Nylon String Trimmer Line Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435013 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Nylon String Trimmer Line Market Size

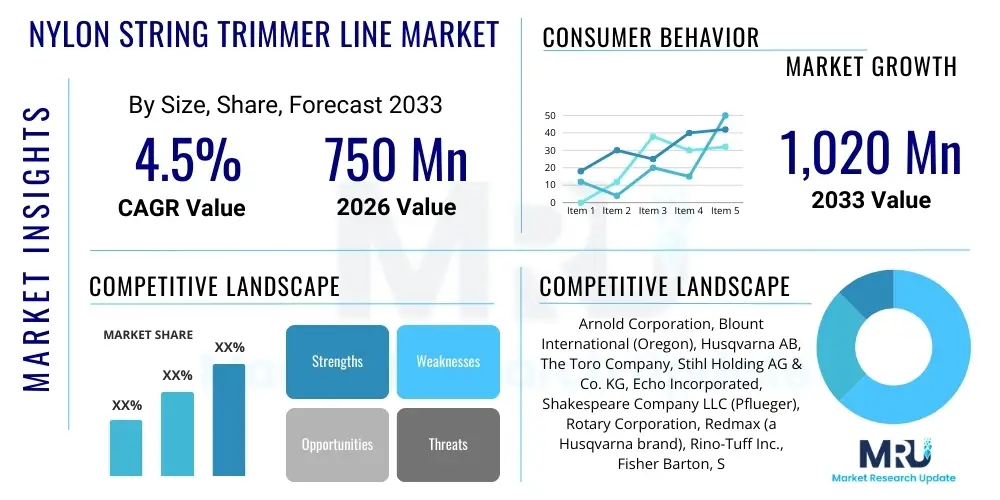

The Nylon String Trimmer Line Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 750 million in 2026 and is projected to reach USD 1,020 million by the end of the forecast period in 2033.

Nylon String Trimmer Line Market introduction

The Nylon String Trimmer Line Market encompasses the global production and distribution of flexible cutting filaments used primarily in gasoline and electric string trimmers (weed eaters). These lines are essential consumable accessories in the landscaping and horticultural maintenance sectors, designed to efficiently cut grass, weeds, and light brush. The fundamental raw material is usually polyamides, commonly Nylon 6 or Nylon 66, chosen for their superior strength, flexibility, heat resistance, and abrasion properties necessary to withstand high rotational speeds and repeated impacts with tough vegetation and hard surfaces. Product characteristics, such as diameter, shape (e.g., round, square, star, twisted), and material composition, are critical factors defining performance, durability, and specific application suitability.

The primary applications of nylon trimmer lines span extensive sectors, including residential lawn care, commercial landscaping services, maintenance of public parks and highway verges (municipal use), and specialized agricultural applications. The market expansion is intrinsically linked to global trends in urbanization, the rise in demand for aesthetically maintained green spaces, and the increasing reliance on power tools for efficient grounds maintenance. Key benefits derived from modern trimmer lines include reduced noise pollution (especially with specialized twisted or spiral lines), extended durability through advanced composite materials, and enhanced cutting efficiency achieved through precision geometry and specialized coatings that reduce melting and welding.

Major driving factors fueling the market growth include the substantial rise in DIY (Do-It-Yourself) gardening and lawn care activities, particularly in developed economies, coupled with significant investment in public infrastructure and green space development in emerging markets. Furthermore, technological advancements in the trimmer line manufacturing process, such as co-extrusion techniques, allow for the production of multi-layered lines offering better abrasion resistance and resilience. The continuous improvement in electric and battery-powered string trimmers, which require robust and efficient line consumption, further stabilizes demand, ensuring steady procurement across professional and consumer segments globally.

Nylon String Trimmer Line Market Executive Summary

The global Nylon String Trimmer Line Market is undergoing steady expansion, characterized by a persistent focus on product innovation aimed at enhancing durability, efficiency, and sustainability. Current business trends indicate a strong shift towards premium lines featuring advanced geometries, such as twisted, serrated, and multi-sided profiles, which offer superior cutting performance and reduced drag compared to traditional round lines. Manufacturing companies are increasingly leveraging advanced polymer blends, including the incorporation of aramid fibers or specialized metallic powders, to create composite lines that exhibit exceptional resistance to fraying and breakage under heavy use, appealing directly to the professional landscaping segment which demands minimal downtime and maximum longevity.

Regionally, North America maintains its position as the dominant market, driven by extensive residential lawn maintenance culture and a large professional landscaping industry that utilizes high-powered equipment and consumes high volumes of commercial-grade trimmer line. Asia Pacific (APAC), however, is emerging as the fastest-growing market, propelled by rapid urbanization, increasing governmental spending on public parks and infrastructure, and the growing adoption of automated gardening equipment by a burgeoning middle class. European markets are heavily influenced by stringent environmental regulations, favoring sustainable and low-noise trimmer line solutions, thus promoting R&D investment into quieter, aero-dynamic shapes and bio-based nylon alternatives where feasible.

Segmentation trends reveal that the professional/commercial segment, though smaller in volume than the residential segment, contributes significantly higher revenue due to the consumption of high-diameter, high-performance lines with superior materials and complex shapes. By material, Nylon 66, known for its higher temperature tolerance and rigidity, is preferred for heavy-duty commercial applications, while standard Nylon 6 remains popular in cost-sensitive residential markets. The market structure remains highly competitive, with strategic initiatives focusing on supply chain resilience, optimization of distribution networks, and targeted marketing emphasizing the performance attributes suitable for specific terrain types and vegetation density.

AI Impact Analysis on Nylon String Trimmer Line Market

Common user questions regarding AI's impact on the Nylon String Trimmer Line Market typically revolve around how artificial intelligence and machine learning (ML) can optimize the complex extrusion process, forecast volatile raw material (polyamide) prices, and enhance inventory management in response to highly seasonal demand fluctuations. Users are also keen to understand if AI integration will lead to the development of 'smart' trimmer lines—potentially lines embedded with micro-sensors for wear detection, or whether AI will be primarily confined to optimizing the cutting efficiency and energy consumption of the trimming equipment itself. The key themes summarized are optimization (reducing waste and cost), predictability (managing seasonality and raw material supply), and the integration of advanced materials monitoring within the manufacturing lifecycle to ensure consistent product quality across various diameters and shapes.

AI's primary influence is currently observed in operational efficiency and supply chain intelligence, rather than in the core functionality of the nylon line itself. Machine learning algorithms are being utilized to analyze historical sales data, localized weather patterns, and regional landscaping trends to create highly accurate demand forecasts, thereby enabling manufacturers to optimize production schedules and minimize holding costs for seasonal inventory. Furthermore, AI-driven quality control systems, employing vision inspection in the manufacturing process, ensure precise monitoring of line diameter, dimensional consistency, and the integrity of complex co-extrusion profiles, significantly reducing defects and material waste inherent in high-speed extrusion lines.

In the long term, AI may influence product design by simulating the aerodynamic properties and abrasion dynamics of novel line shapes before physical prototyping. This computational approach allows R&D teams to rapidly iterate on complex geometries (like helicals or saw-tooth designs) that maximize cutting power while minimizing noise and energy consumption in battery-operated equipment. This shift towards simulation-based design, informed by AI, will accelerate the introduction of high-efficiency, application-specific trimmer lines, reinforcing the competitive advantage of technologically forward-thinking manufacturers in meeting sophisticated professional demands.

- Optimization of Polyamide Extrusion: AI algorithms fine-tune temperature, pressure, and flow rates, leading to minimal material waste and superior line consistency.

- Demand Forecasting Accuracy: ML models predict seasonal spikes and regional variations, optimizing inventory levels and preventing stockouts during peak seasons.

- Predictive Maintenance: AI monitors the performance of extrusion machinery, anticipating failures and reducing unscheduled downtime, thereby ensuring continuous production flow.

- Supply Chain Resilience: Use of AI to monitor global nylon (PA) resin commodity markets, enabling strategic purchasing decisions under volatile pricing environments.

- Advanced Quality Control (QC): Computer vision systems driven by AI identify minute imperfections and dimensional errors at high speeds, improving overall product reliability.

- Enhanced Product Design Simulation: AI accelerates the R&D cycle by simulating the aerodynamic efficiency and wear characteristics of new line geometries.

DRO & Impact Forces Of Nylon String Trimmer Line Market

The Nylon String Trimmer Line Market is driven primarily by the sustained global expansion of landscaping and ground maintenance activities, coupled with significant technological improvements in material science that enhance product performance. However, market expansion faces constraints related to the volatility of raw material prices (Nylon polymers are derived from petrochemicals) and growing environmental concerns regarding the disposal of plastic consumables, which necessitates continuous innovation towards biodegradable or recycled alternatives. Opportunities are largely centered around developing specialized, premium lines for heavy-duty commercial use and integrating sustainable manufacturing practices that align with evolving consumer preferences and regulatory mandates.

Key drivers include the global increase in disposable income leading to higher demand for aesthetically managed residential properties, and the widespread adoption of battery-powered string trimmers, which are convenient and environmentally preferred, yet place higher demands on line durability and efficiency. Restraints involve the inherent material limitations of nylon, which is susceptible to thermal degradation (welding) during intense use, leading to frequent line replacement, and the intensifying competition from low-cost manufacturers, pressuring pricing and profit margins for standardized round lines. Furthermore, the market is cyclical, heavily dependent on weather patterns and the landscaping season, introducing inventory management challenges.

The impact forces influencing the market trajectory include substitution threats from alternative weed control methods (e.g., chemical herbicides, mulching, robotic mowing) and the bargaining power of major retailers and OEM (Original Equipment Manufacturer) tool providers who dictate packaging specifications and pricing structures. However, the low entry barriers for simple round line production are offset by high barriers to entry for advanced, multi-layer, co-extruded lines which require specialized machinery and proprietary polymer knowledge. The primary opportunities lie in developing highly durable, multi-filament lines capable of resisting harsh abrasion on surfaces like concrete and stone, and establishing leadership in the emerging segment of eco-friendly, bio-based nylon trimmer lines to cater to environmentally conscious consumers and municipal contracts.

Segmentation Analysis

The Nylon String Trimmer Line Market is meticulously segmented across multiple parameters, primarily dictated by the line's physical attributes, material composition, and the end-user application. Understanding these segments is crucial as different applications impose distinct demands on line strength, thermal resistance, and cutting efficiency. The core segmentation by line shape (round, square, star, twisted) often correlates directly with the cutting performance, where round lines serve basic residential needs, and angular or twisted lines are favored by professionals for faster, cleaner cuts and reduced noise. Diameter segmentation is critical for compatibility with specific trimmer models, ranging from light-duty lines (under 0.080 inches) for small electric trimmers to heavy-duty industrial lines (over 0.130 inches) used in high-powered gas equipment.

Further segmentation is detailed by the raw material, predominantly Nylon 6 and Nylon 66, and composite variations incorporating additives for enhanced abrasion resistance (e.g., aluminum powder, fillers) or reduced friction (e.g., specialized coatings). The end-user dichotomy between residential (DIY) users and professional/commercial users dictates volume purchasing behavior and preference for premium features. Residential users prioritize ease of use and affordability, often choosing pre-cut or spooled standard lines, whereas commercial users prioritize performance, durability, and bulk purchasing of specialty shapes designed for rugged, extended use.

The intricate nature of these segments reflects the need for manufacturers to provide a broad portfolio tailored to specific cutting conditions—from soft grass cutting on residential lawns to battling dense brush and woody weeds in commercial environments. The trend towards specialized, co-extruded lines combining multiple polymer layers (a hard core for strength and a softer outer shell for flexibility and impact absorption) demonstrates the market's continuous evolution away from generic, monolithic nylon towards high-performance engineered solutions that meet increasingly rigorous consumer and professional expectations regarding longevity and overall value.

- By Material Type:

- Nylon 6 (PA 6)

- Nylon 66 (PA 66)

- Co-Polymer/Composite Blends

- Bio-based/Recycled Nylon

- By Line Diameter:

- Light Duty (< 0.080 inch)

- Medium Duty (0.080 - 0.105 inch)

- Heavy Duty (0.105 - 0.130 inch)

- Commercial/Industrial (> 0.130 inch)

- By Line Shape/Geometry:

- Round

- Square/Star

- Twisted/Spiral

- Serrated/Multi-sided

- By End-User:

- Residential/DIY

- Commercial/Professional Landscaping

- Municipal/Government

- By Distribution Channel:

- Online Retail

- Specialty Stores/Hardware Stores

- Mass Merchandisers

- OEM Channels

Value Chain Analysis For Nylon String Trimmer Line Market

The value chain for the Nylon String Trimmer Line Market begins with the upstream procurement of raw petrochemical-derived materials, primarily polyamide resins (Nylon 6 and Nylon 66 pellets). This stage involves reliance on major chemical producers, making the market susceptible to global fluctuations in crude oil and derivative chemical feedstock prices. Key activities at the upstream level include polymerization and the sourcing of specialized additives, such as colorants, stabilizers, and proprietary composite fillers that enhance the final product's physical properties. Maintaining long-term contractual relationships with reliable resin suppliers is critical for ensuring consistent material quality and stabilizing costs against market volatility, which significantly influences the final manufacturing cost base.

The manufacturing stage involves the highly technical process of extrusion. Midstream activities encompass polymerization, melting, forced extrusion through dies to achieve the desired shape and diameter, and sophisticated cooling and stretching (orientation) processes that align the polymer molecules to impart high tensile strength and durability. Manufacturers specializing in premium lines utilize advanced techniques like co-extrusion to produce multi-layered filaments, integrating different polymer characteristics within a single line. Following extrusion, the line is spooled, cut to specified lengths (for pre-cut blister packs), or wound onto bulk reels, followed by packaging and quality inspection to ensure dimensional accuracy and adherence to industry standards, setting the stage for downstream movement.

Downstream distribution channels are diverse, structured around both direct and indirect routes to the end-user. Indirect distribution heavily relies on large-scale mass merchandisers (e.g., Home Depot, Lowe's), online e-commerce platforms (Amazon, specialized tool websites), and independent hardware stores, which serve the broad residential and light commercial markets. Direct distribution often involves supplying OEMs (e.g., Husqvarna, Stihl, Echo) for their branded accessory lines or directly servicing large professional landscaping and municipal operations through specialized distributors. The efficacy of the value chain relies heavily on logistics efficiency, especially concerning managing the high volume of relatively low-value consumables distributed across global retail networks, making inventory management and timely delivery paramount to market success.

Nylon String Trimmer Line Market Potential Customers

The Nylon String Trimmer Line Market serves a heterogeneous customer base categorized primarily by the frequency and intensity of their maintenance needs, ranging from intermittent residential use to continuous professional operations. Residential homeowners constitute the largest volume segment, purchasing standard-to-medium duty lines for basic lawn upkeep, valuing ease of use, cost-effectiveness, and compatibility with standard electric or low-power gas trimmers. These DIY buyers are highly sensitive to retail pricing and promotional activities, typically sourcing products through mass-market retail channels or seasonal hardware store purchases, and often opting for pre-spooled or blister-packaged lines for convenience.

Conversely, professional landscapers and commercial maintenance firms represent the highest-value segment. These end-users operate powerful, high-RPM trimmers for extended periods in demanding conditions, requiring heavy-duty lines (high diameter, Nylon 66, or composite blends) with superior abrasion resistance, high tensile strength, and minimal thermal welding tendencies. For these customers, product durability and efficiency directly translate into labor cost savings and operational continuity, making them prioritize premium performance over marginal cost savings. They typically purchase in bulk, often through specialized industrial suppliers or OEM accessory channels, focusing on specific shapes like square or twisted lines for optimal cutting density.

The third significant customer segment includes government agencies, municipalities, and institutional buyers responsible for maintaining public parks, highway medians, golf courses, and large university campuses. These buyers often issue tenders requiring specific product certifications, long-term supply agreements, and adherence to environmental standards, increasingly favoring biodegradable or low-noise line options. Additionally, specialized niche applications exist in agriculture, such as vineyard maintenance or specialized crop trimming, which require unique line characteristics designed for specific vegetation types or delicate operations. Meeting the diverse needs of these segments requires manufacturers to maintain a wide product portfolio and tailored distribution strategies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 750 Million |

| Market Forecast in 2033 | USD 1,020 Million |

| Growth Rate | CAGR 4.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arnold Corporation, Blount International (Oregon), Husqvarna AB, The Toro Company, Stihl Holding AG & Co. KG, Echo Incorporated, Shakespeare Company LLC (Pflueger), Rotary Corporation, Redmax (a Husqvarna brand), Rino-Tuff Inc., Fisher Barton, Sunseeker (a Zhejiang Xinhu Power Co.), Greenworks Tools, Tanaka Power Equipment, Maruyama Mfg. Co. Inc., MTD Products, Makita Corporation, Emak S.p.A., Shindaiwa (a Yamabiko Corp.), Excel Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nylon String Trimmer Line Market Key Technology Landscape

The technological landscape of the Nylon String Trimmer Line Market is dominated by advancements in material science and extrusion engineering aimed at maximizing durability, cutting efficiency, and minimizing noise output. A foundational technology is the mastery of polyamide (Nylon 6 and Nylon 66) formulation, where manufacturers manipulate polymerization processes to achieve the optimal balance of rigidity, impact strength, and flexibility required for high-speed rotation. Modern technology involves incorporating specialized additives, such as highly rigid ceramic particles or lubricating compounds, directly into the polymer blend to enhance abrasion resistance, dramatically extending the line's lifespan when interacting with abrasive surfaces like concrete and rocky soil.

A significant innovation driving premium market growth is co-extrusion technology, which allows for the creation of multi-layered lines. This technology typically produces a trimmer line with a tough, high-strength inner core (often Nylon 66 for tensile strength) surrounded by a softer, more flexible outer jacket (often Nylon 6 or a specialized polymer blend) designed for impact absorption and heat dissipation. This layered approach prevents the line from melting and welding within the trimmer head under heavy load, a common failure point for monolithic lines. Co-extrusion also enables manufacturers to incorporate specific performance attributes, such as noise reduction or color coding for easy diameter identification, into the outer layer.

Furthermore, technology related to line geometry and shape optimization is crucial for performance enhancement and AEO (Acoustic and Energy Optimization). Twisted, spiral, and serrated line shapes are engineered using advanced computational fluid dynamics (CFD) modeling to reduce air resistance (drag) and minimize the signature "whipping" noise associated with high-speed rotation. This focus on aerodynamic efficiency not only makes the trimming process quieter, aligning with stringent urban noise regulations, but also reduces the energy required to spin the line, extending the battery life of electric trimmers—a critical factor driving consumer adoption in the modern power tool landscape.

Regional Highlights

- North America: North America, comprising the United States and Canada, represents the largest and most mature market for nylon string trimmer lines, characterized by high rates of homeownership, large average lawn sizes, and a highly mechanized professional landscaping industry. The demand is robust, driven by both the mass retail segment (DIY users seeking standard lines) and the highly demanding commercial sector (requiring premium, high-diameter, and advanced composite lines). The strong presence of leading OEM manufacturers and a developed distribution network ensure consistent, high-volume consumption, particularly during the lengthy warm-weather maintenance season. Innovation here often focuses on lines optimized for the high power output of modern gas trimmers and the increasing prevalence of high-voltage battery-powered units.

- Europe: The European market demonstrates steady growth, significantly influenced by strong environmental and noise pollution regulations, particularly in Western and Northern European countries. This regulatory environment drives a substantial demand for specialized products, including low-noise, aerodynamically optimized trimmer lines (e.g., twisted and spiral shapes) and lines manufactured from sustainable, bio-based, or recycled materials. Germany, the UK, and France are key consumers, with the professional sector valuing efficiency and adherence to ecological standards. The emphasis on high-quality gardening and specialized maintenance tools means that European consumers often show a higher propensity to adopt premium, technology-driven lines.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to rapid urbanization, increasing middle-class disposable income, and massive governmental and commercial investments in infrastructure and green space development (e.g., parks, golf courses, planned communities). Countries like China, India, and Australia are seeing surging demand for both residential and commercial landscaping services. While price sensitivity remains high in some mass-market segments, the growing professionalization of the landscaping sector, especially in developed coastal regions, is boosting the demand for higher-performance, durable trimmer lines, creating significant opportunities for international manufacturers to expand their localized production and distribution footprints.

- Latin America (LATAM): The LATAM market, while generally smaller than North America and Europe, offers significant potential, driven by agricultural applications and rapid residential development in major economies like Brazil and Mexico. The market is highly cost-sensitive, resulting in strong demand for economically priced, standard nylon lines. However, the rise of specialized commercial maintenance in major urban centers is gradually introducing higher-performance products. Challenges include navigating complex distribution logistics and managing currency volatility, making localized manufacturing or strong regional partnerships crucial for market penetration.

- Middle East and Africa (MEA): The MEA region is characterized by niche demand, largely centered around high-end landscaping projects in the Gulf Cooperation Council (GCC) states (due to extensive irrigation systems creating green spaces in arid environments) and essential maintenance in parts of South Africa. Demand is highly seasonal and geographically concentrated, often requiring lines that can withstand extremely high ambient temperatures and dry, abrasive conditions. Commercial and government contracts dominate the high-value segment, preferring heavy-duty lines capable of handling tough, desert-adapted vegetation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nylon String Trimmer Line Market.- Arnold Corporation

- Blount International (Oregon)

- Husqvarna AB

- The Toro Company

- Stihl Holding AG & Co. KG

- Echo Incorporated

- Shakespeare Company LLC (Pflueger)

- Rotary Corporation

- Redmax (a Husqvarna brand)

- Rino-Tuff Inc.

- Fisher Barton

- Sunseeker (a Zhejiang Xinhu Power Co.)

- Greenworks Tools

- Tanaka Power Equipment

- Maruyama Mfg. Co. Inc.

- MTD Products

- Makita Corporation

- Emak S.p.A.

- Shindaiwa (a Yamabiko Corp.)

- Excel Industries

Frequently Asked Questions

Analyze common user questions about the Nylon String Trimmer Line market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Nylon 6 and Nylon 66 trimmer line materials?

Nylon 6 (PA 6) is generally preferred for its flexibility and ease of extrusion, making it cost-effective for standard residential lines. Nylon 66 (PA 66) offers superior tensile strength, higher temperature resistance, and greater rigidity, making it the material of choice for heavy-duty, commercial-grade, and high-performance trimmer lines that endure intense operational heat and abrasion.

How does the shape of the trimmer line (e.g., square vs. round) affect cutting performance?

Round line is the most common and resistant to breakage but offers moderate cutting effectiveness. Angular shapes like square or star lines possess sharp edges, providing a cleaner, faster cut, especially for thick weeds. Twisted or spiral lines are technologically advanced, minimizing air drag and significantly reducing noise while maintaining high cutting efficiency, ideal for noise-restricted areas.

Are bio-based or biodegradable nylon trimmer lines a viable commercial option?

Yes, bio-based nylon lines are emerging as a viable commercial option, particularly in European markets and among environmentally conscious consumers. While currently offering lower market penetration due to potential cost and durability trade-offs compared to traditional petrochemical nylon, advancements in polymer science are rapidly improving their performance and scalability, making them a significant growth opportunity for sustainable landscaping accessories.

What is co-extrusion technology and why is it important for premium trimmer lines?

Co-extrusion is a manufacturing process that creates trimmer lines with multiple distinct layers, typically a hard inner core for tensile strength and a softer outer layer for impact resistance and heat dissipation. This technology is vital for premium lines as it prevents melting (welding) and breakage, significantly enhancing the longevity and overall cutting efficiency required for intense, professional-grade use.

Which regional market is driving the fastest growth in the demand for nylon string trimmer lines?

The Asia Pacific (APAC) region is projected to exhibit the fastest market growth. This acceleration is fueled by rapid infrastructural development, increasing urbanization, rising middle-class disposable incomes leading to greater lawn care investment, and the subsequent professionalization and mechanization of the landscaping service sector across major economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Serrated Nylon String Trimmer Line Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Nylon String Trimmer Line Market Statistics 2025 Analysis By Application (Commercial, Residential), By Type (Round, Multi-sided, Twisted, Serrated), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager