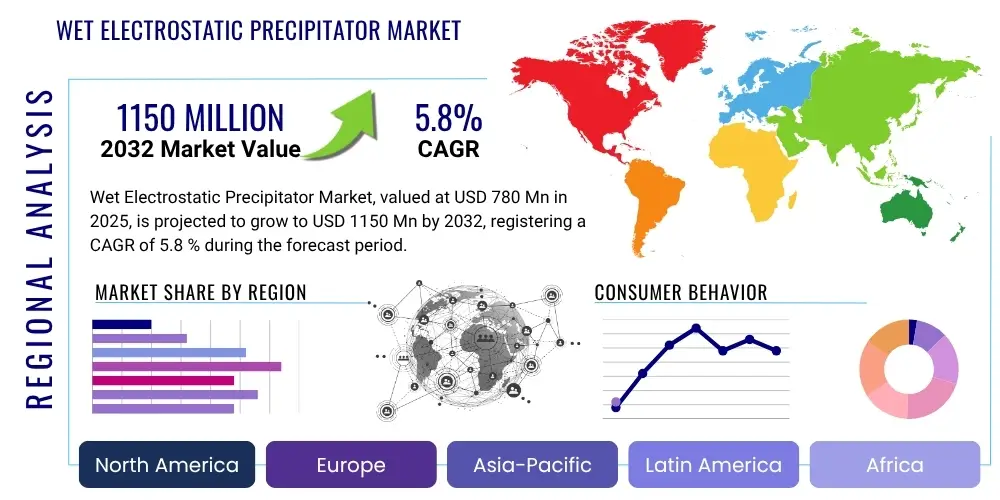

Wet Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428016 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Wet Electrostatic Precipitator Market Size

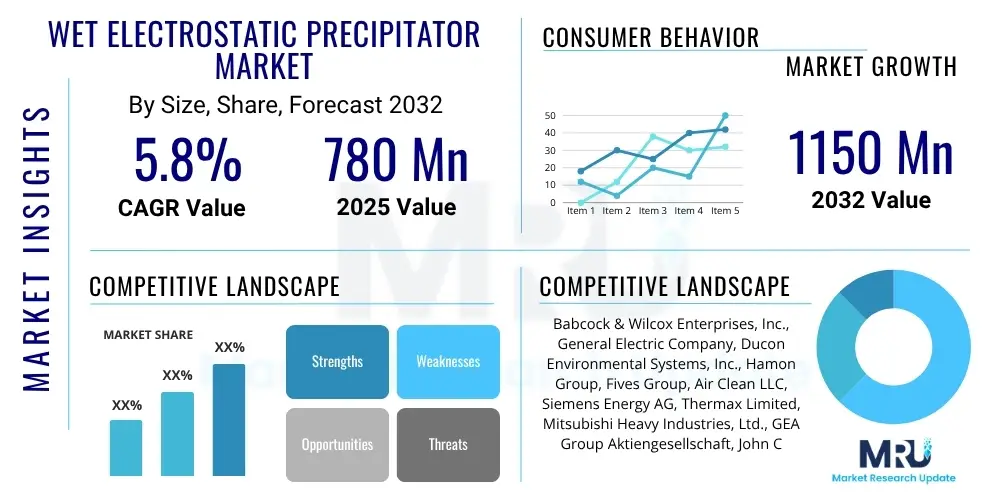

The Wet Electrostatic Precipitator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 780 Million in 2025 and is projected to reach USD 1150 Million by the end of the forecast period in 2032.

Wet Electrostatic Precipitator Market introduction

The Wet Electrostatic Precipitator (WESP) market is characterized by robust growth driven by increasingly stringent global air pollution control regulations and the imperative for industries to mitigate harmful emissions. WESPs are advanced air pollution control devices specifically designed to remove fine particulate matter, acid mists, and sub-micron aerosols from industrial gas streams by utilizing electrostatic forces in a wet environment. This innovative technology efficiently captures pollutants that traditional dry electrostatic precipitators or fabric filters might miss, offering superior performance in challenging industrial applications.

The operational principle of a WESP involves passing the gas stream through a series of electrodes where particulates are electrically charged and then collected on wetted collection plates. A continuous film of water or a weak acid solution flows over these plates, flushing away the captured pollutants and preventing re-entrainment into the gas stream. This wet collection mechanism is particularly effective for sticky, corrosive, or combustible dusts, as well as for removing acid mists like H2SO4, which are prevalent in many industrial processes.

Major applications for WESPs span across a diverse range of heavy industries, including power generation (especially coal-fired power plants, biomass plants), chemical processing, non-ferrous metal smelting, pulp and paper manufacturing, and municipal and hazardous waste incineration facilities. The primary benefits of WESPs include their high collection efficiency for sub-micron particles, low pressure drop, minimal maintenance requirements due to continuous washing, and their ability to handle high-temperature and corrosive gas streams. Key driving factors for market expansion include the global emphasis on cleaner industrial operations, the enforcement of strict emission limits by environmental agencies, and technological advancements enhancing WESP performance and cost-effectiveness.

Wet Electrostatic Precipitator Market Executive Summary

The Wet Electrostatic Precipitator (WESP) market is currently experiencing significant expansion, propelled by a confluence of global business trends focused on environmental sustainability and industrial efficiency. Businesses are increasingly investing in WESP technologies to ensure compliance with escalating air quality standards and to enhance their corporate social responsibility profiles. This trend is particularly evident in sectors prone to heavy emissions, where WESPs offer a reliable and high-performance solution for meeting stringent particulate and acid gas removal targets. The market’s competitive landscape is evolving with a focus on innovation, modular designs, and energy-efficient systems to address diverse industrial demands.

Regional trends indicate a pronounced growth trajectory in Asia Pacific, driven by rapid industrialization, urbanization, and a reactive surge in environmental protection initiatives across countries like China and India. North America and Europe, while mature markets, continue to see steady demand, primarily through retrofitting existing facilities and the adoption of advanced WESP systems for specialized applications in chemical and metals industries. Latin America, the Middle East, and Africa are emerging as significant markets due to infrastructure development and nascent environmental regulatory frameworks. Each region presents unique challenges and opportunities, influencing market penetration strategies for leading WESP manufacturers.

Segmentation trends within the WESP market highlight a growing preference for tube-type WESPs in applications requiring high collection efficiency for fine particulates and acid mists, such as in sulfuric acid plants or waste incinerators. Plate-type WESPs, known for their larger gas handling capacity, remain dominant in power generation and large-scale industrial processes. The application segment continues to be dominated by power generation and chemical industries, but significant growth is anticipated in waste incineration and metals & mining sectors as these industries face increased pressure to reduce their environmental footprint. Technology advancements, focusing on smart controls and material longevity, are key differentiators driving segment-specific growth.

AI Impact Analysis on Wet Electrostatic Precipitator Market

The integration of Artificial Intelligence (AI) is set to significantly revolutionize the Wet Electrostatic Precipitator (WESP) market by enhancing operational efficiency, predictive maintenance capabilities, and real-time emission control, addressing common user questions regarding system optimization and reliability. Users are keen to understand how AI can move WESP systems beyond traditional control mechanisms, offering more proactive management of complex processes and ensuring consistent environmental compliance. There is a strong expectation that AI will provide solutions for reducing downtime, optimizing energy consumption, and adapting WESP performance to fluctuating industrial conditions without human intervention. The primary concerns revolve around the initial investment for AI integration, data security, and the necessity for specialized personnel to manage these advanced systems.

AI's influence extends to various aspects of WESP operation, including advanced diagnostics and performance forecasting. By leveraging machine learning algorithms to analyze vast datasets from sensors monitoring gas flow, temperature, electrical parameters, and particulate concentrations, AI can identify subtle anomalies and predict potential equipment failures before they occur. This predictive maintenance capability dramatically reduces unscheduled downtime and extends the operational lifespan of WESP components, translating into substantial cost savings for industrial operators. Furthermore, AI-driven process optimization can fine-tune voltage and water spray parameters in real-time, ensuring maximum collection efficiency under varying load conditions, which is crucial for meeting dynamic environmental permits.

Beyond operational enhancements, AI is expected to transform the strategic management of WESP systems by offering unprecedented levels of data-driven insights. It facilitates the development of self-optimizing WESP units that can learn from their environment and automatically adjust settings to maintain peak performance and compliance. This not only minimizes manual intervention but also empowers facility managers with comprehensive performance reports and actionable recommendations, thereby contributing to more sustainable and cost-effective industrial operations. The continuous improvement loop enabled by AI will drive innovation in WESP design and application, pushing the boundaries of what is possible in industrial air pollution control.

- AI-powered predictive maintenance reduces WESP downtime and operational costs by forecasting equipment failures.

- Real-time optimization of WESP parameters (e.g., voltage, water flow) using AI ensures peak collection efficiency under varying load conditions.

- Enhanced emission monitoring and reporting through AI-driven analytics provide accurate and compliant data for regulatory bodies.

- AI facilitates adaptive process control, allowing WESPs to autonomously adjust to changes in gas stream composition or temperature.

- Improved energy efficiency through AI algorithms that optimize power consumption based on current operational needs.

- Advanced anomaly detection systems identify potential issues early, preventing costly damages and ensuring system integrity.

DRO & Impact Forces Of Wet Electrostatic Precipitator Market

The Wet Electrostatic Precipitator (WESP) market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and impacting its overall growth potential. One of the primary drivers is the escalating global concern over air quality and public health, which has led to the implementation and strict enforcement of more rigorous environmental regulations worldwide. Governments and international bodies are setting lower permissible limits for particulate matter, acid mists, and other harmful industrial emissions, compelling industries to adopt highly efficient air pollution control technologies like WESPs. The increasing industrialization, particularly in developing economies, further fuels this demand as new manufacturing facilities and power plants seek compliant emission solutions from their inception.

However, the market also faces considerable restraints that temper its growth. The high initial capital investment required for the installation of WESP systems is a significant barrier for many smaller and medium-sized enterprises. The complexity of WESP design and installation, often necessitating custom engineering for specific industrial applications, adds to the overall cost and project lead times. Furthermore, operational challenges such as corrosion in aggressive gas environments, the need for consistent water quality, and the disposal of collected wastewater can present ongoing maintenance and operational expenses. These factors necessitate careful economic assessment and long-term planning by potential adopters, impacting the rate of market penetration.

Despite these challenges, numerous opportunities exist to propel the WESP market forward. Technological advancements focused on developing more energy-efficient designs, corrosion-resistant materials, and smarter control systems are creating new avenues for market expansion. The growing trend of retrofitting existing industrial facilities with advanced WESP units to meet updated environmental standards presents a substantial opportunity. Moreover, the increasing demand for cleaner energy sources, such as biomass and waste-to-energy plants, where WESPs are ideally suited for emission control, offers fertile ground for market development. The expanding applications in emerging industrial sectors, coupled with government incentives for green technologies, further underscore the significant growth prospects for the WESP market, driving innovation and market adoption globally.

Segmentation Analysis

The Wet Electrostatic Precipitator (WESP) market is comprehensively analyzed through various segmentation strategies, primarily categorized by type, application, and geographical region. This granular breakdown provides a nuanced understanding of market dynamics, allowing stakeholders to identify specific growth drivers, competitive landscapes, and consumer preferences within distinct sub-markets. Analyzing these segments is crucial for strategic planning, product development, and market entry strategies, as each segment exhibits unique characteristics and demand patterns shaped by industrial requirements, technological capabilities, and regional regulatory environments. The diverse applications of WESPs across different industries necessitate a clear understanding of which WESP types are most suitable for particular emission challenges, driving the differentiation in market offerings and technological specialization.

Segmentation by type typically includes plate-type and tube-type WESPs, each designed to optimize performance for varying gas volumes, particulate characteristics, and space constraints. Plate-type WESPs are generally preferred for large gas flows and environments where a higher degree of robustness is required, such as in power plants. Tube-type WESPs excel in applications demanding exceptionally high collection efficiencies for fine particulates and acid mists, often seen in chemical processing and specialized incineration facilities. This distinction is vital for manufacturers to tailor their product portfolios and for end-users to select the most appropriate technology for their specific air pollution control needs, influencing both pricing strategies and market share distribution across these types.

Further segmentation by application highlights the diverse industrial sectors that rely on WESP technology for emission control. Key applications include power generation, where WESPs remove fly ash and sulfur trioxide mist; the chemical industry, for acid mist removal from various processes; metals and mining, addressing fumes and fine dust; pulp and paper, controlling boiler emissions and recovery furnace particulates; and municipal and hazardous waste incineration, managing highly toxic and corrosive gas streams. Each of these application segments has distinct requirements in terms of WESP design, material construction, and operational parameters, dictating market demand and innovation priorities within the WESP industry. Geographical segmentation, meanwhile, reveals regional disparities in market size, growth rates, and regulatory pressures, which are critical for global market expansion strategies.

- By Type:

- Plate Type WESP

- Tube Type WESP

- By Application:

- Power Generation

- Chemical Industry

- Metals & Mining

- Pulp & Paper

- Waste Incineration

- Other Industrial Processes

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Wet Electrostatic Precipitator Market

The value chain for the Wet Electrostatic Precipitator (WESP) market is a complex network encompassing multiple stages, from the sourcing of raw materials to the final installation and post-sales support, illustrating the interconnectedness of various stakeholders. Upstream activities involve the procurement of specialized components and raw materials such as corrosion-resistant metals (e.g., stainless steel, alloys), high-voltage electrical components (rectifiers, insulators), control systems, and specialized coatings. Suppliers of these critical inputs play a vital role in ensuring the quality, durability, and performance of the final WESP system, making their partnerships essential for manufacturers. Research and development also form a crucial upstream component, driving innovation in electrode design, material science, and operational efficiency.

Midstream activities primarily focus on the manufacturing and assembly of WESP units. This stage involves sophisticated engineering design, fabrication of collectors and electrodes, integration of electrical systems, and rigorous quality control testing. Leading WESP manufacturers often possess proprietary technologies and advanced fabrication capabilities to produce highly customized systems that meet diverse industrial requirements. The direct manufacturing process is highly specialized, requiring expertise in areas such as fluid dynamics, electrical engineering, and material science, ensuring the efficient and safe operation of the precipitators in demanding industrial environments.

Downstream activities include the distribution, installation, commissioning, and ongoing maintenance of WESP systems. Distribution channels can be both direct, where manufacturers sell and install directly to end-users, or indirect, involving engineering, procurement, and construction (EPC) contractors or specialized distributors. EPC firms often play a critical role, integrating WESPs into larger industrial projects. Post-sales services, including technical support, spare parts supply, and routine maintenance, are crucial for ensuring the long-term reliability and optimal performance of the installed systems. The efficiency of these downstream operations directly impacts customer satisfaction and the overall lifecycle cost for the end-user, thereby influencing market reputation and future sales.

Wet Electrostatic Precipitator Market Potential Customers

The potential customer base for Wet Electrostatic Precipitators (WESPs) is extensive and diverse, primarily comprising industries that generate significant air emissions requiring advanced particulate and acid gas control to comply with environmental regulations and improve operational sustainability. These end-users are characterized by heavy industrial processes that produce fine particulate matter, acid mists, and other challenging air pollutants, making WESPs an indispensable technology for their environmental compliance strategies. Understanding the specific needs and operational constraints of these varied customer segments is paramount for WESP manufacturers and service providers to effectively tailor their offerings and penetrate the market.

One of the largest segments of potential customers includes the power generation sector, particularly coal-fired power plants, biomass power plants, and waste-to-energy facilities. These installations utilize WESPs to remove fine fly ash, sulfur trioxide (SO3) mist, and other sub-micron particles from their flue gas streams, which are critical for meeting stringent emission standards and preventing plume visibility issues. The chemical industry also represents a substantial customer base, with WESPs employed in sulfuric acid plants, fertilizer production, and various other chemical manufacturing processes to capture acid mists and corrosive particulates, protecting downstream equipment and ensuring safe operations. These facilities often deal with highly corrosive gas streams, making WESPs with robust construction and material selection essential.

Further potential customers are found in the non-ferrous metals and mining industry, where WESPs are used to control fumes and fine dust generated during smelting and refining processes, which often contain heavy metals and other hazardous substances. The pulp and paper industry is another key segment, utilizing WESPs to clean emissions from recovery boilers and other combustion sources, removing fine particulates and odors. Additionally, municipal and hazardous waste incineration facilities are crucial adopters of WESP technology, as they require highly efficient systems to manage the complex and often toxic emissions from waste combustion. The increasing global focus on pollution control and sustainable industrial practices continues to expand the pool of potential customers across these and other niche industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 780 Million |

| Market Forecast in 2032 | USD 1150 Million |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises, Inc., General Electric Company, Ducon Environmental Systems, Inc., Hamon Group, Fives Group, Air Clean LLC, Siemens Energy AG, Thermax Limited, Mitsubishi Heavy Industries, Ltd., GEA Group Aktiengesellschaft, John Cockerill, Beltran Technologies, Inc., Filtra Systems, Inc., Cerafil Technologies Private Limited, KCH Group GmbH, Lenntech B.V., Wet-Scrubbing Inc., Southern Environmental, Inc., EnviroCare International, Reitzel Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wet Electrostatic Precipitator Market Key Technology Landscape

The Wet Electrostatic Precipitator (WESP) market's technology landscape is continuously evolving, marked by significant advancements aimed at enhancing performance, energy efficiency, and operational longevity while reducing the total cost of ownership. Innovations are primarily focused on improving the core components and control systems to meet the increasingly stringent demands of industrial emission control. One crucial area of development involves electrode design, where manufacturers are exploring new geometries and materials to optimize the electrical field distribution, improve particle charging efficiency, and minimize re-entrainment. These advancements contribute to higher collection efficiencies for sub-micron particulates and acid mists, which are critical for meeting modern environmental standards.

Material science plays a pivotal role in the technological advancement of WESPs, particularly in developing corrosion-resistant materials for construction. Given that WESPs operate in highly corrosive environments, especially when dealing with acid mists and humid gas streams, the use of advanced alloys, fiberglass reinforced plastics (FRP), and specialized coatings is becoming more prevalent. These materials extend the operational lifespan of WESP units, reduce maintenance requirements, and ensure long-term reliability in aggressive industrial settings. Furthermore, continuous research into new electrode materials and insulator designs aims to improve electrical integrity and prevent arcing, enhancing the overall stability and safety of the system.

Another significant aspect of the technology landscape is the integration of advanced control systems and automation. Modern WESPs are increasingly equipped with intelligent Process Logic Controllers (PLCs), Distributed Control Systems (DCS), and supervisory control and data acquisition (SCADA) systems that allow for precise control of operational parameters such as voltage, water flow, and gas distribution. These smart systems enable real-time monitoring, automated adjustments based on inlet conditions, and remote diagnostics, leading to optimized performance, reduced energy consumption, and proactive maintenance scheduling. The growing adoption of sensor technologies and data analytics, as highlighted in the AI impact section, is further driving the evolution towards more adaptive and autonomous WESP operation, setting new benchmarks for efficiency and environmental compliance.

Regional Highlights

The global Wet Electrostatic Precipitator (WESP) market exhibits distinct regional dynamics, influenced by varying industrial growth rates, regulatory frameworks, and environmental priorities across different geographies. Each region presents a unique combination of drivers and challenges that shape market demand, competitive intensity, and technological adoption patterns, making regional analysis crucial for understanding the overall market landscape. The disparities in environmental enforcement and industrial infrastructure lead to differentiated growth trajectories and investment opportunities, highlighting the importance of localized strategies for WESP manufacturers and service providers. This geographical diversity underscores the need for adaptable product offerings and market penetration approaches tailored to specific regional requirements and prevailing economic conditions.

- North America: A mature market characterized by stringent environmental regulations, particularly in the United States and Canada. Demand is driven by retrofitting existing power plants and industrial facilities, as well as new investments in chemical, metals, and pulp & paper sectors focusing on advanced emission control. Emphasis on energy efficiency and operational reliability fuels technological upgrades.

- Europe: Similarly a mature market with some of the world's strictest air quality standards (e.g., EU Industrial Emissions Directive). Growth is propelled by continued investments in modernizing industrial infrastructure, expanding waste-to-energy facilities, and controlling emissions from specialized chemical processes. Focus on sustainable technologies and circular economy principles.

- Asia Pacific (APAC): The fastest-growing region, driven by rapid industrialization, urbanization, and a reactive surge in environmental protection efforts, especially in China, India, and Southeast Asian countries. Massive investments in new power generation (both coal-fired and renewables), chemical manufacturing, and waste management infrastructure create substantial demand for WESPs. Government initiatives to combat severe air pollution are a primary market driver.

- Latin America: An emerging market with growing industrial sectors and evolving environmental regulations. Brazil, Mexico, and Argentina are key countries exhibiting increasing demand for WESPs in power generation, mining, and industrial manufacturing as they modernize their facilities and address local air quality concerns. Market growth is often tied to infrastructure development projects.

- Middle East & Africa (MEA): A developing market with increasing industrial activity, particularly in oil & gas, petrochemicals, and power generation. The region is gradually adopting more stringent environmental standards, creating opportunities for WESP deployment in new projects and for upgrading existing facilities. Saudi Arabia, UAE, and South Africa are leading the adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wet Electrostatic Precipitator Market.- Babcock & Wilcox Enterprises, Inc.

- General Electric Company

- Ducon Environmental Systems, Inc.

- Hamon Group

- Fives Group

- Air Clean LLC

- Siemens Energy AG

- Thermax Limited

- Mitsubishi Heavy Industries, Ltd.

- GEA Group Aktiengesellschaft

- John Cockerill

- Beltran Technologies, Inc.

- Filtra Systems, Inc.

- Cerafil Technologies Private Limited

- KCH Group GmbH

- Lenntech B.V.

- Wet-Scrubbing Inc.

- Southern Environmental, Inc.

- EnviroCare International

- Reitzel Industries

Frequently Asked Questions

What is a Wet Electrostatic Precipitator (WESP) and how does it work?

A Wet Electrostatic Precipitator (WESP) is an advanced air pollution control device that removes fine particulate matter, acid mists, and sub-micron aerosols from industrial gas streams. It functions by electrically charging particles in the gas flow, which are then attracted to wetted collection plates. A continuous film of water or a weak acid solution on these plates washes away the collected pollutants, preventing re-entrainment and ensuring high removal efficiency, especially for sticky or corrosive substances.

What are the primary advantages of using WESPs over other pollution control technologies?

WESPs offer several key advantages, including exceptionally high collection efficiency for sub-micron particles and acid mists, superior performance in handling sticky, corrosive, or combustible dusts, and a low pressure drop resulting in lower operating costs. Their wet collection mechanism eliminates issues like particulate re-entrainment and allows for effective removal of gaseous pollutants alongside particulates, making them ideal for challenging industrial applications and meeting stringent emission limits.

Which industries are the main adopters of Wet Electrostatic Precipitator technology?

The main adopters of WESP technology include power generation (especially coal-fired and biomass plants), the chemical industry (for acid mist removal), metals and mining (controlling fumes and fine dust), pulp and paper manufacturing (boiler emissions), and municipal and hazardous waste incineration. These industries rely on WESPs to comply with strict air quality regulations and manage diverse, complex emission streams effectively.

What impact do environmental regulations have on the Wet Electrostatic Precipitator market?

Environmental regulations are a primary driver of the WESP market. Increasingly stringent global air quality standards, such as those limiting particulate matter and acid gas emissions, compel industries to adopt high-efficiency pollution control solutions. These regulations necessitate new installations and the retrofitting of existing facilities with advanced WESP systems, ensuring continuous market demand and fostering innovation in emission control technologies.

How is Artificial Intelligence (AI) influencing the Wet Electrostatic Precipitator market?

AI is transforming the WESP market by enabling predictive maintenance, optimizing operational parameters in real-time, and enhancing emission monitoring. AI algorithms analyze sensor data to forecast equipment failures, fine-tune voltage and water flow for peak efficiency, and provide precise data for regulatory compliance. This leads to reduced downtime, lower energy consumption, and more consistent, reliable WESP performance, pushing the industry towards smarter and more autonomous systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager