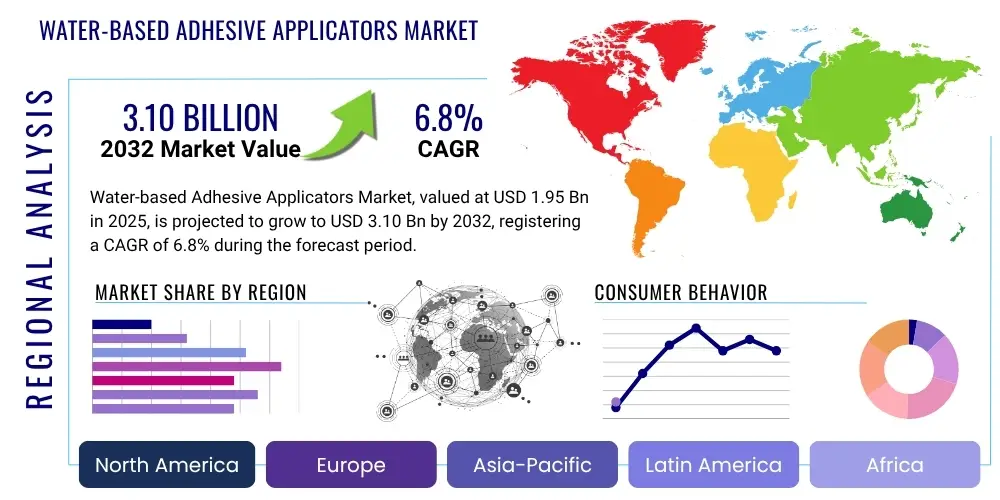

Water-based Adhesive Applicators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430415 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Water-based Adhesive Applicators Market Size

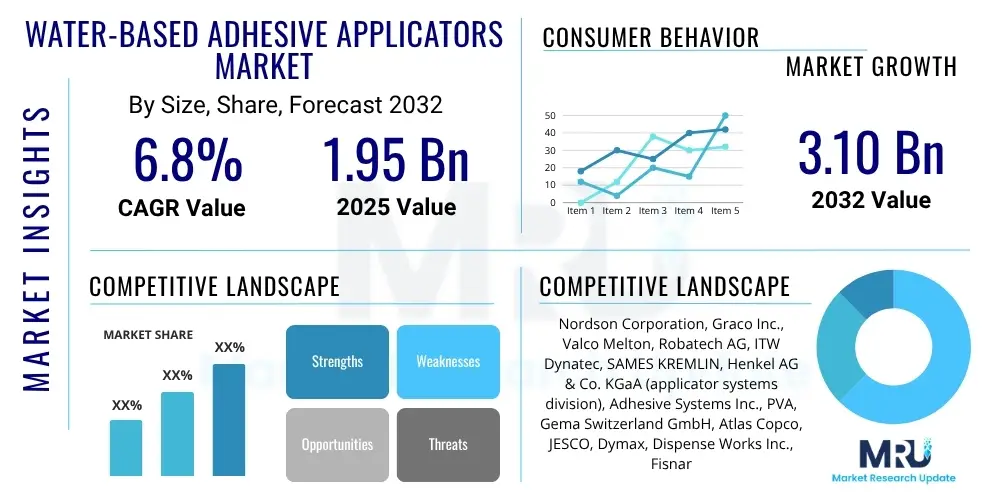

The Water-based Adhesive Applicators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $1.95 Billion in 2025 and is projected to reach $3.10 Billion by the end of the forecast period in 2032.

Water-based Adhesive Applicators Market introduction

The Water-based Adhesive Applicators Market encompasses a range of equipment designed to precisely and efficiently apply water-based adhesives across various industrial applications. These applicators are crucial for delivering liquid adhesives that utilize water as a carrier or solvent, offering numerous environmental and safety advantages over solvent-based alternatives. The market includes manual, semi-automatic, and fully automatic systems, catering to diverse production scales and operational complexities.

The product description spans from simple hand-held dispensers to sophisticated robotic systems integrated into high-speed production lines. Major applications for water-based adhesive applicators are extensive, including the packaging industry for carton sealing and labeling, woodworking for furniture assembly, automotive for interior components, construction for flooring and paneling, and textiles for fabric bonding. The primary benefits driving the adoption of these systems include their environmental friendliness, reduced volatile organic compound (VOC) emissions, enhanced worker safety, and the ability to achieve strong bonds with various substrates.

Key driving factors for market growth include the increasing global emphasis on sustainability and stringent environmental regulations promoting eco-friendly manufacturing processes. Furthermore, the rising demand for automated solutions in industrial settings to improve efficiency and reduce labor costs, coupled with the continuous expansion of end-use industries such as packaging and construction, significantly contributes to the market's positive trajectory. Technological advancements leading to more precise, faster, and versatile applicator systems are also propelling market expansion.

Water-based Adhesive Applicators Market Executive Summary

The Water-based Adhesive Applicators Market is experiencing robust growth driven by a confluence of business trends, regional dynamics, and segmental advancements. A significant business trend is the widespread adoption of automation and digitalization in manufacturing processes, leading to increased demand for high-precision, automated adhesive application systems. Companies are investing in smart applicators equipped with sensors and control systems to optimize adhesive consumption and ensure consistent application quality. The shift towards sustainable manufacturing practices is also a core driver, with water-based adhesives gaining preference due to lower VOC emissions and enhanced worker safety, consequently boosting the market for compatible applicators.

Regionally, Asia Pacific stands out as the fastest-growing market, propelled by rapid industrialization, expanding manufacturing sectors, particularly in packaging, automotive, and electronics, and a growing consumer base demanding packaged goods. North America and Europe demonstrate mature markets characterized by stringent environmental regulations and a strong emphasis on automation and advanced manufacturing technologies, leading to steady demand for sophisticated and efficient applicator solutions. Latin America, the Middle East, and Africa are emerging regions, showcasing promising growth opportunities due to increasing foreign investments and developing industrial infrastructures.

Segmental trends highlight a strong demand for automatic applicators, which offer superior speed, accuracy, and repeatability crucial for high-volume production lines. The packaging industry continues to be the largest end-use segment, driven by the expanding e-commerce sector and the need for efficient and reliable package sealing. Innovations in component technology, such as advanced nozzles and sophisticated control systems, are enhancing the performance and versatility of these applicators, enabling their use across a broader range of applications and materials, thereby contributing significantly to overall market expansion and technological evolution.

AI Impact Analysis on Water-based Adhesive Applicators Market

Common user questions regarding AI's impact on the Water-based Adhesive Applicators Market often revolve around how artificial intelligence can enhance precision, optimize processes, and improve predictive maintenance capabilities. Users are keen to understand how AI can lead to more efficient adhesive usage, reduce waste, and ensure higher quality control in applications ranging from intricate electronics assembly to large-scale packaging operations. There is also significant interest in AI's role in integrating applicator systems within broader Industry 4.0 frameworks, enabling smarter factories and more autonomous production lines, while also addressing concerns about implementation costs and the required technical expertise.

- Enhanced Precision and Consistency: AI algorithms can analyze real-time data from sensors to adjust adhesive flow rates, patterns, and temperatures, ensuring optimal application and bond strength, minimizing defects.

- Predictive Maintenance: AI can monitor applicator performance, identify anomalies, and predict potential equipment failures before they occur, enabling proactive maintenance, reducing downtime, and extending equipment lifespan.

- Process Optimization: Machine learning models can analyze production data to optimize applicator settings for different substrates and environmental conditions, leading to reduced adhesive consumption and increased production efficiency.

- Quality Control and Defect Detection: AI-powered vision systems can inspect applied adhesive patterns for accuracy and consistency, immediately flagging any imperfections or deviations, thereby improving product quality and reducing rework.

- Automation and Robotics Integration: AI facilitates seamless integration of adhesive applicators with robotic systems, enabling complex and repetitive application tasks with greater autonomy, speed, and accuracy, particularly in high-volume manufacturing.

- Supply Chain and Inventory Management: AI can predict adhesive demand based on production schedules and historical data, optimizing inventory levels and ensuring timely procurement of materials for applicator systems.

DRO & Impact Forces Of Water-based Adhesive Applicators Market

The Water-based Adhesive Applicators Market is shaped by a complex interplay of drivers, restraints, and opportunities, all influenced by various impact forces. The primary drivers include the escalating demand for environmentally friendly manufacturing solutions, spurred by global sustainability initiatives and stringent regulations limiting volatile organic compound (VOC) emissions. Furthermore, the growing trend of automation across diverse industrial sectors, aiming to enhance efficiency and productivity, significantly boosts the adoption of advanced adhesive application systems. Expanding end-use industries, particularly packaging, construction, and automotive, due to population growth and urbanization, also fuels market expansion. Technological advancements leading to more precise and versatile applicator designs further contribute to this positive momentum.

However, the market faces several restraints that could impede its growth. The relatively high initial investment cost associated with advanced automated adhesive applicator systems can be a barrier for small and medium-sized enterprises (SMEs), especially in developing regions. Additionally, water-based adhesives often have longer drying or curing times compared to solvent-based alternatives, which can impact production speeds in certain high-throughput applications. Competition from alternative bonding methods and adhesive technologies, such as hot-melt or solvent-based systems, also poses a challenge, particularly where specific performance characteristics are prioritized over environmental considerations. The need for specialized knowledge and training for operating and maintaining sophisticated systems can also be a limiting factor.

Opportunities for market players primarily lie in developing innovative, cost-effective, and highly efficient applicator technologies that cater to niche applications and emerging markets. The increasing focus on smart manufacturing and Industry 4.0 presents avenues for integrating AI and IoT capabilities into applicator systems for predictive maintenance, process optimization, and real-time monitoring. Geographically, expanding into developing economies with burgeoning industrial bases offers substantial growth prospects. The impact forces analysis reveals that the bargaining power of buyers is moderate to high due to the availability of multiple suppliers and alternative solutions, while the bargaining power of suppliers is moderate, dependent on the specialization of components. The threat of new entrants is moderate due to capital requirements and technological expertise, and the threat of substitutes is also moderate given the continuous innovation in adhesive technologies. Competitive rivalry remains high among established players, driving continuous product development and differentiation.

Segmentation Analysis

The Water-based Adhesive Applicators Market is comprehensively segmented based on various criteria to provide a detailed understanding of its dynamics and growth prospects. These segments allow for a granular analysis of market trends, consumer preferences, and technological advancements across different application methods, system types, end-use industries, and specific components. Understanding these segments is crucial for stakeholders to identify key growth areas and formulate effective business strategies, enabling targeted product development and market penetration efforts.

- By Type:

- Manual Applicators

- Semi-Automatic Applicators

- Automatic Applicators

- By End-Use Industry:

- Packaging Industry

- Woodworking Industry

- Automotive Industry

- Construction Industry

- Textile Industry

- Others (e.g., Electronics, Medical, Bookbinding)

- By Component:

- Nozzles and Tips

- Hoses and Connectors

- Pumps and Tanks

- Control Systems

- Filters and Regulators

- Other Accessories

- By Application Method:

- Spraying

- Rolling

- Extrusion

- Brushing

- Troweling

Value Chain Analysis For Water-based Adhesive Applicators Market

The value chain for the Water-based Adhesive Applicators Market begins with upstream activities involving the procurement of raw materials and specialized components. Key upstream suppliers provide metals (such as stainless steel and aluminum), various plastics for casings and non-corrosive parts, electronic components for control systems, and precision-machined parts for nozzles and pumps. These suppliers play a critical role in providing high-quality, durable materials that meet the stringent performance requirements for adhesive application equipment. Manufacturers of applicator systems then engage in design, engineering, assembly, and testing phases to produce a wide range of manual, semi-automatic, and automatic solutions, incorporating advanced technologies to enhance precision and efficiency.

Downstream analysis involves the distribution and ultimate application of these systems by end-users. After manufacturing, the products move through various distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large industrial clients or through their own sales forces, providing customized solutions and after-sales support. Indirect channels include a network of distributors, resellers, and system integrators who market and sell applicators to a broader customer base, often bundled with installation, training, and maintenance services. These intermediaries are vital for reaching diverse end-use industries, including packaging, woodworking, automotive, and construction, which are the ultimate buyers and users of these sophisticated systems.

The distribution channels are crucial for market penetration and customer reach. Direct distribution allows for stronger client relationships and tailored solutions, particularly for complex industrial setups requiring extensive integration. Indirect channels, through specialized distributors, provide broader market access, leverage existing sales networks, and offer localized support and maintenance. Both direct and indirect distribution strategies are essential for manufacturers to effectively serve the diverse needs of the global Water-based Adhesive Applicators Market, ensuring that products reach potential customers efficiently and with appropriate technical assistance.

Water-based Adhesive Applicators Market Potential Customers

Potential customers for Water-based Adhesive Applicators span a wide array of manufacturing and industrial sectors that rely on efficient and precise adhesive bonding for their production processes. The primary end-users are manufacturers engaged in large-scale production where bonding, sealing, or lamination is a critical step. These industries often require solutions that offer high throughput, consistent application quality, and adhere to environmental and safety standards, making water-based applicators a highly attractive option.

A significant segment of buyers originates from the packaging industry, including companies that produce corrugated boxes, flexible packaging, labels, and food and beverage containers. These entities utilize applicators for carton sealing, tray forming, and product labeling, driven by the ever-increasing demand for packaged goods and the need for robust, tamper-evident seals. Another major customer base is the woodworking and furniture manufacturing sector, where these applicators are essential for assembling cabinets, chairs, and various wood components, providing strong and durable bonds.

Other key potential customers include the automotive industry for interior trim bonding and assembly, the construction industry for flooring, paneling, and insulation applications, and the textile industry for fabric lamination and garment assembly. Furthermore, manufacturers in electronics, medical devices, and bookbinding also represent growing segments of end-users who seek precision and reliability in their adhesive application processes, increasingly preferring water-based solutions due to their performance and environmental benefits. The diversity of these sectors highlights the broad applicability and integral role of water-based adhesive applicators in modern manufacturing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.95 Billion |

| Market Forecast in 2032 | $3.10 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nordson Corporation, Graco Inc., Valco Melton, Robatech AG, ITW Dynatec, SAMES KREMLIN, Henkel AG & Co. KGaA (applicator systems division), Adhesive Systems Inc., PVA, Gema Switzerland GmbH, Atlas Copco, JESCO, Dymax, Dispense Works Inc., Fisnar, Sealant Equipment & Engineering, Inc., DP Engineers |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water-based Adhesive Applicators Market Key Technology Landscape

The Water-based Adhesive Applicators Market is characterized by a dynamic technology landscape continually evolving to meet the demands for higher precision, greater efficiency, and seamless integration into modern manufacturing environments. A pivotal technological advancement is the development of highly precise dispensing systems, including advanced nozzles and control valves, which allow for extremely accurate and consistent adhesive application, minimizing waste and optimizing bond quality. These systems often incorporate piezoelectric or servo motor technology for ultrafast and repeatable dispensing, crucial for high-speed production lines.

Another significant area of innovation involves automation and robotics. Collaborative robots (cobots) and industrial robots are increasingly being integrated with water-based adhesive applicators to perform complex and repetitive tasks with superior accuracy and speed, reducing human error and improving ergonomic conditions. This integration is supported by sophisticated software for path planning and real-time adjustments, enabling adaptive application based on varying product geometries or surface conditions. The trend towards Industry 4.0 also drives the adoption of IoT sensors and connectivity, allowing for real-time monitoring of applicator performance, adhesive levels, and system diagnostics.

Furthermore, the development of intelligent control systems, often leveraging AI and machine learning, enables predictive maintenance, process optimization, and enhanced quality control. These smart systems can analyze operational data to anticipate maintenance needs, optimize application parameters for different substrates, and detect anomalies in real-time, significantly boosting overall equipment effectiveness (OEE). Modular designs, user-friendly interfaces, and energy-efficient components are also key technological trends, making these applicators more versatile, easier to maintain, and more sustainable, aligning with the core benefits of water-based adhesive usage.

Regional Highlights

- North America: Characterized by a mature industrial base and stringent environmental regulations, driving demand for advanced, automated, and eco-friendly applicator systems. High adoption of sophisticated equipment in automotive, packaging, and construction sectors.

- Europe: Strong emphasis on sustainable manufacturing and automation, leading to steady growth. Germany, France, and Italy are key contributors, driven by innovation in machinery and high-value manufacturing industries.

- Asia Pacific (APAC): The fastest-growing market, fueled by rapid industrialization, expanding manufacturing capabilities, and increasing consumer demand in countries like China, India, and Japan. Significant investment in automation and adoption of water-based solutions across packaging and electronics.

- Latin America: Emerging market with growing industrialization and increasing foreign investments, particularly in Brazil and Mexico. Demand is rising in packaging and automotive sectors, driven by economic development.

- Middle East and Africa (MEA): Gradually developing market with opportunities in construction and packaging due to infrastructure development and urbanization. Adoption of modern applicator technologies is increasing, albeit at a slower pace compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water-based Adhesive Applicators Market.- Nordson Corporation

- Graco Inc.

- Valco Melton

- Robatech AG

- ITW Dynatec

- SAMES KREMLIN

- Henkel AG & Co. KGaA (applicator systems division)

- Adhesive Systems Inc.

- PVA

- Gema Switzerland GmbH

- Atlas Copco

- JESCO

- Dymax

- Dispense Works Inc.

- Fisnar

- Sealant Equipment & Engineering, Inc.

- DP Engineers

Frequently Asked Questions

What are the primary benefits of using water-based adhesive applicators?

Water-based adhesive applicators offer significant benefits including reduced VOC emissions, improved worker safety, ease of cleanup, and compliance with environmental regulations, making them ideal for sustainable manufacturing practices.

Which industries are the largest users of water-based adhesive applicators?

The packaging industry is the largest end-user, utilizing these applicators for carton sealing, labeling, and product assembly. Other major industries include woodworking, automotive, construction, and textiles.

How does AI impact the efficiency of water-based adhesive applicators?

AI enhances efficiency by enabling real-time process optimization, predictive maintenance to minimize downtime, precise control over adhesive dispensing for reduced waste, and automated quality checks for consistent application.

What are the key types of water-based adhesive applicators available in the market?

The market primarily offers manual applicators for low-volume or specialized tasks, semi-automatic systems for moderate production, and fully automatic applicators for high-speed, high-volume industrial applications.

What challenges does the Water-based Adhesive Applicators Market face?

Key challenges include the relatively higher initial investment costs for advanced systems, the longer drying or curing times of some water-based adhesives, and competition from alternative adhesive technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager