Oxygen Permeability Analyser Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431379 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Oxygen Permeability Analyser Market Size

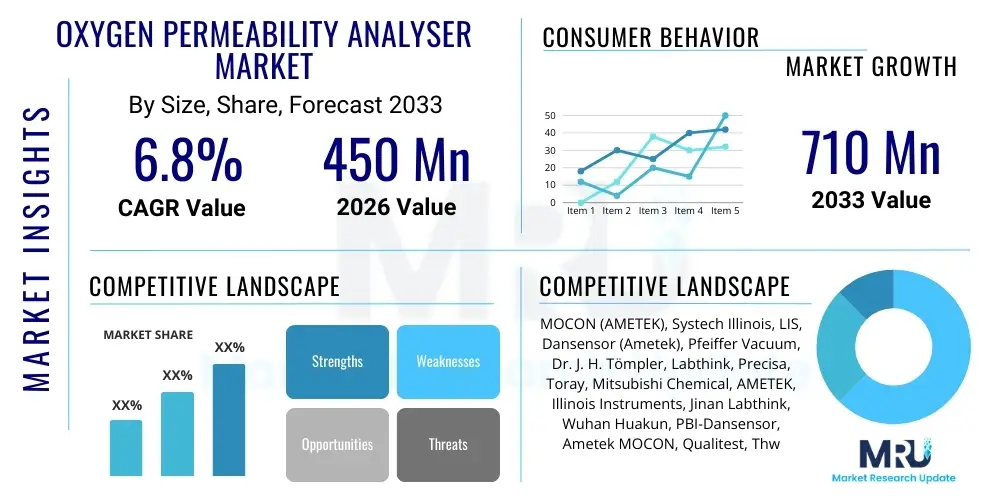

The Oxygen Permeability Analyser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Oxygen Permeability Analyser Market introduction

The Oxygen Permeability Analyser Market encompasses specialized scientific instruments designed to measure the rate at which oxygen gas permeates through barrier materials, primarily films, packaging structures, and coatings. This metric, often quantified as Oxygen Transmission Rate (OTR), is critical for quality control, shelf-life determination, and material research across numerous industries. These analysers utilize advanced technologies, such as coulometric sensors (ASTM D3985), electrochemical methods, and sometimes optical techniques, to ensure precise and repeatable measurements, vital for protecting sensitive products from degradation caused by oxygen exposure.

The core function of oxygen permeability analysers is to provide accurate barrier assessment, which directly correlates with the integrity and effectiveness of protective packaging. Major applications span food and beverage packaging, pharmaceuticals, medical devices, and electronics, where preventing oxidation or contamination is paramount. In the food industry, for instance, high-barrier films tested by these instruments significantly extend the shelf life of perishable goods, reducing waste and maintaining nutritional value. The increasing global demand for extended shelf life, coupled with stringent regulatory requirements concerning packaging integrity and safety, drives the continuous adoption of high-precision analysers.

Key driving factors include the proliferation of flexible packaging, the transition towards sustainable and recyclable materials that require continuous barrier property verification, and the escalating complexity of multilayer structures. Benefits of utilizing these analysers extend beyond simple quality control, facilitating R&D efforts in developing superior barrier polymers and laminates. Furthermore, the analyzers often feature automated testing protocols, enabling high-throughput analysis, reduced operational complexity, and seamless integration into laboratory management systems (LIMS), thereby enhancing overall efficiency in manufacturing and research environments worldwide.

Oxygen Permeability Analyser Market Executive Summary

The Oxygen Permeability Analyser Market is experiencing robust growth fueled by accelerated demand from the food and pharmaceutical sectors, particularly in emerging economies emphasizing advanced packaging solutions and quality assurance protocols. Business trends indicate a strong focus on automation and multi-gas analysis capabilities, moving away from manual testing to fully automated systems that offer higher repeatability and throughput. Key market players are prioritizing the development of high-sensitivity analysers capable of measuring ultra-low OTR values, essential for high-barrier applications such as OLED displays and specialized drug packaging, thus elevating the technological barrier to entry and fostering competitive innovation.

Regional trends reveal that Asia Pacific (APAC) is emerging as the fastest-growing market segment, primarily due to the rapid expansion of the packaging industry, increasing middle-class consumption patterns, and mandatory implementation of food safety standards in populous countries like China and India. North America and Europe, characterized by established pharmaceutical manufacturing bases and sophisticated regulatory frameworks (e.g., FDA and EMA requirements), remain dominant in terms of market value and adoption of premium, high-end instrumentation. Investment in R&D infrastructure and regulatory harmonization across trading blocs further solidify these regions' leadership in advanced material testing technologies.

Segmentation trends highlight the dominance of the Coulometric Sensor technology segment owing to its reliability, established industry standards (ASTM compliance), and exceptional accuracy for standard applications. However, the Optical Sensor segment is poised for significant future growth, driven by its suitability for testing ultra-high barrier films and potential for non-destructive, real-time measurements. Furthermore, the application segment is heavily tilted towards the food and beverage industry, but the pharmaceutical and specialty chemicals sectors are exhibiting high growth rates, demanding more specialized and certified analysers tailored for cleanroom environments and stringent validation processes.

AI Impact Analysis on Oxygen Permeability Analyser Market

Common user questions regarding AI’s impact on the Oxygen Permeability Analyser Market often revolve around predictive modeling, automation of interpretation, and optimization of testing protocols. Users are keen to understand how AI can move beyond simple data capture to offer real-time quality control advice, predict material failure under various environmental stresses, and reduce the extensive time traditionally required for setting up and running stability tests. The key themes summarized from user queries include expectations for AI-driven anomaly detection in permeability data, integration of machine learning algorithms for optimizing multi-layer barrier formulation, and the potential for virtual testing simulations before physical instrumentation is even employed, promising cost savings and faster time-to-market for new packaging innovations.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into oxygen permeability analysis systems is currently transforming data handling and interpretation, transitioning instruments from mere measurement tools to intelligent predictive platforms. AI algorithms can process vast datasets generated during continuous monitoring and quality checks, identifying subtle patterns and correlations between material composition, environmental factors (temperature, humidity), and measured OTR values that human analysts might overlook. This capability is particularly vital in R&D settings where rapid iteration on barrier materials is necessary; AI assists in guiding experimental design, suggesting optimal polymer ratios or coating thicknesses to achieve target permeability specifications with minimal physical prototyping.

Furthermore, AI significantly enhances the operational efficiency and predictive maintenance of the analysers themselves. Machine learning models analyze sensor performance metrics, temperature fluctuations, and calibration history to predict when maintenance or recalibration will be necessary, minimizing unexpected downtime and ensuring data accuracy over long operational periods. This shift towards smart lab equipment, facilitated by AI-powered diagnostics, translates into substantial operational expenditure reduction for end-users, especially in high-throughput manufacturing quality assurance labs. Consequently, the adoption of connected, AI-enabled permeability analysers is becoming a competitive differentiator for manufacturers aiming for Industry 4.0 compliance.

- AI enables predictive barrier failure modeling, forecasting shelf-life degradation accurately.

- Machine Learning algorithms optimize multi-layer packaging formulations for targeted OTR.

- Automated data anomaly detection reduces human error and speeds up quality control reviews.

- AI facilitates predictive maintenance schedules for analyser instrumentation, ensuring uptime.

- Integration with LIMS for automated reporting and compliance validation using smart data processing.

DRO & Impact Forces Of Oxygen Permeability Analyser Market

The dynamics of the Oxygen Permeability Analyser Market are governed by a complex interplay of stringent regulatory demands favoring quality packaging (Drivers), high initial capital expenditure (Restraints), and the burgeoning demand for sustainable, high-barrier materials (Opportunities). These factors collectively define the Impact Forces, which are currently pushing the market towards greater automation, higher measurement sensitivity, and integrated system solutions. The continuous evolution of packaging standards across key industries, such as the mandate for child-resistant and tamper-evident pharmaceutical packaging, necessitates robust testing equipment, maintaining steady demand.

Key drivers underpinning market expansion include the global increase in packaged food consumption, especially ready-to-eat and processed items, requiring maximum barrier protection against spoilage. The pharmaceutical industry's expansion, particularly biologics and sensitive vaccines, demands validated, high-precision barrier testing to maintain drug stability and efficacy throughout the supply chain. Simultaneously, the restraints primarily stem from the high cost of advanced coulometric and optical sensor technology, which poses an adoption barrier for small and medium enterprises (SMEs). Furthermore, the requirement for highly skilled technical personnel to operate, calibrate, and maintain these specialized instruments adds to the operational cost, slowing widespread uptake in regions with limited technical infrastructure.

Opportunities for growth are plentiful, centered on the sustainability movement; the push for mono-material, recyclable packaging structures necessitates new testing methodologies to verify barrier properties of thinner, environmentally friendly films. The development of portable and benchtop analysers offering equivalent performance to traditional floor-standing units presents a significant opportunity to serve remote testing sites and smaller R&D labs. The overall impact forces dictate that innovation must focus on reducing the total cost of ownership (TCO) through automation and durability, while simultaneously enhancing measurement sensitivity to address the demands of ultra-high barrier applications like flexible electronics and advanced thin-film encapsulation technologies.

Segmentation Analysis

The Oxygen Permeability Analyser Market is comprehensively segmented based on technology type, material tested, application industry, and geography, providing granular insights into specific market dynamics. The segmentation structure helps in understanding consumer preferences and technological evolution across different end-user environments. Technological segmentation, differentiating between established coulometric sensors and emerging optical methods, is particularly crucial as it dictates measurement accuracy, throughput capability, and suitability for specific regulatory environments. The diverse applications, ranging from routine quality control in food processing to specialized research in material science, further delineate the competitive landscape.

- Technology Type:

- Coulometric Sensors (Electrochemical)

- Optical Sensors (Fluorescence Quenching)

- Manometric/Pressure Sensors

- Material Tested:

- Films and Sheets

- Finished Packages (Bottles, Blisters, Trays)

- Coatings and Laminates

- Application:

- Food and Beverages

- Pharmaceuticals and Medical Devices

- Chemical and Petrochemical

- Electronics (OLED, Flexible Displays)

- Paints and Coatings

- Measurement Range:

- Standard Barrier (High OTR)

- High Barrier (Low OTR)

- Ultra-High Barrier (Trace OTR)

- End-User:

- Manufacturers and Converters

- Research and Academic Institutions

- Testing Laboratories and Regulatory Bodies

Value Chain Analysis For Oxygen Permeability Analyser Market

The value chain for the Oxygen Permeability Analyser Market commences with upstream activities involving the sourcing of high-precision components, notably advanced sensor technologies (e.g., specialized platinum-based coulometric cells or highly sensitive fluorescent dyes) and complex microcontrollers necessary for data processing. This stage is dominated by specialized component suppliers who maintain stringent quality control over critical parts. Instrument manufacturers then engage in sophisticated R&D and assembly, focusing on software integration, system automation, and compliance with international testing standards (such as ASTM, ISO, and JIS). Intellectual property surrounding sensor design and temperature/humidity control mechanisms constitutes a major competitive advantage at this manufacturing stage.

The distribution channel represents a critical midstream link. Due to the high-value and technical nature of the analysers, sales predominantly occur through direct distribution channels where manufacturers employ highly trained sales engineers to provide pre-sale consulting, installation, and specialized training tailored to complex customer needs (e.g., pharmaceutical validation protocols). Indirect channels, utilizing regional distributors and system integrators, are often used in geographically fragmented or emerging markets, requiring partners with strong local technical support capabilities. Effective calibration and maintenance services, often provided directly by the manufacturer, are crucial for retaining customer satisfaction and ensuring instrument longevity.

Downstream activities involve the end-user deployment across diverse industries. Major buyers—such as large multinational food producers, pharmaceutical giants, and specialized packaging converters—require continuous technical support, regular calibration certification, and sometimes bespoke application development. The data generated by these analysers is immediately fed into the clients' quality assurance and production systems. The lifecycle management of the analyser, including software updates and technology upgrades, ensures sustained value creation, emphasizing the ongoing relationship between the manufacturer and the end-user beyond the initial sale, making the service segment an increasingly important revenue stream.

Oxygen Permeability Analyser Market Potential Customers

The primary end-users and potential customers in the Oxygen Permeability Analyser Market are institutions and corporations whose product integrity is directly dependent on reliable barrier packaging performance. The largest customer base resides within the Food and Beverage industry, encompassing producers of snacks, dried goods, processed meats, and beverages, all of whom rigorously test packaging materials to guarantee shelf life and freshness, thereby minimizing product recalls and inventory loss. These customers demand high-throughput, automated systems capable of handling a wide variety of film types and environmental conditions.

Another highly critical customer segment is the Pharmaceutical and Medical Device manufacturing sector. Companies producing sensitive medications, vaccines, sterile medical consumables, and implantable devices require analyzers capable of meeting extremely high precision and regulatory standards (e.g., USP <671>, 21 CFR Part 11 compliance). These clients prioritize validation documentation, certification services, and highly stable instruments capable of operating within controlled laboratory environments. Their purchasing decisions are heavily influenced by the instrument's compliance record and the manufacturer's reputation for precision and reliability.

Emerging but high-growth potential customers include specialized electronics manufacturers, particularly those involved in producing flexible displays (OLEDs) and solar cells. These applications require testing materials that offer ultra-high barrier performance (measured in 10-5 or 10-6 cc/m²/day), driving demand for the most sensitive optical and high-end coulometric analysers available. Furthermore, polymer manufacturers and academic material science research institutions constitute a steady demand segment, utilizing these analysers for fundamental research into novel barrier polymers and sustainable packaging innovations, focusing on flexibility and customization in testing parameters.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MOCON (AMETEK), Systech Illinois, LIS, Dansensor (Ametek), Pfeiffer Vacuum, Dr. J. H. Tömpler, Labthink, Precisa, Toray, Mitsubishi Chemical, AMETEK, Illinois Instruments, Jinan Labthink, Wuhan Huakun, PBI-Dansensor, Ametek MOCON, Qualitest, Thwing-Albert Instrument. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Oxygen Permeability Analyser Market Key Technology Landscape

The technology landscape of the Oxygen Permeability Analyser Market is dominated by two primary methodologies: the Coulometric Sensor method (or Electrochemical Detection) and the Optical Sensor method (or Fluorescence Quenching). Coulometric technology, utilized extensively in instruments compliant with ASTM D3985, offers exceptional precision and stability for mid- to low-barrier applications, which constitute the majority of food and standard medical packaging. This technology relies on detecting oxygen molecules that permeate through the test sample using an electrochemical cell, converting the oxygen into a measurable electric current. Recent advancements in coulometric systems focus on improving sensor durability, reducing measurement time, and automating the purging and conditioning stages to enhance throughput.

The Optical Sensor method represents the cutting edge, primarily targeting ultra-high barrier applications such as flexible electronics and specialized pharmaceutical packaging demanding OTR measurements below 0.01 cc/m²/day. This technique uses a patch containing a fluorescent dye applied to the inner surface of the package. When excited by light, the dye emits fluorescence; however, the presence of oxygen quenches this fluorescence. By measuring the decrease in fluorescence intensity, the oxygen concentration, and thus the OTR, can be determined. Optical systems offer the advantage of being non-destructive, suitable for testing finished packages without modifying the internal environment, and capable of measuring extremely low transmission rates, positioning them for future growth in specialty sectors.

Furthermore, auxiliary technologies are rapidly integrating into modern analysers, including sophisticated temperature and humidity control modules, which are crucial as OTR is highly sensitive to environmental conditions. High-precision flow control systems ensure accurate carrier gas management, minimizing measurement noise. The industry is also witnessing a pivot towards networked analysers—enabled by IoT—allowing remote monitoring, centralized data management, and seamless integration with LIMS and enterprise resource planning (ERP) systems. Software intelligence, incorporating AI for drift compensation and advanced diagnostics, is the next major focus area, moving towards fully autonomous testing environments where operator intervention is minimal, thereby maximizing reproducibility and reducing labor costs.

Regional Highlights

- North America (NA): NA is a mature market characterized by stringent FDA regulations, a massive pharmaceutical R&D base, and widespread adoption of automated testing systems. The US dominates regional consumption, driven by demand for verified drug packaging integrity and the growth of high-end specialty films. The focus here is on instruments providing compliance and exceptional precision in ultra-low OTR measurements.

- Europe: Europe holds a significant market share, fueled by comprehensive EU food safety directives (e.g., EFSA) and robust manufacturing activities in Germany and Switzerland. Sustainability mandates are driving rapid investment in analyzers capable of characterizing new, recyclable mono-materials and bioplastics. The European market exhibits high demand for multi-functional analysers that can also measure moisture transmission rates (WVTR) simultaneously.

- Asia Pacific (APAC): APAC is the fastest-growing region, powered by industrialization in China, India, and Southeast Asia. Rapid urbanization and a growing consumer base demanding packaged, longer-shelf-life food products are the primary drivers. The market is highly price-sensitive but shows increasing demand for mid-range, reliable analysers to establish foundational quality control infrastructure in local manufacturing hubs.

- Latin America (LATAM): LATAM exhibits moderate growth, focused primarily on expanding local food and beverage processing industries. Brazil and Mexico are key markets, showing a gradual shift from manual, less accurate testing methods towards modern automated analysers to meet international export standards and improve domestic quality assurance processes.

- Middle East and Africa (MEA): Growth in MEA is concentrated around Gulf Cooperation Council (GCC) countries, driven by significant investments in domestic food manufacturing and pharmaceutical cold chain logistics. Demand is project-based, linked to the establishment of new industrial parks and the need to comply with international standards for exported goods.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Oxygen Permeability Analyser Market.- MOCON (AMETEK)

- Systech Illinois

- LIS

- Dansensor (Ametek)

- Pfeiffer Vacuum

- Dr. J. H. Tömpler

- Labthink

- Precisa

- Toray

- Mitsubishi Chemical

- AMETEK

- Illinois Instruments

- Jinan Labthink

- Wuhan Huakun

- PBI-Dansensor

- Ametek MOCON

- Qualitest

- Thwing-Albert Instrument

Frequently Asked Questions

Analyze common user questions about the Oxygen Permeability Analyser market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between coulometric and optical oxygen permeability analysers?

Coulometric analysers (ASTM D3985) use an electrochemical sensor for highly precise measurement across standard to high barriers, focusing on reliability and regulatory compliance. Optical analysers use fluorescence quenching methods, specializing in non-destructive testing and measuring ultra-high barriers (extremely low OTR) required for advanced electronics.

Which industries are the major end-users driving market growth?

The Food and Beverage industry is the largest end-user segment due to shelf-life concerns. The Pharmaceutical and Medical Device sectors are the fastest-growing segments, requiring certified, high-precision analysers for drug stability and sterile packaging verification according to stringent regulatory standards like FDA and EMA.

How does the Oxygen Permeability Analyser market address sustainability trends?

The market addresses sustainability by developing analysers optimized for testing novel, thinner, mono-material, and recyclable films. These instruments help R&D teams verify that environmentally friendly packaging retains sufficient barrier properties without compromising product quality or shelf life.

What key technological advancements are influencing purchasing decisions today?

Purchasing decisions are highly influenced by automation features, the integration of AI for predictive diagnostics and data interpretation, multi-gas analysis capabilities (O2 and H2O simultaneously), and the ability of instruments to measure ultra-low OTR values for specialized barrier applications.

Is Asia Pacific (APAC) expected to surpass North America in terms of market size?

While APAC is currently the fastest-growing region due to expanding manufacturing and growing regulatory focus, North America and Europe currently maintain higher market value dominance due to greater adoption of premium, high-cost instrumentation and established pharmaceutical bases. APAC is anticipated to gain significant share but may not surpass NA in total value within the current forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager