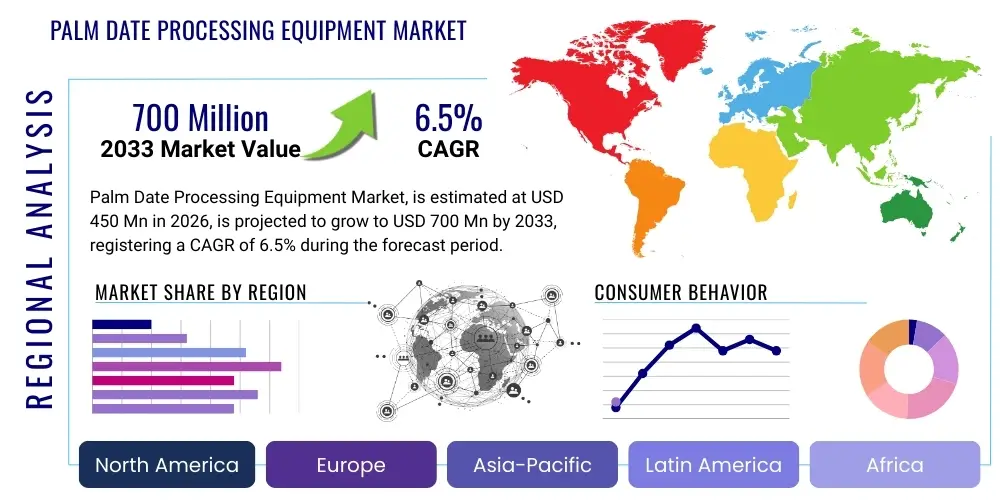

Palm Date Processing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436987 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Palm Date Processing Equipment Market Size

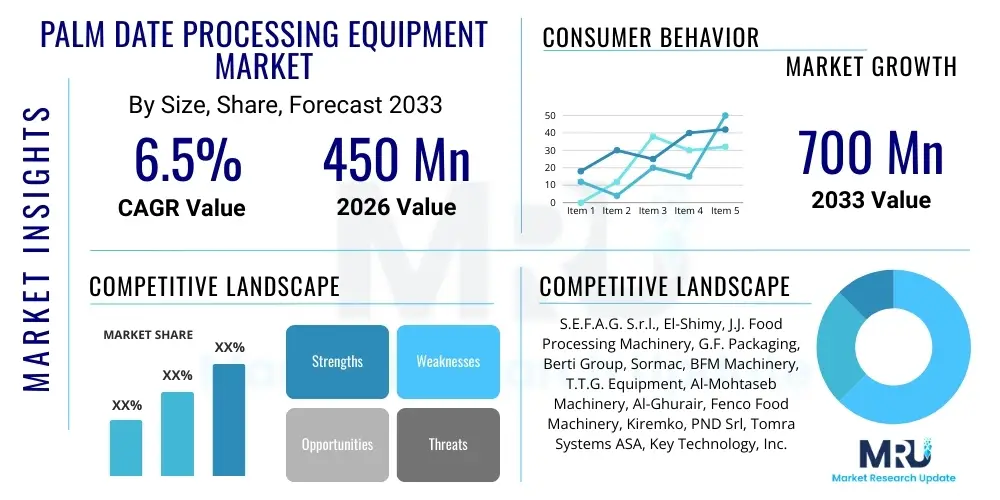

The Palm Date Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 700 Million by the end of the forecast period in 2033. This growth trajectory is strongly influenced by the increasing global demand for processed date derivatives, such as date paste and syrup, coupled with the necessity for mechanized handling to maintain hygiene standards and enhance operational efficiency in major date-producing regions across the Middle East, Africa, and Asia Pacific. Investment in advanced sorting, cleaning, and packaging technologies is accelerating market expansion.

Palm Date Processing Equipment Market introduction

The Palm Date Processing Equipment Market encompasses a range of specialized machinery utilized for preparing raw dates for commercial consumption or further processing. This equipment includes systems for cleaning, washing, sorting, grading, pitting, destoning, polishing, and final packaging. The fundamental objective of this machinery is to increase throughput, ensure standardized quality, and extend the shelf life of date products, thereby meeting stringent international food safety regulations. As global health consciousness rises, dates, being a natural sweetener and nutrient-rich snack, are witnessing surging demand, necessitating reliable and highly efficient processing solutions capable of handling massive volumes while minimizing post-harvest losses.

Major applications of palm date processing equipment span across the production of whole dates for direct consumption, date paste used extensively in baking and confectionery, date syrup serving as a natural sweetener alternative, and specialized products like date powder and vinegar. The benefits derived from employing advanced processing equipment are substantial, including enhanced product uniformity, significant reduction in manual labor costs, and improved hygiene compliance, which opens doors to lucrative export markets. Furthermore, modern machinery allows for precision grading based on size, color, and moisture content, maximizing the value extraction from the raw date harvest.

Driving factors for this market include the sustained growth of the global population and urbanization, leading to higher consumption of convenience food products, where dates are increasingly incorporated. Technological advancements, particularly in automated optical sorting systems and precision pitting machinery that minimizes pulp loss, are key determinants of market momentum. Government initiatives in major date-producing countries, aimed at modernizing agricultural infrastructure and reducing reliance on traditional labor-intensive methods, further catalyze the adoption of high-capacity date processing lines.

Palm Date Processing Equipment Market Executive Summary

The Palm Date Processing Equipment Market is characterized by robust growth driven by accelerating automation across the date supply chain and increasing health-conscious consumer preferences globally. Business trends indicate a strong shift towards integrated, high-capacity processing lines capable of multi-stage handling, from initial cleaning to final vacuum packaging. Manufacturers are focusing heavily on modular and customizable solutions that can adapt to different date varieties and output requirements, emphasizing energy efficiency and reduced water consumption. Strategic collaborations between machinery providers and large-scale date growers are common, aiming to optimize system integration and maintenance support, thereby lowering the total cost of ownership for end-users.

Regionally, the Middle East and Africa (MEA), dominated by countries like Saudi Arabia, UAE, and Egypt, remain the largest consumers and producers of this equipment due to their dominance in global date production. However, Asia Pacific (APAC), particularly India and China, is emerging as the fastest-growing market, driven by rising disposable incomes and expanding food processing sectors seeking alternative natural ingredients. North America and Europe demonstrate mature markets focused on equipment upgrades to meet high standards for traceability, hygiene, and sophisticated packaging designs catering to premium date products and date-based specialty foods.

Segment trends highlight the dominance of the sorting and grading equipment segment, fueled by the demand for uniformity and premium quality assurance in export markets. The automatic operation segment is experiencing exponential adoption, replacing semi-automatic and manual systems to address labor shortages and ensure consistent processing speeds. Furthermore, there is a pronounced upward trend in demand for specialized equipment geared towards producing date derivatives, specifically high-purity date syrup and paste, reflecting shifting consumer culinary preferences and industrial applications in beverages and confectionery manufacturing.

AI Impact Analysis on Palm Date Processing Equipment Market

User queries regarding AI's influence in date processing predominantly center on precision quality control, predictive maintenance, and operational efficiency gains. Users frequently ask how AI-driven vision systems can differentiate between subtle quality defects (e.g., insect damage, minor bruising) at high processing speeds, a task challenging for traditional optical sorters. There is significant interest in understanding the feasibility and cost-effectiveness of implementing machine learning algorithms for optimizing equipment settings based on the input characteristics of varying date batches (e.g., moisture, size heterogeneity). Furthermore, maintenance managers are keen on leveraging AI for predictive fault detection in complex machinery components like destoners and washers to minimize unexpected downtime during peak harvest seasons, seeking a quantifiable return on investment from such advanced deployments.

The application of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the date processing sector, moving it away from reactive quality assurance towards proactive, real-time management. AI-powered optical sorters utilize deep learning models trained on vast datasets of date images to achieve unprecedented levels of accuracy in identifying defects, foreign materials, and classifying dates by commercial grade far beyond the capabilities of conventional color and shape sensors. This enhanced precision is crucial for maintaining brand reputation and accessing premium export channels that enforce stringent quality criteria. The integration of AI extends to optimizing resource utilization, such as monitoring water consumption during washing and adjusting air pressure settings in drying tunnels based on ambient conditions and date characteristics, leading to significant operational cost savings and environmental benefits.

Beyond quality control, AI is instrumental in developing robust predictive maintenance schedules for sophisticated processing lines. Sensors embedded in critical components—such as bearings in conveyor systems, motors in pitting machines, and pumps in washing units—feed operational data to ML algorithms. These algorithms analyze subtle anomalies in vibration, temperature, and power consumption patterns to predict equipment failure moments before they occur. This proactive approach allows maintenance teams to schedule interventions during planned pauses, drastically increasing overall equipment effectiveness (OEE) and ensuring uninterrupted production flow during the sensitive harvest period, thereby mitigating revenue losses associated with unexpected breakdowns.

- AI-driven optical sorting enhances defect detection and grading accuracy using deep learning models.

- Predictive maintenance systems minimize downtime by analyzing sensor data for potential equipment failures.

- Machine learning optimizes processing parameters (e.g., drying time, washing cycles) based on real-time fruit conditions.

- Automated quality assurance reduces reliance on manual inspections, ensuring higher hygienic standards.

- Supply chain optimization through AI models forecasts optimal harvesting, storage, and processing schedules.

DRO & Impact Forces Of Palm Date Processing Equipment Market

The Palm Date Processing Equipment Market is propelled by increasing consumer preference for healthy, natural food products, driving demand for high-quality processed dates and derivatives globally. This demand necessitates higher throughput and consistent quality, achievable only through automation, which forms the primary driver. However, the market faces significant restraints, chiefly the high initial capital investment required to purchase and install sophisticated, high-capacity machinery, making adoption challenging for smaller and medium-sized date processors, particularly in developing regions. Opportunities abound in expanding the product portfolio into niche markets, such as functional date ingredients, and developing energy-efficient, water-saving processing technologies, capitalizing on growing sustainability concerns. These dynamics collectively shape the market landscape, influencing strategic decisions regarding technology adoption and regional market focus.

Drivers: Automation and Global Demand

The primary driver is the accelerating trend toward automation in agriculture and food processing sectors worldwide. Automation addresses critical issues prevalent in the date industry, including severe labor shortages in manual pitting and sorting operations, inconsistency in manual grading, and the necessity to meet increasingly stringent global hygiene standards required for export. Modern automated equipment offers precise control over processing variables, significantly reduces contamination risks, and allows processors to handle massive volumes of dates efficiently, ensuring year-round supply capabilities. Furthermore, the rising operating costs associated with manual labor are making the long-term investment in automated machinery increasingly economically viable for large-scale producers seeking competitive advantages.

A secondary yet equally powerful driver is the sustained increase in global consumption of dates and date-based products. Dates are increasingly marketed as a superfood and a natural alternative to refined sugars, appealing to health-conscious consumers in Western and Asian markets. This surge in demand necessitates processors to scale up operations rapidly. Equipment capable of producing high-value derivatives, such as date sugar and concentrated date syrup, is experiencing particularly high demand, driving innovation in extraction and dehydration technologies. The ability of specialized machinery to maintain the nutritional integrity and sensory characteristics of the date during processing is a key factor encouraging investment.

Restraints: High Investment and Seasonality

The most significant restraint is the substantial initial capital outlay required for purchasing advanced date processing lines. High-capacity cleaning, optical sorting, and automated pitting machinery represents a major financial barrier, especially for small and medium-sized enterprises (SMEs) that dominate the processing landscape in several key date-producing countries. This high entry cost often necessitates complex financing structures or government subsidies, slowing down the pace of modernization. Moreover, the integration of new, high-tech equipment requires specialized technical expertise for operation and maintenance, a skilled labor pool that is often scarce in remote agricultural regions, further increasing operational overheads and complexity.

Another major restraint involves the highly seasonal nature of date harvesting. Processing equipment often remains idle for a substantial portion of the year outside the harvest and immediate post-harvest periods. This seasonality negatively impacts the return on investment (ROI) calculation for high-cost machinery, as the utilization rate is inherently limited. Furthermore, the variability in date quality and characteristics (moisture content, size, variety) across different growing seasons requires equipment to be highly flexible, which adds complexity and cost to machine design and operation. Managing inventory and maintenance during the prolonged off-season poses distinct challenges for equipment owners.

Opportunities: Market Diversification and Sustainability

A significant opportunity lies in the diversification of date-derived products beyond conventional whole dates and paste. There is a growing market for specialized ingredients like date fiber, date seed oil, and functional ingredients derived from date remnants, which require unique, purpose-built processing equipment for extraction and refinement. Tapping into the neutraceutical and cosmetic industries offers high-margin potential. Processors who invest in advanced extraction and fractionating technologies can create new revenue streams from previously considered waste materials, thereby maximizing the overall economic value of the date harvest and contributing to a circular economy model within the industry.

Furthermore, the focus on sustainable and resource-efficient processing presents a major market opportunity. Developing and adopting equipment that minimizes water usage during cleaning and washing phases, or utilizes energy-efficient drying techniques (such as heat pump dryers or solar-assisted systems), is becoming critical due to environmental regulations and corporate sustainability mandates. Equipment manufacturers who can deliver demonstrable reductions in environmental footprint, coupled with low operating costs, will gain a significant competitive edge, especially when targeting environmentally conscious processors in developed economies and regions facing water scarcity issues.

Segmentation Analysis

The Palm Date Processing Equipment Market is segmented based on Type, Capacity, Application, and Operation, providing a granular view of market dynamics and adoption trends. The analysis highlights how technological complexity correlates directly with investment levels and output demands, with major processors favoring integrated systems that combine multiple functions. Segmentation by application demonstrates the growing industrial demand for processed derivatives, moving beyond the traditional consumption of whole dates. These segmentations are crucial for understanding procurement patterns and the strategic focus areas of equipment manufacturers.

The Type segment, including cleaning, sorting, pitting, and packaging machinery, forms the core of the market, with automated sorting technology experiencing the highest growth due to the need for precise grading. The capacity segment (low, medium, high) directly reflects the scale of the end-user operation, ranging from small regional packers to global commodity suppliers requiring lines capable of handling dozens of tons per hour. The transition from medium to high-capacity solutions is particularly evident in large date-producing nations aiming for export market dominance.

The operation segment underscores the industry's shift towards automation, driven by efficiency and consistency requirements. While manual and semi-automatic equipment still services smaller operations, automatic lines are setting the standard for quality and throughput. This trend is expected to continue as the costs of advanced automation decrease and labor costs increase, making fully automatic, integrated lines the preferred choice for new facility installations or major modernization projects worldwide.

- By Type:

- Cleaning and Washing Equipment

- Sorting and Grading Equipment

- Pitting and Destoning Equipment

- Polishing and Coating Equipment

- Packaging and Sealing Equipment

- By Capacity:

- Low Capacity (Under 1 Ton/Hour)

- Medium Capacity (1 to 5 Tons/Hour)

- High Capacity (Above 5 Tons/Hour)

- By Application:

- Whole Dates

- Date Paste and Puree

- Date Syrup and Honey

- Date Powder and Sugar

- Others (Date Vinegar, Date Seed Oil)

- By Operation:

- Automatic

- Semi-Automatic

- Manual

Value Chain Analysis For Palm Date Processing Equipment Market

The value chain for the Palm Date Processing Equipment Market begins with upstream activities involving the sourcing and manufacturing of specialized components, including high-grade stainless steel, advanced optical sensors, proprietary motor systems, and control electronics. Upstream analysis highlights the critical reliance on specialized component suppliers, often located in industrialized economies (Europe, North America), which contributes significantly to the final equipment cost. Component quality, particularly sensor technology for sorting and durable materials for high-wear parts like pitting blades, directly dictates the longevity and performance of the final processing line. Equipment manufacturers then engage in complex design, integration, and assembly processes, requiring highly specialized engineering expertise to ensure food safety compliance and operational efficiency tailored to specific date varieties.

Downstream analysis focuses on the installation, commissioning, and maintenance phases carried out at the date processing facilities. The key actors downstream are the large-scale date growers, cooperatives, and dedicated food processing companies that act as the primary buyers. Distribution channels typically involve a mix of direct sales, especially for customized, high-value integrated lines, and indirect sales through local agents or distributors who provide crucial regional support, spare parts inventory, and necessary technical services. The reliability of the after-sales support and the availability of localized technical training are paramount considerations for end-users, given the remote locations of many processing plants and the sensitive nature of the harvest season.

Direct sales are common for premium, custom-engineered processing solutions, allowing manufacturers to maintain tight control over installation quality and client relationships, offering tailored maintenance contracts and software updates. Indirect distribution, leveraging established regional dealers, is essential for reaching smaller clients and providing quick access to replacement parts and routine maintenance services. Successful players in this market maintain a balance, using indirect channels for broad market coverage and standard equipment sales, while reserving direct engagement for strategic accounts and major infrastructure projects in key date-producing geographies.

Palm Date Processing Equipment Market Potential Customers

Potential customers for palm date processing equipment primarily comprise entities involved in the commercial preparation, packaging, and export of dates and their derivatives. The largest segment of buyers includes large integrated date farms and agricultural conglomerates, particularly prevalent in the Middle East and North Africa (MENA) region, who seek high-capacity, automated lines to handle their vast harvests efficiently and maintain strict quality standards necessary for lucrative international markets. These entities prioritize scalability, speed, and the integration of advanced sorting technologies to maximize yield and minimize labor dependence. Investment decisions are often based on reducing long-term operational costs and achieving rapid payback through increased export volumes and premium pricing for consistently graded products.

A second significant customer base is represented by specialized food and beverage processing companies. These customers typically do not grow dates but purchase raw or semi-processed material to manufacture value-added products like date paste for infant food, date syrup for beverages and confectionery, or functional date ingredients. These buyers often demand equipment with advanced refinement and extraction capabilities, such as vacuum evaporators for syrup concentration or specialized milling equipment for fine date powder. Their focus is less on initial cleaning and more on transformation technology that ensures product purity, specific textures, and high shelf stability tailored to industrial specifications.

Furthermore, small and medium-sized cooperative associations and independent regional packers constitute a viable customer segment, particularly for medium-capacity and semi-automatic equipment. While their budget constraints are tighter, they represent a high volume of transactions, especially in emerging markets. These customers require robust, easy-to-operate machinery that offers a good balance between cost and performance, allowing them to improve their processing hygiene and extend product shelf life, enabling them to transition from local to regional distribution. Government agricultural modernization programs often target these SMEs with subsidized equipment purchase schemes, further boosting adoption in this segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 700 Million |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | S.E.F.A.G. S.r.l., El-Shimy, J.J. Food Processing Machinery, G.F. Packaging, Berti Group, Sormac, BFM Machinery, T.T.G. Equipment, Al-Mohtaseb Machinery, Al-Ghurair, Fenco Food Machinery, Kiremko, PND Srl, Tomra Systems ASA, Key Technology, Inc., Bühler Group, Heat and Control, Inc., Marel, GEA Group, FPS Food Process Solutions |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Palm Date Processing Equipment Market Key Technology Landscape

The technology landscape of the Palm Date Processing Equipment Market is dominated by advancements in automation, precision mechanics, and computer vision systems. A key technology is high-resolution optical sorting, which employs advanced cameras and hyperspectral imaging combined with machine learning algorithms (as noted in the AI section) to inspect dates for minute defects, size variance, color inconsistency, and foreign material contamination at speeds exceeding hundreds of dates per second. This non-destructive inspection ensures superior product quality and uniformity, which is vital for maintaining export standards and reducing product recalls. Furthermore, the integration of robotics for pick-and-place tasks, especially in highly delicate sorting or specialized packaging phases, is gaining traction to minimize physical handling damage and ensure hygienic conditions.

Another crucial technological area is destoning and pitting machinery. Modern destoners have moved away from conventional punch mechanisms to advanced, high-speed rotary cutters or vacuum-assisted systems that maximize pulp retention and minimize damage to the fruit's integrity, crucial for high-quality whole dates. For derivative processing, technologies like ultrafiltration and reverse osmosis are being implemented for purifying date syrup, ensuring a highly consistent sugar concentration and removing unwanted particulate matter without resorting to chemical processes. This focus on natural, chemical-free processing aligns with consumer preferences for clean label ingredients and enhances the nutritional profile of the final date derivative product, driving the demand for specialized, high-purity equipment.

The rise of Industry 4.0 principles is evident in the adoption of IoT (Internet of Things) connectivity across processing lines. Equipment is increasingly fitted with sensors that monitor operational performance metrics such as throughput, energy consumption, temperature, and moisture levels in real-time. This data is leveraged for sophisticated monitoring, remote diagnostics, and seamless integration with Enterprise Resource Planning (ERP) systems. The shift towards modular design also represents a significant technological advancement, allowing processors to easily reconfigure or scale their lines to accommodate different date varieties or switch between producing whole dates and date paste, offering enhanced flexibility and maximizing the utilization of the substantial capital investment throughout the year.

Regional Highlights

- Middle East and Africa (MEA): MEA holds the dominant market share due to its foundational role in global date production, with key contributors being Saudi Arabia, Iran, Egypt, and Algeria. The region is characterized by substantial government investments aimed at modernizing aging infrastructure and increasing export capacity, especially for premium varieties like Medjool and Deglet Noor. Demand is high for high-capacity, robust equipment built to withstand challenging operational environments and handle large volumes immediately post-harvest. The focus here is on scaling production efficiently while adopting international hygiene standards.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing regional market, driven by rapidly increasing date consumption in countries like India, Pakistan, and China, where dates are utilized both as a traditional snack and an industrial ingredient. The growth is fueled by expanding food manufacturing sectors and rising urbanization. Local processors are investing in entry-level and medium-capacity automated systems to improve the quality of domestic offerings and compete with imported products. The emphasis in APAC is on flexible packaging solutions tailored to diverse local retail formats and varying climate conditions.

- North America: The North American market is highly mature and focused on premium, processed date products, particularly date paste and syrup, marketed toward health-conscious consumers. Demand for processing equipment here is driven primarily by the stringent regulatory requirements for food safety and the need for sophisticated, highly automated optical sorting and packaging machinery capable of detailed traceability. Equipment providers specializing in high-precision, low-waste technologies and compliance certifications find substantial opportunity within this high-value market segment.

- Europe: Europe represents a significant import market for dates, driving demand for advanced processing equipment that caters to strict EU quality and environmental regulations. European processors focus on specialization, converting imported raw dates into high-value ingredients for the thriving organic and natural food industries. Key demand areas include advanced hygiene control systems, energy-efficient drying and sterilization equipment, and precision packaging technologies that extend shelf life and maintain aesthetic quality for premium retail placement.

- Latin America (LATAM): The LATAM market, while smaller, is witnessing steady growth, particularly in countries with established agricultural bases that are exploring date cultivation or processing imported dates for local markets. Investment is concentrated on semi-automatic to medium-capacity equipment that offers a balance between cost and efficiency. The market is slowly transitioning towards modernization, spurred by regional trade agreements and the growing influence of global food industry standards, necessitating improvements in basic cleaning and standardized packaging capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Palm Date Processing Equipment Market.- S.E.F.A.G. S.r.l.

- El-Shimy

- J.J. Food Processing Machinery

- G.F. Packaging

- Berti Group

- Sormac

- BFM Machinery

- T.T.G. Equipment

- Al-Mohtaseb Machinery

- Al-Ghurair

- Fenco Food Machinery

- Kiremko

- PND Srl

- Tomra Systems ASA

- Key Technology, Inc.

- Bühler Group

- Heat and Control, Inc.

- Marel

- GEA Group

- FPS Food Process Solutions

- FT System Srl

- Mecaplanta S.L.

- Agrifac Machinery B.V.

- Wyma Solutions

- R&D Process Engineering

- Hitech Food Systems

- Cabinplant A/S

- Ishida Co., Ltd.

- Tna Solutions Pty Ltd

- Durand S.A.S.

Frequently Asked Questions

Analyze common user questions about the Palm Date Processing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Palm Date Processing Equipment Market?

The Palm Date Processing Equipment Market is projected to exhibit a CAGR of 6.5% during the forecast period from 2026 to 2033, driven by increasing automation and global demand for high-quality date products.

Which segment of palm date processing equipment is experiencing the fastest technological adoption?

The Sorting and Grading Equipment segment, particularly high-speed optical sorters utilizing AI and machine vision, is experiencing the fastest technological adoption due to stringent quality standards and the need for precision grading in export markets.

What are the primary drivers influencing the growth of the date processing equipment market?

Key drivers include the global shift towards automated processing to mitigate labor shortages, the rising consumer demand for natural date derivatives (like syrup and paste), and the necessity to meet rigorous international food safety and hygiene regulations.

Which geographical region dominates the palm date processing equipment market?

The Middle East and Africa (MEA) region currently dominates the market share due to its established position as the largest global producer of dates and heavy government investment in modernizing high-capacity processing facilities for export.

How is AI impacting the maintenance and efficiency of date processing lines?

AI is significantly improving efficiency by enabling predictive maintenance through sensor data analysis, minimizing unplanned equipment downtime, and optimizing operational parameters in real-time to maximize throughput and ensure consistent output quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager