Welded Steel Tanks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429661 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Welded Steel Tanks Market Size

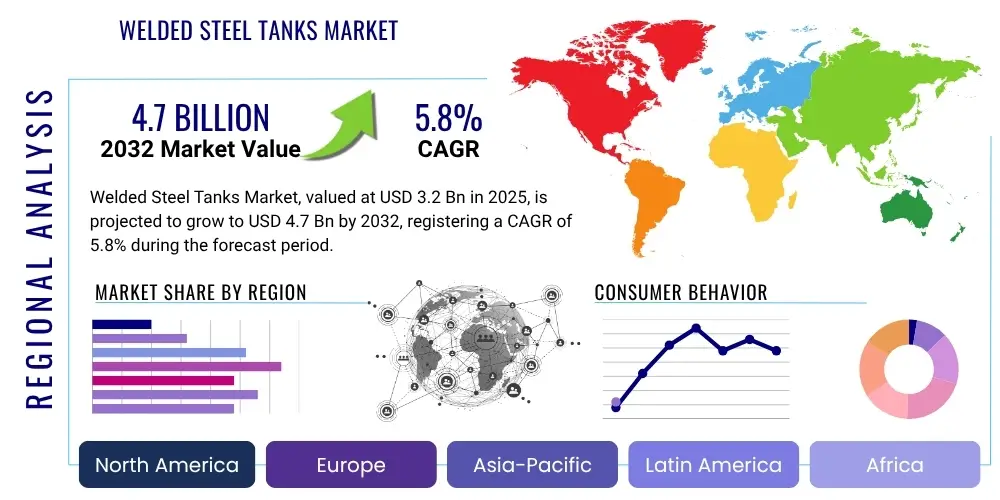

The Welded Steel Tanks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $3.2 Billion in 2025 and is projected to reach $4.7 Billion by the end of the forecast period in 2032.

Welded Steel Tanks Market introduction

The Welded Steel Tanks Market encompasses the design, fabrication, and installation of large-capacity storage tanks made from steel plates joined by welding. These robust structures are primarily utilized for the safe and efficient storage of various liquids and gases, including crude oil, refined petroleum products, chemicals, water, and wastewater. The inherent strength and durability of steel, combined with advanced welding techniques, ensure the integrity and longevity of these tanks, making them indispensable across numerous industrial sectors.

Major applications span critical infrastructure, energy, and industrial processes. The benefits associated with welded steel tanks include their substantial storage capacity, high structural integrity, adaptability to diverse environmental conditions, and the ability to customize designs to meet specific operational requirements. Key driving factors for market growth include accelerating global industrialization, increasing demand for energy storage infrastructure, expanding municipal water and wastewater treatment facilities, and stringent regulatory frameworks mandating safe storage solutions. Continuous advancements in material science and fabrication technologies further enhance their performance and cost-effectiveness, securing their vital role in global supply chains.

Welded Steel Tanks Market Executive Summary

The Welded Steel Tanks Market is experiencing significant expansion driven by robust industrial growth and infrastructure development worldwide. Business trends indicate a focus on advanced fabrication techniques, enhanced safety features, and smart tank technologies for remote monitoring and predictive maintenance. Companies are increasingly investing in automation and digital tools to optimize production processes and improve supply chain efficiency, aiming to meet rising demand for larger and more complex storage solutions while adhering to stringent environmental and safety regulations.

Regionally, the Asia Pacific market is poised for substantial growth due to rapid industrialization, urbanization, and large-scale infrastructure projects, particularly in emerging economies. North America and Europe demonstrate a steady demand, primarily driven by the need for maintenance, upgrading of aging infrastructure, and compliance with evolving environmental standards. Segments trends highlight a strong demand for tanks in the oil and gas sector, particularly for crude oil and LNG storage, alongside a growing need for water and wastewater treatment tanks due to global efforts in water resource management and conservation. The chemical industry also presents a consistent demand for specialized storage solutions, further diversifying market opportunities.

AI Impact Analysis on Welded Steel Tanks Market

Common user questions regarding AI's impact on the Welded Steel Tanks Market frequently center on how artificial intelligence can enhance efficiency, reduce costs, improve safety, and extend the lifespan of these critical assets. Users are keen to understand AI's role in optimizing design processes, automating quality control during fabrication, facilitating predictive maintenance, and streamlining complex supply chain logistics. There is also a strong interest in how AI can contribute to real-time monitoring and anomaly detection, addressing concerns about operational downtime and potential environmental hazards, ultimately leading to more resilient and intelligent storage infrastructure.

- Predictive maintenance for structural integrity and equipment longevity.

- Optimized design and engineering through AI-driven simulations and material selection.

- Automated quality control and inspection during fabrication to reduce defects.

- Enhanced safety protocols and risk assessment using AI for operational monitoring.

- Supply chain optimization for raw materials and logistics management.

- Real-time monitoring and anomaly detection for operational efficiency and early fault identification.

- Robotic welding and automated manufacturing processes for increased precision and speed.

DRO & Impact Forces Of Welded Steel Tanks Market

The Welded Steel Tanks Market is significantly propelled by the increasing global demand for energy, particularly from the oil and gas sector, necessitating vast storage infrastructure. Concurrently, rapid urbanization and industrial growth drive the need for reliable water and wastewater storage solutions, alongside expanding chemical and food processing industries. However, market growth is often constrained by the volatile prices of raw materials, primarily steel, and increasingly stringent environmental regulations regarding tank emissions and safety, which can escalate operational costs and project timelines. The high initial capital investment required for large-scale tank projects also poses a barrier, especially for smaller market players or projects in developing regions. Despite these challenges, substantial opportunities exist in the burgeoning renewable energy sector, suchating demand for energy storage systems, and in the adoption of smart tank technologies for improved monitoring and management. Furthermore, the immense potential of emerging economies undergoing rapid industrialization offers new avenues for market expansion.

Impact forces within the market are multifaceted, influencing competitive dynamics and profitability. The bargaining power of buyers is moderate to high, as large industrial clients often have significant negotiation leverage due to project scale and long-term contracts, while the bargaining power of suppliers, particularly steel manufacturers, is also moderate due to raw material price fluctuations and consolidation in the steel industry. The threat of new entrants is relatively low owing to the high capital intensity, specialized technical expertise, and stringent regulatory compliance required in tank fabrication. Conversely, the threat of substitutes is moderate; while alternatives like pre-stressed concrete tanks or underground storage exist for specific applications, they do not universally replace welded steel tanks due to capacity, cost, or material compatibility considerations. Competitive rivalry is intense, characterized by a fragmented market with numerous regional and global players vying for contracts, leading to continuous innovation in design, fabrication efficiency, and service offerings.

Segmentation Analysis

The Welded Steel Tanks Market is comprehensively segmented based on various critical attributes, including the type of tank construction, the materials used, their storage capacity, and the specific applications they serve across diverse industries. This segmentation provides a granular view of market dynamics, allowing for a detailed understanding of demand patterns and growth drivers within each sub-segment. Analyzing these segments helps in identifying niche markets, assessing competitive landscapes, and formulating targeted strategies for product development and market penetration.

- By Type

- Flat Bottom Tanks

- Cone Bottom Tanks

- Dish Bottom Tanks

- Floating Roof Tanks (Internal and External)

- Fixed Roof Tanks

- By Material

- Carbon Steel Tanks

- Stainless Steel Tanks

- Alloy Steel Tanks

- By Capacity

- Small (Up to 10,000 Gallons)

- Medium (10,001 to 100,000 Gallons)

- Large (Above 100,000 Gallons)

- By Application

- Oil & Gas (Crude Oil, Refined Products, LNG)

- Water & Wastewater Treatment

- Chemical Processing

- Food & Beverage

- Pharmaceuticals

- Power Generation

- Other Industrial Applications

Value Chain Analysis For Welded Steel Tanks Market

The value chain for the Welded Steel Tanks Market begins with upstream activities focused on raw material procurement, primarily encompassing steel plates, pipes, fittings, and coating materials. Key upstream players include major steel manufacturers and specialized component suppliers who provide materials meeting industry standards like API 650 and API 620. Following material acquisition, fabrication processes involve cutting, rolling, welding, and assembling the tank components, often leveraging advanced machinery and skilled labor. This phase also includes quality control and inspection to ensure structural integrity and compliance with design specifications. Downstream activities involve logistics, transportation of tank components to the installation site, and the actual erection and commissioning of the tanks. This stage often requires specialized construction equipment, expertise in heavy lifting, and adherence to site-specific safety protocols.

Distribution channels for welded steel tanks typically involve a combination of direct and indirect approaches. Direct sales are common for large-scale, custom projects where tank fabricators engage directly with end-users such as national oil companies, major chemical producers, or municipal water authorities. This allows for close collaboration on design, specification, and project management. Indirect distribution often involves engineering, procurement, and construction (EPC) contractors who serve as intermediaries, managing the entire project lifecycle, including the sourcing and installation of tanks as part of a larger industrial facility. These contractors play a crucial role in integrating various components and ensuring project success. Aftermarket services, including maintenance, repairs, inspections, and retrofitting, constitute another vital part of the value chain, ensuring the long-term operational integrity and safety of the installed tanks.

Welded Steel Tanks Market Potential Customers

Potential customers for welded steel tanks represent a broad spectrum of industrial and governmental entities requiring robust and reliable storage solutions for liquids and gases. The primary end-users are concentrated within sectors critical to energy, infrastructure, and basic industries. These customers prioritize safety, durability, compliance with regulatory standards, and the ability to store large volumes efficiently. Their purchasing decisions are often influenced by project scale, specific fluid characteristics, environmental conditions, and the need for long-term operational integrity.

Key buyers include oil and gas exploration and production companies, refiners, and petrochemical plants for crude oil, refined products, and chemical storage. Municipal water and wastewater treatment agencies are significant customers, investing in tanks for potable water storage, sewage treatment, and effluent management. Chemical manufacturers, food and beverage processing units, and pharmaceutical companies also rely on these tanks for storing raw materials, intermediate products, and finished goods, often requiring specialized coatings or stainless steel for purity and corrosion resistance. Additionally, power generation facilities, particularly those utilizing fossil fuels or biomass, and renewable energy projects requiring thermal or energy storage, represent a growing customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.2 Billion |

| Market Forecast in 2032 | $4.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CST Industries, Inc., McDermott International, Inc., Chicago Bridge & Iron Company (CB&I), ZCL Composites Inc., Tank Connection, S. C. Hondor Company, Inc., Synalloy Corporation, Paul Mueller Company, Containment Solutions Inc., Superior Tank Co., Inc., Caldwell Tanks, Inc., Greatbays Fabrication & Construction, Fisher Tank Company, Pfaudler Group, TIC The Industrial Company, Conservatek Industries, Inc., Tarsco Bolted Tank, Palmer Tank, Modern Welding Company, Advance Tank and Construction Co. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Welded Steel Tanks Market Key Technology Landscape

The Welded Steel Tanks Market is continuously evolving with the integration of advanced manufacturing processes and digital technologies aimed at enhancing efficiency, safety, and operational performance. Modern welding techniques, such as automated orbital welding and robotic welding, are increasingly employed to ensure higher precision, consistent weld quality, and faster fabrication times, reducing the margin for human error and improving structural integrity. Furthermore, advancements in materials science have led to the development of specialized steel alloys and advanced coating systems that offer superior corrosion resistance and extend the lifespan of tanks, particularly in harsh operating environments or for storing aggressive chemicals.

The technological landscape also includes the adoption of smart tank solutions and the Internet of Things (IoT) for real-time monitoring. These systems integrate sensors for parameters like level, temperature, pressure, and leakage detection, transmitting data wirelessly to centralized control systems. This enables predictive maintenance, remote diagnostics, and improved inventory management, minimizing downtime and optimizing operational efficiency. Additionally, non-destructive testing (NDT) methods like ultrasonic testing, radiographic testing, and magnetic particle inspection are routinely utilized during fabrication and throughout the tank’s lifecycle to ensure structural soundness and compliance with stringent industry standards, further bolstering safety and reliability. Computational fluid dynamics (CFD) and finite element analysis (FEA) are also employed in the design phase to optimize tank geometry and predict structural behavior under various loads and environmental conditions.

Regional Highlights

- North America: A mature market characterized by stringent regulatory frameworks, significant investments in upgrading aging infrastructure, and a strong emphasis on safety and environmental compliance. Demand is steady from the oil & gas, chemical, and municipal water sectors.

- Europe: Driven by environmental regulations, industrial retrofitting, and renewable energy projects. Countries like Germany and the UK are investing in advanced storage solutions, focusing on sustainability and efficiency.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, urbanization, and large-scale infrastructure development in countries like China, India, and Southeast Asia. Significant demand from the petrochemical, power generation, and water management sectors.

- Latin America: Growth is primarily linked to resource extraction industries, including oil, gas, and mining. Investments in new projects and infrastructure improvements contribute to market expansion, albeit with economic and political volatilities.

- Middle East and Africa (MEA): Dominated by massive investments in the oil & gas sector, particularly in crude oil and LNG storage. Water scarcity issues also drive demand for large-scale water storage and desalination plants, contributing to market growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Welded Steel Tanks Market.- CST Industries, Inc.

- McDermott International, Inc.

- Chicago Bridge & Iron Company (CB&I)

- ZCL Composites Inc.

- Tank Connection

- S. C. Hondor Company, Inc.

- Synalloy Corporation

- Paul Mueller Company

- Containment Solutions Inc.

- Superior Tank Co., Inc.

- Caldwell Tanks, Inc.

- Greatbays Fabrication & Construction

- Fisher Tank Company

- Pfaudler Group

- TIC The Industrial Company

- Conservatek Industries, Inc.

- Tarsco Bolted Tank

- Palmer Tank

- Modern Welding Company

- Advance Tank and Construction Co.

Frequently Asked Questions

What are the primary applications of welded steel tanks?

Welded steel tanks are primarily used for storing crude oil, refined petroleum products, chemicals, water, wastewater, and other industrial liquids and gases across sectors like oil & gas, petrochemicals, municipal services, and manufacturing.

What drives the growth of the Welded Steel Tanks Market?

Market growth is driven by increasing global energy demand, rapid industrialization, expansion of water and wastewater treatment infrastructure, and stringent safety regulations for industrial storage, alongside technological advancements in tank design and fabrication.

How does AI impact welded steel tanks?

AI impacts the market through optimized design, automated quality control, predictive maintenance, enhanced safety monitoring, and streamlined supply chain logistics, leading to improved efficiency, cost reduction, and extended asset lifespan.

What are the main types of welded steel tanks?

The main types include flat bottom, cone bottom, dish bottom, fixed roof, and floating roof tanks, each designed for specific storage requirements and fluid characteristics.

Which region dominates the Welded Steel Tanks Market?

The Asia Pacific region currently dominates the market and is projected to exhibit the highest growth due to rapid industrialization, urbanization, and large-scale infrastructure development in key economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager