OSD Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434998 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

OSD Machine Market Size

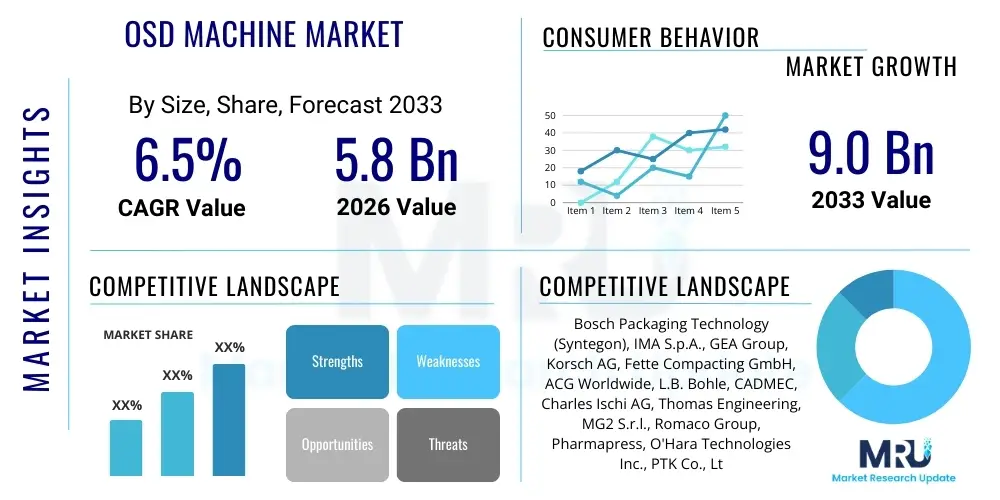

The OSD Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 5.8 Billion in 2026 and is projected to reach USD 9.0 Billion by the end of the forecast period in 2033.

OSD Machine Market introduction

The Oral Solid Dosage (OSD) machine market encompasses specialized machinery used in the pharmaceutical industry for manufacturing tablets, capsules, and powders. These machines cover the entire production lifecycle, including blending, granulation, compression, coating, and packaging. The increasing global demand for pharmaceuticals, especially generic drugs and over-the-counter (OTC) medications, acts as a fundamental driver. OSD remains the most preferred dosage form due to its ease of administration, high patient compliance, superior stability, and cost-effectiveness in production, thereby ensuring sustained investment in advanced manufacturing equipment.

Key products within this sector include high-speed tablet presses, encapsulators, fluid bed processors, and specialized coating systems. Major applications are concentrated in large-scale pharmaceutical manufacturing units, contract manufacturing organizations (CMOs), and nutraceutical companies seeking efficient, high-throughput production lines that meet stringent regulatory standards (e.g., FDA, EMA). The primary benefits of advanced OSD machines include improved process control, reduced batch variation, enhanced operational efficiency, and minimized cross-contamination risk, all crucial for maintaining Good Manufacturing Practice (GMP) compliance.

Market growth is significantly driven by rapid technological advancements focusing on automation, integration with continuous manufacturing principles, and the requirement for containment solutions to handle highly potent active pharmaceutical ingredients (HPAPIs). Furthermore, the expanding geriatric population and the resultant rise in chronic disease prevalence globally necessitate larger volumes of oral medication, fueling the capacity expansion plans of major pharmaceutical manufacturers and consequently driving the adoption of sophisticated, high-capacity OSD machinery.

OSD Machine Market Executive Summary

The OSD Machine Market is characterized by a strong shift toward digitalization and integrated manufacturing systems, where equipment suppliers are increasingly offering turnkey solutions that include data analytics and predictive maintenance capabilities. Business trends highlight strategic mergers and acquisitions among key machinery manufacturers aimed at expanding product portfolios, particularly into high-containment and continuous processing technology segments. The demand for flexible equipment capable of handling diverse product specifications and smaller batch sizes, driven by personalized medicine trends, is compelling manufacturers to invest in modular and easily reconfigurable machine designs, prioritizing total cost of ownership (TCO) alongside initial capital expenditure.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, primarily due to expanding domestic pharmaceutical manufacturing capabilities in countries like China and India, coupled with significant foreign direct investment aimed at establishing export-oriented facilities. North America and Europe, while mature, remain dominant in terms of adopting advanced technologies, particularly high-speed tablet compression and integrated continuous manufacturing systems, driven by stringent regulatory environments and a focus on operational excellence. Latin America and the Middle East & Africa are showing steady growth, supported by governmental initiatives to localize pharmaceutical production and reduce reliance on imported medicines.

Segment trends reveal a strong preference for high-speed tablet presses in mass production scenarios, while sophisticated fluid bed systems are growing rapidly due to their versatility in handling complex granulation and coating tasks. By application, the production of generic drugs accounts for the largest market share, though specialized machinery for biologics and advanced therapies requiring high containment is witnessing the fastest growth rate. The market is moving away from traditional batch processing toward continuous manufacturing systems (CMS), which promise superior quality control, reduced footprint, and lower operational overhead, representing a long-term transformative segment within the OSD machinery landscape.

AI Impact Analysis on OSD Machine Market

User queries regarding the impact of Artificial Intelligence (AI) on the OSD Machine Market primarily revolve around operational efficiency, predictive maintenance, and quality assurance compliance. Users frequently ask how AI can optimize granulation and coating parameters in real-time to prevent batch failures, how machine learning algorithms predict equipment breakdowns, and the feasibility of autonomous OSD manufacturing lines. The central theme is the expectation that AI integration will shift OSD manufacturing from reactive fault detection to proactive, self-optimizing process control, thereby minimizing downtime and maximizing product quality conformity without human intervention.

The introduction of AI and machine learning (ML) algorithms allows OSD machines to process massive datasets generated during compression, drying, and coating stages. This computational power enables machines to identify subtle deviations from optimal performance parameters far more quickly and accurately than traditional Statistical Process Control (SPC) methods. AI-driven models analyze variables such as tablet weight variation, compression force, and coating uniformity, facilitating immediate adjustments to operational settings. This capability is paramount for companies aiming to implement Quality by Design (QbD) principles and achieve seamless transition toward continuous manufacturing methodologies, where instantaneous feedback loops are essential.

Furthermore, AI significantly enhances asset performance management (APM) within the OSD sector. By analyzing sensor data from vibratory feeders, turret rotations, and hydraulic systems, AI models can forecast the Remaining Useful Life (RUL) of critical components, enabling maintenance staff to schedule repairs precisely before failure occurs. This predictive maintenance approach drastically reduces unexpected downtime—a costly issue in high-throughput pharmaceutical manufacturing. Beyond maintenance, AI is also crucial for validating regulatory compliance by documenting and analyzing every operational variable, creating immutable audit trails required by global regulatory bodies, thereby streamlining the validation process for new equipment installations.

- AI-Powered Process Optimization: Real-time adjustment of compression force and coating parameters to maintain critical quality attributes (CQAs).

- Predictive Maintenance (PdM): Use of ML models to analyze equipment sensor data, predicting component failure and reducing unplanned downtime by up to 30%.

- Enhanced Quality by Design (QbD): Algorithms monitor raw material variability and automatically adjust machine settings to ensure consistent finished product quality.

- Autonomous Operation and Control: Facilitating closed-loop control systems, moving towards fully autonomous OSD manufacturing lines with minimal human oversight.

- Improved Data Integrity and Compliance: Automated data logging and analysis supporting regulatory audits and streamlined validation processes (e-g., 21 CFR Part 11).

- Optimized Energy Consumption: AI tools analyze usage patterns and adjust motor speeds and heater cycles to improve energy efficiency during high-volume production.

DRO & Impact Forces Of OSD Machine Market

The OSD Machine Market is primarily driven by the escalating global pharmaceutical production requirements, especially for affordable generic drugs, alongside rigorous regulatory demands for quality and efficiency, compelling manufacturers to upgrade their machinery fleets. Restraints include the extremely high initial capital investment required for high-containment and continuous processing equipment, coupled with the need for specialized technical expertise for operation and maintenance. Opportunities lie significantly in the burgeoning adoption of Continuous Manufacturing Systems (CMS) and the integration of Industry 4.0 technologies, allowing for modular upgrades and enhanced process control. These factors collectively create a dynamic market environment where technological innovation determines strategic success and market penetration.

A primary driver is the widespread application of automation across the OSD production line, which mitigates human error, increases throughput, and ensures consistency across batches, aligning directly with GMP requirements. The shift toward high-potency drugs (HPAPIs) also mandates the use of specialized containment OSD machines, creating a niche growth area driven by occupational safety regulations. Conversely, the market faces constraints related to long qualification cycles and validation periods for new equipment purchases in the highly regulated pharmaceutical sector, often leading to delayed adoption of cutting-edge technology. Furthermore, the global supply chain volatility impacting component costs and lead times also acts as a short-term restraint.

The major impact forces include the increasing consolidation within the pharmaceutical industry, where large firms demand standardized, scalable, and globally supported equipment platforms. Regulatory forces, particularly those encouraging continuous manufacturing (e.g., FDA initiatives), strongly push innovation towards real-time release testing (RTRT) capabilities integrated into OSD equipment. The growing focus on sustainability and energy efficiency also acts as a structural force, compelling machinery manufacturers to design systems with reduced power consumption and waste generation. The confluence of these drivers and opportunities, while navigating capital constraints and regulatory hurdles, shapes the strategic direction of OSD machine development.

Segmentation Analysis

The OSD machine market is segmented based on product type, operation mode, application, and end-user, providing a granular view of demand dynamics across the pharmaceutical manufacturing ecosystem. Analyzing these segments helps stakeholders understand which technologies are gaining traction (e.g., continuous versus batch processing) and which end-user groups (pharmaceuticals vs. nutraceuticals) are driving investment cycles. High-speed, automated equipment dominates the product landscape, reflecting the industry's focus on maximizing efficiency and minimizing costs per dose, while containment machinery addresses safety and regulatory prerequisites for handling hazardous compounds.

- By Product Type:

- Tablet Compression Machines (Single-rotary, Multi-layer, High-speed)

- Capsule Fillers (Tamping pin, Dosing disc, Auger system)

- Granulation Equipment (High Shear Mixer Granulators, Fluid Bed Processors)

- Coating Systems (Perforated pan, Conventional pan, Fluidized bed coaters)

- Blenders and Mixers

- Ancillary Equipment (De-dusters, Metal detectors, Checkweighers)

- By Operation Mode:

- Batch Processing

- Continuous Processing (CMS)

- By Application:

- Pharmaceutical Manufacturing (Generics, Branded Drugs)

- Nutraceutical and Dietary Supplements

- Contract Manufacturing Organizations (CMOs)

- R&D Laboratories

- By End-User:

- Large Pharmaceutical Companies

- Small and Medium-sized Pharmaceutical Companies (SMEs)

- Academic and Research Institutes

Value Chain Analysis For OSD Machine Market

The value chain for OSD machinery begins with upstream analysis, which involves the sourcing of critical high-precision components, specialized materials (such as stainless steel alloys resistant to corrosion), sensors, and advanced control systems (PLCs, HMIs). Key upstream activities include R&D focusing on component longevity, materials science, and integrating complex software necessary for automation and data integrity. Manufacturers rely heavily on specialized suppliers for components like turret tooling, high-precision gears, and pharmaceutical-grade pumps, meaning supply chain stability and quality control at this stage are paramount for the final machine performance and longevity.

The mid-stream segment is dominated by the OSD machine original equipment manufacturers (OEMs). Activities here encompass machine design, engineering, assembly, rigorous factory acceptance testing (FAT), and complex software integration. Manufacturers add value through specialization in particular machine types (e.g., high-speed compression or contained encapsulation) and by offering modular, customizable designs that allow pharmaceutical clients to scale operations easily. Intellectual property related to containment mechanisms, dust handling, and advanced sensor technology represents a significant value addition at this stage, establishing competitive differentiation among major players.

Downstream analysis focuses on distribution, installation, and post-sales support, which is critical in this high-CAPEX industry. Distribution often occurs through a mix of direct sales channels, especially for large, complex installations, and indirect channels involving specialized distributors or regional agents who handle logistics, customs clearance, and local technical support. The most significant downstream value is derived from comprehensive post-installation services, including validation protocols (IQ/OQ/PQ), operator training, maintenance contracts, and the timely supply of validated spare parts, ensuring maximum uptime for the end-user. Strong service support significantly influences repeat purchasing decisions and customer loyalty in the OSD machine market.

OSD Machine Market Potential Customers

The primary customers for OSD machines are diversified across the global pharmaceutical manufacturing landscape, characterized by distinct needs based on operational scale, geographic location, and product type specialization. Large, multinational pharmaceutical corporations constitute a major segment, continuously seeking state-of-the-art, high-throughput, and fully automated machinery capable of handling blockbuster drug volumes while complying with multiple international regulatory standards. These entities drive demand for integrated continuous processing lines and highly sophisticated containment technology necessary for managing potent active ingredients effectively.

Contract Manufacturing Organizations (CMOs) represent another rapidly expanding segment of potential customers. CMOs require highly flexible and versatile OSD equipment capable of rapidly switching between different drug formulations and batch sizes to serve various clients. Their focus is often on quick changeover times, ease of cleaning (Wash-in-Place systems), and modularity to optimize resource utilization across diverse manufacturing campaigns. The growing trend of pharmaceutical outsourcing globally directly translates into increased capital expenditure on OSD machinery by CMOs to enhance capacity and technical capabilities.

Furthermore, generic drug manufacturers, especially in high-growth regions like Asia Pacific, are massive volume buyers, primarily targeting robust, cost-effective, and high-speed batch processing equipment to minimize production costs per tablet. In contrast, smaller biotechnology firms and academic research laboratories constitute a niche but essential market for bench-top or pilot-scale OSD machines used for early-stage formulation development and clinical trial material production. Lastly, nutraceutical and dietary supplement producers, driven by surging consumer health trends, increasingly require pharmaceutical-grade OSD equipment to ensure product quality and meet evolving quality regulations specific to food and supplement manufacturing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 Billion |

| Market Forecast in 2033 | USD 9.0 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Packaging Technology (Syntegon), IMA S.p.A., GEA Group, Korsch AG, Fette Compacting GmbH, ACG Worldwide, L.B. Bohle, CADMEC, Charles Ischi AG, Thomas Engineering, MG2 S.r.l., Romaco Group, Pharmapress, O'Hara Technologies Inc., PTK Co., Ltd., ZAMBON Group S.p.A., Freund-Vector Corporation, Nicomac Cleanrooms. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

OSD Machine Market Key Technology Landscape

The OSD machine market is undergoing a fundamental technological transformation driven by the principles of Industry 4.0, focusing heavily on connectivity, data processing, and integrated control systems. A primary technological advancement is the shift towards Continuous Manufacturing Systems (CMS). Unlike traditional batch processing, CMS integrates all OSD steps (blending, granulation, compression, coating) into a single, uninterrupted line, drastically reducing process time, minimizing human intervention, and providing real-time quality assurance through integrated Process Analytical Technology (PAT) tools. This integration allows for instantaneous quality testing and automated adjustment of process variables, moving the industry closer to the goal of Right First Time manufacturing.

Containment technology is another vital area of innovation, particularly with the proliferation of highly potent active pharmaceutical ingredients (HPAPIs) used in oncology and other specialized treatments. OSD machinery now incorporates sophisticated isolation barriers, closed transfer systems (e.g., split butterfly valves), and integrated Wash-in-Place (WIP) or Clean-in-Place (CIP) functionalities. These technologies ensure operator safety, prevent environmental contamination, and maintain the integrity of the manufacturing environment, which is crucial for multi-product facilities. The design complexity of these containment systems adds significant technical value to modern OSD equipment.

Furthermore, digitalization permeates the entire OSD production lifecycle. Key technologies include advanced Supervisory Control and Data Acquisition (SCADA) systems, Manufacturing Execution Systems (MES), and robust data integrity solutions compliant with regulatory requirements (like FDA 21 CFR Part 11). Sensor technology, including near-infrared (NIR) spectroscopy, Raman spectroscopy, and ultrasonic sensors, are embedded within the machines to enable PAT, allowing critical process parameters (CPPs) and critical quality attributes (CQAs) to be monitored continuously. This sophisticated real-time monitoring capability is essential for validating continuous processes and achieving regulatory acceptance for modern OSD manufacturing methods.

Regional Highlights

The OSD Machine Market exhibits significant regional variations in growth trajectory and technological adoption, reflecting differences in regulatory maturity, manufacturing capacity, and market demand for pharmaceuticals.

North America, led by the United States, holds a dominant position in terms of market value, driven by high R&D expenditure, stringent quality standards, and early adoption of premium technologies like continuous manufacturing and high-containment systems. The presence of major pharmaceutical innovators and a strong push towards efficiency necessitate continuous equipment upgrades. Europe follows closely, characterized by a sophisticated manufacturing base in Germany, Switzerland, and Italy, focusing heavily on precision engineering and offering specialized machinery catering to HPAPIs and small-to-medium batch sizes, often driven by the regulatory environment set by the European Medicines Agency (EMA).

Asia Pacific (APAC) is projected to be the fastest-growing market during the forecast period. This rapid expansion is primarily fueled by the burgeoning generic drug industry in India and China, massive population bases driving domestic drug consumption, and increasing government initiatives to boost local pharmaceutical manufacturing capacity. The region is seeing strong investment in reliable, high-speed batch processing equipment to meet volume demands, although there is a nascent but growing demand for CMS driven by export requirements to Western markets. Latin America and the Middle East & Africa (MEA) are emerging regions, exhibiting steady growth propelled by infrastructure development in local healthcare and pharmaceutical sectors, primarily focusing on essential OSD forms and relying on cost-effective, durable machinery solutions.

- North America: Dominant market share; highest adoption rates for Continuous Manufacturing and high-containment equipment; robust regulatory framework driving quality upgrades.

- Europe: Strong focus on precision-engineered machinery and specialized solutions for complex formulations; major technology hub for tablet compression and coating.

- Asia Pacific (APAC): Fastest growth due to generic drug manufacturing boom (India, China); high volume demand for traditional batch processing and increasing capacity expansion.

- Latin America: Steady demand growth driven by local pharmaceutical industry development and expanding access to essential medicines.

- Middle East & Africa (MEA): Emerging market; increasing investment in local manufacturing to reduce import reliance; focus on standard, reliable OSD equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the OSD Machine Market.- Bosch Packaging Technology (Syntegon)

- IMA S.p.A.

- GEA Group

- Korsch AG

- Fette Compacting GmbH

- ACG Worldwide

- L.B. Bohle

- CADMEC

- Charles Ischi AG

- Thomas Engineering

- MG2 S.r.l.

- Romaco Group

- Pharmapress

- O'Hara Technologies Inc.

- PTK Co., Ltd.

- ZAMBON Group S.p.A.

- Freund-Vector Corporation

- Nicomac Cleanrooms

- Heino Ilsemann GmbH

- Sejong Pharmatech

Frequently Asked Questions

Analyze common user questions about the OSD Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of Continuous Manufacturing Systems (CMS) in OSD production?

The primary driver is the necessity for real-time quality assurance and improved efficiency, enabling manufacturers to reduce batch sizes, lower operational costs, and achieve faster product release times. CMS also supports Quality by Design (QbD) principles mandated by major regulatory bodies, minimizing traditional batch variability.

How is regulatory compliance influencing the design of new OSD machinery?

Regulatory bodies emphasize data integrity (e.g., FDA 21 CFR Part 11) and process control, mandating OSD machines to feature advanced, tamper-proof audit trails, sophisticated sensor technology (PAT), and closed-loop automation systems to ensure verifiable adherence to Good Manufacturing Practices (GMP).

Which regional market is exhibiting the fastest growth in the OSD Machine sector?

The Asia Pacific (APAC) region, specifically driven by countries like China and India, is registering the fastest growth. This is attributed to the substantial expansion of local pharmaceutical production, focused heavily on meeting the soaring global demand for generic and essential drugs.

What role does AI play in optimizing OSD equipment maintenance and performance?

AI utilizes machine learning to analyze operational data for Predictive Maintenance (PdM), accurately forecasting component wear and potential failure. This reduces unscheduled downtime and optimizes equipment utilization by suggesting real-time process adjustments to enhance yield and maintain product consistency.

What are the key technical differences between high-containment and standard OSD machines?

High-containment OSD machines are designed with integrated physical barriers, negative pressure environments, and automated cleaning systems (WIP/CIP) to safely handle highly potent or toxic materials (HPAPIs), protecting both the operator and the external environment from contamination, a feature not prioritized in standard machinery.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager