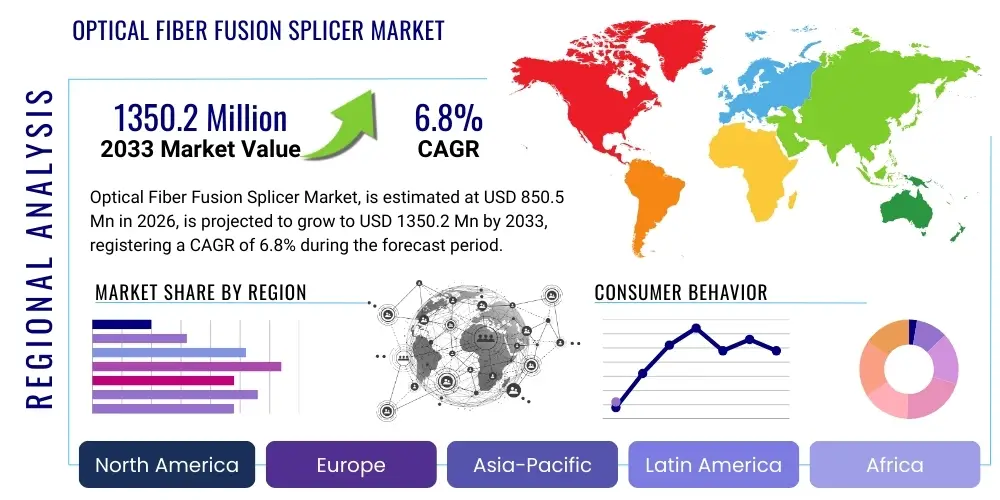

Optical Fiber Fusion Splicer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438433 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Optical Fiber Fusion Splicer Market Size

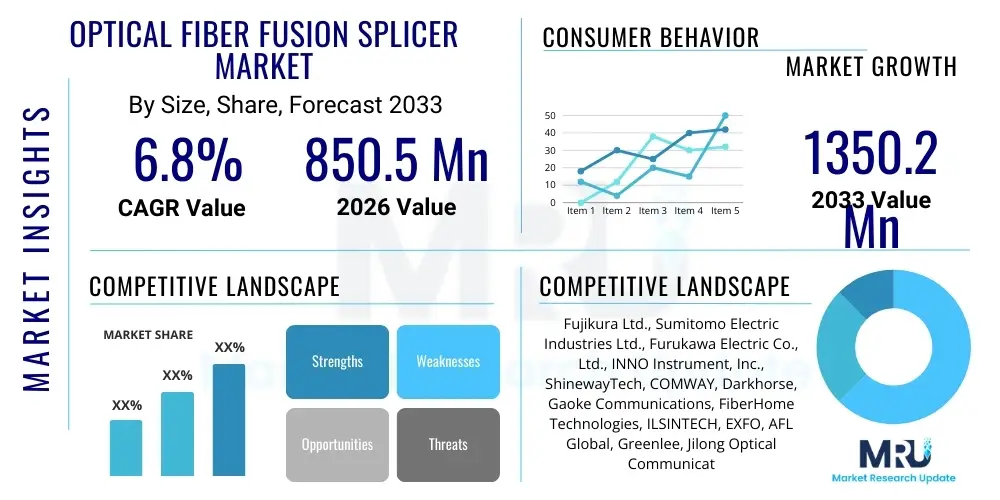

The Optical Fiber Fusion Splicer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $850.5 Million in 2026 and is projected to reach $1350.2 Million by the end of the forecast period in 2033.

Optical Fiber Fusion Splicer Market introduction

The Optical Fiber Fusion Splicer Market encompasses devices crucial for joining two optical fibers end-to-end using heat, creating a permanent, low-loss connection that allows light signals to pass through without scattering. These sophisticated devices are vital components in building and maintaining high-speed fiber optic networks globally, ensuring signal integrity across long distances. The primary function involves aligning the fiber cores precisely and then melting the glass ends together using an electric arc, resulting in a splice loss often less than 0.05 dB, which is essential for modern telecommunications infrastructure demanding ultra-reliable connectivity.

The core product categories include Core Alignment Splicers and Cladding Alignment Splicers, distinguished by their alignment precision and cost. Core alignment models, offering superior accuracy, are predominantly used in critical long-haul, backbone, and FTTx deployments where minimal signal loss is paramount. Major applications span telecommunications (5G backhaul, FTTX deployments), cable television (CATV) networks, enterprise data centers, defense, and specialized industrial sensing. The versatility and necessity of these devices underscore their foundational role in the global transition toward ubiquitous high-bandwidth communication.

Driving factors for market expansion include massive global investments in 5G infrastructure, which necessitate dense, high-capacity fiber networks extending deeper into urban and suburban areas. Furthermore, the relentless surge in internet data traffic, fueled by cloud computing, streaming services, and IoT devices, compels service providers to continuously expand and upgrade their optical network capacity, directly increasing the demand for reliable and efficient fusion splicing equipment. The benefits delivered by these splicers—including mechanical strength, excellent optical transparency, and rapid deployment capabilities—cement their indispensable status in the fiber optic deployment lifecycle.

Optical Fiber Fusion Splicer Market Executive Summary

The Optical Fiber Fusion Splicer Market is undergoing a rapid technological transformation characterized by increased automation, faster splicing times, and enhanced ruggedization for field use. Business trends indicate a strong competitive focus on developing Artificial Intelligence (AI) and Machine Learning (ML) integrated features, allowing splicers to predict maintenance needs, automatically optimize arc power based on fiber type, and improve overall field efficiency. The market is witnessing consolidation among key manufacturers, aiming to acquire complementary technologies related to fiber inspection and testing equipment, thus offering end-to-end solutions to network operators and contractors. Furthermore, there is a distinct shift toward handheld and lighter models to facilitate easy deployment in challenging environments, especially crucial for final-mile fiber installations.

Regionally, Asia Pacific (APAC) continues to dominate the market, primarily driven by massive government-led initiatives to deploy FTTx networks across countries like China, India, and Southeast Asia. The region benefits from lower manufacturing costs and intense competitive pressure accelerating network rollouts. North America and Europe, while mature, exhibit strong growth driven by the continuous upgrade of backbone networks to support 5G rollout and hyperscale data center construction. These regions demand high-precision, core alignment splicers suitable for specialized applications like Polarization Maintaining (PM) fiber splicing, pushing innovation toward higher levels of sophistication and repeatability in the equipment.

Segment trends highlight the persistent dominance of Core Alignment Splicers due to their superior performance, despite their higher initial cost. However, the Cladding Alignment segment is growing steadily, especially in access networks and specific FTTx drop cable applications where extreme precision is less critical than speed and lower capital expenditure. By application, the Telecommunication sector remains the largest consumer, but the Enterprise/Data Center segment is exhibiting the fastest growth rate. This accelerated growth is attributed to the need for high-density fiber connectivity within data centers (e.g., interconnecting servers and storage area networks), requiring quick and reliable splicing solutions for multi-fiber ribbon cables.

AI Impact Analysis on Optical Fiber Fusion Splicer Market

User inquiries regarding the impact of AI on the Optical Fiber Fusion Splicer Market often center on whether AI can enhance splicing accuracy, automate calibration processes, and reduce the dependency on highly skilled technicians. Common questions relate to predictive maintenance capabilities, the optimization of arc discharge settings for exotic fiber types, and the integration of machine vision for improved fiber end-face inspection. Users are keen to understand if AI can significantly decrease splice loss variability across different operating conditions (temperature, humidity) and how AI-driven analytics can contribute to quality control documentation and overall project management efficiency in large-scale deployments.

The integration of Artificial Intelligence and Machine Learning into fusion splicing technology is poised to revolutionize field operations by transforming splicers into intelligent, self-optimizing devices. AI algorithms are increasingly being used to analyze real-time video feedback during the alignment process, adjusting motors with microsecond precision to achieve near-perfect core concentricity, particularly beneficial when handling older or non-standard fibers. Furthermore, ML models trained on vast datasets of splicing attempts can dynamically adjust arc parameters (time, power) based on ambient conditions and automatically identify and compensate for subtle defects on the cleaved fiber end-face before the fusion process even begins. This automation minimizes human error, standardizes splice quality regardless of the operator's experience level, and significantly reduces the total time required for installation, yielding substantial operational cost savings for network providers.

- AI enables predictive maintenance by analyzing motor load, electrode wear, and battery performance.

- Machine Learning optimizes arc discharge parameters dynamically based on fiber geometry and environmental conditions.

- AI-driven machine vision enhances automated end-face inspection, rejecting poorly cleaved fibers before splicing.

- Automated quality assurance and reporting features simplify compliance documentation for network acceptance testing.

- Reduced reliance on extensive manual calibration, leading to faster deployment times in the field.

DRO & Impact Forces Of Optical Fiber Fusion Splicer Market

The Optical Fiber Fusion Splicer market is primarily driven by global infrastructure development projects, specifically the aggressive rollout of 5G networks and FTTx projects, demanding rapid and reliable fiber deployment. Opportunities arise from technological advancements, such as the miniaturization of high-precision core alignment systems and the development of specialized ribbon fiber splicers capable of handling 12 or more fibers simultaneously, catering to high-density data center and backbone requirements. The market faces restraints, primarily high initial capital expenditure for advanced core alignment models and the need for highly specialized training for field technicians to operate and maintain these precision instruments, particularly in emerging markets where skill gaps persist. These forces collectively shape the competitive landscape and technological roadmap for manufacturers, focusing innovation on achieving greater automation and durability while reducing operational complexity.

The primary driver impacting market momentum is the relentless global data consumption growth, necessitating deeper fiber penetration. Governments and private enterprises are pouring billions into network upgrades, directly translating into demand for high-throughput, low-loss splicing solutions. Conversely, the market is restrained by the cyclical nature of telecommunication capital expenditure and the increasing adoption of alternative, non-fusion termination methods (like mechanical splicing) in low-capacity, temporary, or repair applications, though mechanical splicing offers inferior long-term optical performance compared to fusion splicing. Furthermore, intellectual property complexities and intense patent competition among leading vendors often influence pricing structures and market accessibility, particularly in highly sophisticated core alignment technology segments.

The overall impact forces are strongly positive, driven by the foundational role fiber plays in all next-generation digital platforms (IoT, AI, 5G, Cloud). While initial investment costs act as a barrier for small contractors, the long-term total cost of ownership (TCO) calculation overwhelmingly favors high-quality fusion splicing due to dramatically reduced network failure rates and superior optical performance. The persistent demand for bandwidth guarantees that the market trajectory will remain upward, with opportunities focused on developing robust, weather-resistant, and highly automated splicers tailored for harsh field environments and diverse fiber types, including specialty fibers used in sensing and defense applications.

Segmentation Analysis

The Optical Fiber Fusion Splicer Market is intricately segmented based on technology type, alignment method, application, and end-user vertical. This segmentation allows for targeted product development catering to specific operational requirements, ranging from high-precision, long-haul telecommunications backbone construction to basic field repairs in access networks. The key differentiating factor remains the alignment mechanism—Core Alignment versus Cladding Alignment—which determines the achievable splice loss and the suitability for various network tiers. Analyzing these segments is critical for manufacturers to align their R&D investments with the fastest-growing application areas, such as high-capacity ribbon splicing demanded by data center operators and 5G network backhaul providers.

- By Type:

- Core Alignment Splicers (Profile Alignment System - PAS)

- Cladding Alignment Splicers (Fixed V-groove)

- Mass/Ribbon Fusion Splicers

- By Application:

- Telecommunications (Long-Haul, Metro, Access, FTTx)

- Cable Television (CATV)

- Enterprise and Data Centers

- Utility and Government (Defense, Smart Grids)

- R&D and Specialty Applications

- By End-User:

- Network Service Providers (Tier 1 & 2 Carriers)

- Contractors and Installers

- Private Network Owners

- By Component:

- Splicing Unit

- Cleavers and Tools

- Accessories (Electrodes, Fiber Holders)

Value Chain Analysis For Optical Fiber Fusion Splicer Market

The value chain for the Optical Fiber Fusion Splicer Market begins with upstream suppliers providing critical, high-precision components such as advanced optical imaging systems (cameras and lenses), motion control components (stepper motors and alignment mechanisms), high-voltage power supplies for the electric arc, and specialized microprocessor units for algorithmic control. Manufacturing involves precise assembly, calibration, and rigorous testing of these components to ensure reliability and ultra-low tolerances required for core alignment. The technological barrier to entry at the manufacturing stage is high due to the necessity for proprietary core alignment and arc stabilization technologies, leading to dominance by a few key patent-holding companies.

The midstream involves the core activities of the original equipment manufacturers (OEMs), including product design, software integration (especially for automated features and cloud reporting), and branding. Distribution channels are varied: large global manufacturers often utilize a combination of direct sales teams for major telecom contracts and indirect sales through certified regional distributors and authorized resellers who provide essential local support, maintenance, and training. Direct channels are crucial for securing large volume deals with Tier 1 carriers, while indirect channels ensure market penetration into smaller contractors and specialized industrial users.

Downstream analysis focuses on the end-users—primarily telecommunications carriers, network installation contractors, and enterprise IT departments. The purchasing decision is heavily influenced not just by the initial unit cost, but critically by factors such as splicing time, average splice loss, battery life, environmental ruggedization (IP rating), and the quality of local after-sales support and calibration services. The lifecycle maintenance and recurrent costs associated with consumables (electrodes, cleaver blades) also form a significant part of the downstream value proposition. Effective distribution and robust local service centers are vital for market success, as splicers are high-value tools requiring frequent professional calibration and repair.

Optical Fiber Fusion Splicer Market Potential Customers

The primary customers for Optical Fiber Fusion Splicers are organizations involved in the deployment, maintenance, and repair of fiber optic networks across various sectors globally. Telecommunication service providers represent the largest buying group, spanning from multinational Tier 1 carriers deploying transcontinental submarine cables and 5G backhaul to local municipal providers implementing FTTx (Fiber-to-the-Home/Curb/Building) networks. Their demand is continuous and focuses predominantly on fast, high-accuracy core alignment splicers and mass ribbon splicers to efficiently handle high fiber count cables necessary for future-proofing bandwidth capacity.

The secondary major customer base includes specialized network contractors and installation firms hired by large carriers or governments. These contractors require durable, portable, and reliable splicers suitable for harsh outdoor conditions. Furthermore, utility companies managing smart grid infrastructure and specialized government agencies (defense, research laboratories) represent growing niches requiring specialized fusion splicers for harsh environment fiber or Polarization Maintaining (PM) fiber applications. Finally, large enterprises and hyperscale data center operators are increasingly becoming significant buyers as they build out massive internal fiber optic infrastructures to manage high-speed server interconnects and storage area networks, requiring devices optimized for high-density, multi-fiber splicing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850.5 Million |

| Market Forecast in 2033 | $1350.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fujikura Ltd., Sumitomo Electric Industries Ltd., Furukawa Electric Co., Ltd., INNO Instrument, Inc., ShinewayTech, COMWAY, Darkhorse, Gaoke Communications, FiberHome Technologies, ILSINTECH, EXFO, AFL Global, Greenlee, Jilong Optical Communication, DVP Fiber Optic, Fitel, Sinyung, Miller, Grandway, Skycom Communication. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Optical Fiber Fusion Splicer Market Key Technology Landscape

The technology landscape of the Optical Fiber Fusion Splicer Market is dominated by advancements in alignment precision, automation, and robustness. Core Alignment Technology, primarily using the Profile Alignment System (PAS), remains the gold standard, employing highly sophisticated optics and image processing to ensure the precise centering of the fiber cores before splicing, regardless of minor variations in cladding geometry. Recent innovations focus on ultra-fast splicing cycles, reducing the typical splicing time from 15-20 seconds to under 7 seconds, significantly boosting productivity for high-volume network deployment projects. Manufacturers are also integrating features like automatic cleave inspection and contamination detection to minimize splice failures caused by poor preparation.

A crucial technological trend is the rise of Mass or Ribbon Fusion Splicers. As network density increases, especially in data centers and high-capacity central offices, cables containing 12, 24, or even 48 fibers are commonly used. Ribbon splicers are designed to handle multiple fibers simultaneously (e.g., a ribbon of 12 fibers in one operation), drastically reducing installation time compared to single-fiber splicing. These advanced units require robust V-groove technology and highly controlled heat application to ensure uniform, low-loss splicing across all fibers in the ribbon, representing a complex engineering challenge that only a few major players have successfully mastered.

Furthermore, the market is rapidly adopting smart technologies, including Internet of Things (IoT) connectivity and cloud integration. Modern fusion splicers feature built-in Wi-Fi or Bluetooth capabilities, allowing technicians to upload splice data (loss values, time stamps, GPS location) directly to centralized management platforms. This facilitates remote monitoring of job progress, automatic inventory management of consumables, and quality control oversight by project managers. The ruggedization of the equipment, including high Ingress Protection (IP) ratings against dust and water, is also a critical technological requirement, ensuring reliable operation in adverse weather conditions common in field deployment environments.

The ongoing development of specialized fiber types, such as Polarization-Maintaining (PM) fibers used in optical sensing and coherent transmission, necessitates highly specialized PM fusion splicers. These devices must align the polarization axis of the fibers with extreme angular precision, requiring advanced rotational alignment stages alongside standard core alignment. This niche segment drives technological boundaries, pushing the limits of mechanical and optical precision far beyond standard telecommunication requirements. Finally, battery technology improvements, moving towards lighter, longer-lasting lithium-ion power packs, are enhancing the portability and usability of splicers during prolonged field operations where external power sources are unavailable or unreliable.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market and the fastest-growing region for optical fiber fusion splicers, driven primarily by ambitious government policies supporting universal fiber broadband access and the world's most extensive 5G network rollouts in China, South Korea, and Japan. India and Southeast Asian nations like Indonesia and Vietnam are investing heavily in FTTx infrastructure, creating massive demand for both high-end core alignment models for backbone links and cost-effective cladding alignment splicers for last-mile deployments. The presence of major, cost-competitive manufacturing hubs within this region further fuels market expansion.

- North America: North America represents a mature, high-value market characterized by robust demand for high-precision, automated core alignment splicers and advanced ribbon splicers, supporting extensive data center build-outs and the rapid deployment of 5G infrastructure. Government initiatives, such as funding programs aimed at bridging the digital divide, are spurring fiber expansion into rural areas. The region prioritizes reliability, speed, and integrated reporting capabilities, driving technological adoption toward IoT-enabled, high-speed splicing equipment.

- Europe: Europe exhibits strong growth fueled by the mandated transition toward next-generation access networks (NGAN) and the European Commission’s connectivity goals. Countries like Germany, France, and the UK are intensifying fiber deployment, replacing legacy copper infrastructure. European carriers demand high-quality, durable equipment compliant with stringent environmental and safety standards, favoring established Japanese and European manufacturers known for product longevity and precise performance.

- Latin America (LATAM): The LATAM market is characterized by sporadic, yet significant, growth, particularly in Brazil and Mexico, driven by increasing competition among telecom operators and improving regulatory environments encouraging foreign investment in infrastructure. Demand is often price-sensitive, balancing the need for reliable equipment with budgetary constraints, leading to a strong market presence for mid-range cladding alignment and older generation core alignment models.

- Middle East and Africa (MEA): The MEA region, particularly the Gulf Cooperation Council (GCC) countries, shows high growth due to significant governmental spending on smart city projects (e.g., NEOM in Saudi Arabia) and substantial fiber backbone expansion. Africa's market remains challenging but presents long-term opportunities as mobile carriers invest in fiberizing their tower infrastructure (Fibre-to-the-Tower or FTTT) to handle escalating mobile data traffic.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Optical Fiber Fusion Splicer Market.- Fujikura Ltd.

- Sumitomo Electric Industries Ltd.

- Furukawa Electric Co., Ltd. (Fitel)

- INNO Instrument, Inc.

- ShinewayTech

- COMWAY

- Darkhorse

- Gaoke Communications

- FiberHome Technologies

- ILSINTECH

- EXFO

- AFL Global

- Greenlee

- Jilong Optical Communication

- DVP Fiber Optic

- Sinyung

- Miller

- Grandway

- Skycom Communication

- Deviser Instruments

Frequently Asked Questions

Analyze common user questions about the Optical Fiber Fusion Splicer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Core Alignment and Cladding Alignment fusion splicers?

Core Alignment splicers (using PAS technology) achieve precise alignment by focusing on the actual fiber core, resulting in minimal splice loss (typically < 0.05 dB), making them ideal for long-haul and sensitive applications. Cladding Alignment splicers align based on the outer glass surface (cladding), offering faster, lower-cost operation but with slightly higher loss, suitable primarily for FTTx drop cables and local area networks.

How is the 5G rollout impacting the demand for optical fiber fusion splicers?

The 5G rollout is significantly boosting demand, as it requires fiber optic cables to be extended much closer to the cell sites (fiber densification). This necessitates a vast increase in the volume of splicing operations in metro and access networks, driving demand for high-speed, durable, and automated splicers capable of handling high fiber count ribbon cables efficiently.

What is the expected average lifespan of a modern fusion splicer and its electrodes?

A high-quality fusion splicer typically has a operational lifespan exceeding five to ten years with regular maintenance and calibration. Electrodes, which generate the arc, are consumables; their lifespan generally ranges from 3,000 to 5,000 splice cycles, depending on the fiber type and the arc power settings used, requiring replacement after this cycle count to maintain optimal splice quality.

Which geographic region currently holds the largest market share for fusion splicers?

The Asia Pacific (APAC) region currently holds the largest market share, driven by massive and ongoing government and carrier investments in FTTx infrastructure, particularly in populous countries like China and India, alongside extensive 5G network expansion projects throughout the region.

Are handheld fusion splicers suitable for demanding telecommunication backbone projects?

While traditional large core alignment splicers are preferred for ultra-critical backbone infrastructure, modern compact or handheld core alignment splicers offer sufficient precision and durability for many demanding telecom applications, including metro and distribution networks, provided they maintain extremely low splice loss specifications and robust environmental protection features.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Optical Fiber Fusion Splicer Market Statistics 2025 Analysis By Application (CATV, Telecom, Premises& Enterprise, Military), By Type (Single Fiber Fusion Splicer, Ribbon Fiber Fusion Splicer, Special Fiber Fusion Splicer), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Optical Fiber Fusion Splicer Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Single fiber fusion splicer, Ribbon fiber fusion splicer, Special fiber fusion splicer), By Application (CATV, Telecom, Premises& Enterprise, Military, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager