Ozone Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433441 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Ozone Machines Market Size

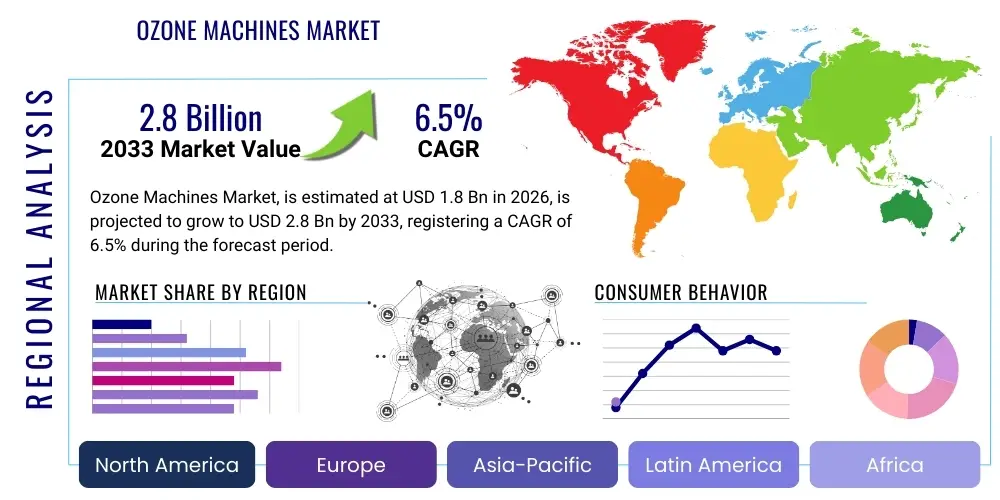

The Ozone Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033. This substantial expansion is primarily driven by the increasing global focus on non-chemical disinfection methods, stringent environmental regulations regarding industrial effluent discharge, and the rising demand for purified water and air quality management systems across residential and commercial sectors. The efficiency and environmental advantages of ozone generation, particularly in large-scale municipal water treatment plants and food processing facilities, cement its critical role in sustainable infrastructure development. Furthermore, the continuous technological improvements in ozone generator design, leading to enhanced energy efficiency and extended operational lifespans, are making these systems more economically viable for a broader range of end-users.

Ozone Machines Market introduction

Ozone machines, or ozone generators, are devices engineered to produce ozone (O3), a potent oxidizing agent created by electrically charging oxygen (O2). This triatomic molecule is highly effective in oxidizing and neutralizing contaminants, making it a critical tool in various sterilization and purification applications. The market encompasses a wide range of products, from small residential air purifiers to large industrial systems used in municipal water treatment, wastewater processing, food and beverage sterilization, and medical equipment disinfection. The fundamental mechanism often involves either corona discharge (CD) or ultraviolet (UV) radiation, each optimized for different output capacities and operational environments. The primary product benefits include the elimination of viruses, bacteria, and spores, the reduction of reliance on traditional chemical disinfectants like chlorine, and the efficient removal of color, taste, and odor from water sources, leaving no harmful residuals behind.

Major applications of ozone machines span critical infrastructure and consumer health sectors. In the industrial segment, they are indispensable for treating highly contaminated process water and effluents before environmental discharge, ensuring compliance with strict governmental standards. The food and beverage industry heavily utilizes ozone for surface sanitation, extending the shelf life of produce, and treating bottling water, capitalizing on ozone's ability to act quickly and decompose back into oxygen. Residential and commercial use is centered on improving indoor air quality, particularly in mitigating mold, volatile organic compounds (VOCs), and persistent odors, driven by increasing public awareness regarding airborne pollutants and health implications associated with poor ventilation. The versatility and high efficacy of ozone machines position them as a preferred, environmentally friendly alternative to traditional disinfection methods, fueling steady market expansion.

The market is predominantly driven by escalating global health and safety concerns, especially post-pandemic, which have intensified the focus on robust sterilization protocols in public and private spaces. Further impetus is derived from favorable regulatory frameworks, particularly in developed economies, that mandate superior water quality standards and encourage the adoption of sustainable treatment technologies. Key driving factors include the rapid industrialization in emerging economies, leading to increased wastewater generation requiring advanced treatment solutions, and the ongoing innovations in ozone generation technology focused on reducing energy consumption and increasing the purity of ozone output. However, the market must navigate challenges related to the toxicity of ozone at high concentrations, necessitating strict safety protocols, and the relatively high initial capital investment required for high-capacity industrial systems.

Ozone Machines Market Executive Summary

The Ozone Machines Market is experiencing robust growth fueled by irreversible global trends toward sustainable sanitation and environmental protection. Business trends indicate a strong shift towards advanced, energy-efficient Corona Discharge (CD) systems, which offer higher concentration output suitable for demanding industrial applications such as cooling tower treatment and aquaculture. Key market participants are focusing on vertical integration and developing modular systems that allow for scalability and easier deployment across various operational sizes, from small-scale agricultural usage to large municipal plants. Furthermore, there is a distinct competitive emphasis on incorporating smart monitoring capabilities, including Internet of Things (IoT) sensors, to ensure real-time ozone level management and optimize energy usage, addressing key constraints related to operational costs and safety.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, primarily due to rapid urbanization, increasing industrial wastewater discharge, and massive governmental investments in upgrading municipal water infrastructure in countries like China and India. North America and Europe, while mature, maintain dominant market shares driven by stringent regulatory environments (e.g., EPA and EU directives on disinfection byproducts) that favor ozone technology over chlorine. These regions are also the early adopters of highly automated, AI-integrated ozone systems for optimizing large utility operations. The Middle East and Africa (MEA) are emerging as high-potential markets, particularly due to severe water scarcity issues necessitating advanced water reclamation and desalination pretreatment processes where ozone plays a critical role in removing challenging contaminants and organic matter.

Segment trends reveal that the Application segment dominated by water treatment (municipal and industrial) remains the largest revenue generator. However, the air treatment segment, particularly high-capacity commercial air purification systems for hospitals and food storage facilities, is projecting the highest CAGR, driven by heightened air quality standards. By Technology, the Corona Discharge segment holds the majority share due to its superior efficiency and ability to produce high concentrations of ozone required for heavy-duty sanitation. The market structure is moderately fragmented, with specialized technology providers competing against large multinational conglomerates that offer integrated water and air treatment solutions. Future growth is strongly linked to successful penetration in agricultural and healthcare sanitation verticals, leveraging ozone’s potent germicidal properties.

AI Impact Analysis on Ozone Machines Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Ozone Machines Market commonly center on predictive maintenance, optimization of ozone dosing, regulatory compliance assurance, and the overall enhancement of operational efficiency. Users frequently ask how AI algorithms can prevent equipment failures in high-pressure industrial settings, minimize the energy footprint associated with ozone generation, and ensure that ozone levels remain within optimal, yet safe, ranges for specific applications (e.g., adjusting output based on real-time water quality metrics). The consensus concern revolves around transitioning from manual, scheduled maintenance to dynamic, data-driven system management, focusing on maximizing the lifespan of critical components like high-voltage dielectrics and UV lamps while drastically reducing downtime and chemical usage. Users expect AI integration to transform ozone generators from standalone sterilization units into sophisticated, self-regulating environmental management systems.

The integration of AI into Ozone Machines manifests primarily through advanced sensor fusion and machine learning models applied to the generation and application processes. AI algorithms process large volumes of data—including input water parameters (pH, turbidity, dissolved organics), ambient environmental conditions (temperature, humidity), and equipment performance metrics (voltage, current, flow rate)—to dynamically adjust the ozone output. This capability ensures precise ‘dose on demand,’ preventing under-dosing (which compromises sanitation effectiveness) or over-dosing (which wastes energy and potentially poses safety risks). Furthermore, AI powers anomaly detection, predicting potential faults in the corona discharge cells or cooling systems long before they lead to catastrophic failure, thereby shifting the industry paradigm from reactive repair to proactive maintenance scheduling, significantly enhancing asset utilization and reliability in critical public health applications.

This technological shift is leading to the development of 'smart' ozone purification plants. AI-driven systems are capable of simulating various operational scenarios and training models to manage complex water matrices common in industrial wastewater treatment. For regulatory compliance, AI platforms automatically log and analyze performance data, generating immutable reports required by environmental agencies, significantly reducing the administrative burden on operators. This evolution not only reduces the operational cost per unit of ozone produced but also broadens the applicability of ozone technology, especially in fluctuating environments such as large-scale aquaculture facilities where environmental stability is paramount. The long-term impact of AI is expected to democratize high-efficiency ozone usage, making it viable for smaller, decentralized water treatment initiatives by lowering the expertise barrier required for optimal operation.

- AI optimizes energy consumption by dynamically adjusting ozone output based on real-time sensor data and fluctuating environmental loads.

- Predictive maintenance algorithms drastically reduce downtime and component failure rates by monitoring subtle variations in electrical signatures and cooling system performance.

- Machine learning models improve dosing accuracy in complex water treatment scenarios, ensuring optimal sterilization efficiency while adhering to safety thresholds.

- AI-enabled smart monitoring ensures automated compliance logging and reporting, simplifying regulatory adherence for municipal and industrial operators.

- Integration facilitates remote diagnostics and control, allowing centralized management of geographically dispersed ozone generation units.

DRO & Impact Forces Of Ozone Machines Market

The Ozone Machines Market is primarily propelled by stringent regulatory mandates concerning water quality and public health safety, coupled with the inherent advantages of ozone as an eco-friendly disinfectant that minimizes harmful disinfection byproducts (DBPs) such as trihalomethanes (THMs). The restraint landscape is dominated by the high initial capital expenditure associated with high-capacity industrial ozone generation systems, complexities related to safely handling and monitoring ozone gas in enclosed spaces due to its toxicity, and competition from established and evolving alternative disinfection technologies like UV light and advanced oxidation processes (AOPs). Significant opportunities lie in the rapidly expanding food and beverage sector for surface and water sanitation, the penetration of residential markets through compact, high-efficiency air purification systems, and leveraging ozone in specialized niche markets such as medical device sterilization and pharmaceutical manufacturing, requiring ultra-pure water. The market impact forces are strongly weighted toward environmental necessity and public health pressures, which consistently outweigh cost constraints and safety challenges through ongoing technological mitigation.

Driving factors are numerous and interconnected. The increasing incidence of waterborne diseases globally, coupled with greater public awareness regarding the environmental consequences of chemical reliance, strongly favors ozone adoption. Governments and international bodies are tightening standards for potable water and industrial effluent quality, effectively mandating the use of advanced treatment methods that ozone generators can fulfill efficiently. Furthermore, rapid infrastructural expansion in developing nations, particularly related to centralized municipal water supply systems, creates a large addressable market for industrial-grade ozone systems. The technological maturity of Corona Discharge (CD) systems, offering reliable, high-concentration ozone generation at scalable rates, accelerates adoption in industrial settings where throughput and effectiveness are paramount.

Conversely, market growth faces limitations, chiefly stemming from the logistical and safety requirements inherent in ozone utilization. Ozone is a powerful oxidizer, and its misuse or failure to properly ventilate treatment areas poses significant health risks, necessitating sophisticated monitoring equipment and specialized training for operators. This complexity adds to operational costs. Furthermore, the longevity and efficiency of ozone generators can be susceptible to factors like feed gas quality (requiring expensive air preparation units) and ambient humidity, which can degrade internal components. Opportunities, however, present compelling avenues for future growth, particularly the shift towards decentralized water treatment systems utilizing smaller, smart ozone generators, and the burgeoning use of ozone in precision agriculture for pathogen control and irrigation water treatment, providing diversification beyond traditional municipal applications.

Segmentation Analysis

The Ozone Machines Market is comprehensively segmented based on technology, application, capacity, and end-user, allowing for a detailed analysis of specific market dynamics and growth trajectories within different operational environments. The core differentiation rests between Corona Discharge (CD) technology, favored for high-concentration and large-scale needs, and Ultraviolet (UV) technology, typically used for smaller-scale, low-concentration requirements such as residential air purification. The application spectrum is vast, spanning critical sectors like municipal water treatment, pharmaceutical sterilization, cooling tower disinfection, and food preservation. Understanding these segment interactions is vital for manufacturers to tailor product development, focusing on modularity and energy efficiency specific to the operational demands of each end-user category, whether it be a heavily regulated hospital or a cost-sensitive agricultural farm.

The segmentation by capacity—low (up to 5 g/h), medium (5 g/h to 1 kg/h), and high (above 1 kg/h)—further defines the market's structure, reflecting the disparity between consumer-grade equipment and massive industrial installations. High-capacity units, indispensable for city water purification and pulp bleaching in paper industries, contribute the most significantly to overall revenue due to their high unit cost and necessary integration with complex infrastructure. Conversely, the medium-capacity segment shows the highest growth trajectory, driven by commercial applications such as laundries, small bottling plants, and large office HVAC system retrofits. This detailed segmentation aids in strategic forecasting, identifying areas where technological innovation (e.g., maximizing g/h output per watt of power input) can most effectively capture untapped market share, particularly in emerging economies where modular and scalable solutions are highly prized.

- By Technology:

- Corona Discharge (CD)

- Ultraviolet (UV) Radiation

- Electrolytic

- By Application:

- Water Treatment (Municipal, Industrial Wastewater, Swimming Pools, Aquaculture)

- Air Treatment (HVAC, Residential, Commercial Odor Removal)

- Food & Beverage Processing (Surface Sanitation, Bottling Water, Storage)

- Healthcare and Medical (Sterilization, Dialysis Water Treatment)

- By Capacity:

- Low Capacity (Up to 5 g/h)

- Medium Capacity (5 g/h to 1 kg/h)

- High Capacity (Above 1 kg/h)

- By End-User:

- Residential

- Commercial

- Industrial

- Healthcare

Value Chain Analysis For Ozone Machines Market

The value chain for the Ozone Machines Market commences with the upstream analysis, focusing on the sourcing and preparation of critical raw materials and components. Key inputs include specialized high-voltage transformers, dielectric ceramics or glass for corona discharge cells, high-purity oxygen feed systems (oxygen concentrators), and UV lamps for lower-capacity units. Manufacturers rely heavily on specialized suppliers for these components, as the quality and purity directly influence the efficiency and lifespan of the generated ozone. Managing the supply chain stability for high-quality ceramics and robust power electronics is crucial, particularly given the specialized nature of high-frequency power supplies required for optimal ozone generation. The competitive advantage upstream often lies in long-term supply agreements and quality control mechanisms to ensure component resilience under high-stress operating conditions.

The midstream phase involves the core manufacturing, assembly, and integration of the ozone machine systems. This stage includes complex engineering related to cooling mechanisms (to dissipate heat generated during discharge, which otherwise rapidly degrades ozone output), integration of sophisticated process controls, and ensuring containment and safety features. Manufacturers invest heavily in R&D to enhance energy efficiency (measured in g O3/kWh) and increase the concentration purity of the output ozone. Downstream analysis focuses on distribution and end-user deployment. Due to the technical nature of the equipment, distribution relies significantly on specialized engineering firms and system integrators who can design, install, and commission ozone systems tailored to specific client needs, such as integrating the generator into an existing municipal water treatment train or a food processing clean-in-place (CIP) system.

The distribution channel is characterized by a mix of direct and indirect sales models. Direct sales dominate the high-capacity industrial segment, where manufacturers maintain direct relationships with major utility companies and large industrial clients, offering custom solutions, installation supervision, and comprehensive after-sales service agreements. Indirect channels, involving authorized distributors, value-added resellers (VARs), and engineering procurement construction (EPC) firms, handle the medium and low-capacity commercial and residential markets. Crucial post-sale activities include routine maintenance of oxygen concentrators, periodic replacement of high-wear components like dielectric cells, and providing continuous remote monitoring support. The strong reliance on technical expertise for both installation and ongoing service makes the post-sales support segment a significant competitive differentiator and a key source of recurring revenue within the market structure.

Ozone Machines Market Potential Customers

Potential customers for Ozone Machines are highly diversified, reflecting the broad applicability of ozone across sanitation, purification, and industrial processing. The largest end-user segment is the municipal water and wastewater treatment industry, where large-scale ozone generators are deployed to disinfect potable water supplies, oxidize micro-pollutants, and improve the quality of treated wastewater before discharge. These organizations, often government-owned utilities or large private contractors, are driven by regulatory compliance and public health mandates, requiring high-reliability, multi-kilogram-per-hour capacity systems. Another significant customer base includes industrial manufacturers, particularly those in the pulp and paper industry (for bleaching processes), chemical manufacturing (for oxidation reactions), and power generation facilities (for cooling water treatment to prevent biofouling).

The food and beverage (F&B) sector represents a rapidly expanding customer segment, driven by global trends toward safer food handling and minimizing chemical residues. F&B users, including meat packers, vegetable processors, breweries, and bottled water companies, utilize ozone for sanitizing processing equipment, sterilizing packaging materials, and maintaining pathogen-free storage environments. Their purchasing criteria prioritize compact, food-grade systems that comply with FDA and equivalent international standards. Furthermore, the healthcare industry, encompassing hospitals, pharmaceutical companies, and biotechnology labs, relies on ozone for sterilizing critical medical devices and producing ultra-pure water required for drug formulations and laboratory processes, emphasizing precision control and validation capabilities.

Lastly, the commercial and residential segments form the consumer end of the market. Commercial customers include hotels, laundry facilities, educational institutions, and large office complexes using ozone for air duct sanitation, laundry disinfection, and odor removal within HVAC systems. Residential customers purchase smaller, often UV-based, ozone generators primarily for mold remediation, smoke odor removal, and general air purification, with purchasing decisions heavily influenced by ease of use and perceived health benefits. The increasing demand for indoor air quality improvements, particularly in densely populated urban areas and among allergy sufferers, ensures consistent demand from this decentralized customer base, requiring robust marketing and retail distribution strategies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Xylem Inc., Suez SA, De Nora Water Technologies, Pacific Ozone Technology, Absolute Systems Inc., ClearWater Tech LLC, A2Z Ozone Systems, BES Group, AquaZone Ozone, Ozomax, Taotwins, Lenntech B.V., Toshiba Corporation, Mitsubishi Electric, Foremost Environmental, WaterSurplus, Ozone Solutions, Korona Environmental, Purgon, Weinig Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ozone Machines Market Key Technology Landscape

The Ozone Machines Market is primarily characterized by two foundational technologies: Corona Discharge (CD) and Ultraviolet (UV) light generation, with electrolytic methods gaining traction in specialized applications. CD technology, which involves passing dry, oxygen-rich air through a high-voltage electrical field (corona), remains the dominant method for industrial and high-capacity applications. Recent advancements in CD focus heavily on optimizing the dielectric material composition, often utilizing ceramic or glass materials with superior thermal properties, to increase ozone output purity and longevity while minimizing energy consumption. Modern CD generators integrate Pulse Width Modulation (PWM) power supplies, allowing for precise control over the high voltage frequency and duty cycle, which is crucial for achieving high g/h efficiency and stable operation under variable load conditions prevalent in wastewater treatment plants.

UV ozone generation, utilizing specific wavelengths of UV light (typically 185 nm) to split oxygen molecules, is favored for low-concentration and residential air treatment applications due to its simplicity, lack of complex cooling requirements, and lower capital cost. However, its efficiency is inherently lower than CD technology. The technological evolution in this segment focuses on developing longer-lasting, high-output UV lamps and integrating advanced reflection chambers to maximize O3 yield within compact footprints. A significant emerging technological trend across both CD and UV platforms is the deep integration of Internet of Things (IoT) sensors and connectivity. These smart components allow for continuous monitoring of key operational parameters, including residual ozone levels, ambient temperature, and humidity, facilitating remote diagnostics and adherence to safety limits. This convergence of hardware and digital infrastructure is creating a new generation of sophisticated, self-regulating ozone treatment systems.

Furthermore, attention is being increasingly directed towards electrolytic ozone generators, which produce ozone directly from water, requiring no external air preparation or oxygen feed, thus eliminating the complexity of managing dry feed gas. While historically limited by lower output capacity, electrolytic systems are proving highly valuable in niche markets requiring hyper-pure, dissolved ozone, such as semiconductor manufacturing, medical applications requiring point-of-use disinfection, and small-scale clean-in-place (CIP) operations in food service. Research and development efforts are currently dedicated to improving the catalytic electrode materials and enhancing the membrane technology within these electrolytic cells to increase ozone dissolution efficiency and extend the operational life, ultimately positioning this technology as a compelling alternative for decentralized or mobile sanitation solutions where space and logistical complexity are major constraints.

Regional Highlights

- North America: North America holds a significant share of the global Ozone Machines Market, primarily driven by strict environmental regulations enforced by the Environmental Protection Agency (EPA) pertaining to drinking water standards and industrial emissions. The region is characterized by high adoption rates of advanced oxidation processes (AOPs), often utilizing ozone, particularly in major municipal utilities upgrading infrastructure to combat emerging contaminants like pharmaceutical residues and microplastics. The United States and Canada are also leading the charge in implementing AI-integrated smart ozone systems for optimized water resource management and reduced operational costs in large-scale facilities.

- Europe: Europe represents a mature market with robust growth, spurred by the European Union’s commitment to minimizing disinfection byproducts (DBPs) and promoting circular economy principles, making ozone technology highly attractive for water reuse and reclamation projects. Germany, France, and the UK are key contributors, demonstrating high adoption in industrial wastewater treatment, pharmaceutical manufacturing, and the food safety sector. The region heavily emphasizes safety standards and sustainable technology, favoring manufacturers that can demonstrate superior energy efficiency and robust maintenance protocols compliant with stringent European health directives.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) over the forecast period. This rapid expansion is driven by unparalleled infrastructural development, fast-paced urbanization, and the resulting massive increase in wastewater generation across China, India, and Southeast Asian nations. Governments in this region are heavily investing in new municipal water and sewage treatment plants, providing substantial opportunities for high-capacity ozone generator deployment. The growing middle class and heightened consumer awareness regarding air quality also fuel demand for commercial and residential air purifiers, further diversifying the market landscape.

- Latin America (LATAM): The LATAM market is marked by moderate but accelerating growth, linked closely to improving public health standards and addressing challenges related to aging water infrastructure and inconsistent sanitation coverage. Countries like Brazil and Mexico are increasing their investments in modern water treatment technologies. The food processing and agriculture sectors in LATAM, key economic pillars, are increasingly adopting ozone for sanitization to meet export quality standards, signaling a growing industrial segment demand.

- Middle East and Africa (MEA): The MEA region is crucial due to severe water stress, driving intense focus on desalination and water reuse projects. Ozone machines play an essential role in pretreating source water for desalination and ensuring high-quality reclaimed water. Demand is concentrated in highly developed urban centers and industrial zones, particularly in the UAE and Saudi Arabia, where large, high-throughput systems are required for cooling towers and municipal supplies. Economic diversification efforts away from oil also encourage industrial growth, subsequently boosting the need for advanced wastewater treatment solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ozone Machines Market.- Xylem Inc.

- Suez SA

- De Nora Water Technologies

- Pacific Ozone Technology

- Absolute Systems Inc.

- ClearWater Tech LLC

- A2Z Ozone Systems

- BES Group

- AquaZone Ozone

- Ozomax

- Taotwins

- Lenntech B.V.

- Toshiba Corporation

- Mitsubishi Electric

- Foremost Environmental

- WaterSurplus

- Ozone Solutions

- Korona Environmental

- Purgon

- Weinig Group

Frequently Asked Questions

Analyze common user questions about the Ozone Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Corona Discharge (CD) and UV Ozone Generators?

Corona Discharge (CD) generators utilize high-voltage electricity to produce high concentrations of ozone, making them ideal for large-scale industrial water treatment and complex oxidation processes. In contrast, Ultraviolet (UV) generators use UV light (185 nm) and produce lower ozone concentrations, generally suitable for small-scale air purification or residential use, offering simplicity and lower maintenance but less efficiency for heavy-duty applications.

How does the Ozone Machines Market address safety concerns related to ozone toxicity?

The market addresses safety concerns through the integration of sophisticated real-time ozone monitoring sensors, automated ventilation systems, and regulatory standards that mandate precise residual ozone level controls. Modern industrial systems incorporate fail-safe shutoff mechanisms and advanced control systems that automatically modulate output to ensure ozone concentration remains below occupational safety limits within operational areas, minimizing health risks.

What are the main drivers of growth for the industrial application segment?

The industrial segment's growth is primarily driven by increasingly stringent global environmental regulations concerning industrial effluent discharge, mandating advanced treatment technologies to remove recalcitrant pollutants. Furthermore, the rising demand for efficient, chemical-free sterilization in the food and beverage industry and the need for biofouling control in cooling towers are key contributing factors.

Which geographical region is anticipated to see the fastest adoption of Ozone Machines?

The Asia Pacific (APAC) region is projected to experience the fastest market growth. This acceleration is due to substantial governmental investments in water infrastructure upgrades, rapid industrialization, and high levels of urbanization, creating massive demand for effective water and wastewater treatment solutions across major economies like China and India.

How does AI technology enhance the performance of modern Ozone Machines?

AI technology enhances ozone machine performance by enabling predictive maintenance, optimizing energy consumption through dynamic output adjustment based on real-time process data, and ensuring precise dosing accuracy. AI systems analyze complex variables to maximize ozone generation efficiency while maintaining optimal safety and operational parameters, significantly reducing human error and operational costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager