a mix of direct and indirect approaches. Direct sales are common for large-scale, complex projects, where manufacturers or system integrators engage directly with major industrial clients to offer tailored solutions, technical consultancy, and comprehensive after-sales support. Indirect channels involve a network of distributors, value-added resellers (VARs), and regional partners who cater to smaller enterprises or specific geographical markets, providing localized support, installation, and maintenance services. This hybrid approach ensures broad market reach and caters to the diverse needs of the global customer base, leveraging specialized expertise at each stage of the distribution process.

Visual surface inspection Market Potential Customers

Potential customers for visual surface inspection systems are diverse and span a wide array of manufacturing and production industries, all united by a common need for stringent quality control, defect reduction, and process optimization. Primarily, these include quality control managers, production supervisors, manufacturing engineers, and R&D departments within companies engaged in high-volume or high-precision manufacturing. These individuals and teams are continuously seeking solutions to improve product reliability, reduce costly recalls, and comply with increasingly strict industry standards and customer expectations.

Specific end-user/buyers are found in sectors such as electronics manufacturing, where the inspection of printed circuit boards (PCBs), semiconductors, and display panels for minute defects is critical. The automotive industry is another major consumer, requiring inspection for surface imperfections on engine components, body panels, and interior parts to ensure safety and aesthetic quality. In the medical device and pharmaceutical industries, visual inspection is indispensable for ensuring the sterility, integrity, and accurate dosing of products like syringes, pills, and packaging, directly impacting patient safety and regulatory compliance.

Beyond these, the food and beverage industry utilizes these systems for packaging integrity, foreign object detection, and product quality verification. Aerospace and defense manufacturers depend on visual inspection for critical components like turbine blades and structural parts, where even minor flaws can have catastrophic consequences. Other significant potential customers include manufacturers in the plastics and rubber, metals and machinery, textiles, and packaging sectors, all of whom can leverage visual surface inspection to enhance their operational efficiency, reduce waste, and uphold their brand reputation through superior product quality.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.1 Billion |

| Market Forecast in 2032 | USD 7.6 Billion |

| Growth Rate | CAGR 9.3% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cognex Corporation, Keyence Corporation, Basler AG, Omron Corporation, Teledyne DALSA, National Instruments Corporation, ISRA VISION AG, JAI A/S, Stemmer Imaging AG, Industrial Vision Systems Ltd., Mettler-Toledo International Inc., Baumer Holding AG, Datalogic S.p.A., Sick AG, Allied Vision Technologies GmbH, Opto Engineering S.p.A., LMI Technologies Inc., Edmund Optics Inc., Tordivel AS, Microscan Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Visual surface inspection Market Key Technology Landscape

The Visual surface inspection market is underpinned by a sophisticated and rapidly evolving technological landscape, where advancements in various fields converge to create highly precise and efficient inspection solutions. At its core, the technology relies on high-performance machine vision cameras, which range from standard CCD and CMOS sensors to ultra-high-resolution, line scan, and 3D cameras capable of capturing minute details. These cameras are complemented by advanced optical systems, including specialized lenses, filters, and prisms, designed to optimize image acquisition for diverse surface types and defect characteristics. Crucial to effective inspection is the use of intelligent lighting techniques, such as diffused, bright-field, dark-field, structured light, and coaxial lighting, which are meticulously selected to highlight specific surface features or defects under various environmental conditions.

Beyond hardware, the software component forms the intelligence of visual surface inspection systems. This includes advanced image processing algorithms for noise reduction, feature extraction, and pattern recognition. The growing integration of Artificial Intelligence (AI) and Machine Learning (ML), particularly deep learning neural networks, represents a significant technological leap. These AI algorithms enable systems to learn from vast datasets of images, classify defects with high accuracy, reduce false positives, and adapt to variations in production, moving beyond rigid rule-based programming. Furthermore, the incorporation of robotic integration allows for automated handling and positioning of products, enhancing throughput and consistency, while cloud computing and Industrial Internet of Things (IIoT) technologies facilitate data storage, remote monitoring, and real-time analytics, enabling predictive maintenance and comprehensive quality management across distributed manufacturing operations.

Emerging technologies continue to shape the market, including hyperspectral imaging for detecting material composition anomalies, multispectral imaging for distinguishing subtle surface variations, and enhanced 3D vision systems that provide volumetric data for complex geometries and precise defect localization. The ongoing trend towards edge computing also plays a vital role, allowing for faster, decentralized processing of visual data directly on the factory floor, thereby reducing latency and improving decision-making speed. These technological advancements collectively drive the market forward, enabling more versatile, accurate, and cost-effective visual surface inspection solutions for a wide range of industrial applications, and pushing the boundaries of what is achievable in automated quality assurance.

Regional Highlights

- North America: This region represents a mature market with significant adoption of visual surface inspection systems, particularly in automotive, aerospace, and electronics industries. High investment in R&D, coupled with the presence of key technology providers, drives innovation and demand for advanced AI-integrated solutions. The emphasis on high-quality production and automation further fuels market growth.

- Europe: Europe is a strong market driven by stringent quality standards in industries like automotive, pharmaceuticals, and precision engineering. Countries like Germany, France, and the UK are at the forefront of adopting sophisticated machine vision technologies. The region also benefits from robust manufacturing infrastructure and a focus on Industry 4.0 initiatives, promoting the integration of smart inspection systems.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily due to rapid industrialization, expansion of manufacturing capabilities, and increasing investments in automation across countries like China, India, Japan, and South Korea. The electronics and automotive sectors are major contributors to market demand, with a rising emphasis on cost-effective yet high-precision inspection solutions.

- Latin America: This region shows emerging potential with growing manufacturing activities and increasing foreign investments, particularly in countries like Brazil and Mexico. The adoption of visual surface inspection systems is driven by the need to enhance product quality and meet international standards, though market penetration is still in its early stages compared to more developed regions.

- Middle East & Africa (MEA): The MEA region is witnessing gradual adoption of visual surface inspection technologies, primarily in the oil and gas, automotive assembly, and packaging industries. Economic diversification efforts and increasing industrialization are creating new opportunities for market expansion, with a growing focus on efficiency and quality control in emerging manufacturing hubs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Visual surface inspection Market.- Cognex Corporation

- Keyence Corporation

- Basler AG

- Omron Corporation

- Teledyne DALSA

- National Instruments Corporation

- ISRA VISION AG

- JAI A/S

- Stemmer Imaging AG

- Industrial Vision Systems Ltd.

- Mettler-Toledo International Inc.

- Baumer Holding AG

- Datalogic S.p.A.

- Sick AG

- Allied Vision Technologies GmbH

- Opto Engineering S.p.A.

- LMI Technologies Inc.

- Edmund Optics Inc.

- Tordivel AS

- Microscan Systems Inc.

Frequently Asked Questions

What is visual surface inspection?

Visual surface inspection involves automated systems utilizing cameras, optics, and software to detect and analyze defects or characteristics on product surfaces, ensuring quality control in manufacturing.

How does AI enhance visual surface inspection?

AI significantly improves accuracy, reduces false positives, enables faster processing, and allows systems to adaptively learn new defect types, leading to more efficient and reliable quality control.

What industries benefit most from visual surface inspection?

Industries such as electronics, automotive, medical devices, food and beverage, and aerospace highly benefit due to their stringent quality requirements and high-volume production needs.

What are the primary challenges in implementing visual surface inspection?

Key challenges include high initial investment costs, the technical complexity of system integration, the need for specialized expertise, and variability in product surfaces that require customized solutions.

What is the future outlook for the visual surface inspection market?

The market is projected for strong growth, driven by increasing automation, advanced AI and 3D vision integration, expansion into emerging markets, and continuous innovation in sensor and software technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager