Open Wedge Sockets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438100 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Open Wedge Sockets Market Size

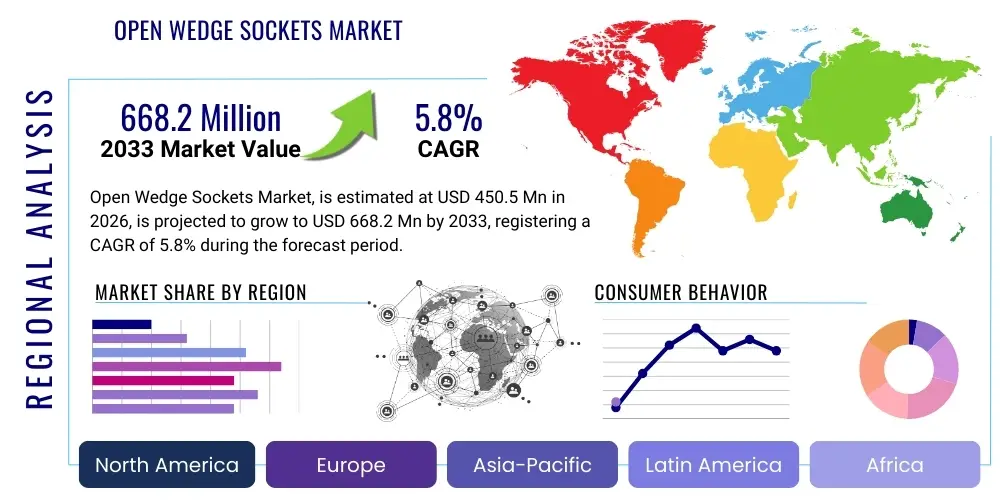

The Open Wedge Sockets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.2 Million by the end of the forecast period in 2033.

Open Wedge Sockets Market introduction

The Open Wedge Sockets Market encompasses the manufacturing, distribution, and utilization of specialized termination fittings designed primarily for steel wire ropes used in heavy lifting and rigging operations. These sockets provide a highly reliable, robust, and permanent end termination, crucial for applications where the load is dynamic or requires frequent adjustments. Unlike poured resin sockets, the wedge socket design relies on mechanical friction and the geometry of a precision-machined wedge component to secure the wire rope, enabling quick assembly and disassembly, a significant advantage in demanding field environments such as construction sites, deep-sea exploration vessels, and surface mining operations. The primary function is to securely anchor the working end of the rope to the lifting equipment, ensuring safety and operational efficiency.

Open wedge sockets are indispensable in industries prioritizing robust safety standards and extreme load capacities, including oil and gas exploration, large-scale infrastructure construction, and marine activities like salvage and offshore mooring. Key applications involve connecting hoist lines to drums, securing boom pendants on cranes, and terminating anchor lines in hostile environments. The benefits derived from using certified open wedge sockets are manifold: high strength-to-weight ratio, ease of inspection, superior resistance to fatigue compared to alternative terminations, and the capability to maintain structural integrity under severe shock loading. Their inherent design allows for rapid field installation and replacement, minimizing equipment downtime and contributing directly to improved project schedules.

Driving factors for this market are intrinsically linked to global capital expenditure in infrastructure and energy sectors. Increased investment in renewable energy projects, particularly offshore wind farms requiring extensive heavy lifting apparatus, coupled with persistent demand for commodities necessitating advanced mining and excavation, sustains the growth trajectory. Furthermore, stringent global safety regulations, enforced by organizations like OSHA and DNV, mandate the use of high-quality, certified lifting hardware, compelling end-users to upgrade or replace older, less reliable socket systems, thereby providing a continuous refresh cycle for the market. Technological advancements focusing on material science, such as higher tensile strength steel alloys, also enhance the performance envelope of modern open wedge sockets.

Open Wedge Sockets Market Executive Summary

The Open Wedge Sockets Market is characterized by stable growth, underpinned by persistent global infrastructure development and stringent regulatory frameworks governing heavy lifting safety. Business trends indicate a strong move towards traceability, driven by the need for regulatory compliance and proactive maintenance scheduling, leading manufacturers to incorporate unique serialization and IoT-ready features into high-capacity sockets. Consolidation among major rigging hardware manufacturers continues, aiming to leverage scale, enhance distribution networks, and standardize product offerings globally. Furthermore, the rising cost of raw materials, particularly high-grade steel, is pressuring profit margins, although this is partially offset by the premium associated with certified, high-performance lifting components.

Regionally, the Asia Pacific (APAC) area stands as the primary engine of growth, spurred by massive governmental investments in urbanization, rapid industrialization, and significant infrastructure projects like high-speed rail networks and port expansions. North America and Europe maintain strong market shares, driven by replacement cycles, modernization of existing infrastructure (especially oil and gas pipelines and established bridges), and robust demand from the advanced offshore wind sector. Trends in segments show high-capacity open wedge sockets dominating revenue, particularly those certified for deep-water and extreme tension applications. Material science innovation focuses on reducing weight while maintaining or increasing Maximum Working Load (MWL), favoring alloy steel over traditional carbon steel in specialized applications.

Key segment trends highlight the increasing specialization of products, with demand rising for sockets tailored to synthetic ropes, although wire rope applications remain foundational. The end-user analysis shows the construction sector, particularly heavy construction and tunneling, retaining the largest share due to the ubiquitous need for cranes and hoists. The shift towards greater operational efficiency is fostering opportunities for suppliers who can bundle their sockets with inspection and maintenance services, moving the market dynamics from pure hardware provision to comprehensive lifting solutions. The convergence of safety requirements, technological integration, and large-scale infrastructure spending defines the market landscape.

AI Impact Analysis on Open Wedge Sockets Market

User queries regarding AI's influence on the Open Wedge Sockets Market predominantly revolve around optimizing product design for extreme conditions, enhancing safety monitoring during operation, and streamlining complex supply chain logistics for high-value components. Users are keen to understand how computational intelligence can be leveraged to conduct predictive failure analysis and simulate operational stresses with greater accuracy than traditional finite element analysis (FEA). Key themes include the use of machine learning to analyze historical failure data for material specification optimization, and the integration of smart sensors into sockets, utilizing AI algorithms to interpret real-time tension, temperature, and vibration data to predict wear and scheduled component replacement before catastrophic failure occurs. The overarching expectation is that AI will move the industry from reactive maintenance to true predictive asset management, significantly reducing risks and extending the service life of expensive lifting equipment.

The application of AI in the manufacturing process itself offers significant opportunities, particularly in quality control and precision machining. Machine vision systems, powered by deep learning models, can inspect the critical load-bearing surfaces and internal geometry of newly manufactured sockets, identifying micro-fractures or dimensional inconsistencies far quicker and more accurately than human inspectors. This enhancement in quality assurance directly translates to higher product reliability, a paramount concern in liability-heavy lifting operations. Furthermore, AI-driven demand forecasting can optimize inventory management for socket distributors, ensuring timely supply of specialized or custom-ordered components to remote or rapidly developing project sites.

However, the deployment of AI in this traditionally conservative, standards-driven industry also raises concerns about data security, system integration complexity, and the necessary certification procedures required for 'smart' lifting hardware. While the benefits of predictive maintenance are clear, the industry requires standardized protocols for validating the outputs of AI models, ensuring that decisions related to critical safety equipment are based on verified, reliable data. The convergence of mechanical engineering excellence with robust digital intelligence will be the defining factor in determining the speed and extent of AI adoption within this niche market segment, ultimately moving towards truly autonomous safety systems.

- AI-driven optimization of socket geometry using computational fluid dynamics and stress modeling to enhance fatigue resistance.

- Predictive maintenance analytics achieved through ML processing of sensor data (IoT integration) embedded in critical lifting hardware.

- Enhanced quality control during manufacturing via AI-powered machine vision systems detecting microscopic flaws in forged materials.

- Supply chain optimization using algorithms for real-time tracking, inventory management, and forecasting specialized socket demand.

- Development of digital twins for high-capacity rigging setups, simulating socket performance under varying environmental and load conditions.

DRO & Impact Forces Of Open Wedge Sockets Market

The Open Wedge Sockets Market dynamics are shaped by a complex interplay of regulatory drivers, infrastructure demand, material constraints, and continuous safety innovation. Drivers include the increasing global emphasis on worker safety, mandating the use of certified, high-quality lifting gear, alongside substantial public and private investment in massive infrastructure projects (e.g., bridges, high-rise construction, offshore energy platforms). Restraints primarily stem from volatility in raw material prices, particularly high-strength steel alloys, which increases production costs and potentially suppresses adoption in cost-sensitive emerging markets. Additionally, the prevalence of counterfeit or substandard rigging components, especially in unregulated regions, poses a persistent threat to market integrity and safety standards. Opportunities lie in developing lighter, stronger, and more corrosion-resistant sockets through advanced material science (e.g., specialized coatings and composite reinforcements) and integrating smart technology for remote monitoring and certification tracking.

Impact forces influencing the market are significant and multidimensional. The shift towards higher load capacities in modern construction and energy equipment necessitates constant product redesign and re-certification, pushing manufacturers to invest heavily in R&D and testing facilities. Environmental, Social, and Governance (ESG) criteria are increasingly impacting procurement decisions, favoring manufacturers who can demonstrate sustainable sourcing and ethical manufacturing practices. Furthermore, geopolitical instability can disrupt the global supply chain for specialized steel products, affecting lead times and inventory reliability for socket manufacturers and distributors. Regulatory harmonization across international standards bodies (ISO, EN, ASME) also acts as a profound influence, facilitating global trade but requiring costly compliance updates.

The strongest impact force is arguably technological acceleration coupled with heightened accountability. As lifting operations become more complex (e.g., installing multi-megawatt wind turbines), the failure tolerance decreases dramatically, amplifying the demand for precision-engineered, traceable sockets. This demand drives innovation in manufacturing precision and traceability features, such as integrated RFID chips or blockchain-based certification records, transforming the wedge socket from a simple mechanical component into a critical, traceable asset. This push for total quality assurance mitigates the restraint imposed by substandard products and accelerates the opportunity for premium market players.

Segmentation Analysis

The Open Wedge Sockets Market is comprehensively segmented based on the product characteristics, the materials utilized in their construction, the specific load capacity they are designed to handle, and the various end-user applications where they are critically employed. This segmentation allows for precise market sizing and strategic targeting, recognizing the diverse demands of heavy industry. The primary segments differentiate between standard and high-capacity designs, reflecting the divergent needs between everyday construction lifting and specialized applications like deep-sea exploration or ultra-heavy shipyard operations. Analyzing these segments reveals varying growth rates, with specialized, high-capacity segments experiencing faster expansion due to large-scale energy projects.

Further granularity is achieved by considering material composition, where forged alloy steel dominates due to its superior strength, toughness, and durability under cyclic loading conditions. The application segmentation provides the clearest view of demand drivers, with the marine and offshore sector showing persistent resilience due to continuous maintenance requirements for fleets and platforms, while infrastructure and mining sectors provide bulk demand tied to macroeconomic cycles. The increasing complexity of lifting tasks, requiring precise and documented safety features, pushes demand toward premium, certified socket categories.

- By Type:

- Standard Open Wedge Sockets (up to 50 tons)

- High-Capacity Open Wedge Sockets (above 50 tons)

- Stainless Steel Open Wedge Sockets (for corrosive environments)

- Tapered and Straight Barrel Sockets

- By Application/End-User:

- Construction (Heavy Infrastructure and Commercial Building)

- Marine & Offshore (Mooring, Towing, Deep-Sea Lifting)

- Mining & Excavation

- Oil & Gas (Upstream and Downstream Operations)

- Industrial Lifting and Rigging

- By Material:

- Forged Alloy Steel

- Forged Carbon Steel

- Stainless Steel

- By Size/Rope Diameter:

- Small Diameter Ropes (Up to 1 inch)

- Medium Diameter Ropes (1 inch to 2.5 inches)

- Large Diameter Ropes (Above 2.5 inches)

Value Chain Analysis For Open Wedge Sockets Market

The value chain for the Open Wedge Sockets Market begins with the highly specialized upstream procurement of high-grade steel alloys, often sourced from specialized mills that meet rigorous metallurgical standards. This phase is critical as the quality of the raw material directly dictates the final product’s working load limit and safety factor. Key activities in the upstream sector include forging, heat treatment, and precision machining, often requiring high capital investment in sophisticated CNC equipment and testing facilities to ensure dimensional accuracy and material integrity. Strict quality assurance procedures, including magnetic particle inspection and ultrasonic testing, are integrated early in the manufacturing process to minimize latent defects.

Midstream activities primarily involve branding, certification, and distribution. Manufacturers invest heavily in obtaining certifications from globally recognized bodies (e.g., DNV, ABS, Lloyd's Register), which is essential for market acceptance, especially in high-liability sectors like marine and offshore. The distribution channel is bifurcated: direct sales channels handle large, custom orders placed by major crane manufacturers or drilling contractors, emphasizing technical consultation and specialized logistics. Indirect channels rely on a vast network of authorized distributors, rigging hardware suppliers, and regional wholesalers who provide necessary inventory management, regional availability, and smaller, immediate supply requirements for local construction projects or maintenance schedules.

The downstream segment focuses on the end-user application and post-sales support, including installation assistance, periodic inspection services, and mandatory re-certification or replacement cycles. End-users, who are typically highly trained riggers and engineers, prioritize product reliability and traceability features. This emphasis drives demand for value-added services offered by manufacturers and distributors, such as proof testing, non-destructive testing (NDT), and documented traceability systems. The efficiency of the downstream servicing network is a crucial competitive factor, ensuring minimal downtime for mission-critical heavy machinery and reinforcing customer loyalty through high safety standards.

Open Wedge Sockets Market Potential Customers

The potential customer base for Open Wedge Sockets is highly specialized, encompassing entities that operate or service heavy machinery requiring secure and robust wire rope terminations for critical lifting applications. The primary buyers are large-scale construction conglomerates engaged in infrastructure development (bridges, ports, high-rises) and specialized engineering, procurement, and construction (EPC) firms managing major industrial projects. These buyers prioritize safety records, load capacity certification, and long-term durability when selecting suppliers, often purchasing in bulk for fleet standardization.

A second crucial segment includes companies operating in the energy sector, specifically offshore oil and gas drilling contractors, wind farm developers (both onshore and offshore), and major utility providers. For this group, resistance to corrosive environments (salt water, harsh chemicals) and reliable performance under dynamic loading conditions are non-negotiable requirements, often leading to demand for custom materials like stainless steel or specialized coatings. Maintenance, repair, and overhaul (MRO) service providers also represent a continuous source of demand, regularly requiring replacements due to wear and mandatory inspection criteria.

Furthermore, global shipping and marine industries, including salvage operations, container terminal operators, and naval fleets, are core end-users. Their procurement decisions are often governed by international maritime safety standards and classification society rules. Finally, large mining and earth-moving operations, which rely on massive excavators and draglines utilizing thick wire ropes, constitute a steady, volume-based market for high-capacity open wedge sockets, where resistance to abrasion and shock loading is paramount.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | The Crosby Group, WireCo WorldGroup, PFEIFER Group, Hendrik Veder Group, RUD Ketten Rieger & Dietz GmbH u. Co. KG, GN Rope Fittings, Esco Group, F.S. Wires and Ropes, Suncor Stainless, Van Beest B.V., Columbus McKinnon Corporation (CMCO), Kito Corporation, Certex USA, DSR Corporation, Brunton Shaw, Teufelberger, Loadpoint Limited, Talurit Group, Latch & Batch, Lift-All Company Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Open Wedge Sockets Market Key Technology Landscape

The manufacturing and application of Open Wedge Sockets rely heavily on advanced metallurgical and digital technologies to ensure maximum safety and performance. The foundational technology landscape centers on precision forging and heat treatment processes, which are crucial for achieving the required material hardness, ductility, and fatigue strength essential for high-stress lifting components. Modern manufacturers utilize sophisticated computer-controlled forging presses and induction heating systems to maintain extremely tight tolerances and ensure consistent crystalline structure throughout the steel alloy, thereby mitigating potential failure points caused by inconsistencies in material integrity. Furthermore, specialized protective coatings, such as galvanization or powder coating, are widely employed to enhance corrosion resistance, particularly for applications in marine and coastal environments, extending the operational lifespan significantly.

In the design phase, the reliance on advanced simulation and modeling tools, primarily sophisticated Finite Element Analysis (FEA), is paramount. Manufacturers use FEA not only to optimize the socket’s physical geometry—ensuring the wedge retains the rope optimally under various load angles—but also to simulate cyclic loading and extreme shock events, allowing for predictive failure analysis and optimization of the safety factor without requiring extensive, costly physical prototypes. This integration of virtual testing accelerates the product development cycle and ensures compliance with increasingly rigorous performance standards. The drive for continuous improvement focuses on materials science, specifically exploring proprietary alloy compositions that offer superior strength-to-weight ratios, crucial for reducing the overall weight of heavy rigging systems without compromising safety.

The emerging technological landscape is defined by digitization and the integration of the Industrial Internet of Things (IIoT). Leading manufacturers are beginning to embed micro-sensors, often integrated with RFID or NFC tags, directly into the socket bodies. These embedded technologies enable real-time tracking of asset usage, environmental exposure, and most importantly, load history. This data is critical for accurate predictive maintenance planning, allowing users to understand the component's remaining service life based on actual usage rather than conservative time-based estimates. Furthermore, the adoption of blockchain technology is being explored to create immutable records of certification, inspection, and proof testing, dramatically improving transparency and combating the issue of counterfeit components in the global supply chain, thereby ensuring the highest level of regulatory compliance and operational safety for all stakeholders.

Regional Highlights

- Asia Pacific (APAC): APAC is anticipated to demonstrate the highest growth rate, fueled primarily by extensive government investment in infrastructure development, notably in China, India, and Southeast Asian nations. The region’s massive urbanization projects, coupled with the expansion of maritime trade and associated port facilities, drive consistent demand for high-capacity lifting hardware. Furthermore, emerging regional manufacturing hubs and significant resource extraction activities contribute substantially to the local market volume, often prioritizing cost-effectiveness alongside adherence to international safety standards.

- North America: North America represents a mature, high-value market driven by rigorous safety standards and substantial investment in the modernization of existing infrastructure and the domestic energy sector. The market is characterized by a strong emphasis on certified, traceable products. Demand is particularly robust from the oil and gas industry (pipeline construction and maintenance) and the heavy construction sector, where specialized, custom-engineered sockets for extreme loads are frequently required, ensuring high average selling prices.

- Europe: Europe maintains a strong market presence, driven significantly by the rapid expansion of the offshore wind energy sector, which demands highly durable, corrosion-resistant wedge sockets for permanent mooring and specialized lifting operations. Strict EU directives regarding machinery safety ensure that replacement demand and new installations overwhelmingly favor high-quality, certified products. Germany, the UK, and Scandinavia are key markets, focusing heavily on technological integration and environmental compliance in manufacturing processes.

- Middle East and Africa (MEA): Growth in the MEA region is closely tied to large-scale oil and gas extraction projects, particularly in the Arabian Gulf states, and significant urban development programs. While highly sensitive to commodity price fluctuations, the large-scale nature of energy and infrastructure developments necessitates the procurement of robust lifting equipment, often imported under strict international engineering standards, offering strong demand for premium suppliers.

- Latin America: This region presents moderate growth, largely correlated with the cycles of the mining industry (copper, iron ore) and associated port infrastructure investment in countries like Brazil and Chile. The market often seeks a balance between cost and compliance, with international companies driving demand for globally certified equipment, while local operations may rely on regional suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Open Wedge Sockets Market.- The Crosby Group

- WireCo WorldGroup

- PFEIFER Group

- Hendrik Veder Group

- RUD Ketten Rieger & Dietz GmbH u. Co. KG

- GN Rope Fittings

- Esco Group

- F.S. Wires and Ropes

- Suncor Stainless

- Van Beest B.V.

- Columbus McKinnon Corporation (CMCO)

- Kito Corporation

- Certex USA

- DSR Corporation

- Brunton Shaw

- Teufelberger

- Loadpoint Limited

- Talurit Group

- Latch & Batch

- Lift-All Company Inc.

Frequently Asked Questions

Analyze common user questions about the Open Wedge Sockets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for high-capacity Open Wedge Sockets?

The primary driver is the increasing scale and complexity of global infrastructure and energy projects, particularly the construction of larger cranes, massive bridges, and high-load offshore wind turbine installations, which require certified hardware capable of handling extreme working load limits (WLLs).

How do Open Wedge Sockets compare to traditional poured socket terminations?

Open Wedge Sockets offer significant advantages in terms of installation speed, ease of inspection, and rapid field replacement. While poured sockets generally offer higher efficiency, wedge sockets are preferred in dynamic environments where rapid rigging changes and frequent safety checks are essential.

Which geographical region exhibits the fastest growth rate in the Open Wedge Sockets Market?

The Asia Pacific (APAC) region is projected to register the fastest growth rate, driven by significant capital expenditure on massive public infrastructure projects, rapid industrialization, and expansion of port and logistics capabilities across key economies like China, India, and Vietnam.

What role does technology play in ensuring the safety and reliability of Open Wedge Sockets?

Technology ensures safety through advanced Finite Element Analysis (FEA) for design optimization, use of specialized alloy steels, and emerging integration of IoT sensors (RFID/NFC) for real-time load monitoring, traceability, and predictive maintenance scheduling, moving beyond traditional visual inspections.

What material considerations are most important for Open Wedge Sockets used in marine environments?

For marine environments, material considerations center on high corrosion resistance and fatigue strength. Forged alloy steel with specialized galvanization or coatings is standard, but stainless steel sockets are often preferred for critical, long-term immersion, or highly corrosive applications despite the higher initial cost.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager