Online Conductivity Detector Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431472 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Online Conductivity Detector Market Size

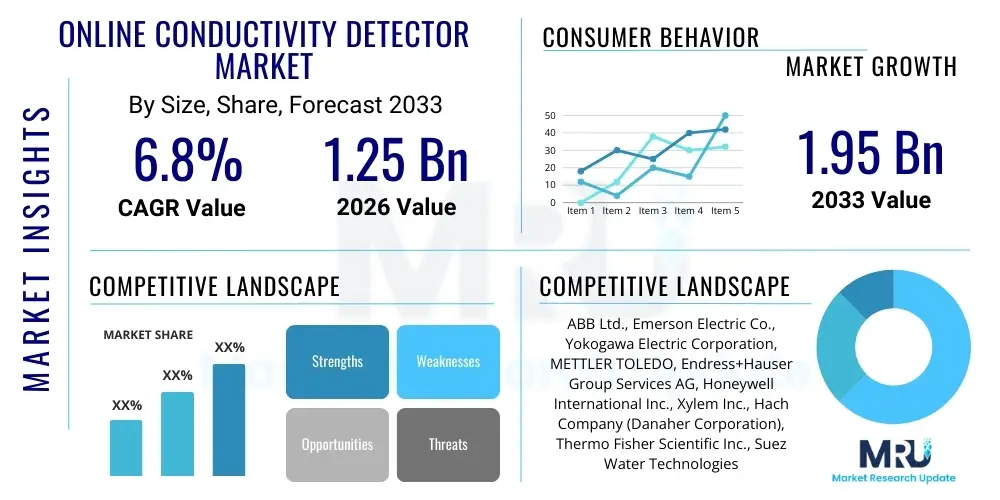

The Online Conductivity Detector Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.95 Billion by the end of the forecast period in 2033. This consistent expansion is underpinned by the increasing stringency of regulatory standards across various industrial sectors, particularly in wastewater treatment and pharmaceutical manufacturing, where precise monitoring of water quality parameters is non-negotiable for operational compliance and product integrity. The inherent reliability and continuous measurement capabilities of online systems further solidify their indispensable role in modern industrial process control infrastructure, driving substantial investment globally.

Online Conductivity Detector Market introduction

The Online Conductivity Detector Market encompasses instruments designed for the continuous, real-time measurement of electrical conductivity in liquid solutions, serving as a critical indicator of total dissolved solids (TDS) and ionic contamination. These sophisticated devices are integral components of automated process control and monitoring systems, offering superior accuracy and rapid response compared to offline laboratory analysis methods. They are widely deployed across industries that rely on maintaining precise water quality, including power generation, microelectronics, chemical processing, and life sciences. The primary function of these detectors is to ensure optimal process conditions, safeguard equipment from corrosion or scaling, and guarantee the final product adheres to specified purity levels.

Product descriptions for online conductivity detectors typically highlight features such as advanced temperature compensation, multiple calibration points, and robust sensor materials (e.g., stainless steel, titanium, or PEEK) capable of withstanding harsh industrial environments. These systems often integrate seamlessly with Distributed Control Systems (DCS) or Supervisory Control and Data Acquisition (SCADA) platforms via standardized communication protocols, enabling centralized data logging and remote operational adjustments. Major applications include monitoring boiler feedwater, ensuring the quality of WFI (Water for Injection) in pharmaceutical facilities, controlling reverse osmosis (RO) system efficiency, and tracking salinity levels in industrial effluent streams.

The market growth is fundamentally driven by the escalating demand for high-purity water across nearly all manufacturing domains, coupled with mandatory environmental regulations compelling industries to monitor and limit discharge contaminants. Key benefits derived from utilizing online detectors include enhanced operational efficiency, reduced maintenance costs through early detection of process deviations, and compliance risk mitigation. Furthermore, technological advancements leading to non-contacting sensors and improved signal processing capabilities are broadening the applicability of these detectors to highly corrosive or high-temperature processes, fueling sustained market expansion globally.

Online Conductivity Detector Market Executive Summary

The Online Conductivity Detector Market is characterized by robust growth, primarily propelled by global regulatory pressures demanding superior water and process quality management across key vertical industries. Current business trends indicate a strong preference for multi-parameter instruments that combine conductivity measurement with pH, dissolved oxygen, or resistivity monitoring, offering integrated solutions that reduce complexity and installation footprint. The transition towards smart factory environments is accelerating the adoption of detectors featuring advanced IoT capabilities, enabling predictive maintenance and cloud-based data analytics for improved decision-making and operational transparency across decentralized facilities.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, driven by massive infrastructure investments in manufacturing, rapid urbanization leading to increased municipal water treatment demands, and the expansion of the electronics and semiconductor industries which require ultra-pure water. North America and Europe, while mature, maintain strong market shares fueled by strict environmental protection laws and continuous technological upgrades in established industrial bases, especially in pharmaceuticals and power generation sectors. The Middle East and Africa (MEA) are also emerging areas, notably due to large-scale desalination projects and investments in oil and gas processing facilities where accurate conductivity monitoring is essential for process safety and efficiency.

Segmentation trends reveal that contact conductivity sensors continue to dominate the market by volume, owing to their cost-effectiveness and reliability in standard water applications, but toroidal (inductive) sensors are gaining significant traction in high-concentration or fouling applications due to their low maintenance requirements. End-use segmentation highlights the Power Generation sector as the largest consumer, given the critical necessity of monitoring boiler water quality to prevent costly turbine damage, closely followed by the Chemicals and Pharmaceuticals segments, which prioritize product quality assurance. The convergence of hardware manufacturing with specialized software platforms for data interpretation represents a major strategic focus for leading market players, ensuring competitive differentiation through service offerings.

AI Impact Analysis on Online Conductivity Detector Market

User questions related to the impact of Artificial Intelligence (AI) on the Online Conductivity Detector Market primarily center on how AI can enhance measurement accuracy, facilitate predictive maintenance, and integrate diverse sensor data for holistic process optimization. Users are keen to understand if AI can compensate for sensor drift or fouling effects, thereby extending calibration cycles and reducing operational downtime. There is also significant interest in leveraging machine learning algorithms to identify subtle, non-linear correlations between conductivity variations and other critical process parameters, enabling earlier detection of anomalies than traditional alarm systems allow. The key themes revolve around automation, improved reliability, and the potential for AI-driven analytics to transform reactive maintenance schedules into highly accurate, predictive models, ultimately maximizing efficiency and regulatory compliance while minimizing human intervention in routine monitoring tasks.

The integration of AI into online conductivity monitoring systems is moving beyond simple data logging to advanced diagnostic capabilities. By applying algorithms such as clustering and regression analysis to historical and real-time conductivity data, AI systems can automatically detect patterns indicative of impending equipment failure, sensor degradation, or unexpected chemical intrusions. This shift towards cognitive monitoring not only improves the reliability of the measurements themselves but also allows facility operators to manage complex, multi-stage water treatment processes with unprecedented precision. For example, in reverse osmosis systems, AI can dynamically adjust chemical dosing or backwash cycles based on instantaneous predictive fouling rates derived from conductivity trends, leading to substantial savings in chemical usage and extending membrane lifespan.

Furthermore, AI-powered systems are facilitating seamless integration across disparate industrial control platforms. By utilizing standardized communication frameworks and machine learning models trained on diverse datasets, AI acts as an interpreter, correlating conductivity readings from one point in the process with flow rates, temperature, and pressure readings elsewhere. This holistic view is crucial for industries like semiconductor manufacturing, where ultra-pure water specifications are extremely tight. The ability of AI to provide prescriptive recommendations—rather than just descriptive data—allows operators to preemptively intervene, optimizing the entire water loop for maximum purity and minimal waste, thereby realizing significant gains in sustainability and cost-efficiency.

- AI enables predictive calibration scheduling, minimizing unnecessary maintenance downtime.

- Machine learning algorithms detect subtle process anomalies faster than traditional threshold alarms, enhancing safety.

- AI facilitates multi-sensor data fusion, providing holistic insights into water quality dynamics.

- Automated drift compensation using neural networks improves long-term measurement accuracy.

- Generative AI tools assist in simulating complex process failures and optimizing system response protocols.

- Enhanced data pattern recognition supports better compliance reporting and audit trail generation.

DRO & Impact Forces Of Online Conductivity Detector Market

The Online Conductivity Detector Market is shaped by a powerful matrix of Drivers, Restraints, and Opportunities (DRO), all contributing to distinct Impact Forces. Key drivers include the global mandate for environmental sustainability, leading to stringent regulations on industrial wastewater discharge and the pervasive need for high-purity process water in manufacturing. Restraints primarily involve the high initial capital expenditure associated with installing high-precision online monitoring systems and the complexity of integrating diverse sensor technologies into legacy industrial infrastructure. Opportunities lie significantly in developing wireless and IoT-enabled detectors that minimize installation costs and enable remote monitoring, alongside the expansion into emerging markets requiring substantial upgrades in water treatment infrastructure.

The strongest impact force driving market acceleration is regulatory compliance, particularly within the pharmaceutical, food and beverage, and power generation sectors, where product purity and plant safety are directly tied to consistent water quality monitoring. International bodies and national agencies continuously update standards for contaminants and water resistivity (the inverse of conductivity), forcing industries to adopt reliable online solutions capable of continuous, auditable data collection. This regulatory push ensures a steady demand, regardless of short-term economic fluctuations, as non-compliance carries severe penalties and operational shutdowns.

Conversely, a restraining force that subtly affects growth is the ongoing challenge of sensor fouling and maintenance in high-solids or high-temperature applications, which can compromise the accuracy of contact-based conductivity probes. While technological advancements, such as inductive (toroidal) sensors, mitigate this, the total cost of ownership remains a critical factor for small and medium-sized enterprises (SMEs). However, the overarching opportunity presented by the Industrial Internet of Things (IIoT) is rapidly overcoming these restraints by enabling real-time remote diagnostics and predictive maintenance alerts, significantly improving the effective lifespan and operational cost-efficiency of advanced online detectors across all market segments.

Segmentation Analysis

The Online Conductivity Detector Market is comprehensively segmented based on the core components of the monitoring systems, the technology utilized, the end-user applications they serve, and the geographic regions where they are deployed. This detailed segmentation allows manufacturers to tailor product development and marketing strategies to meet the specific requirements of highly technical industries. The primary modes of segmentation focus on differentiating between the sensor types—contacting, which are highly accurate for low to medium conductivity ranges, and non-contacting (inductive or toroidal), which excel in high-concentration or aggressive media where fouling is a concern. Furthermore, segmentation by application highlights the distinct performance needs of sectors such as ultrapure water monitoring in semiconductors versus high-salinity monitoring in desalination plants, showcasing the technological diversity required across the market.

Segmentation by components is crucial, differentiating between sensors/probes, transmitters/analyzers, and accessories/software platforms. Transmitters have become highly sophisticated, often featuring integrated data logging, diagnostic capabilities, and robust communication protocols necessary for integration into large-scale control systems. Geographically, the market is divided into established regions like North America and Europe, which focus on technological upgrades and replacement cycles, and high-growth areas like Asia Pacific, which are driven by rapid new industrial infrastructure development. Understanding these segments is vital for stakeholders looking to identify lucrative niches, such as detectors optimized for explosion-proof environments (oil and gas) or ultra-low conductivity ranges (pharmaceuticals).

- By Type (Sensor Technology):

- Contacting Conductivity Detectors (2-Electrode, 4-Electrode)

- Inductive (Toroidal) Conductivity Detectors

- High Purity/Resistivity Detectors

- Non-Contacting Flow-Through Detectors

- By Component:

- Sensors/Probes

- Transmitters/Analyzers

- Software and Communication Modules

- Cables and Accessories

- By Application:

- Water and Wastewater Treatment (Municipal and Industrial)

- Boiler and Cooling Tower Water Monitoring (Power Generation)

- Process Control in Chemical and Petrochemical Industries

- Pharmaceutical and Biotechnology (WFI, USP Grade Water)

- Semiconductor and Microelectronics Manufacturing (Ultrapure Water)

- Food and Beverage Processing

- Desalination Plants

- By Industry Vertical:

- Chemicals and Petrochemicals

- Power Generation

- Pharmaceuticals and Life Sciences

- Food and Beverages

- Oil and Gas

- Other Industrial Manufacturing

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Online Conductivity Detector Market

The value chain for the Online Conductivity Detector Market begins with raw material sourcing, involving specialized materials like high-grade stainless steel, titanium, PEEK polymers, and precision electronic components required for robust sensor and transmitter manufacturing. The upstream analysis focuses heavily on securing reliable suppliers for high-tolerance electrical components and temperature compensation mechanisms, as the accuracy and durability of the final product are highly dependent on the quality of these foundational elements. Sensor manufacturers often engage in intense R&D activities at this stage to develop proprietary electrode coatings or advanced sensor geometries that resist fouling and degradation in challenging industrial media, providing a crucial competitive edge early in the chain.

Midstream activities involve the intricate process of manufacturing, assembly, and rigorous calibration and testing of the detectors and associated analyzers. Manufacturers must adhere to strict quality control standards, such as ISO certifications, especially when supplying critical industries like pharmaceuticals and power generation. Distribution channels are typically complex, utilizing a combination of direct sales for large-scale, customized industrial projects and indirect channels through specialized distributors, system integrators, and OEM partnerships who possess the necessary expertise for installation, commissioning, and long-term maintenance support. Effective management of the supply chain, ensuring timely delivery and minimizing inventory costs for sophisticated components, is essential for maintaining profitability.

Downstream analysis focuses on installation, integration, and post-sales support services provided to the end-users. Direct distribution channels are preferred when servicing large, strategic clients who require complex integration with existing DCS/SCADA systems, ensuring technical alignment and specialized service. Indirect channels, through local representatives and third-party service providers, handle routine sales and support for smaller installations and regional maintenance needs. The provision of technical training, calibration services, and timely software updates represents a significant recurring revenue stream and is a vital component of customer retention in this highly technical market, completing the value cycle by ensuring optimal performance throughout the detector’s operational life.

Online Conductivity Detector Market Potential Customers

Potential customers for online conductivity detectors span a diverse range of industrial sectors globally, with any operation relying on precise liquid quality control representing a key buying demographic. The primary end-users are large utility providers and major manufacturing companies whose operations are fundamentally dependent on water quality, either as a reactant, a solvent, or a heating/cooling medium. These customers prioritize reliability, auditability, and integration capabilities to maintain operational uptime and strict regulatory adherence. Specific buyers within these organizations often include process engineers, instrumentation and control specialists, environmental compliance officers, and plant managers responsible for asset integrity and operational efficiency.

The power generation sector, encompassing thermal, nuclear, and concentrated solar power plants, represents one of the largest buyer groups. In these facilities, conductivity detection is non-negotiable for monitoring boiler feed water, condensate returns, and cooling water loops to prevent corrosion, scaling, and costly turbine damage, making conductivity detectors critical safety and efficiency assets. Another critical segment is the pharmaceutical and life sciences industry, where ultra-high-purity water (USP grade, WFI) is essential for product formulation and cleaning processes. These customers require highly specialized, high-resolution resistivity detectors that can meet stringent pharmacopeia standards and provide comprehensive validation documentation, often favoring suppliers offering calibration traceability and robust data integrity features.

Furthermore, municipal and industrial wastewater treatment facilities are rapidly expanding their adoption of online detectors to monitor effluent quality before discharge, ensuring adherence to environmental permits. The semiconductor and microelectronics industries, demanding ultrapure water (UPW) with extremely low conductivity levels, represent a high-value, niche customer base that requires detectors with superior resolution and precision capabilities. Finally, the food and beverage industry utilizes these detectors for quality control, mixing precision, and critical cleaning-in-place (CIP) process verification, where timely conductivity shifts indicate the transition between product, rinse water, and cleaning solutions, optimizing efficiency and preventing product contamination.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Emerson Electric Co., Yokogawa Electric Corporation, METTLER TOLEDO, Endress+Hauser Group Services AG, Honeywell International Inc., Xylem Inc., Hach Company (Danaher Corporation), Thermo Fisher Scientific Inc., Suez Water Technologies & Solutions, GF Piping Systems (Georg Fischer), KNICK Elektronische Messgeräte GmbH & Co. KG, Sensorex, Rosemount Analytical (Emerson), Myron L Company, Swan Analytische Instrumente AG, Cole-Parmer Instrument Company LLC, Walchem (Iwaki America Inc.), JUMO GmbH & Co. KG, OMEGA Engineering Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Online Conductivity Detector Market Key Technology Landscape

The technology landscape of the Online Conductivity Detector Market is characterized by continuous innovation focused on improving accuracy, robustness, and connectivity. A foundational technology remains the electrochemical measuring cell, which utilizes two or four electrodes made of materials resistant to corrosion, such as graphite, stainless steel, or platinum, to measure the conductance of the liquid. Modern advancements in contacting technology center on sophisticated temperature compensation algorithms—crucial for accurate readings, as conductivity is highly sensitive to temperature—and improved electrode fouling resistance through specialized coatings and self-cleaning mechanisms. These innovations allow contacting probes to maintain high precision even in challenging process streams and high-purity water applications.

Another dominant technological trend involves the increasing prevalence of inductive (toroidal) conductivity sensors. These non-contacting systems use magnetic induction to measure conductivity, circumventing the need for direct physical contact between the electrodes and the solution. This design provides significant advantages in applications involving high concentrations of dissolved solids, viscous liquids, or highly corrosive chemicals where traditional contacting sensors would quickly foul or degrade. The integration of advanced microprocessors within the transmitters associated with these sensors enables superior signal processing, noise reduction, and the capability to store multiple calibration sets, enhancing overall reliability and reducing maintenance requirements substantially across heavy industry usage.

The most transformative recent technology is the integration of Industrial Internet of Things (IIoT) capabilities and smart sensor technology. New-generation online detectors are equipped with built-in digital communication protocols (e.g., Modbus, HART, Profibus) and wireless connectivity (Wi-Fi, LoRaWAN), enabling seamless integration into cloud-based data platforms and enterprise resource planning (ERP) systems. This shift facilitates remote monitoring, predictive maintenance based on sensor diagnostics, and advanced data analytics, moving the market toward a service-oriented model where actionable intelligence derived from the detector data is as valuable as the hardware itself. Furthermore, the miniaturization of sensors and the development of specialized detectors for microfluidics and small-scale applications are expanding market reach into laboratory automation and niche industrial segments.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to exhibit the highest growth rate, fueled by rapid industrialization, particularly in China, India, South Korea, and Southeast Asian nations. Massive investments in infrastructure, the proliferation of the semiconductor industry requiring stringent ultra-pure water standards, and escalating governmental emphasis on environmental protection and pollution control drive the demand for reliable online conductivity monitoring across wastewater treatment and manufacturing sectors.

- North America: This region holds a significant market share due to the early adoption of advanced monitoring technologies and the presence of a robust pharmaceutical, petrochemical, and power generation base. Market growth is sustained by the continuous replacement and upgrade of aging infrastructure, coupled with strict regulatory enforcement by agencies like the EPA, which mandates continuous, verifiable monitoring data for water discharge permits and process control optimization.

- Europe: Europe is characterized by a strong focus on high-quality manufacturing standards (e.g., ISO 9001, European Pharmacopeia) and stringent environmental directives. Germany, the UK, and France are key contributors, driven by mature water treatment technologies and significant demand from the chemical and food and beverage industries for accurate process control. Innovation here is centered on energy-efficient and smart IIoT-enabled systems.

- Middle East and Africa (MEA): Growth in MEA is highly concentrated around major oil and gas operations and extensive desalination projects, particularly in the Gulf Cooperation Council (GCC) states. Online conductivity detectors are critical for monitoring brine disposal, ensuring proper functioning of desalination plants, and protecting upstream oil and gas equipment from corrosion due to high salinity, positioning the region as a vital growth area for heavy-duty industrial detectors.

- Latin America: This region is experiencing steady market expansion, supported by increasing investments in modernizing municipal water infrastructure and the growth of the local pharmaceutical and mining sectors, particularly in Brazil and Mexico. The adoption is primarily driven by the need to manage water scarcity effectively and comply with national regulations concerning industrial waste management.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Online Conductivity Detector Market.- ABB Ltd.

- Emerson Electric Co.

- Yokogawa Electric Corporation

- METTLER TOLEDO

- Endress+Hauser Group Services AG

- Honeywell International Inc.

- Xylem Inc.

- Hach Company (Danaher Corporation)

- Thermo Fisher Scientific Inc.

- Suez Water Technologies & Solutions

- GF Piping Systems (Georg Fischer)

- KNICK Elektronische Messgeräte GmbH & Co. KG

- Sensorex

- Rosemount Analytical (Emerson)

- Myron L Company

- Swan Analytische Instrumente AG

- Cole-Parmer Instrument Company LLC

- Walchem (Iwaki America Inc.)

- JUMO GmbH & Co. KG

- OMEGA Engineering Inc.

Frequently Asked Questions

Analyze common user questions about the Online Conductivity Detector market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between contacting and inductive conductivity detectors?

Contacting detectors measure conductivity by passing an electrical current directly through the solution via metallic electrodes, offering high accuracy for low to moderate concentrations, particularly in high-purity applications. Inductive (toroidal) detectors use electromagnetic fields to induce a current in the solution without physical contact, making them ideal for high-concentration solutions or media prone to coating and fouling, as they require less maintenance.

Which industrial sector is the largest end-user of online conductivity detectors?

The Power Generation sector is currently the largest end-user, due to the critical requirement for continuously monitoring the purity of boiler feed water, steam, and cooling systems. Precise conductivity monitoring prevents corrosion, scaling, and costly damage to high-pressure turbines and associated capital equipment, ensuring both operational safety and thermal efficiency.

How does temperature affect conductivity measurement, and how do online detectors compensate?

Electrical conductivity is highly sensitive to temperature; an increase in temperature generally leads to higher conductivity readings. Online detectors utilize integrated temperature sensors (typically RTDs or thermistors) near the conductivity cell to automatically compensate the raw measurement using established algorithms (e.g., standard NaCl curve or linear compensation) to reference the reading to a standard 25°C, ensuring reported values are accurate and comparable.

What role does the Industrial Internet of Things (IIoT) play in modern conductivity detection?

IIoT integration equips modern detectors with digital communication capabilities, enabling real-time data transmission to cloud platforms and control systems. This allows for remote monitoring, centralized data analysis, and the deployment of AI-driven predictive maintenance models that enhance asset performance, optimize calibration cycles, and ensure regulatory reporting compliance without constant on-site intervention.

What key factors should be considered when selecting an online conductivity sensor?

Key selection factors include the conductivity range of the application (e.g., ultra-pure vs. high-salinity), the potential for sensor fouling or coating (favoring inductive sensors if high), the temperature and pressure requirements, the corrosiveness of the liquid, and the specific regulatory compliance standards that the detector must meet, particularly concerning accuracy and data auditability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager