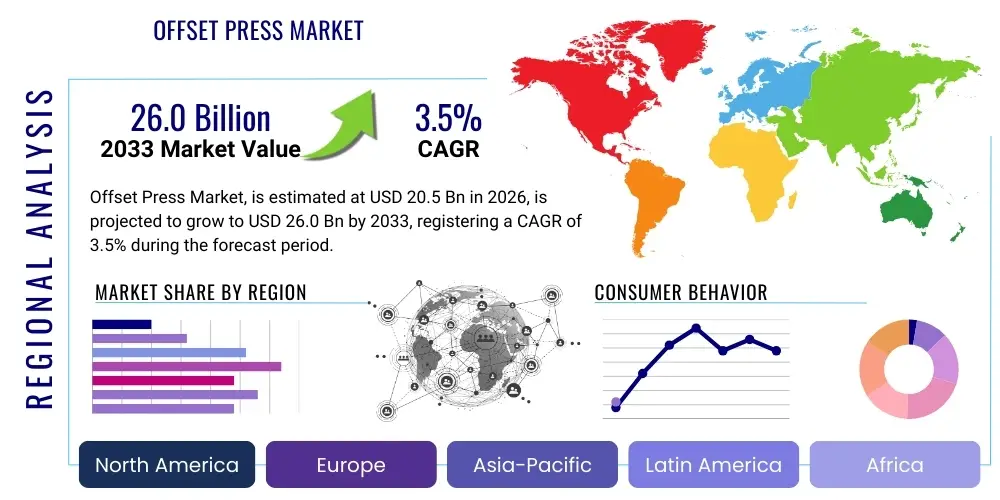

Offset Press Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437801 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Offset Press Market Size

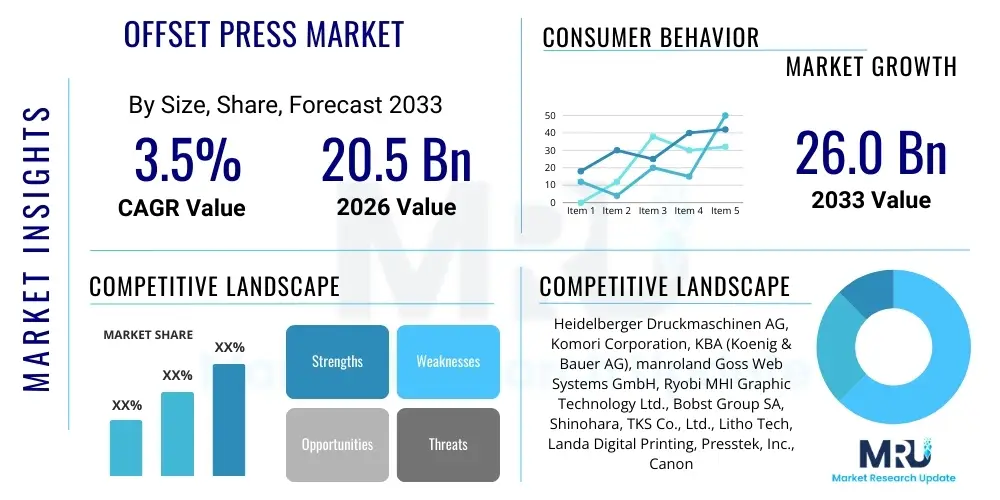

The Offset Press Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.5% between 2026 and 2033. The market is estimated at $20.5 Billion in 2026 and is projected to reach $26.0 Billion by the end of the forecast period in 2033. This consistent, albeit moderate, growth is driven primarily by sustained demand from the packaging industry and the continued need for high-quality, large-volume commercial printing applications worldwide. While digital printing continues to capture the short-run market, offset technology maintains a dominant position in high-fidelity, long-run production due to superior cost efficiency and image quality.

Offset Press Market introduction

The Offset Press Market encompasses the manufacturing, distribution, and utilization of sophisticated printing machines that employ the lithographic technique, transferring an inked image from a plate to a rubber blanket, and then onto the printing surface. Offset printing, characterized by its ability to deliver consistent high quality and exceptional cost efficiency for large-volume print jobs, remains the backbone of the commercial, publishing, and increasingly, the packaging sectors. Key products within this market include sheet-fed presses, favored for versatile commercial and short-to-medium run applications, and web-fed presses, essential for high-speed, continuous-run operations like newspapers and high-volume magazines.

Major applications of offset presses span across numerous industries. In the commercial sphere, they are utilized for printing marketing materials, brochures, and catalogs. In packaging, they are crucial for producing folding cartons, labels, and flexible packaging with high precision and demanding color fidelity. The core benefits driving the adoption of offset technology include unparalleled image sharpness, precise color registration (especially crucial for branded materials), and the lowest cost per unit achievable when print quantities exceed established thresholds, typically tens of thousands of copies. This high volume efficiency ensures offset presses remain indispensable for global production chains.

Driving factors for market stability and moderate growth include the robust expansion of the global packaging industry, which relies heavily on the quality and format flexibility of offset printing, particularly in consumer goods markets. Furthermore, technological advancements, such as hybrid systems integrating digital modules and enhanced automation features like Computer-to-Plate (CtP) and closed-loop color control, are mitigating some historical drawbacks related to lengthy setup times and waste. These innovations ensure that offset printing maintains its competitive edge against fully digital alternatives in the medium-to-long run printing segment, sustaining investment in new and refurbished equipment.

- Product Description: Printing machinery utilizing lithography, transferring ink via a blanket cylinder to produce high-resolution, long-run prints.

- Major Applications: Commercial Printing (brochures, catalogs), Packaging (folding cartons, labels), Publishing (magazines, books, newspapers).

- Benefits: Superior print quality, consistent color fidelity, highest speed and lowest cost per unit for high-volume jobs, versatility in substrate handling.

- Driving Factors: Global packaging market growth, need for high-quality brand materials, technological advancements in automation and waste reduction.

Offset Press Market Executive Summary

The Offset Press Market demonstrates resilience, characterized by strategic shifts toward enhanced automation and integration with Industry 4.0 principles, allowing traditional offset manufacturers to maintain relevance despite intense competition from digital printing solutions. Current business trends indicate a strong polarization where high-end, highly automated sheet-fed presses (focused on packaging and premium commercial work) are seeing significant investment, while basic, lower-cost presses face margin pressure. Key industry players are focusing on developing hybrid technologies that combine the volume efficiency of offset with the personalization capabilities of inkjet, providing flexible solutions for modern print buyers who demand both quality and customization.

Regionally, the Asia Pacific (APAC) continues to dominate the market in terms of volume and installed base, driven by massive manufacturing output in countries like China and India, particularly within the booming consumer packaging sector. However, North America and Europe lead in terms of technological adoption, prioritizing advanced automation, eco-friendly printing solutions (such as UV LED curing), and sophisticated workflow software. Emerging markets in Latin America and MEA are exhibiting high growth potential as commercial printing infrastructures modernize to meet growing local consumer demand for packaged goods and educational materials.

Segment trends highlight the packaging application segment as the primary growth engine, where the demand for specialized formats, security features, and precise color management is paramount, favoring the strengths of offset technology. Within the technology segment, the sheet-fed press category remains the largest contributor to revenue due to its versatility and established use in commercial and folding carton printing. Conversely, the traditional publishing segment, particularly newspaper web-fed printing, faces structural challenges due to digital migration, necessitating consolidation and focused investment only in high-efficiency, narrow-web operations tailored for specialized publications or localized news delivery.

AI Impact Analysis on Offset Press Market

User queries regarding the impact of Artificial Intelligence (AI) on the Offset Press Market frequently center on themes of automation displacing skilled labor, the efficiency gains achievable in prepress, and the role of AI in predictive maintenance to minimize downtime. Users express concerns about the complexity of integrating AI tools into legacy equipment but hold high expectations for AI’s potential in optimizing supply chain logistics and reducing material waste, a critical cost factor in offset printing. The overriding perception is that AI will not replace the fundamental lithographic process but will revolutionize the operational efficiency and decision-making processes surrounding the press, enabling commercial printers to compete more effectively with the speed and flexibility offered by purely digital alternatives. Key discussions revolve around using machine learning for real-time color adjustment and anomaly detection, significantly reducing makeready time and improving consistency across massive print runs.

- Predictive Maintenance and Downtime Reduction: AI algorithms analyze sensor data from press components (e.g., rollers, motors, dampening systems) to predict potential mechanical failures before they occur, enabling proactive servicing and maximizing press uptime.

- Automated Prepress Workflow Optimization: Machine learning handles complex prepress tasks such as intelligent imposition, automated image enhancement, and optimized color separation, drastically cutting down manual setup time and minimizing human error.

- Real-Time Color and Quality Control: AI-driven closed-loop systems monitor print output continuously, making micro-adjustments to ink keys and dampening solutions in real time to maintain absolute color consistency throughout the entire job run, surpassing the capabilities of conventional densitometers.

- Supply Chain and Inventory Management: AI optimizes ink, substrate, and plate ordering based on predictive models of job schedules and consumption rates, reducing carrying costs and ensuring timely availability of necessary consumables.

- Energy Consumption Optimization: AI adjusts press operational settings (speed, temperature, drying systems) based on substrate type and environmental conditions to minimize energy usage without sacrificing print quality or production speed.

- Enhanced Print Security and Integrity: AI systems can quickly detect unauthorized reproduction or counterfeiting features during the printing process, essential for security printing and high-value brand packaging.

- Hybrid System Integration: AI facilitates the seamless blending of offset and digital printing processes, determining the optimal run length cutoff point and managing the workflow transition between the two technologies efficiently.

DRO & Impact Forces Of Offset Press Market

The dynamics of the Offset Press Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively determine the impact forces acting upon manufacturers and end-users. Primary drivers include the global surge in demand for high-quality packaging, particularly folding cartons and flexible packaging that require precise, large-format printing capabilities, where offset remains the most economically viable option for high volumes. Furthermore, advancements in automation technology, such as fully automated plate changing systems and rapid color profiling, significantly reduce setup times, addressing a key historical weakness of offset printing and reinforcing its competitive stance against digital methods in the mid-to-long run segment. The need for specialized printing features like metallic inks, varnishes, and high-fidelity screening in commercial and security printing also favors offset technology.

Conversely, significant restraints hinder more rapid market expansion. The high initial capital investment required for new offset press systems presents a substantial barrier to entry for smaller print shops and limits the frequency of replacement cycles even for established players. Moreover, intense and continuous competition from high-speed digital inkjet and toner presses, which excel in short runs, variable data printing, and personalized applications, consistently pressures offset pricing and erodes market share in the commercial short-run sector. Environmental concerns related to traditional printing processes, including waste paper, solvent-based inks, and high energy consumption (despite improvements), necessitate ongoing and costly investment in sustainable technologies, such as UV LED curing and process-less plates.

Opportunities for growth are centered on niche markets and technological hybridization. The development of hybrid offset/digital presses allows printers to leverage the cost-effectiveness of offset for static elements while integrating digital modules for variable data, opening new avenues in personalized packaging and targeted direct mail. The increasing demand for large-format offset printing, especially for specialized corrugated and flexible packaging, represents a high-value opportunity. Furthermore, the focus on developing advanced workflow software integrated with AI and cloud solutions provides opportunities for existing users to modernize their operations, increase overall equipment effectiveness (OEE), and gain a competitive advantage by maximizing the efficiency of their current press assets, thereby sustaining long-term market value. These factors ensure that despite competition, offset presses remain a vital component of the global printing infrastructure.

Segmentation Analysis

The Offset Press Market is meticulously segmented based on key functional attributes and end-user demands, including Type, Application, and Format Size, allowing for precise market evaluation and strategic planning. The segmentation by Type, encompassing sheet-fed, web-fed, and digital offset presses (often referred to as hybrid solutions), clearly delineates technologies based on speed and material handling capabilities. Sheet-fed presses, dominant in commercial and packaging sectors, are highly versatile, while web-fed presses cater exclusively to continuous, high-speed needs like newspapers and long-run catalogs. Analyzing segments by Application—Commercial Printing, Packaging, and Publishing—reveals that Packaging is the most resilient and fastest-growing segment, primarily due to the global boom in consumer goods packaging requiring high aesthetic quality and durability.

- By Type:

- Sheet-fed Offset Presses (Largest Revenue Share)

- Web-fed Offset Presses (Focus on high-speed long runs)

- Digital Offset/Hybrid Presses (Integration of digital components)

- By Application:

- Packaging (Fastest Growing Segment - Folding Cartons, Flexible Packaging)

- Commercial Printing (Brochures, Catalogs, Direct Mail)

- Publishing (Books, Magazines, Newspapers)

- By Format Size:

- Small Format (B3 and smaller)

- Medium Format (B2, B1)

- Large Format (VLF - Very Large Format, typically exceeding 40 inches/B0)

Value Chain Analysis For Offset Press Market

The value chain for the Offset Press Market begins with robust upstream activities involving critical suppliers of raw materials and specialized components. This tier includes highly specialized manufacturers providing precision engineering components like cylinders and gears, electronics for control systems, and essential consumables such as offset printing plates (including CTP plates, thermal and violet), printing blankets, and various types of inks (UV, conventional oil-based, and UV LED inks). The quality and innovation within the upstream segment, particularly in plate technology and ink formulation, directly impact the performance metrics—such as makeready time, environmental footprint, and print quality—of the final printing press equipment. Strong, long-term relationships between press manufacturers and key component suppliers are vital for ensuring technological leadership and reliable production schedules.

Midstream activities are dominated by Original Equipment Manufacturers (OEMs) who design, assemble, and rigorously test the final offset press machines. This stage encompasses significant Research and Development (R&D) investment focused on enhancing automation, improving energy efficiency, and integrating software for press management and workflow. Distribution channels are typically a mix of direct sales and indirect agent networks. Large, global OEMs often employ a direct sales model for high-value machinery purchases, ensuring specialized installation, training, and ongoing technical support. Conversely, regional or smaller markets are often served by authorized distributors and agents who manage local sales, logistics, and localized servicing, acting as crucial intermediaries in market penetration.

Downstream activities involve the end-users—the commercial printers, packaging companies, and publishers—who utilize the equipment for mass production. The effectiveness of the press in the hands of the end-user is heavily dependent on comprehensive after-sales support, including maintenance contracts, spare parts availability, and software updates. Direct service models provide manufacturers with critical feedback loops for future product enhancements, while indirect channels must ensure their local technical staff are certified and trained to handle complex troubleshooting. The focus downstream is increasingly on maximizing Overall Equipment Effectiveness (OEE) through preventative maintenance and software optimization, driving demand not just for new equipment but also for high-value servicing and performance upgrades throughout the machine's lifespan.

Offset Press Market Potential Customers

The primary consumers and end-users of offset press technology are entities that require high-volume, high-quality color printing on a consistent basis, where the cost-per-unit metric is paramount. These include large-scale commercial printing houses that handle external contracts for marketing materials, annual reports, and general commercial collateral. These commercial entities rely on offset's speed and consistency to meet demanding client specifications and tight deadlines, often utilizing highly automated sheet-fed presses capable of quick changeovers and sophisticated finishing.

A rapidly expanding customer base is found within the packaging manufacturing sector, including converters specializing in folding cartons, flexible packaging, and rigid boxes for consumer goods, pharmaceuticals, and food and beverage industries. These buyers demand VLF (Very Large Format) and specialized presses equipped with features necessary for printing on thick substrates and utilizing specialized inks (like low-migration inks for food packaging). The quality and color standardization (e.g., adherence to G7 or ISO standards) achievable through offset printing are non-negotiable requirements for brand integrity in this segment.

Finally, the publishing industry, though contracting in certain areas, remains a core customer, specifically for high-volume catalog production, educational textbooks, and long-run magazine printing, which typically require high-speed web-fed presses for efficiency. In-house corporate print departments of major corporations, particularly those with vast internal documentation or product manuals, also constitute potential customers, although many have shifted towards high-end digital solutions for internal use, reserving offset for outsourced bulk projects.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $20.5 Billion |

| Market Forecast in 2033 | $26.0 Billion |

| Growth Rate | 3.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Heidelberger Druckmaschinen AG, Komori Corporation, KBA (Koenig & Bauer AG), manroland Goss Web Systems GmbH, Ryobi MHI Graphic Technology Ltd., Bobst Group SA, Shinohara, TKS Co., Ltd., Litho Tech, Landa Digital Printing, Presstek, Inc., Canon Inc. (Océ Technologies), RMGT (Ryobi MHI Graphic Technology), Shanghai Electric Group (Goss International), Sakurai Graphic Systems Corp., Zhejiang Jinbao Machinery Co. Ltd., Mitsubishi Heavy Industries Printing & Packaging Machinery, Hamada Printing Press Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Offset Press Market Key Technology Landscape

The contemporary Offset Press Market is defined by technological advancements primarily focused on enhancing efficiency, reducing waste, and facilitating quicker changeovers to better compete with digital solutions. A pivotal technology is Computer-to-Plate (CtP) systems, which bypass the traditional film process entirely by imaging directly onto the offset plate. The widespread adoption of thermal and violet laser CtP systems has dramatically cut down makeready time, improved registration accuracy, and lowered the environmental impact associated with film processing chemicals, making the offset process significantly leaner and more responsive to modern production timelines.

Furthermore, automation and closed-loop control are standard features in high-end presses today. Automated features include simultaneous plate loading, blanket washing, and fully automatic ink adjustment systems that leverage spectrophotometric readings to instantaneously match printed color against preset standards (closed-loop color control). This technological sophistication minimizes human intervention during the run, ensures absolute color consistency from the first sheet to the last, and crucially reduces the initial paper waste associated with color stabilization. Press manufacturers are heavily investing in software interfaces that consolidate complex controls into user-friendly digital dashboards, often integrated with plant-wide Manufacturing Execution Systems (MES).

Another transformative area is the integration of specialized drying and curing technologies. UV and, more recently, UV LED curing systems have become critical, particularly in the packaging and high-end commercial segments. UV LED technology offers immediate drying, enabling faster subsequent processing (such as cutting and folding), reduces energy consumption compared to traditional heat drying, and allows printing on a wider array of non-porous substrates, including plastics and foils, which are essential for durable packaging. The shift towards waterless offset printing and process-less plates also represents an environmental technology trend aimed at reducing water consumption and chemical usage in the pressroom.

Regional Highlights

- Asia Pacific (APAC): Dominates the market in volume due to robust manufacturing capabilities and expansive growth in the consumer goods and e-commerce sectors, fueling massive demand for packaging and commercial print. China, India, and Japan are major hubs for both press manufacturing and high-volume press utilization, often focusing on large format and high-speed web presses.

- North America: Characterized by high technological maturity and a strong preference for automation and high-end, specialized presses. While the market is stable, investments are focused on replacing older machinery with highly efficient, highly automated sheet-fed presses capable of handling complex packaging jobs and short-to-medium runs with minimal operator intervention.

- Europe: A key region for innovation, particularly in sustainable printing technologies (UV LED, process-less plates) and highly specialized niche applications. Germany and Italy, home to major global manufacturers, drive the adoption of sophisticated presses for high-quality commercial, label, and specialized packaging markets, emphasizing environmental compliance and energy efficiency.

- Latin America (LATAM): Exhibits significant growth potential driven by industrialization and the expansion of local manufacturing capacity, increasing the need for both packaging and educational materials. The market is primarily served by imported second-hand or newly manufactured medium-format presses, with increasing investment in automation capabilities.

- Middle East and Africa (MEA): A high-potential emerging market experiencing infrastructure development, leading to increased demand for high-quality packaging materials and commercial printing services. Investment is often targeted in strategic hubs like the UAE and South Africa, focusing on modernizing existing print facilities to meet rapidly evolving quality standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Offset Press Market.- Heidelberger Druckmaschinen AG

- Komori Corporation

- KBA (Koenig & Bauer AG)

- manroland Goss Web Systems GmbH

- Ryobi MHI Graphic Technology Ltd. (RMGT)

- Bobst Group SA

- Screen Holdings Co., Ltd. (via digital integration)

- Landa Digital Printing (Hybrid systems focus)

- Shanghai Electric Group (Goss International)

- TKS Co., Ltd.

- Dainippon Screen Mfg. Co., Ltd.

- Fuji Machine Mfg. Co., Ltd.

- Canon Inc. (Océ Technologies - indirect competitor/partner)

- Xerox Corporation (Indirect competitor/partner)

- Duplo International

- Mitsubishi Heavy Industries Printing & Packaging Machinery

- Hamada Printing Press Co., Ltd.

- Zhejiang Jinbao Machinery Co. Ltd.

- Shinohara

- Presstek, Inc.

Frequently Asked Questions

Analyze common user questions about the Offset Press market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for offset presses, despite competition from digital printing?

The primary driver is the sustained global demand for high-quality, large-volume packaging, such as folding cartons and labels. Offset printing offers superior cost efficiency, exceptional color fidelity, and the necessary substrate versatility for high-volume, static-content production, making it indispensable for major brand owners.

How are offset press manufacturers incorporating digital technologies into their machines?

Manufacturers are developing hybrid offset-digital presses that integrate digital inkjet heads directly onto the offset frame. This strategy allows the press to handle long runs with offset efficiency while using the digital component for variable data printing, personalization, and late-stage customization.

Which geographical region holds the highest market share in the Offset Press Market?

The Asia Pacific (APAC) region currently holds the highest market share, driven by rapid industrial expansion, massive print volumes generated by packaging for e-commerce, and high manufacturing output across countries like China and India.

What is the role of automation and AI in modern offset press operations?

Automation, often enhanced by AI and machine learning, is critical for reducing makeready time, minimizing waste, and ensuring color consistency. AI enables predictive maintenance, automated prepress imposition, and closed-loop color control, boosting Overall Equipment Effectiveness (OEE) significantly.

What technological advancements are addressing the environmental concerns associated with offset printing?

Key advancements include the widespread adoption of UV LED curing systems (reducing energy consumption), process-less printing plates (eliminating chemical use), and the development of specialized, eco-friendly vegetable and low-migration inks, all aimed at reducing the environmental footprint of the pressroom.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager