Wafer Cleaning Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428521 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Wafer Cleaning Equipment Market Size

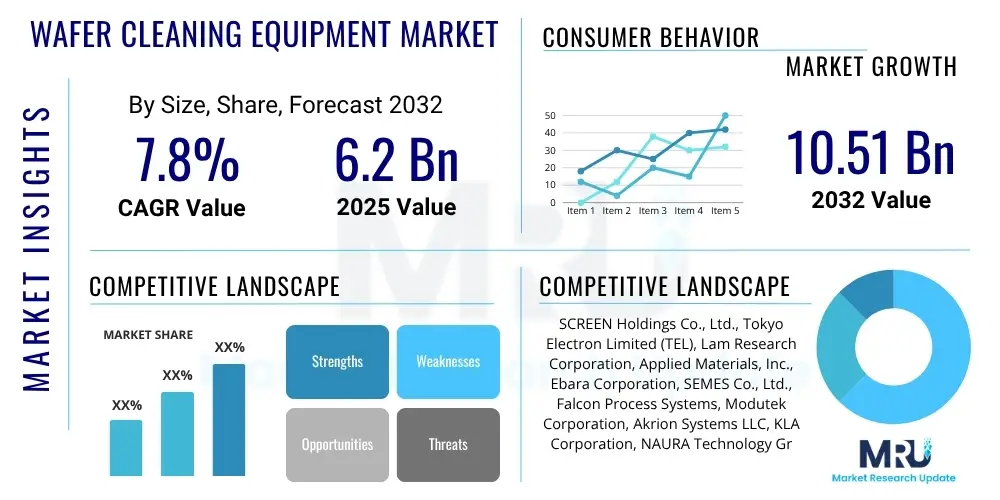

The Wafer Cleaning Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $6.2 Billion in 2025 and is projected to reach $10.51 Billion by the end of the forecast period in 2032.

Wafer Cleaning Equipment Market introduction

The Wafer Cleaning Equipment Market is an indispensable segment within the broader semiconductor manufacturing industry, playing a critical role in ensuring the quality, performance, and reliability of semiconductor devices. As the foundational step in the fabrication process, wafer cleaning involves the meticulous removal of various contaminants, including particulate matter, organic residues, metallic impurities, and native oxides from silicon or other substrate wafers. This rigorous cleaning is crucial at multiple stages of wafer processing, preventing defects that could compromise device functionality and yield.

Wafer cleaning equipment encompasses a range of sophisticated systems designed to perform these intricate cleaning operations. These systems employ various technologies such as wet chemical processes, dry cleaning methods, and advanced physical techniques to achieve ultra-high purity levels on the wafer surface. Major applications for this equipment span across the manufacturing of logic and memory chips, microelectromechanical systems (MEMS), power devices, and optoelectronics, all of which demand pristine surfaces for optimal performance.

The primary benefits derived from advanced wafer cleaning include significantly improved device yield, enhanced electrical performance, and increased long-term reliability of semiconductor components. The market is fundamentally driven by the relentless pursuit of semiconductor miniaturization, the escalating demand for high-performance computing, artificial intelligence (AI), the Internet of Things (IoT), and the rapid expansion of advanced packaging technologies. These factors collectively necessitate increasingly sophisticated and efficient cleaning solutions to meet the stringent quality requirements of next-generation devices.

Wafer Cleaning Equipment Market Executive Summary

The Wafer Cleaning Equipment Market is experiencing robust growth, primarily fueled by global semiconductor industry expansion, technological advancements in chip design, and the increasing complexity of manufacturing processes. Business trends indicate a strong focus on automation, integration of advanced analytics for process control, and the development of eco-friendly cleaning solutions to address environmental concerns. Key players are investing heavily in research and development to offer high-throughput, high-precision equipment capable of handling smaller nodes and larger wafer sizes, driving innovation in both wet and dry cleaning technologies. There is also a notable trend towards strategic partnerships and mergers among equipment manufacturers to consolidate market share and leverage complementary expertise, enhancing competitive advantages and offering integrated solutions to semiconductor fabs.

Regionally, the Asia Pacific (APAC) continues to dominate the market, propelled by significant investments in new fabrication facilities and the expansion of existing ones, particularly in countries like China, Taiwan, South Korea, and Japan, which are global hubs for semiconductor manufacturing. North America and Europe are also witnessing steady growth, driven by investments in advanced research and development, particularly for cutting-edge logic and memory technologies, as well as specialized applications such as automotive and industrial semiconductors. Governments worldwide are also supporting domestic semiconductor production through subsidies and incentives, further stimulating regional market growth and influencing supply chain dynamics.

Segmentation trends highlight a growing preference for single-wafer cleaning systems due to their ability to offer superior process control, reduced chemical consumption, and minimized cross-contamination, especially crucial for advanced technology nodes. While batch immersion systems remain relevant for certain applications and larger wafer volumes, single-wafer solutions are gaining significant traction for high-value and leading-edge device fabrication. Furthermore, there is an increasing demand for dry cleaning technologies, such as plasma and cryogenic cleaning, for specific applications where wet processes might be detrimental, particularly in post-etch residue removal and critical defect reduction, showcasing a diversified technological adoption across various manufacturing steps.

AI Impact Analysis on Wafer Cleaning Equipment Market

Users frequently inquire about how Artificial Intelligence will transform wafer cleaning processes, focusing on predictive maintenance, real-time process optimization, and enhanced defect detection capabilities. There is considerable interest in whether AI can reduce chemical usage, improve energy efficiency, and enable more adaptive cleaning recipes for heterogeneous integration and new materials. Concerns often revolve around the complexity of integrating AI into existing infrastructure, the need for vast datasets, and the cybersecurity implications of connected cleaning equipment. Expectations are high for AI to lead to smarter, more autonomous cleaning systems that can preemptively address issues and significantly boost manufacturing yields and overall operational efficiency.

- Predictive Maintenance: AI algorithms analyze equipment sensor data to forecast potential failures, enabling proactive maintenance and minimizing unscheduled downtime, thereby improving equipment uptime and overall factory throughput.

- Process Optimization: AI-driven systems dynamically adjust cleaning parameters, such as chemical concentrations, temperature, and flow rates, based on real-time wafer conditions and process feedback, ensuring optimal contaminant removal and minimal wafer damage.

- Real-time Defect Detection: AI-powered vision systems enhance the identification and classification of minuscule defects and residues on wafer surfaces with unprecedented speed and accuracy, surpassing human capabilities and enabling immediate corrective actions.

- Intelligent Recipe Adjustment: Machine learning models analyze historical cleaning data and yield results to generate and refine cleaning recipes, adaptively optimizing them for different wafer types, process steps, and evolving contamination challenges.

- Enhanced Resource Management: AI optimizes the usage of expensive cleaning chemicals and ultrapure water, contributing to significant cost savings and reducing the environmental footprint of semiconductor manufacturing by identifying the most efficient consumption patterns.

- Automated Fault Diagnostics: AI systems can quickly pinpoint the root cause of cleaning anomalies or equipment malfunctions, drastically reducing diagnostic times and accelerating the resolution of complex operational issues within the fab.

DRO & Impact Forces Of Wafer Cleaning Equipment Market

The Wafer Cleaning Equipment Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers propelling market growth include the relentless miniaturization of semiconductor devices, which necessitates increasingly stringent cleaning requirements to prevent yield losses at advanced process nodes. The surging global demand for consumer electronics, driven by 5G, AI, IoT, and high-performance computing applications, directly translates into higher production volumes for semiconductors and consequently, wafer cleaning equipment. Furthermore, the rapid expansion of advanced packaging technologies, such as 3D ICs and fan-out wafer-level packaging, introduces new cleaning challenges that require specialized and more sophisticated solutions, further boosting market demand.

However, the market also faces considerable restraints. The extremely high capital expenditure required for advanced wafer cleaning equipment acts as a significant barrier for new entrants and smaller foundries. The complexity of modern cleaning processes, often involving multi-step sequences with various chemistries, demands highly skilled personnel and poses challenges in process control and optimization. Moreover, increasingly stringent environmental regulations regarding the disposal of hazardous chemicals and the consumption of ultrapure water force manufacturers to invest in costly abatement systems and develop more eco-friendly cleaning solutions, adding to operational expenses. Supply chain vulnerabilities, exacerbated by geopolitical tensions and global events, can also disrupt the availability of critical components and raw materials.

Opportunities within the market abound, particularly with the emergence of novel cleaning chemistries and advanced physical cleaning methods that promise improved efficiency and reduced environmental impact. The ongoing development of 3D ICs and heterogeneous integration technologies presents unique cleaning challenges and opportunities for specialized equipment. Increased automation and the integration of AI and machine learning into cleaning processes offer avenues for significant efficiency gains, predictive maintenance, and adaptive process control. Additionally, the growing focus on sustainability and green manufacturing practices worldwide opens doors for innovative, resource-efficient cleaning solutions. The expansion of fabrication capacity globally, driven by various government incentives and strategic investments, creates new installation opportunities for wafer cleaning equipment manufacturers.

Segmentation Analysis

The Wafer Cleaning Equipment Market is comprehensively segmented across several crucial dimensions to provide a granular understanding of its dynamics and growth trajectories. These segmentations typically include classifications by technology, cleaning method, wafer size, and specific application areas. Each segment highlights distinct market needs, technological preferences, and growth drivers, reflecting the diverse requirements of the semiconductor manufacturing ecosystem. Understanding these segments is vital for stakeholders to identify niche opportunities, tailor product development, and strategize market entry effectively, addressing the unique demands from different end-user industries and fabrication processes.

- By Technology

- Wet Cleaning: Predominantly uses chemical solutions and ultrapure water.

- SC-1 (Standard Clean 1)

- SC-2 (Standard Clean 2)

- Diluted Hydrofluoric Acid (DHF)

- Ozonated Water Cleaning

- Advanced Megasonic/Ultrasonic Cleaning

- SPM (Sulfuric Peroxide Mixture) Cleaning

- Dry Cleaning: Utilizes physical or chemical reactions in a gaseous or non-liquid phase.

- Plasma Cleaning

- Laser Cleaning

- UV Ozone Cleaning

- Cryogenic Aerosol Cleaning (CO2 Snow)

- Supercritical CO2 Cleaning

- Vapor Phase Cleaning

- Wet Cleaning: Predominantly uses chemical solutions and ultrapure water.

- By Cleaning Method

- Single-Wafer Cleaning: Processes one wafer at a time, offering precise control and minimal cross-contamination.

- Batch Immersion Cleaning: Cleans multiple wafers simultaneously in a batch, typically in wet benches.

- By Wafer Size

- 200mm Wafer: Used for mature technologies and specialty devices.

- 300mm Wafer: Dominant size for advanced logic and memory manufacturing.

- Emerging Wafer Sizes (e.g., 450mm): Research and development phase, with potential for future high-volume manufacturing.

- By Application

- Logic & Memory: Largest segment, driven by CPUs, GPUs, DRAM, and NAND flash.

- MEMS & Sensors: Requires specialized cleaning for delicate structures.

- Power Devices: High-voltage, high-current applications.

- Advanced Packaging: Cleaning before and after packaging steps (e.g., FOWLP, 3D ICs).

- LED & Optoelectronics: Specific cleaning needs for light-emitting and optical devices.

- Analog & Mixed Signal: Cleaning for devices combining analog and digital functionalities.

Value Chain Analysis For Wafer Cleaning Equipment Market

The value chain for the Wafer Cleaning Equipment Market is intricate, involving a series of interconnected stages from raw material sourcing to end-user application, highlighting the complex ecosystem of semiconductor manufacturing. At the upstream level, the chain begins with suppliers of critical components and materials essential for building the cleaning machinery. This includes specialized chemical manufacturers providing high-purity cleaning agents, ultrapure water systems, robotic arm suppliers for automated wafer handling, advanced pump and valve manufacturers for fluid delivery, and precision engineering firms for various mechanical and optical components. The quality and reliability of these upstream inputs directly influence the performance and longevity of the final cleaning equipment.

The midstream of the value chain is dominated by the wafer cleaning equipment manufacturers themselves. These companies engage in extensive research and development, designing, assembling, and testing sophisticated cleaning systems. Their activities involve integrating various technologies, ensuring high precision, throughput, and process control. Downstream, the primary users or buyers of this equipment are semiconductor fabrication plants (fabs), including integrated device manufacturers (IDMs), pure-play foundries, and outsourced semiconductor assembly and test (OSAT) companies. These end-users integrate the cleaning equipment into their complex manufacturing lines, where it performs critical functions at various stages of wafer processing, from initial bare wafer cleaning to post-etch and pre-deposition cleaning steps.

Distribution channels for wafer cleaning equipment are primarily direct, given the high value, technical complexity, and customization often required. Equipment manufacturers typically sell directly to major semiconductor fabs, providing extensive pre-sales consultation, installation, and ongoing maintenance and support services. Indirect channels, involving specialized distributors or agents, may also be utilized for reaching smaller regional players or for specific component sales. Post-sales services, including spare parts supply, software updates, and technical training, form a crucial part of the value chain, ensuring the continuous optimal performance of the equipment throughout its lifecycle and maintaining strong customer relationships. The entire value chain is characterized by a strong emphasis on precision, quality, and close collaboration between suppliers, manufacturers, and end-users to meet the rigorous demands of the semiconductor industry.

Wafer Cleaning Equipment Market Potential Customers

Potential customers for wafer cleaning equipment primarily comprise entities engaged in the various stages of semiconductor manufacturing, ranging from initial wafer fabrication to final device assembly. These end-users are characterized by their critical need for ultra-clean wafer surfaces to ensure high yields, device performance, and long-term reliability of integrated circuits. The rigorous demands of advanced technology nodes mean that cleaning equipment is an indispensable capital investment for any facility producing cutting-edge semiconductor devices, making these companies the core target market.

Integrated Device Manufacturers (IDMs) represent a significant customer segment. These companies design, manufacture, and sell their own semiconductor products, often managing their entire fabrication process internally. Leading IDMs like Intel, Samsung (for its memory and logic divisions), Micron Technology, and SK Hynix operate extensive fabs that require a constant supply of state-of-the-art wafer cleaning solutions to support their diverse product portfolios, from advanced processors to memory chips. Their continuous investment in new fabs and technology upgrades drives consistent demand.

Pure-play foundries, such as TSMC, GlobalFoundries, and UMC, constitute another major customer base. These companies specialize exclusively in manufacturing chips designed by other fabless semiconductor companies. As they serve a wide array of clients across various technology nodes and applications, foundries demand highly versatile, efficient, and reliable wafer cleaning equipment to handle diverse manufacturing requirements at very high volumes. Additionally, Outsourced Semiconductor Assembly and Test (OSAT) companies, while primarily focused on later stages, may also require specialized cleaning equipment for post-dicing, post-grinding, or advanced packaging processes to remove residues before final assembly and testing, ensuring the integrity of packaged devices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $6.2 Billion |

| Market Forecast in 2032 | $10.51 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCREEN Holdings Co., Ltd., Tokyo Electron Limited (TEL), Lam Research Corporation, Applied Materials, Inc., Ebara Corporation, SEMES Co., Ltd., Falcon Process Systems, Modutek Corporation, Akrion Systems LLC, KLA Corporation, NAURA Technology Group Co., Ltd., Rorze Corporation, Hantech Co., Ltd., ACM Research, Inc., Entegris, Inc., Hitachi Kokusai Electric Inc., FSI International, Inc., Mattson Technology, Inc., Recif Technologies, Veeco Instruments Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wafer Cleaning Equipment Market Key Technology Landscape

The Wafer Cleaning Equipment Market is characterized by a rapidly evolving technological landscape, driven by the relentless pursuit of smaller feature sizes, novel materials, and increasingly complex device architectures. Traditional wet cleaning processes remain foundational, leveraging sophisticated chemical mixtures like Standard Clean (SC-1, SC-2), diluted hydrofluoric acid (DHF), and sulfuric peroxide mixtures (SPM) combined with ultrapure water. However, these methods are continuously being refined with advancements such as megasonic and ultrasonic agitation, which enhance particle removal efficiency by inducing cavitation and acoustic streaming near the wafer surface, improving cleaning effectiveness for sub-nanometer contaminants without causing damage.

Beyond conventional wet cleaning, the industry is witnessing significant innovation in dry cleaning technologies, particularly as an alternative for sensitive materials and processes where liquid exposure can be detrimental. Plasma cleaning, for instance, utilizes reactive gases to remove organic residues and native oxides through chemical reactions and physical sputtering, offering a residue-free and precise cleaning solution. Cryogenic aerosol cleaning, employing CO2 snow jets, provides a gentle yet effective way to remove particles from delicate structures without chemical etching or static discharge issues. UV ozone cleaning is another dry method gaining traction for organic contamination removal, leveraging ultraviolet light to generate ozone that oxidizes organic films into volatile compounds.

Furthermore, there is a growing emphasis on developing environmentally sustainable cleaning solutions, leading to research in advanced methodologies like supercritical CO2 cleaning. This technique uses CO2 in its supercritical state, which possesses properties of both a gas and a liquid, to dissolve and remove contaminants, offering a solvent-free and residue-free cleaning process with minimal environmental impact. The integration of advanced process control, real-time monitoring, and data analytics, often powered by AI and machine learning, is also becoming a critical technological trend, enabling adaptive cleaning recipes, predictive maintenance, and optimized chemical usage, thereby pushing the boundaries of cleaning efficiency and yield enhancement in semiconductor manufacturing.

Regional Highlights

- Asia Pacific (APAC): This region stands as the undisputed leader in the Wafer Cleaning Equipment Market, driven by its extensive and rapidly expanding semiconductor manufacturing base. Countries like China, Taiwan, South Korea, and Japan host the majority of the world's leading foundries, IDMs, and advanced packaging facilities. Significant government investments, alongside private sector expansion, particularly in mainland China and Taiwan, are fueling unprecedented demand for advanced wafer cleaning equipment to support increased production capacity and the development of next-generation logic and memory chips. The region's strategic importance in the global technology supply chain means that any advancements or shifts in semiconductor manufacturing directly translate into high adoption rates for cutting-edge cleaning technologies here.

- North America: Known for its strong research and development capabilities and home to major technology innovators, North America represents a crucial market for wafer cleaning equipment. The region focuses heavily on advanced process nodes, R&D for new materials, and specialized applications like AI accelerators and high-performance computing. Recent initiatives to bring semiconductor manufacturing back onshore, coupled with substantial investments in new fabrication plants and technology upgrades, are stimulating demand. While perhaps not matching APAC's sheer volume of production, North America excels in driving innovation and developing highly sophisticated cleaning solutions for critical applications, maintaining a significant share in the high-end equipment segment.

- Europe: The European market for wafer cleaning equipment is characterized by its focus on niche applications, including automotive semiconductors, industrial IoT, and advanced research. Countries such as Germany, France, and the Netherlands house specialized fabs and research institutions that demand high-precision cleaning solutions. Although smaller in scale compared to APAC or North America in terms of overall fab capacity, Europe is a significant player in specific segments, particularly for power semiconductors and MEMS. The region is also at the forefront of developing sustainable manufacturing practices, driving demand for eco-friendly and resource-efficient cleaning technologies and processes.

- Latin America, Middle East, and Africa (MEA): These regions currently hold a smaller share of the global Wafer Cleaning Equipment Market but are emerging with nascent growth opportunities. While semiconductor manufacturing facilities are less concentrated here, increasing investments in technology infrastructure, particularly in countries like Israel (for R&D and specialized production) and other emerging economies, indicate potential for future market expansion. The demand is primarily driven by localized assembly and packaging operations, along with a growing interest in establishing domestic semiconductor capabilities, which may gradually increase the need for wafer cleaning solutions over the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wafer Cleaning Equipment Market.- SCREEN Holdings Co., Ltd.

- Tokyo Electron Limited (TEL)

- Lam Research Corporation

- Applied Materials, Inc.

- Ebara Corporation

- SEMES Co., Ltd.

- Falcon Process Systems

- Modutek Corporation

- Akrion Systems LLC

- KLA Corporation

- NAURA Technology Group Co., Ltd.

- Rorze Corporation

- Hantech Co., Ltd.

- ACM Research, Inc.

- Entegris, Inc.

- Hitachi Kokusai Electric Inc.

- FSI International, Inc.

- Mattson Technology, Inc.

- Recif Technologies

- Veeco Instruments Inc.

Frequently Asked Questions

Why is wafer cleaning critical in semiconductor manufacturing?

Wafer cleaning is paramount because microscopic contaminants, even at sub-nanometer scales, can cause catastrophic defects in integrated circuits. These defects lead to device failures, reduced yield, and diminished performance, especially in advanced nodes where feature sizes are extremely small. Effective cleaning ensures a pristine surface, crucial for subsequent critical processes like deposition, lithography, and etching, thereby maximizing device functionality and reliability.

What are the primary types of wafer cleaning technologies?

The two primary categories are wet cleaning and dry cleaning. Wet cleaning utilizes chemical solutions and ultrapure water, often employing megasonic or ultrasonic agitation, for broad-spectrum contaminant removal. Dry cleaning involves gaseous plasmas, UV light, lasers, or cryogenic aerosols to remove specific contaminants without liquid contact, which is often preferred for delicate structures or sensitive materials. Both types are essential, often used in combination throughout the fabrication process.

How is AI impacting the wafer cleaning equipment market?

AI is transforming wafer cleaning by enabling advanced process control, predictive maintenance, and real-time defect detection. AI algorithms analyze vast datasets to optimize cleaning recipes, anticipate equipment failures, and improve efficiency. This leads to reduced chemical usage, lower operational costs, higher yields, and more adaptive cleaning solutions that can handle the complexities of advanced semiconductor manufacturing with greater precision and autonomy.

What are the key drivers for the growth of the Wafer Cleaning Equipment Market?

The market's growth is primarily driven by the continuous demand for semiconductor miniaturization, pushing towards smaller and more complex device structures. The global expansion of the semiconductor industry, fueled by applications in 5G, AI, IoT, and high-performance computing, necessitates increased production. Furthermore, the rising adoption of advanced packaging technologies and the need for higher manufacturing yields at critical process nodes significantly contribute to market expansion.

What are the emerging trends in wafer cleaning equipment?

Emerging trends include the development of eco-friendly and sustainable cleaning solutions to reduce chemical and water consumption, advanced single-wafer cleaning systems for enhanced process control and reduced cross-contamination, and the integration of AI and machine learning for predictive capabilities and autonomous operation. There's also a growing focus on cleaning solutions tailored for novel materials, 3D ICs, and heterogeneous integration, addressing unique challenges in next-generation device fabrication.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager