Water Tube Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427842 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Water Tube Chemical Boiler Market Size

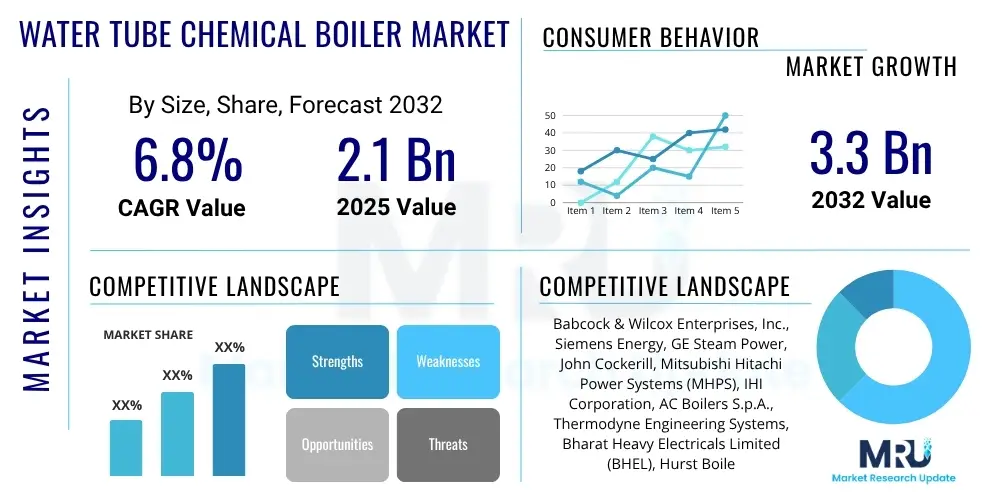

The Water Tube Chemical Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.1 Billion in 2025 and is projected to reach USD 3.3 Billion by the end of the forecast period in 2032.

Water Tube Chemical Boiler Market introduction

The Water Tube Chemical Boiler Market is a critical segment within the industrial equipment landscape, serving as the backbone for various energy-intensive processes across diverse sectors. These specialized boilers are engineered to produce high-pressure and high-temperature steam or hot water by circulating water through tubes heated by hot gases, a design renowned for its efficiency, reliability, and safety in demanding industrial environments. Their robust construction and capability to handle varying loads make them indispensable for applications requiring consistent and reliable energy supply.

The product's description centers on its unique design where water flows inside tubes, which are then externally heated by hot combustion gases. This configuration allows for rapid steam generation, excellent heat transfer efficiency, and superior performance under high-pressure conditions compared to fire tube designs. Water tube boilers are particularly favored in chemical processing due, in part, to their ability to provide the precise temperature and pressure controls necessary for complex reactions and energy recovery systems. Furthermore, they are adaptable to various fuel types, including natural gas, oil, biomass, and industrial waste heat, offering operational flexibility and contributing to energy diversification strategies.

Major applications for water tube chemical boilers span a broad spectrum of industries, including petrochemicals, power generation, pulp and paper, metals and mining, and food and beverage manufacturing. In chemical plants, they are crucial for driving separation processes, heating reactors, and generating power for plant operations. Benefits of these boilers include enhanced operational safety due to their inherent design that minimizes explosion risks, superior energy efficiency resulting in lower fuel consumption, and reduced environmental impact through optimized combustion and emission control. Driving factors for market growth include the ongoing industrialization in emerging economies, the escalating demand for energy-efficient solutions, and increasingly stringent environmental regulations mandating cleaner energy production and waste heat recovery.

Water Tube Chemical Boiler Market Executive Summary

The Water Tube Chemical Boiler Market is experiencing dynamic shifts driven by global industrial expansion, technological advancements, and a growing emphasis on sustainability and operational efficiency. Current business trends indicate a strong focus on modular designs, automation, and digital integration, including the adoption of Industrial Internet of Things (IIoT) for enhanced monitoring and predictive maintenance. Companies are investing in R&D to develop boilers that offer greater fuel flexibility, reduced emissions, and improved thermal performance, aligning with global efforts to decarbonize industrial processes and enhance energy security.

Regional trends reveal significant growth in Asia-Pacific, particularly in countries undergoing rapid industrialization such as China, India, and Southeast Asian nations, where robust demand from chemical, petrochemical, and power generation sectors fuels market expansion. North America and Europe, while mature markets, are witnessing a surge in demand for boiler modernizations, upgrades, and replacements that comply with stringent environmental regulations and leverage advanced technologies for greater energy efficiency. Latin America and the Middle East & Africa regions are also showing steady growth, driven by investments in new infrastructure projects and the expansion of oil & gas and chemical processing industries, highlighting the global relevance of water tube chemical boiler solutions.

Segmentation trends indicate increasing demand for high-capacity, high-pressure boilers capable of producing superheated steam for advanced industrial processes and combined cycle power plants. There is also a notable shift towards boilers designed for waste heat recovery, enabling industries to maximize energy utilization and reduce operational costs. The end-user landscape sees chemical and petrochemical industries remaining dominant, but significant growth is also observed in the power generation sector, particularly with the transition towards more efficient thermal power plants and the integration of renewable energy sources, underscoring the versatility and critical role of water tube chemical boilers in diverse industrial ecosystems.

AI Impact Analysis on Water Tube Chemical Boiler Market

The integration of Artificial Intelligence (AI) is set to revolutionize the Water Tube Chemical Boiler Market by addressing key operational challenges, enhancing efficiency, and ensuring greater safety and reliability. Common user questions revolve around how AI can optimize boiler performance, predict maintenance needs, reduce energy consumption, and contribute to safer operations. Users are keen to understand AI's role in improving combustion efficiency, automating control systems, and transforming traditional maintenance practices into more proactive, data-driven strategies. The overarching expectation is that AI will unlock new levels of operational intelligence and cost savings in complex industrial boiler systems.

AI's influence extends across the entire lifecycle of water tube chemical boilers, from design and manufacturing to operational management and maintenance. In the design phase, AI can accelerate the simulation and optimization of boiler configurations, material selection, and fluid dynamics, leading to more efficient and robust designs. During operation, AI-powered control systems can dynamically adjust parameters such as fuel-air ratios, feedwater flow, and steam output in real-time, based on predictive models and operational data, thereby maximizing thermal efficiency and minimizing fuel consumption. This intelligent automation contributes significantly to reducing greenhouse gas emissions and operational costs, a major concern for industrial end-users.

Furthermore, AI is transforming boiler maintenance from reactive to predictive. By analyzing vast datasets from sensors monitoring temperature, pressure, vibration, and chemical composition, AI algorithms can detect subtle anomalies and predict potential equipment failures before they occur. This enables timely interventions, reduces unscheduled downtime, and extends the operational lifespan of critical components. The ability of AI to process and interpret complex operational data provides operators with actionable insights, leading to more informed decision-making, enhanced safety protocols, and a significant reduction in operational risks associated with high-pressure boiler systems. As a result, AI is becoming an indispensable tool for achieving higher levels of operational excellence and sustainability in the water tube chemical boiler sector.

- Predictive Maintenance: AI algorithms analyze sensor data to forecast equipment failures, enabling proactive repairs and significantly reducing unscheduled downtime and maintenance costs for water tube chemical boilers.

- Operational Optimization: AI-powered control systems dynamically adjust combustion processes, fuel-air mixture, and steam generation parameters in real-time to maximize thermal efficiency and minimize fuel consumption.

- Enhanced Safety: AI-driven anomaly detection and predictive analytics identify potential hazards, pressure fluctuations, or material degradation, allowing for early intervention and improving overall operational safety of boiler units.

- Design and Engineering: AI facilitates rapid simulation and optimization of boiler designs, material selection, and component configurations, leading to more efficient, cost-effective, and robust chemical boiler systems.

- Emission Reduction: By precisely controlling combustion, AI helps to optimize fuel usage and reduce the emission of pollutants, aligning with stringent environmental regulations and sustainability goals.

DRO & Impact Forces Of Water Tube Chemical Boiler Market

The Water Tube Chemical Boiler Market is profoundly shaped by a confluence of Drivers, Restraints, and Opportunities, which collectively constitute its Impact Forces. Key drivers include the relentless expansion of industrial sectors globally, particularly in chemical processing, power generation, and manufacturing, all of which require reliable and efficient steam generation. Furthermore, the increasing global emphasis on energy efficiency and waste heat recovery solutions is pushing industries to adopt advanced boiler technologies that can convert waste energy into usable steam or electricity, thereby reducing operational costs and environmental footprints. Stringent environmental regulations aimed at reducing carbon emissions and improving air quality are also significant drivers, compelling industries to invest in cleaner, more efficient boiler systems and advanced emission control technologies.

However, several restraints temper the market's growth trajectory. The high initial capital investment required for purchasing and installing water tube chemical boilers poses a significant barrier, especially for smaller enterprises or those in developing regions. The operational complexity associated with managing high-pressure, high-temperature systems, coupled with the need for highly skilled personnel for maintenance and operation, adds to the overall operational expenditure. Additionally, the fluctuating prices of raw materials, such as steel and specialized alloys, and the volatility of fuel prices, can impact manufacturing costs and end-user adoption rates, creating economic uncertainties for market players. Regulatory hurdles, while driving innovation, can also present challenges in terms of compliance costs and delays in project approvals.

Despite these restraints, the market is rich with opportunities. The growing adoption of industrial digitalization and the Industrial Internet of Things (IIoT) offers immense potential for integrating advanced monitoring, predictive maintenance, and remote operational control capabilities into boiler systems, enhancing efficiency and reliability. Opportunities also emerge from the increasing demand for cogeneration and combined heat and power (CHP) systems, which leverage water tube boilers to produce both electricity and useful heat, maximizing energy utilization. Furthermore, the development of boilers capable of utilizing alternative fuels, including biomass, industrial waste, and hydrogen, presents a pathway for market diversification and sustainable growth. The expansion of chemical and petrochemical industries in emerging economies, coupled with modernization efforts in developed regions, further solidifies the market's long-term growth prospects, making the strategic management of these impact forces crucial for market success.

Segmentation Analysis

The Water Tube Chemical Boiler Market is comprehensively segmented to provide a detailed understanding of its diverse landscape, enabling stakeholders to identify specific growth areas, competitive advantages, and unmet needs. This segmentation is primarily based on boiler type, capacity, application, and end-user industry, reflecting the varied requirements and operational contexts across the global industrial sector. Each segment plays a crucial role in shaping market dynamics, influencing product development, distribution strategies, and market penetration efforts. Analyzing these segments helps in pinpointing market saturation levels, emerging demand patterns, and the technological preferences of different industrial users, thereby guiding strategic business decisions and investment priorities within the market.

- By Type: D-type Boiler, O-type Boiler, A-type Boiler, Other Types (e.g., M-type, Bi-drum)

- By Capacity: Small (Up to 10 TPH - Tons Per Hour), Medium (10-50 TPH), Large (Above 50 TPH)

- By Application: Steam Generation, Heat Recovery Steam Generators (HRSG), Power Generation, Cogeneration (CHP - Combined Heat and Power)

- By End-User Industry: Chemical & Petrochemical, Power Generation (Thermal, Nuclear), Pulp & Paper, Metals & Mining, Food & Beverage, Pharmaceuticals, Textiles, Others (e.g., Waste-to-Energy, District Heating)

Value Chain Analysis For Water Tube Chemical Boiler Market

The value chain for the Water Tube Chemical Boiler Market encompasses a comprehensive network of activities, starting from raw material sourcing through manufacturing, distribution, and ultimately to end-user operations and post-sales support. Understanding this chain is crucial for identifying key cost drivers, potential areas for optimization, and strategic opportunities for stakeholders. The efficiency and integration across these stages directly influence product quality, cost-effectiveness, and market competitiveness, driving value creation for both manufacturers and end-users alike. Effective management of each segment within this value chain is paramount for ensuring sustainable growth and market leadership in a highly competitive industrial landscape.

Upstream activities involve the procurement of specialized raw materials, including high-grade steel alloys for tubes, drums, and headers, refractory materials for insulation, specialized instrumentation components, and auxiliary equipment from various suppliers. These upstream partners are critical for ensuring the quality, durability, and operational safety of the boilers, as the performance of the final product is heavily dependent on the integrity of its constituent materials. Manufacturers engage in rigorous supplier selection and quality control processes to mitigate risks and ensure compliance with stringent industry standards, emphasizing reliability and material specifications vital for high-pressure applications.

Midstream activities primarily focus on the core manufacturing processes, which include the precision fabrication of boiler components, complex welding, assembly, and integration of sophisticated control systems. This stage also involves rigorous testing and quality assurance to meet international codes and client-specific requirements. Downstream activities cover the distribution, installation, commissioning, operation, and ongoing maintenance services for water tube chemical boilers. Distribution channels are varied, involving direct sales to large industrial clients, partnerships with engineering, procurement, and construction (EPC) firms, and a network of authorized distributors and agents. Post-sales support, including spare parts supply, technical assistance, and predictive maintenance programs, forms a crucial part of the value proposition, ensuring long-term operational reliability and customer satisfaction for the industrial end-user.

Water Tube Chemical Boiler Market Potential Customers

The potential customers for the Water Tube Chemical Boiler Market represent a diverse array of heavy industries and utility providers that rely heavily on robust and efficient steam generation for their core operations. These end-users are characterized by their substantial energy demands, their need for high-pressure and high-temperature steam, and often, stringent operational safety and environmental compliance requirements. Identifying and understanding the specific needs of these customer segments is vital for manufacturers and service providers to tailor their offerings, develop targeted marketing strategies, and foster long-term client relationships. The widespread utility of water tube boilers makes them indispensable across a multitude of industrial processes globally.

Primary end-users include the chemical and petrochemical sectors, where boilers are essential for heating reactors, driving distillation columns, and generating electricity for plant operations. Refineries, in particular, demand high-reliability boilers for continuous processing of crude oil into various petroleum products. Another significant customer base is the power generation industry, including thermal power plants and facilities utilizing combined heat and power (CHP) systems, which depend on water tube boilers to produce superheated steam for turbines to generate electricity. These customers prioritize efficiency, fuel flexibility, and compliance with emission regulations, driving demand for technologically advanced boiler solutions.

Beyond these major segments, the pulp and paper industry utilizes large water tube boilers for process heating, drying, and power generation from biomass waste. The metals and mining sector requires boilers for various heating processes and power supply, while the food and beverage industry uses them for sterilization, cooking, and pasteurization, albeit often at smaller scales. Furthermore, pharmaceuticals, textiles, and waste-to-energy plants also constitute important customer segments. The common thread among these diverse buyers is the critical need for a reliable, safe, and efficient source of steam or hot water to maintain production, ensure quality, and adhere to environmental standards, positioning water tube chemical boilers as a foundational industrial asset.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises, Inc., Siemens Energy, GE Steam Power, John Cockerill, Mitsubishi Hitachi Power Systems (MHPS), IHI Corporation, AC Boilers S.p.A., Thermodyne Engineering Systems, Bharat Heavy Electricals Limited (BHEL), Hurst Boiler & Welding Co., Inc., Cleaver-Brooks, Clayton Industries, Rentech Boiler Systems Inc., Foster Wheeler (now part of Amec Foster Wheeler / Wood Group), Doosan Lentjes, Kawasaki Heavy Industries, Miura America Co., Ltd., Superior Boiler Works, ZG Boiler (Zhengzhou Boiler Co., Ltd.), Hangzhou Boiler Group Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water Tube Chemical Boiler Market Key Technology Landscape

The Water Tube Chemical Boiler Market is continually evolving, driven by significant advancements in technology aimed at enhancing efficiency, reducing environmental impact, and improving operational safety and reliability. The key technology landscape is characterized by the integration of advanced materials, sophisticated control systems, and digital solutions that collectively optimize every aspect of boiler performance. These technological innovations are not only addressing current industrial demands but are also paving the way for future-proof energy solutions, ensuring that water tube boilers remain at the forefront of industrial steam and power generation. The push towards sustainable and smarter operations is a central theme within this technological evolution, influencing investment and development strategies across the market.

One prominent area of technological development involves the use of advanced materials science. Manufacturers are increasingly adopting high-strength, corrosion-resistant alloys for boiler tubes and components, which allows for operation at higher temperatures and pressures, thereby improving thermal efficiency and extending the operational lifespan of the boilers. New refractory materials and insulation techniques are also being implemented to minimize heat losses and enhance overall energy conservation. These material innovations contribute significantly to reducing maintenance requirements and ensuring the structural integrity of the boilers under extreme operating conditions, directly impacting the safety and reliability of chemical processing plants and power generation facilities.

Furthermore, the integration of digital technologies, including the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and advanced automation, is transforming boiler operation and maintenance. IIoT sensors collect real-time data on critical parameters, feeding into AI-driven analytics platforms that enable predictive maintenance, anomaly detection, and operational optimization. Digital twins, virtual replicas of physical boilers, are being used for simulation, performance analysis, and training, leading to more efficient designs and safer operational procedures. Advanced combustion control systems, often leveraging AI, ensure optimal fuel-air ratios, reducing emissions and maximizing energy conversion. These technologies collectively contribute to a paradigm shift towards smarter, more autonomous, and environmentally responsible water tube chemical boiler systems, providing operators with unprecedented levels of control and insight into their energy assets.

Regional Highlights

- North America: A mature market characterized by a strong focus on modernization, regulatory compliance for emission reduction, and the adoption of advanced boiler technologies for enhanced energy efficiency and industrial safety. The demand here is largely driven by replacements and upgrades in the chemical, petrochemical, and power generation sectors.

- Europe: Driven by stringent environmental regulations, a commitment to decarbonization, and investments in energy-efficient and waste-to-energy solutions. The market emphasizes high-performance boilers, integration with renewable energy systems, and advanced emission control technologies.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning demand from chemical, petrochemical, power generation, and manufacturing sectors in countries like China, India, and Southeast Asia. Significant infrastructure development and increasing energy demands are key market drivers.

- Latin America: Showing steady growth, primarily driven by investments in new industrial projects, expansion of the mining and oil & gas sectors, and infrastructure development. The region presents opportunities for both new installations and technology upgrades to meet growing industrial needs.

- Middle East and Africa (MEA): Growth is propelled by extensive investments in the oil & gas, chemical, and petrochemical industries, alongside increasing power generation capacity to support economic diversification and population growth. Demand for robust and reliable boiler systems is high in this resource-rich region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water Tube Chemical Boiler Market.- Babcock & Wilcox Enterprises, Inc.

- Siemens Energy

- GE Steam Power

- John Cockerill

- Mitsubishi Hitachi Power Systems (MHPS)

- IHI Corporation

- AC Boilers S.p.A.

- Thermodyne Engineering Systems

- Bharat Heavy Electricals Limited (BHEL)

- Hurst Boiler & Welding Co., Inc.

- Cleaver-Brooks

- Clayton Industries

- Rentech Boiler Systems Inc.

- Foster Wheeler (now part of Amec Foster Wheeler / Wood Group)

- Doosan Lentjes

- Kawasaki Heavy Industries

- Miura America Co., Ltd.

- Superior Boiler Works

- ZG Boiler (Zhengzhou Boiler Co., Ltd.)

- Hangzhou Boiler Group Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Water Tube Chemical Boiler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a water tube chemical boiler?

A water tube chemical boiler is an industrial heat exchanger where water circulates inside tubes heated by hot combustion gases, generating high-pressure steam or hot water for chemical processes, power generation, and other heavy industrial applications. Its design prioritizes efficiency, safety, and reliability under demanding conditions.

What are the primary applications of water tube chemical boilers?

Primary applications include steam generation for chemical and petrochemical processes, electricity production in power plants (thermal, combined cycle), heat recovery steam generation (HRSG), and process heating in industries such as pulp & paper, metals & mining, and food & beverage manufacturing.

How do water tube boilers contribute to energy efficiency?

Water tube boilers enhance energy efficiency through superior heat transfer, rapid steam generation, and the ability to operate at high pressures and temperatures. Modern designs often incorporate economizers and air preheaters, alongside advanced combustion controls, to maximize fuel utilization and minimize heat losses, often integrating waste heat recovery systems.

What impact do environmental regulations have on this market?

Environmental regulations significantly drive the market by mandating lower emissions (NOx, SOx, CO2) and promoting energy efficiency. This pushes manufacturers to innovate with cleaner combustion technologies, alternative fuel capabilities (e.g., biomass, hydrogen), and advanced flue gas treatment systems, leading to investments in modern, compliant boilers.

What are the key technological trends shaping the water tube boiler market?

Key trends include the integration of Industrial Internet of Things (IIoT) for real-time monitoring and predictive maintenance, AI-powered operational optimization and control systems, advanced material science for enhanced durability and efficiency, and the development of boilers compatible with diverse and sustainable fuel sources.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager