Open Fire Pressure Cooker Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434109 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Open Fire Pressure Cooker Market Size

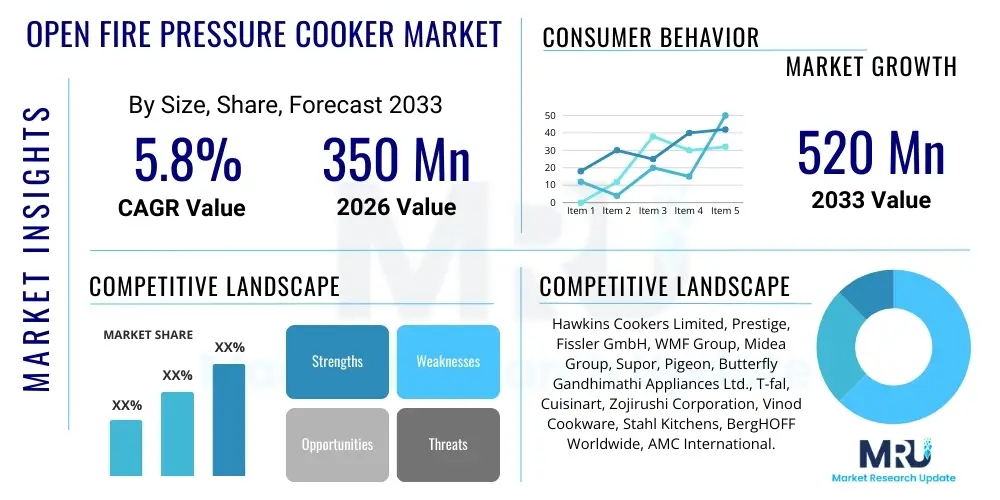

The Open Fire Pressure Cooker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 520 Million by the end of the forecast period in 2033.

Open Fire Pressure Cooker Market introduction

The Open Fire Pressure Cooker Market encompasses the manufacturing, distribution, and sale of specialized cooking vessels designed to operate effectively and safely over traditional heat sources, particularly open flames, wood stoves, or high-intensity gas burners commonly found in residential settings across developing economies and specialized outdoor cooking environments globally. These cookers are engineered with robust materials, typically heavy-gauge aluminum or stainless steel, capable of withstanding the uneven heating and high thermal stress characteristic of direct open-fire exposure, offering a crucial combination of durability, efficiency, and speed in food preparation. The primary function remains consistent with standard pressure cooking—utilizing steam pressure to raise water's boiling point, significantly reducing cooking times, thereby conserving fuel, and preserving nutrient content.

Product descriptions emphasize safety features tailored for variable heat environments, including multi-level safety valves, secure locking mechanisms, and heat-resistant handles built to manage the challenging operating conditions associated with open flames. Major applications of open fire pressure cookers span wide-ranging culinary needs, from basic staple food preparation like boiling grains and pulses to complex stewing and meat tenderization, making them indispensable kitchen appliances in areas where access to electricity or regulated induction cooktops is limited. The enhanced cooking speed significantly alleviates the burden of fuel gathering and reduces household exposure to smoke and combustion particulates, directly contributing to public health and environmental sustainability initiatives.

The market's driving factors are profoundly linked to demographic shifts, urbanization patterns, and evolving consumer awareness regarding energy efficiency in cooking. Rapid population growth and increasing disposable incomes in regions like Asia Pacific and Africa have spurred demand for resilient and time-saving cooking appliances. Furthermore, the inherent benefits, such as significant fuel savings compared to traditional open pot cooking, the retention of flavor and nutritional value, and enhanced food safety due to high-temperature sterilization, solidify the open fire pressure cooker’s position as a foundational tool for household food security and quality of life improvement.

Open Fire Pressure Cooker Market Executive Summary

The Open Fire Pressure Cooker Market is exhibiting robust growth, driven primarily by strong demand from emerging economies prioritizing fuel efficiency and accelerated cooking times. Business trends highlight a pronounced shift towards stainless steel variants over traditional aluminum, spurred by growing consumer preference for perceived safety, longevity, and ease of maintenance, despite the higher initial cost. Key manufacturers are focusing on integrating advanced safety features, such as multiple safety redundancies and enhanced heat diffusion bases, to specifically address the unique challenges presented by high, unregulated heat sources prevalent in rural and semi-urban settings. Competitive strategies involve expanding localized distribution networks and leveraging digital platforms to educate consumers on product benefits, particularly concerning fuel savings and nutritional preservation, positioning these appliances as essential tools for modern, sustainable cooking practices.

Regional trends indicate that the Asia Pacific (APAC) region maintains market dominance, driven by massive population bases in India, China, and Southeast Asian nations where reliance on liquefied petroleum gas (LPG) and solid fuels for cooking remains high, creating a sustained need for efficient pressure cooking technology. However, the Middle East and Africa (MEA) region is emerging as the fastest-growing market segment, fueled by infrastructural development projects and humanitarian efforts promoting efficient cooking solutions to reduce reliance on biomass. In contrast, mature markets in North America and Europe see demand concentrated in specialized niche applications such as camping, outdoor cooking, and emergency preparedness kits, where rugged construction and portability are key differentiators, leading to higher average selling prices for premium, small-volume units.

Segmentation trends demonstrate that the Household segment accounts for the vast majority of market revenue, although the Commercial segment, including small restaurants, catering services, and institutional kitchens in fuel-scarce areas, is expanding rapidly due to the need for high-volume, quick food preparation solutions. Furthermore, the Distribution Channel analysis reveals a complex transition: while traditional Offline Stores, such as local hardware shops and specialty appliance retailers, remain crucial for visibility and trust-building in rural areas, Online Retail is gaining significant traction in urban centers, offering greater product variety, price transparency, and direct-to-consumer accessibility. Technological advancements primarily revolve around material science—improving alloy conductivity and durability to handle extreme thermal cycling without warping or compromising sealing integrity, thereby enhancing the overall lifespan and performance of the cookers.

AI Impact Analysis on Open Fire Pressure Cooker Market

User queries regarding AI's influence on the Open Fire Pressure Cooker Market often revolve around optimizing the supply chain, enhancing manufacturing precision, and improving consumer safety mechanisms. A dominant theme centers on how AI-driven predictive maintenance and quality control systems can minimize defects, particularly those related to valve performance and sealing integrity under extreme thermal stress, which are crucial for safety in open-fire applications. Users are also keen to understand if AI can personalize cooking recommendations or provide real-time thermal monitoring through smart sensors, although the core product (a non-electric device) currently limits sophisticated connectivity. Concerns mainly focus on whether AI-led automation will increase production costs, potentially pricing the resulting specialized cookers out of reach for lower-income households that are the primary end-users.

The application of Artificial Intelligence within this traditional market segment is less about direct product enhancement and more focused on enterprise operations. AI algorithms are increasingly deployed in demand forecasting, enabling manufacturers to accurately predict regional consumption spikes linked to seasonal changes or government subsidy programs, thus optimizing inventory management and reducing storage costs. Moreover, AI-powered image recognition and machine learning tools are vital in the manufacturing process for non-destructive testing, rapidly scanning weld joints and material thickness deviations that could lead to catastrophic failure under pressure. This enhances overall product reliability, which is paramount when the cooking environment is inherently less controlled than standard kitchen use.

Ultimately, AI's principal impact is expected to stabilize and standardize product quality across diverse manufacturing sites globally. By analyzing massive datasets related to material stress testing, temperature fluctuations, and usage patterns collected through digital feedback loops, AI can inform material selection and design modifications, making the cookers safer and more durable when exposed to the harsh conditions of open fire cooking. This indirect impact on safety and supply efficiency provides a competitive edge to companies that invest in these advanced operational technologies, mitigating risks and improving brand trustworthiness among safety-conscious consumers.

- AI-driven supply chain optimization reducing lead times and material waste.

- Predictive maintenance analytics for manufacturing equipment ensuring consistent product quality.

- Machine learning deployed in non-destructive testing for defect detection in welds and materials.

- Enhanced demand forecasting based on regional demographic and seasonal cooking patterns.

- AI-informed material science research to develop more robust, heat-resistant alloys for open flame exposure.

DRO & Impact Forces Of Open Fire Pressure Cooker Market

The dynamics of the Open Fire Pressure Cooker Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and internal and external Impact Forces. Key drivers include the overwhelming global need for fuel-efficient cooking methods, particularly in economies heavily reliant on solid fuels or expensive LPG, where pressure cookers offer substantial time and energy savings. The continuous rise in global energy prices further incentivizes households to adopt technologies that minimize fuel consumption. These drivers create a sustained baseline demand, particularly across high-density population zones in Asia and Africa. However, this momentum is counteracted by significant restraints, primarily revolving around safety concerns stemming from historical incidents related to malfunctioning or improperly used pressure cookers. This perception requires extensive consumer education and regulatory scrutiny regarding product quality.

Opportunities in the market emerge from technological advancements in material science, allowing for the creation of lighter, more durable, and corrosion-resistant alloys that perform better under extreme thermal cycling. Furthermore, the rising global emphasis on climate action and reducing household air pollution (HAP) presents a substantial opportunity for manufacturers to align their products with sustainable development goals (SDGs). Governments and NGOs are increasingly initiating programs to subsidize or promote efficient cooking devices, opening new distribution channels and expanding market access into underserved communities. These opportunities suggest that strategic market penetration and product innovation focused on sustainability will yield significant long-term returns.

The impact forces influencing the market are multifaceted, encompassing intense competition among major manufacturers striving for cost leadership and product differentiation, alongside regulatory forces mandating stringent safety standards (e.g., ISO and national certifications) for pressure-retaining devices. Sociocultural factors, such as traditional cooking methods and resistance to change, pose a slow but persistent constraint, requiring sustained marketing and educational efforts to overcome. Economic volatility, particularly currency fluctuations in developing markets, affects the cost of imported raw materials (aluminum, stainless steel), directly impacting final consumer pricing and profit margins. Successful market navigation requires continuous monitoring of both material costs and shifting consumer safety perceptions.

Segmentation Analysis

The Open Fire Pressure Cooker Market is primarily segmented based on material type, end-user application, and distribution channel, reflecting the varied needs across global consumer bases. The Material Type segmentation, including Stainless Steel, Aluminum, and Other Alloys, is crucial as it directly impacts product durability, thermal efficiency, price point, and consumer preference related to food safety and maintenance. Stainless steel variants, while expensive, are gaining prominence due to superior corrosion resistance and longevity. In contrast, aluminum cookers dominate the volume segment, owing to their affordability and excellent heat conduction, making them highly favored in cost-sensitive markets. The continuous interplay between cost and quality defines competitive strategy across these material sub-segments.

The End-User segmentation distinguishes between Household (residential use) and Commercial (restaurants, catering, institutions). The Household segment is the foundational revenue driver, characterized by purchases of medium-sized, versatile cookers. However, the Commercial segment demands larger volume capacity cookers with enhanced durability and reinforced safety features necessary for continuous, heavy-duty operation. Growth in the commercial sector is accelerated by the need for quick turnaround times in small food service businesses operating in environments where fuel efficiency is critical to profit margins. Analyzing the distinct needs of these two segments allows manufacturers to tailor product capacity and warranty support accordingly.

Distribution Channel analysis examines how products reach the end-user, differentiating between Online Retail and Offline Stores. Offline Stores, encompassing traditional markets, specialized appliance outlets, and supermarkets, remain indispensable for serving rural and semi-urban populations, facilitating tangible inspection and direct interaction. Online Retail, conversely, serves increasingly sophisticated urban consumers who seek convenience, wider product comparison, and competitive pricing. The strategic necessity for manufacturers is to maintain a robust omnichannel presence, ensuring broad market accessibility while balancing logistical complexities, particularly in ensuring the safe delivery of heavy, specialized kitchenware.

- Material Type:

- Stainless Steel

- Aluminum

- Other Alloys (e.g., Hard Anodized Aluminum)

- End-User:

- Household

- Commercial

- Distribution Channel:

- Online Retail

- Offline Stores (Supermarkets, Specialty Stores, Traditional Markets)

Value Chain Analysis For Open Fire Pressure Cooker Market

The Value Chain for the Open Fire Pressure Cooker Market begins with upstream activities focused on raw material sourcing and primary component manufacturing. This stage is dominated by procurement of high-grade aluminum, stainless steel, and specialized polymers for gaskets and safety valve components. Efficiency at this stage is highly contingent on global commodity pricing and stable trade relations, as volatility in metal markets directly impacts manufacturing costs. Upstream analysis involves assessing the reliability and compliance of metal suppliers, ensuring that materials meet stringent safety and thermal resistance specifications required for pressure vessels exposed to open flames. Long-term contracts with established material producers are vital for mitigating price risks and ensuring a consistent supply of quality raw input.

Midstream activities encompass the core manufacturing and assembly processes, including stamping, deep drawing, welding, surface finishing (e.g., polishing, anodizing), and final quality control checks. This phase focuses on achieving production scale while maintaining zero-defect rates, especially concerning the precise calibration of pressure release mechanisms and the structural integrity of the vessel body to prevent catastrophic failure. Manufacturers invest heavily in automated machinery and robust quality assurance protocols to manage the complexity of high-pressure assembly. Downstream activities involve managing inventory and distribution channels, moving finished products from manufacturing facilities to regional warehouses and ultimately to end-users.

The distribution channel network is segmented into direct and indirect routes. Direct distribution involves manufacturers selling through their own branded stores or proprietary e-commerce platforms, offering higher margins and direct consumer feedback loops. Indirect distribution, which accounts for the majority of market volume, utilizes third-party intermediaries: large retailers (supermarkets), specialized kitchenware distributors, local hardware stores, and online marketplaces. The effectiveness of the indirect channel depends on logistical efficiency, especially in reaching remote areas where open fire cooking is most prevalent. Optimizing this network involves strategic warehousing and leveraging regional logistics partners to ensure products are readily available and competitively priced across diverse geographical markets.

Open Fire Pressure Cooker Market Potential Customers

The Open Fire Pressure Cooker Market targets a broad demographic spectrum, primarily defined by access to and reliance on specific cooking energy sources. The largest segment of potential customers comprises households in developing and emerging economies (Asia Pacific, MEA, Latin America) that frequently use solid fuels (wood, charcoal) or utilize LPG/kerosene burners inefficiently. These end-users are highly motivated by the promise of reduced cooking time, which directly translates into significant savings on fuel costs and valuable time freed from labor-intensive cooking tasks. The high population density and rising middle class in these regions make them the primary drivers of volume demand, often prioritizing robust, affordable aluminum models.

A secondary, rapidly growing customer base includes urban middle and upper-middle-class households globally that prioritize stainless steel products for health reasons, aesthetic appeal, and long-term investment. While these users might utilize gas or electric stoves predominantly, they often employ open fire cookers for specific cooking techniques (e.g., deep frying or high-pressure cooking of tough ingredients) or for outdoor/recreational activities such as camping, tailgating, and preparedness for emergencies. This group seeks premium features, enhanced safety mechanisms, and multi-functional designs, often purchased through specialized retail outlets or high-end online marketplaces.

Finally, institutional and commercial buyers, such as small-to-medium restaurants, institutional cafeterias, and non-governmental organizations (NGOs) involved in disaster relief or community feeding programs, constitute a niche but high-value customer segment. These buyers require extra-large capacity pressure cookers (10 liters and above) that are exceptionally durable, easy to clean, and certified for heavy commercial use. For NGOs, the purchase decision is often driven by criteria related to fuel efficiency, durability under adverse conditions, and standardized global safety certifications, ensuring the equipment can support sustained high-volume food production in challenging, fuel-scarce environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 520 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hawkins Cookers Limited, Prestige, Fissler GmbH, WMF Group, Midea Group, Supor, Pigeon, Butterfly Gandhimathi Appliances Ltd., T-fal, Cuisinart, Zojirushi Corporation, Vinod Cookware, Stahl Kitchens, BergHOFF Worldwide, AMC International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Open Fire Pressure Cooker Market Key Technology Landscape

The technological landscape of the Open Fire Pressure Cooker Market is primarily defined by material science innovation, precision engineering of safety mechanisms, and advanced heat management systems optimized for irregular flame exposure. Given that the product is non-electric, technological development focuses heavily on passive, material-based improvements rather than smart connectivity. A crucial area of research involves developing specialized composite base materials, often involving tri-ply or encapsulated bases (aluminum layers sandwiched between stainless steel) even for traditional aluminum cookers, which help distribute the high, concentrated heat of an open fire more evenly. This innovation prevents localized scorching, warping, and premature degradation of the cooker base, thereby extending the product lifespan and improving food quality under challenging cooking conditions.

Safety technology represents another cornerstone of market innovation. Modern open fire pressure cookers must incorporate multiple redundancies to manage sudden pressure spikes caused by unpredictable flame intensity. Key advancements include spring-loaded or precise weight valve mechanisms that offer more reliable pressure regulation than older, simpler weight-based systems. Additionally, the integration of fusible safety plugs and secondary pressure indicators ensures that consumers receive clear warnings and automatic pressure relief in over-pressure scenarios. Manufacturing processes utilize advanced CNC machining and robotics to ensure that all locking mechanisms and safety feature installations meet extremely tight tolerances, critical for performance longevity under repetitive thermal stress. These rigorous standards are vital for maintaining consumer trust in products used over unregulated heat.

Furthermore, technology is applied to surface treatments and design ergonomics. Hard anodization technology, particularly for aluminum cookers, provides a non-porous, highly durable surface that resists scratching, corrosion, and reaction with acidic foods, enhancing both the safety and maintenance ease of the product. Design research also focuses on ergonomic, heat-resistant handles and secure lid-locking systems that can be operated safely even when the cooker body is exposed to intense, surrounding heat. These continuous, subtle technological improvements in materials, safety protocols, and manufacturing precision collectively ensure that modern open fire pressure cookers maintain their reputation as robust, efficient, and reliable kitchen tools in diverse global settings.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, product preferences, and competitive landscape of the Open Fire Pressure Cooker Market. Demand levels and segmentation vary significantly between emerging and developed economies.

- Asia Pacific (APAC): APAC is the largest and most dynamic market globally, driven by high population density, ongoing urbanization, and persistent reliance on fuel-efficient cooking devices in both rural and semi-urban areas, particularly in India, China, and Indonesia. Volume sales are massive, often dominated by affordable aluminum models, although the rising middle class is rapidly adopting premium stainless steel cookers. Government efforts promoting LPG adoption and efficient cooking methods further stimulate market growth.

- Middle East and Africa (MEA): Projected to be the fastest-growing region, MEA exhibits high demand driven by population expansion and significant fuel costs. The market is crucial due to the prevalence of outdoor cooking and the necessity for robust, durable cookers that can withstand high temperatures and varied fuel sources. Safety and durability are key purchasing criteria, often supported by international humanitarian and developmental organizations promoting efficient cooking interventions.

- Latin America: This region shows stable growth, characterized by strong consumer brand loyalty and a preference for traditional, heavy-duty pressure cooking. Demand is consistent, driven by established culinary practices that favor slow-cooked or tenderized foods. Brazil and Mexico represent the largest markets, featuring a healthy mix of local and international manufacturers competing on material quality and advanced safety features.

- North America and Europe: These regions represent mature markets where open fire pressure cookers cater to niche demand. Key market relevance is concentrated in outdoor and adventure segments (camping, RV usage, specialized off-grid cooking) and high-end, specialized kitchen appliances. Consumers here prioritize highly certified safety standards, complex multi-pressure settings, and aesthetic design, leading to significantly higher average selling prices compared to high-volume developing markets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Open Fire Pressure Cooker Market.- Hawkins Cookers Limited

- Prestige

- Fissler GmbH

- WMF Group

- Midea Group

- Supor

- Pigeon

- Butterfly Gandhimathi Appliances Ltd.

- T-fal

- Cuisinart

- Zojirushi Corporation

- Vinod Cookware

- Stahl Kitchens

- BergHOFF Worldwide

- AMC International

- Kuhn Rikon

- Silit

- SEB Group

- Zhejiang ASD Electric Appliance Co., Ltd.

- TTK Prestige Ltd.

Frequently Asked Questions

Analyze common user questions about the Open Fire Pressure Cooker market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary safety considerations when using a pressure cooker over an open fire?

The primary safety considerations involve ensuring the cooker's base can withstand high, unregulated heat without warping, verifying that multiple safety mechanisms (valves, gaskets, and pressure indicators) are functional, and strictly adhering to recommended pressure limits. Uneven heating from an open flame necessitates constant monitoring to prevent localized overheating and subsequent pressure build-up beyond the cooker's design limits. Always use cookers specifically rated and engineered for open fire use.

How does the material (stainless steel vs. aluminum) affect performance on an open flame?

Aluminum pressure cookers offer superior heat conductivity, leading to quicker pressure attainment and lower cost, making them preferred for high-volume, cost-sensitive markets. However, stainless steel cookers are more durable, less prone to staining or corrosion, and warp less under sustained high, uneven heat, providing a longer service life and greater overall safety margin for rigorous open-fire use, justifying their higher price point.

What drives the sustained high demand for open fire pressure cookers in emerging economies?

Sustained high demand is driven primarily by the need for enhanced fuel efficiency and time savings. In many emerging economies, fuel (LPG, wood, charcoal) is costly or scarce, and using a pressure cooker dramatically reduces cooking time by 50% to 70%, directly translating to significant savings in household operational expenses and reducing the labor burden associated with fuel gathering and long cooking hours.

Are open fire pressure cookers compatible with standard induction cooktops or electric stoves?

Yes, many modern open fire pressure cookers, particularly those made of magnetic stainless steel or featuring tri-ply encapsulated bases, are engineered for multi-stove compatibility, including induction, electric, gas, and open flame. However, consumers must verify the specific base material and certification of the cooker model, as traditional, thin-base aluminum cookers designed strictly for open flame may not function optimally or safely on regulated electric surfaces.

How does the Open Fire Pressure Cooker Market contribute to environmental sustainability goals?

The market contributes significantly to environmental sustainability by promoting fuel-efficient cooking. By drastically reducing the cooking time, these appliances lower the consumption of solid biomass fuels (wood/charcoal), thereby mitigating deforestation and significantly decreasing household air pollution (HAP) and associated carbon emissions, aligning with global efforts to achieve cleaner and more sustainable household energy practices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager