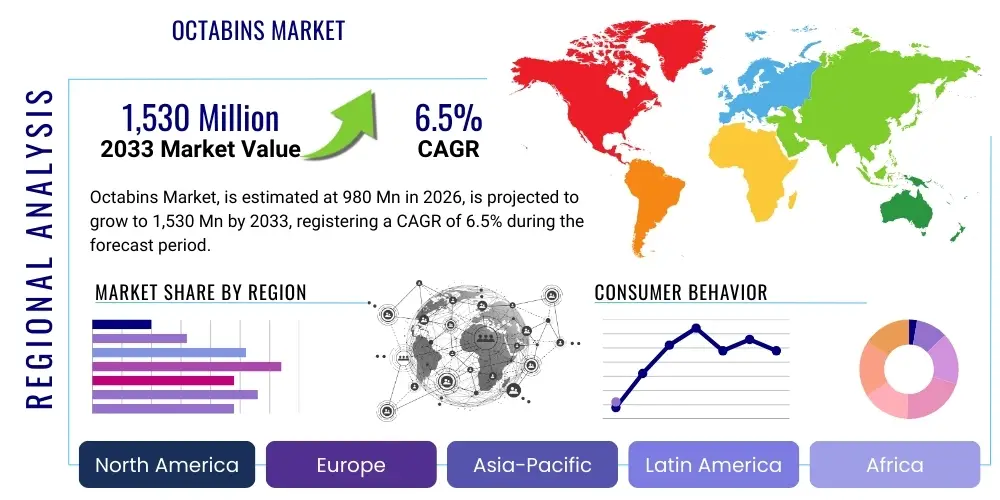

Octabins Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440415 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Octabins Market Size

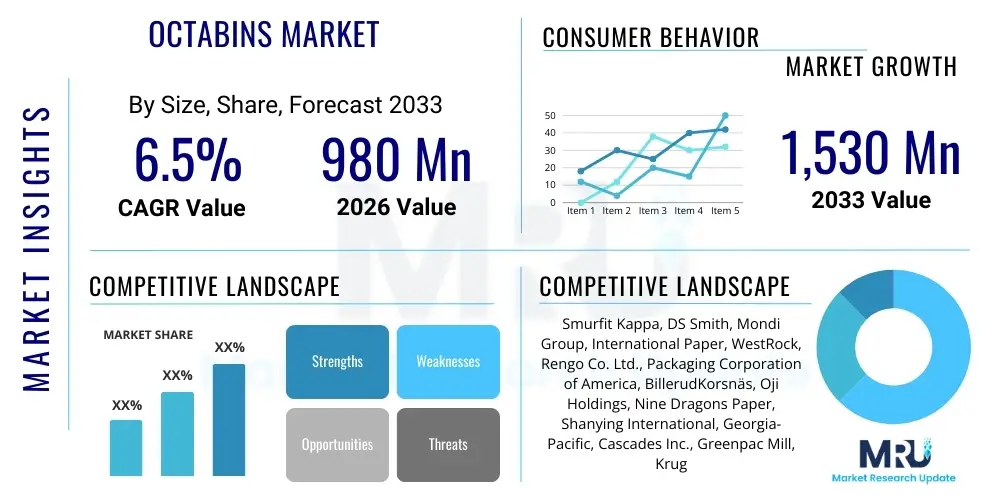

The Octabins Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 980 Million in 2026 and is projected to reach USD 1,530 Million by the end of the forecast period in 2033.

Octabins Market introduction

The Octabins market refers to the global industry involved in the manufacturing, distribution, and application of octagonal bulk containers, primarily constructed from heavy-duty corrugated cardboard. These robust and versatile packaging solutions are specifically designed for the safe and efficient transport and storage of a wide array of bulk materials, ranging from dry granules and powders to viscous liquids when used with appropriate liners. Octabins serve as a critical component in various supply chains, offering an economical and environmentally conscious alternative to traditional rigid containers like drums or intermediate bulk containers (IBCs) for certain applications. Their inherent structural integrity, often reinforced with multiple layers of corrugated board, allows for significant stacking capabilities, optimizing warehouse space and logistics efficiency. Key benefits driving their adoption include their lightweight nature, which reduces shipping costs; their collapsibility for return logistics and space-saving storage when empty; and their recyclability, aligning with global sustainability initiatives. Major applications span across diverse sectors such as food and beverages, chemicals, pharmaceuticals, agriculture, and general industrial goods, where they facilitate the bulk movement of ingredients, finished products, or waste materials. The increasing demand for sustainable packaging solutions, coupled with the expansion of global trade and the industrial manufacturing base, represents significant driving factors for the Octabins market. These containers are increasingly preferred for their ability to streamline operations, minimize material handling requirements, and contribute to a reduced carbon footprint, positioning them as an indispensable tool in modern bulk logistics and packaging strategies.

Octabins Market Executive Summary

The Octabins market is experiencing robust growth, driven by an accelerating shift towards sustainable and cost-effective bulk packaging solutions across various industries globally. A prominent business trend observed is the continuous innovation in material science and design, leading to Octabins with enhanced barrier properties, moisture resistance, and improved structural integrity, thereby expanding their applicability to more sensitive or challenging products. Manufacturers are increasingly focusing on incorporating recycled content and ensuring full recyclability of Octabins, responding to both regulatory pressures and growing corporate sustainability commitments. Automation in filling, handling, and emptying processes of Octabins is also a key development, aimed at improving operational efficiency and reducing labor costs for end-users. From a regional perspective, Asia Pacific continues to emerge as a dominant growth engine, propelled by rapid industrialization, expanding manufacturing sectors, and increasing intra-regional trade, particularly in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate a mature yet growing market, characterized by strong demand for eco-friendly packaging and the adoption of advanced logistics technologies, driving the replacement of less sustainable alternatives. Latin America, the Middle East, and Africa are showing nascent but significant growth, fueled by investments in infrastructure and the burgeoning demand from chemical, food processing, and agricultural industries. Segment-wise, the market is broadly characterized by variations in material type, capacity, and end-use industry. The food and beverages sector consistently remains a leading segment due to the high volume of bulk ingredients and finished goods requiring efficient transport. The chemicals and pharmaceuticals sectors are also significant contributors, driven by stringent safety and purity requirements, necessitating specialized liners and advanced material Octabins. The emphasis on tailored solutions, offering optimal protection and handling characteristics for specific product types and logistical chains, underscores the dynamic and evolving nature of the Octabins market.

AI Impact Analysis on Octabins Market

The integration of Artificial Intelligence (AI) is set to profoundly influence the Octabins market, primarily by enhancing efficiency, optimizing supply chains, and fostering innovation in product design and application. Users frequently inquire about how AI can improve demand forecasting for Octabins, leading to more precise inventory management for manufacturers and reduced waste across the value chain. There's also significant interest in AI's role in optimizing logistics and routing for bulk goods packaged in Octabins, aiming to minimize transportation costs and delivery times. Furthermore, discussions often revolve around AI-powered quality control systems that can detect manufacturing defects in Octabins more accurately and rapidly, ensuring product integrity. Users also express expectations regarding AI's contribution to developing smarter Octabins, potentially through embedded sensors that monitor conditions like temperature, humidity, or impact during transit, providing real-time data for proactive intervention and enhanced product safety. The overarching theme is a desire for greater predictability, efficiency, and intelligence within the Octabins ecosystem, transforming traditional bulk packaging into a more data-driven and responsive component of the supply chain.

- AI-driven demand forecasting: Optimizes production schedules and inventory levels for Octabin manufacturers and users, minimizing overproduction and stockouts.

- Logistics and route optimization: AI algorithms can analyze complex data to determine the most efficient routes and loading patterns for Octabins, reducing fuel consumption and transit times.

- Enhanced quality control: AI-powered vision systems can detect subtle flaws or inconsistencies in Octabin manufacturing, ensuring higher product quality and reliability.

- Predictive maintenance for machinery: AI can anticipate equipment failures in Octabin production lines, allowing for proactive maintenance and reducing downtime.

- Smart packaging integration: AI can process data from sensors embedded in Octabins to monitor environmental conditions (temperature, humidity, shock) during transport, providing real-time insights into product integrity.

- Supply chain visibility and traceability: AI enhances transparency across the Octabins supply chain, from raw material sourcing to final delivery, improving accountability and reducing risks.

- Customization and design optimization: AI tools can analyze specific product requirements and logistical constraints to recommend optimal Octabin designs and material specifications, leading to tailored and efficient solutions.

- Automated warehousing and material handling: AI-powered robotics can automate the movement, stacking, and retrieval of filled Octabins within warehouses, boosting operational speed and safety.

- Waste reduction and sustainability analytics: AI can identify inefficiencies in packaging usage and recommend strategies for material optimization and improved recycling rates for Octabins.

- Market trend analysis: AI algorithms can process vast amounts of market data to identify emerging trends, consumer preferences, and competitive landscapes, informing strategic decisions for Octabin market players.

DRO & Impact Forces Of Octabins Market

The Octabins market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, all underpinned by various Impact Forces that influence its growth trajectory and evolutionary path. A primary driver is the escalating global demand for sustainable and recyclable packaging solutions, as industries increasingly seek to minimize their environmental footprint and comply with evolving regulatory frameworks for waste reduction and circular economy principles. The inherent cost-effectiveness of Octabins, particularly in reducing transportation expenses due to their lightweight and collapsible nature, along with optimized storage space, further propels their adoption. The continuous expansion of industrial manufacturing activities worldwide, coupled with the growth in international trade, necessitates efficient and reliable bulk packaging, directly boosting the demand for Octabins across diverse sectors like chemicals, food processing, and pharmaceuticals. On the other hand, certain restraints temper market expansion. These include the vulnerability of standard Octabins to moisture and extreme humidity without specialized linings or coatings, limiting their use in certain environments or for specific products. Intense competition from alternative bulk packaging solutions such as Flexible Intermediate Bulk Containers (FIBCs), rigid IBCs, and drums also presents a significant challenge, requiring Octabin manufacturers to constantly innovate and differentiate their offerings. Opportunities abound for market players willing to invest in research and development. Innovations in barrier materials and advanced coatings that enhance moisture resistance and product protection, as well as the integration of smart packaging technologies (e.g., IoT sensors for condition monitoring), represent significant avenues for growth. Furthermore, the expansion of global recycling infrastructure and the development of advanced material recovery processes can bolster the end-of-life management of Octabins, strengthening their sustainable appeal. The primary impact forces influencing this market include technological advancements in corrugated board manufacturing and converting processes, leading to stronger yet lighter materials; evolving environmental regulations that favor eco-friendly packaging; and shifting consumer and corporate preferences towards more sustainable and efficient supply chain practices. Economic growth in emerging markets, driving increased industrial output and consumption, also serves as a crucial underlying force. The competitive landscape and strategic collaborations among key players further dictate market dynamics, influencing pricing, innovation, and market penetration strategies, collectively steering the Octabins market towards a future marked by efficiency, sustainability, and technological integration.

Segmentation Analysis

The Octabins market is comprehensively segmented to provide a detailed understanding of its diverse landscape, categorized primarily by the material type used in their construction, their volumetric capacity, and the specific end-use industries they serve. This multifaceted segmentation allows for precise market analysis, identifying key trends, growth drivers within specific niches, and the unique demands of various applications. Each segment possesses distinct characteristics influenced by factors such as cost, performance requirements, regulatory compliance, and logistical considerations. For instance, the choice of material directly impacts the container's strength, recyclability, and barrier properties, while capacity dictates its suitability for different scales of bulk transport. The end-use industry segmentation highlights the varied product types handled and the sector-specific standards that Octabins must meet, from hygiene in food and pharmaceuticals to chemical resistance in industrial applications. This granular approach is vital for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate and efficient Octabin solutions for their operational needs, ultimately contributing to the market's overall growth and specialization.

- By Material Type:

- Virgin Kraft Paper: Octabins made from pure, unbleached wood pulp, known for superior strength, durability, and tear resistance, often preferred for heavy-duty applications or where pristine material quality is crucial.

- Recycled Kraft Paper: Octabins incorporating a significant proportion of recycled fibers, offering a more environmentally friendly and cost-effective option, widely used for general industrial applications where high strength is still required.

- Other Specialty Papers: Includes paper types with specific coatings, laminations, or treatments (e.g., wax-coated, polyethylene-lined) to enhance moisture resistance, barrier properties, or chemical compatibility for specialized applications.

- By Capacity:

- Up to 500 Liters: Smaller capacity Octabins typically used for more manageable quantities, specialized chemicals, or pharmaceutical intermediates, offering flexibility in handling.

- 501-1000 Liters: Medium-sized Octabins, a popular choice for a wide range of applications including food ingredients, powders, and granular products, balancing capacity with ease of handling.

- 1001-1500 Liters: Larger capacity Octabins suitable for substantial bulk transport, common in agricultural products, bulk chemicals, and certain industrial goods, optimizing logistics for higher volumes.

- Above 1500 Liters: Very large Octabins designed for maximum bulk capacity, ideal for industries requiring high-volume shipping and storage, minimizing the number of containers needed.

- By End-Use Industry:

- Food & Beverages: Octabins used for transporting dry food ingredients (e.g., sugar, flour, grains, spices), liquid concentrates (with liners), and processed food products, requiring hygienic and often food-grade compliant solutions.

- Chemicals: Applications include bulk chemicals, resins, pellets, and hazardous materials (with appropriate liners and UN certification), emphasizing strength, chemical resistance, and safety features.

- Pharmaceuticals: Transport of active pharmaceutical ingredients (APIs), excipients, and other bulk pharmaceutical compounds, demanding high levels of cleanliness, sterility, and traceability.

- Agriculture: Used for seeds, fertilizers, animal feed, bulk produce, and other agricultural commodities, focusing on durability, weather resistance, and cost-effectiveness.

- Industrial Goods: Encompasses a broad spectrum including plastic granules, automotive parts, metal components, minerals, and other manufactured goods, prioritizing protection, stacking strength, and efficient logistics.

- Other Industries: Includes applications in waste management, construction materials, textiles, and various other sectors requiring bulk packaging solutions.

Value Chain Analysis For Octabins Market

The value chain for the Octabins market is an intricate network of interconnected stages, beginning with raw material sourcing and culminating in the end-user application and eventual recycling or disposal. Upstream analysis focuses on the foundational inputs required for Octabin production. This primarily involves the pulp and paper industry, which supplies virgin or recycled kraft paperboard, the core material for Octabins. Key activities at this stage include sustainable forestry practices, pulp production, paperboard manufacturing, and the supply of specialized coatings or additives that impart properties like moisture resistance or barrier protection. The quality and availability of these raw materials significantly impact the cost-effectiveness and performance characteristics of the final Octabin product. Suppliers of adhesive agents, inks, and internal liners (such as polyethylene or metallic films for liquid or sensitive products) also form a crucial part of the upstream segment, ensuring the functionality and integrity of the bulk container. As the value chain moves into the midstream, corrugated board manufacturers convert the paperboard into heavy-duty corrugated sheets, often multi-layered, which are then die-cut, creased, and printed to form the components of the Octabin. This manufacturing stage involves precision engineering to ensure the structural strength, collapsibility, and ease of assembly of the Octabins. Downstream analysis then concentrates on the distribution and end-user segments. Once manufactured, Octabins are distributed through a combination of direct and indirect channels. Direct distribution involves Octabin manufacturers selling directly to large industrial end-users or contract packaging companies that require bulk quantities consistently. This channel allows for direct negotiation, customized solutions, and closer relationships between producer and consumer. Indirect distribution leverages a network of packaging distributors, wholesalers, and logistics providers who stock various packaging solutions, including Octabins, and serve a broader base of smaller to medium-sized enterprises. These intermediaries play a vital role in market reach, inventory management, and providing localized support and delivery services. End-users, encompassing a wide array of industries such as food and beverages, chemicals, pharmaceuticals, and agriculture, then integrate Octabins into their bulk packaging operations for storage, transport, and distribution of their products. The efficiency of the entire value chain is paramount, as any disruptions in raw material supply, manufacturing bottlenecks, or inefficient distribution can impact lead times, costs, and ultimately, the market competitiveness of Octabins. Furthermore, the downstream also includes post-consumption activities such as recycling and waste management, which are increasingly important for closing the loop in a circular economy model and enhancing the overall sustainability profile of Octabins.

Octabins Market Potential Customers

Potential customers for the Octabins market span across an extensive range of industrial sectors, all united by a common need for efficient, secure, and often sustainable solutions for bulk storage and transportation of various materials. These end-users are typically large-scale manufacturers, processors, and distributors who handle significant volumes of raw materials, intermediate products, or finished goods that can be efficiently contained within octagonal bulk boxes. A primary demographic includes companies within the food and beverage industry, such as producers of grains, sugar, flour, coffee beans, cocoa powder, dairy powders, and liquid concentrates, who require hygienic and often food-grade compliant packaging for their ingredients and bulk products. Similarly, the chemical sector represents a substantial customer base, comprising manufacturers of polymers, resins, pigments, adhesives, fertilizers, and other industrial chemicals, where Octabins provide a robust and often chemical-resistant solution, especially when paired with specialized liners. The pharmaceutical industry also constitutes a critical segment of potential customers, particularly for the transport of active pharmaceutical ingredients (APIs), excipients, and bulk drug intermediates, necessitating packaging that meets stringent cleanliness standards and offers product protection. Agricultural enterprises, including large farms, seed producers, and agricultural cooperatives, utilize Octabins for seeds, animal feed, fertilizers, and bulk produce, valuing their durability and capacity for large volumes. Furthermore, a wide array of industrial goods manufacturers, ranging from plastic processors using granules and pellets, to automotive suppliers moving components, and companies dealing with minerals, aggregates, or general industrial components, find Octabins ideal for streamlining their internal logistics and outbound shipping. Logistics and third-party warehousing providers also act as significant indirect customers, as they integrate Octabins into their service offerings for various clients across multiple industries, optimizing their storage and freight operations. The increasing focus on sustainability across all these sectors further drives the adoption of Octabins, as companies seek packaging solutions that are recyclable, reduce waste, and contribute positively to their environmental, social, and governance (ESG) objectives. Ultimately, any business involved in the bulk handling of non-liquid, semi-liquid, or granular products, seeking to optimize supply chain efficiency, reduce packaging costs, and improve environmental performance, represents a potential customer for the Octabins market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 980 Million |

| Market Forecast in 2033 | USD 1,530 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Smurfit Kappa, DS Smith, Mondi Group, International Paper, WestRock, Rengo Co. Ltd., Packaging Corporation of America, BillerudKorsnäs, Oji Holdings, Nine Dragons Paper, Shanying International, Georgia-Pacific, Cascades Inc., Greenpac Mill, Kruger Inc., Sonoco Products Company, Huhtamäki, Segezha Group, Saica, Tri-Wall Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Octabins Market Key Technology Landscape

The Octabins market is increasingly shaped by advancements in several key technological areas that contribute to enhanced product performance, manufacturing efficiency, and sustainability. At the core, advancements in corrugated board manufacturing technology are paramount. This includes innovations in paper-making processes that produce stronger, lighter, and more moisture-resistant kraft papers, allowing for the creation of multi-layered corrugated structures that offer superior stacking strength and burst resistance without excessive material usage. High-speed, precision converting machinery, such as sophisticated die-cutting and gluing equipment, plays a crucial role in the efficient and accurate production of Octabin components, enabling complex designs and rapid assembly. Furthermore, printing technologies have evolved to allow for high-quality graphics and branding directly onto the Octabins, adding value beyond mere containment. Beyond the core material and manufacturing, the technology landscape extends to barrier coatings and lamination techniques. These involve the application of specialized polymers, waxes, or metallic films to the inner or outer surfaces of the Octabins. This significantly improves their resistance to moisture, grease, and chemicals, broadening their applicability to products that require enhanced protection or hygienic conditions, such as certain food ingredients or pharmaceutical compounds. The development of advanced adhesive technologies ensures the integrity of these coatings and the overall structural stability of the Octabins under various environmental stresses. Furthermore, the integration of smart packaging technologies is an emerging trend. This includes the incorporation of RFID tags, QR codes, or even embedded sensors that can monitor parameters like temperature, humidity, shock, or location during transit. These technologies leverage the Internet of Things (IoT) to provide real-time data, enhancing traceability, supply chain visibility, and product safety. Such innovations enable proactive interventions in case of adverse conditions, reducing spoilage and improving overall logistical efficiency. Automation technologies, particularly in the filling, handling, and palletizing of Octabins at end-user facilities, are also critical. Robotic systems and automated material handling equipment streamline operations, reduce labor costs, and minimize human error, further solidifying Octabins' position as a preferred bulk packaging solution. The drive towards sustainability also fuels technological innovation, with ongoing research into biodegradable coatings, plant-based adhesives, and advanced recycling processes for corrugated materials, ensuring that Octabins remain at the forefront of eco-friendly packaging solutions. These technological advancements collectively contribute to making Octabins more versatile, robust, intelligent, and environmentally responsible, meeting the evolving demands of modern global supply chains.

Regional Highlights

- North America: This region represents a mature yet dynamic market for Octabins, characterized by a strong emphasis on supply chain efficiency, sustainability, and technological integration. The United States and Canada are major consumers, driven by robust manufacturing sectors (chemicals, food & beverages, industrial goods) and a well-developed logistics infrastructure. Demand is particularly high for custom-designed Octabins and those offering enhanced performance features like superior moisture resistance or smart tracking capabilities. Regulatory pressures and corporate sustainability initiatives are significant drivers for the adoption of recyclable and eco-friendly Octabins.

- Europe: Europe is a key market, propelled by stringent environmental regulations, a strong focus on circular economy principles, and a highly diversified industrial base. Countries such as Germany, France, the UK, and Italy are leading consumers, particularly within the chemical, pharmaceutical, and food processing industries. Innovation in material science, including lightweighting and improved barrier properties, is a prominent trend. The region also exhibits a high demand for high-quality, certified Octabins that adhere to strict safety and hygiene standards.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for Octabins, fueled by rapid industrialization, expanding manufacturing capabilities, and increasing trade activities in countries like China, India, Japan, South Korea, and Southeast Asian nations. The burgeoning food & beverage, chemical, and agricultural sectors in this region are creating immense demand for cost-effective and efficient bulk packaging. The rise of e-commerce for bulk goods and growing awareness about sustainable packaging solutions further contribute to market expansion.

- Latin America: This region presents emerging opportunities for the Octabins market, primarily driven by growth in the agricultural, food processing, and mining sectors. Countries like Brazil, Mexico, and Argentina are experiencing increasing industrial output and investments in logistics infrastructure. While price sensitivity can be a factor, the demand for economical and sturdy bulk packaging solutions is steadily rising, encouraging the adoption of Octabins.

- Middle East and Africa (MEA): The MEA market for Octabins is witnessing gradual growth, mainly influenced by investments in petrochemicals, agriculture, and infrastructure development. The need for efficient packaging solutions for raw materials and finished products, particularly in the Gulf Cooperation Council (GCC) countries and parts of Africa, is driving demand. Focus on diversifying economies and enhancing regional supply chains is expected to further boost the market in the coming years.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Octabins Market.- Smurfit Kappa

- DS Smith

- Mondi Group

- International Paper

- WestRock

- Rengo Co. Ltd.

- Packaging Corporation of America

- BillerudKorsnäs

- Oji Holdings Corporation

- Nine Dragons Paper (Holdings) Limited

- Shanying International Holdings Co., Ltd.

- Georgia-Pacific LLC

- Cascades Inc.

- Greenpac Mill LLC

- Kruger Inc.

- Sonoco Products Company

- Huhtamäki Oyj

- Segezha Group

- Saica S.A.

- Tri-Wall Limited

Frequently Asked Questions

Analyze common user questions about the Octabins market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Octabins and what are their primary uses?

Octabins are large, octagonal bulk containers typically made from heavy-duty corrugated cardboard, designed for the efficient and cost-effective transport and storage of bulk granular, powdered, or liquid products (with liners). They are widely used across industries like food & beverages, chemicals, pharmaceuticals, and agriculture for ingredients, finished goods, and waste.

What are the main advantages of using Octabins over other bulk packaging solutions?

Key advantages include their lightweight nature, which reduces shipping costs; their collapsibility for space-saving return logistics; strong stacking capabilities for optimized warehousing; and their excellent recyclability, aligning with sustainability goals. They offer a cost-effective alternative to rigid containers for many bulk applications.

How do Octabins contribute to sustainability initiatives?

Octabins significantly contribute to sustainability by being primarily made from renewable, recyclable corrugated cardboard. Their lightweight design reduces fuel consumption during transport, and their ability to be collapsed minimizes logistical impact. Utilizing recycled content in their manufacturing further enhances their environmental profile, supporting circular economy principles.

What factors influence the growth of the Octabins market?

The market's growth is primarily driven by increasing global demand for sustainable and cost-effective packaging, the expansion of industrial manufacturing and international trade, and the lightweight and space-saving benefits of Octabins in logistics. Innovations in material science and smart packaging integration also act as significant growth catalysts.

Can Octabins be customized for specific product requirements or industries?

Yes, Octabins are highly customizable. Manufacturers can tailor their size, capacity, and material specifications, including various barrier coatings or specialized liners (e.g., for moisture, chemicals, or food-grade products), to meet the unique protection, hygiene, and handling requirements of different products and end-use industries, ensuring optimal performance and compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager