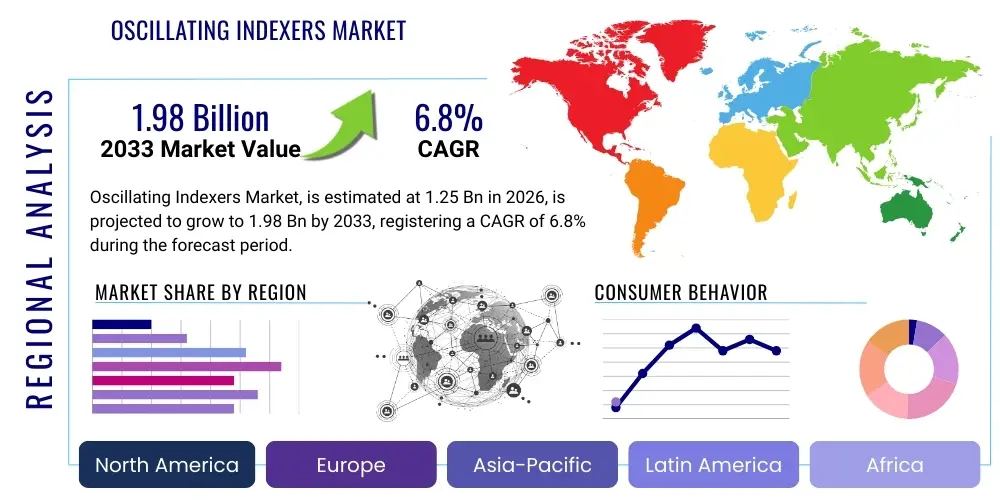

Oscillating Indexers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440154 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Oscillating Indexers Market Size

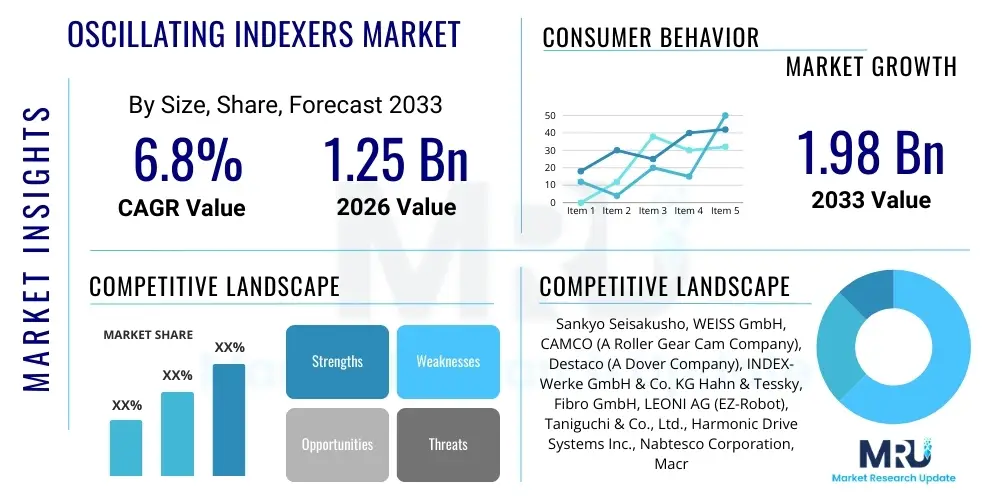

The Oscillating Indexers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.98 billion by the end of the forecast period in 2033.

Oscillating Indexers Market introduction

Oscillating indexers are precision mechanical devices crucial for automating various industrial processes, enabling intermittent, controlled rotational or linear movement of a workpiece or tool. These systems are integral to modern manufacturing, facilitating precise positioning for tasks like assembly, packaging, and testing where accuracy and repeatability are paramount. Their robust design allows them to operate reliably in demanding industrial environments, making them indispensable components in advanced automation lines. The primary applications span across diverse sectors including automotive, electronics, food and beverage, pharmaceuticals, and general manufacturing, where they enhance operational efficiency and product quality.

The core benefit of deploying oscillating indexers lies in their ability to significantly boost production throughput and reduce manual labor dependency, thereby lowering operational costs. They provide accurate indexing, crucial for sequential operations in high-speed production lines, minimizing errors and scrap rates. Key driving factors for market growth include the increasing global demand for industrial automation solutions, the continuous adoption of Industry 4.0 principles, rising labor costs in developed economies necessitating automated alternatives, and the growing complexity of manufacturing processes that require exact positional control. Furthermore, the push towards smart factories and integrated production systems continues to fuel innovation and demand for these essential automation components.

Oscillating Indexers Market Executive Summary

The Oscillating Indexers Market is witnessing robust expansion driven by an escalating global demand for enhanced manufacturing automation and precision engineering across various industries. Business trends indicate a strong focus on integration with advanced robotic systems, the development of more energy-efficient and compact indexers, and a growing emphasis on customization to meet specific industry requirements. Manufacturers are increasingly seeking solutions that offer higher speeds, greater accuracy, and reduced maintenance, pushing innovation towards servo-driven and direct-drive indexing technologies. The competitive landscape is characterized by established players and emerging innovators striving to offer superior performance and cost-effectiveness, leading to a dynamic market environment.

Regionally, Asia Pacific continues to emerge as the fastest-growing market, propelled by rapid industrialization, expansion of manufacturing bases in countries like China, India, and Southeast Asia, and significant investments in automation infrastructure. North America and Europe, while mature markets, demonstrate steady growth due to the ongoing modernization of existing factories, adoption of advanced manufacturing techniques, and a strong emphasis on smart factory initiatives. Segment-wise, the market is primarily driven by the automotive and electronics industries, which demand high-precision and high-speed indexing solutions for assembly and testing processes. The demand for electric and servo-driven indexers is also experiencing substantial growth, outperforming traditional mechanical and pneumatic variants due to their superior control capabilities and flexibility, aligning with the broader trends in industrial automation.

AI Impact Analysis on Oscillating Indexers Market

Users frequently inquire about how Artificial Intelligence (AI) can transform the functionality and maintenance of oscillating indexers, focusing on themes such as predictive analytics for operational longevity, intelligent control for adaptive performance, and seamless integration within larger AI-driven manufacturing ecosystems. There's a strong interest in understanding how AI can optimize indexing cycles, minimize downtime through early fault detection, and enable more autonomous and flexible production lines. Concerns often revolve around the complexity of implementation, data security, and the necessity for skilled personnel to manage these advanced systems. Users anticipate that AI will primarily enhance efficiency, reliability, and the overall intelligence of indexing operations, moving towards self-optimizing mechanisms.

- AI-powered predictive maintenance reduces downtime by forecasting component failures in indexers.

- Optimized indexing cycles through machine learning algorithms for improved efficiency and throughput.

- Real-time adaptive control of indexer parameters based on production demands and sensor feedback.

- Enhanced quality control by integrating AI vision systems with precise indexing for defect detection.

- Autonomous fault detection and self-correction capabilities in complex indexing sequences.

- Seamless integration with robotic systems and smart factory platforms for holistic automation.

- Data analytics from indexer operations providing insights for process improvement and resource allocation.

- Energy consumption optimization through AI-driven load management and cycle adjustments.

DRO & Impact Forces Of Oscillating Indexers Market

The Oscillating Indexers Market is primarily driven by the escalating global adoption of industrial automation across various manufacturing sectors, coupled with the increasing demand for high-precision, high-speed, and repeatable positioning solutions in complex production lines. The widespread implementation of Industry 4.0 technologies and the rising cost of manual labor further compel manufacturers to invest in automated indexing systems. However, the market faces significant restraints, including the substantial initial capital investment required for these sophisticated machines, the technical complexity involved in their integration and maintenance, and a persistent shortage of skilled personnel capable of operating and servicing advanced automation equipment. Economic uncertainties and fluctuations in raw material prices can also impact market growth.

Opportunities for growth are abundant, particularly in emerging economies undergoing rapid industrialization and in the development of highly customized and flexible indexing solutions that cater to niche applications. The miniaturization of components, the integration with collaborative robots, and the advancement of smart factory ecosystems present avenues for innovative product development and market penetration. Key impact forces shaping the market include continuous technological advancements in motor control, sensor technology, and communication protocols, which are enhancing the performance and connectivity of indexers. Regulatory changes concerning workplace safety and environmental standards also influence design and operational considerations, while intense competition among manufacturers drives innovation and competitive pricing strategies across the globe.

Segmentation Analysis

The Oscillating Indexers Market is comprehensively segmented to provide a detailed understanding of its diverse applications and technological advancements. This segmentation helps in analyzing market trends, identifying growth opportunities, and understanding competitive dynamics across various product types, operational mechanisms, end-use industries, and geographical regions. Understanding these distinct segments is crucial for stakeholders to tailor strategies, optimize product offerings, and capitalize on specific market demands. The market’s segmentation reflects the evolving needs of industrial automation, from basic indexing tasks to highly complex, integrated manufacturing processes requiring specialized solutions.

- By Type

- Electric/Servo-Driven Indexers

- Mechanical Indexers (Cam-driven, Roller Gear)

- Pneumatic Indexers

- Hydraulic Indexers

- Direct Drive Indexers

- By Application

- Assembly Automation

- Packaging Machinery

- Material Handling

- Testing & Inspection

- Welding & Forming

- Medical Device Manufacturing

- Electronics Manufacturing

- By End-Use Industry

- Automotive

- Electronics & Semiconductor

- Food & Beverage

- Pharmaceuticals & Medical Devices

- Packaging

- General Manufacturing

- Aerospace & Defense

- By Speed

- High-Speed Indexers

- Medium-Speed Indexers

- Low-Speed Indexers

- By Axis Configuration

- Single-Axis Indexers

- Multi-Axis Indexers

Value Chain Analysis For Oscillating Indexers Market

The value chain for the Oscillating Indexers Market begins with upstream activities involving the procurement of essential raw materials such as high-grade steel, aluminum, and various alloys, along with specialized electronic components like servo motors, sensors, and control units from a diverse network of suppliers. Precision machining companies and component manufacturers play a crucial role in providing the intricate gears, cams, and shafts required for indexer mechanisms. Efficient management of these supplier relationships is critical for ensuring material quality, cost-effectiveness, and timely delivery, directly impacting the final product's performance and market competitiveness. Innovation in material science and component technology significantly influences product development at this stage.

Moving downstream, the value chain encompasses the manufacturing, assembly, testing, and distribution of oscillating indexers. Manufacturers often employ advanced CNC machining and robotic assembly to ensure high precision and quality. Post-production, these indexers reach end-users primarily through a combination of direct sales channels, where manufacturers engage directly with large industrial clients and system integrators, and indirect distribution networks involving a global network of distributors, value-added resellers (VARs), and original equipment manufacturers (OEMs). OEMs integrate indexers into larger machinery and automation systems, offering complete solutions to their customers. After-sales services, including installation, maintenance, and technical support, form a critical part of the downstream activities, ensuring customer satisfaction and fostering long-term relationships, thereby strengthening market presence and brand loyalty.

Oscillating Indexers Market Potential Customers

Potential customers for oscillating indexers primarily consist of manufacturing companies across a wide spectrum of industries that require precise, repeatable, and intermittent motion for their production processes. This includes automotive manufacturers who utilize indexers for assembly lines, robotic work cells, and welding applications, ensuring accurate positioning of components during various stages of vehicle production. The electronics and semiconductor industry represents another significant customer base, employing indexers in automated assembly, testing, and packaging of delicate electronic components and devices where high precision is paramount to prevent damage and ensure functionality.

Furthermore, the food and beverage sector increasingly adopts oscillating indexers for high-speed packaging, filling, and labeling operations, where consistent product handling is essential for maintaining hygiene and efficiency. Pharmaceutical and medical device manufacturers are also key end-users, leveraging these devices for sterile assembly, inspection, and packaging processes that demand extreme accuracy and reliability to meet stringent regulatory standards. General manufacturing, material handling, and custom automation solution providers (system integrators) also form a substantial part of the customer base, as they design and implement bespoke automation systems that frequently incorporate oscillating indexers to achieve specific production goals and enhance operational throughput.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sankyo Seisakusho, WEISS GmbH, CAMCO (A Roller Gear Cam Company), Destaco (A Dover Company), INDEX-Werke GmbH & Co. KG Hahn & Tessky, Fibro GmbH, LEONI AG (EZ-Robot), Taniguchi & Co., Ltd., Harmonic Drive Systems Inc., Nabtesco Corporation, Macron Dynamics, Inc., Central Control Inc., Dorner Mfg. Corp., Promess Inc., Motion Index Drives, TJR Precision Technology Co., Ltd., Gudel AG, Parker Hannifin Corporation, Rockwell Automation, Siemens AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Oscillating Indexers Market Key Technology Landscape

The Oscillating Indexers Market is characterized by a dynamic technology landscape continually evolving to meet the demands for higher precision, speed, flexibility, and connectivity in industrial automation. A core technology is the advancement in servo motor and drive systems, which provide highly accurate, programmable, and dynamic control over indexing movements, surpassing the capabilities of traditional mechanical or pneumatic systems. This allows for customized motion profiles, on-the-fly adjustments, and seamless integration with complex automation sequences. Coupled with sophisticated control systems, including Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), these indexers offer unparalleled operational flexibility and diagnostic capabilities, enabling real-time monitoring and predictive maintenance strategies.

Precision gearing and cam mechanisms remain foundational, with continuous improvements in materials and manufacturing processes leading to reduced backlash, increased rigidity, and extended service life. Innovations in sensor technology, such as high-resolution encoders and proximity sensors, further enhance positional accuracy and feedback loops, crucial for closed-loop control systems. Furthermore, the integration of industrial communication protocols like EtherCAT, PROFINET, and Ethernet/IP is transforming indexers into smart, connected devices, facilitating their seamless incorporation into Industry 4.0 environments and allowing for remote diagnostics and data exchange with central control systems. This technological synergy drives the development of more intelligent, efficient, and robust oscillating indexers, capable of meeting the stringent requirements of modern manufacturing facilities and enabling greater automation intelligence.

Regional Highlights

- North America: A mature market characterized by robust investment in industrial automation, particularly in the automotive, aerospace, and electronics sectors. The region focuses on integrating advanced technologies like AI and robotics, driving demand for high-end, customizable oscillating indexers. Strong emphasis on upgrading existing manufacturing infrastructure and addressing labor shortages fuels sustained growth.

- Europe: Similar to North America, Europe is a well-established market with a strong manufacturing base, especially in Germany (Industry 4.0 hub), Italy, and France. The region prioritizes precision engineering, energy efficiency, and regulatory compliance. Adoption of smart factory solutions and advanced automation in automotive, machinery, and pharmaceutical industries contributes significantly to market demand.

- Asia Pacific (APAC): The fastest-growing market globally, driven by rapid industrialization, expanding manufacturing capabilities, and significant government investments in automation across countries like China, India, Japan, and South Korea. The region is a major hub for electronics, automotive, and general manufacturing, leading to high volume demand for oscillating indexers, including both cost-effective and high-performance solutions.

- Latin America: An emerging market showing steady growth due to increasing foreign direct investment in manufacturing and the ongoing modernization of industrial sectors, particularly in Brazil and Mexico. The adoption of automation technologies is on the rise, creating demand for both new installations and retrofitting projects in various industries.

- Middle East and Africa (MEA): This region is experiencing nascent but growing adoption of industrial automation, primarily driven by economic diversification efforts and investments in non-oil sectors like manufacturing and logistics. Development of new industrial zones and increasing awareness of automation benefits contribute to the gradual expansion of the oscillating indexers market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Oscillating Indexers Market.- Sankyo Seisakusho

- WEISS GmbH

- CAMCO (A Roller Gear Cam Company)

- Destaco (A Dover Company)

- INDEX-Werke GmbH & Co. KG Hahn & Tessky

- Fibro GmbH

- LEONI AG (EZ-Robot)

- Taniguchi & Co., Ltd.

- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Macron Dynamics, Inc.

- Central Control Inc.

- Dorner Mfg. Corp.

- Promess Inc.

- Motion Index Drives

- TJR Precision Technology Co., Ltd.

- Gudel AG

- Parker Hannifin Corporation

- Rockwell Automation

- Siemens AG

Frequently Asked Questions

Analyze common user questions about the Oscillating Indexers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an oscillating indexer?

An oscillating indexer is a precision mechanical device providing intermittent, controlled rotational or linear movement to accurately position a workpiece or tool in automated manufacturing processes, crucial for sequential operations.

How does AI influence the Oscillating Indexers Market?

AI enhances indexers through predictive maintenance, optimizing operational cycles, enabling real-time adaptive control, and facilitating integration into smart factory ecosystems for improved efficiency and reliability.

What are the primary applications of oscillating indexers?

Oscillating indexers are widely used in assembly automation, packaging machinery, material handling, testing and inspection, and medical device manufacturing, where precise and repeatable positioning is critical.

What key factors are driving the growth of this market?

Market growth is primarily driven by increasing industrial automation, demand for high-precision manufacturing, rising labor costs, and the widespread adoption of Industry 4.0 principles across various industries.

What are the main types of oscillating indexers available?

The main types include electric/servo-driven indexers, mechanical (cam-driven) indexers, pneumatic indexers, hydraulic indexers, and direct-drive indexers, each offering distinct advantages in terms of control, speed, and precision.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager