Paper Bed Filter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433712 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Paper Bed Filter Market Size

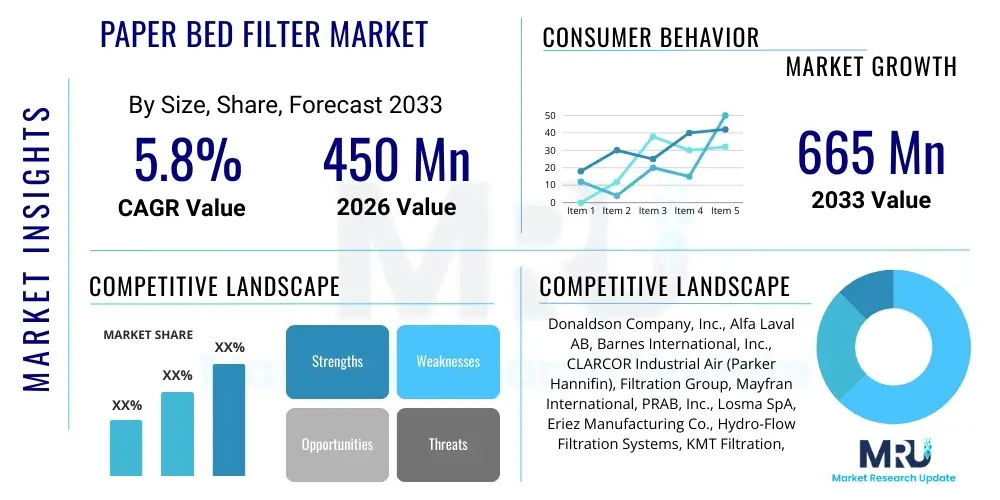

The Paper Bed Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033.

Paper Bed Filter Market introduction

The Paper Bed Filter Market encompasses specialized industrial filtration equipment utilizing non-woven filter media (often paper-based rolls or fabric) gravity-fed over a conveyor or flat bed to separate solids from liquid coolants or lubricants, predominantly in machining, grinding, and metalworking processes. These filters are essential for maintaining the quality and longevity of expensive coolants while simultaneously protecting precision machinery components from abrasive contaminants. The basic mechanism involves the contaminated fluid passing through the paper media under gravity; as solids accumulate, the flow rate decreases, triggering an automated system to advance a new section of clean filter media, ensuring continuous operation with minimal downtime. The primary applications span across automotive manufacturing, aerospace component production, heavy equipment fabrication, and general metal finishing shops where efficient fluid management is paramount.

The core product offering includes gravity filters, vacuum filters, and indexing media filters, designed to handle various fluid viscosities and particulate loads. Benefits derived from utilizing paper bed filters are significant, including improved surface finish quality on manufactured parts, reduced machine tool wear, extended coolant life resulting in lower disposal costs, and compliance with stringent environmental regulations regarding industrial effluent. These systems are highly valued for their simplicity, cost-effectiveness, and reliability in achieving high levels of filtration efficiency, often down to fine micron ratings depending on the chosen filter media.

Driving factors propelling market growth are directly linked to the expansion of global manufacturing output, particularly in Asia Pacific, coupled with the increasing adoption of automated and high-precision machining centers that necessitate ultra-clean fluids. Furthermore, growing emphasis on sustainability and circular economy principles is prompting manufacturers to invest in advanced filtration solutions to minimize coolant replacement and waste generation. Regulatory pressures regarding industrial waste disposal also mandate the use of efficient solid-liquid separation technologies, cementing the paper bed filter’s role as a critical component in modern industrial infrastructure.

Paper Bed Filter Market Executive Summary

The Paper Bed Filter Market is experiencing stable growth driven by global industrial resurgence and increasing demand for precision components across the automotive and aerospace sectors. Business trends indicate a strong move toward high-capacity, automated filter units integrated with real-time monitoring systems to minimize manual intervention and optimize media consumption. Manufacturers are focusing on developing biodegradable and environmentally friendly filter media to align with corporate sustainability goals and reduce the environmental footprint associated with spent filter materials. Key strategic developments include regional expansions, particularly in high-growth manufacturing hubs like China and India, and vertical integration by filter manufacturers to control the supply chain of specialized non-woven media.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market segment, primarily due to the massive scale of metal fabrication and machining activities occurring there, fueled by foreign direct investment and burgeoning domestic demand for manufactured goods. North America and Europe remain mature markets characterized by replacement demand, strict regulatory environments, and a high uptake of sophisticated, digitally integrated filtration systems. Europe, in particular, is witnessing robust demand driven by advanced automation standards and strong emphasis on occupational safety and environmental protection, requiring superior coolant quality control.

Segmentation trends reveal that the Automatic Indexing Type filters are gaining significant traction over manual or semi-automatic variants, attributed to improved efficiency and reduced labor costs. Furthermore, the market for High Flow Rate filters is expanding rapidly, necessitated by the implementation of large-scale central coolant systems in modern factories. The End-User segment analysis confirms that the Automotive industry remains the largest consumer, while the General Manufacturing and Heavy Machinery sectors are poised for substantial growth, necessitating customizable filter solutions capable of handling diverse contaminant characteristics.

AI Impact Analysis on Paper Bed Filter Market

User queries regarding AI's influence typically revolve around predictive maintenance, optimization of filter media usage, and achieving 'lights-out' operation in filtration systems. Users are concerned about how AI algorithms can interpret sensor data (flow rates, differential pressure, particulate count) to predict filter bed blinding, determine the precise moment for media indexing, and automatically adjust system parameters for optimal efficiency. Key themes include reducing media waste, minimizing operator intervention, and integrating filtration data with overall factory IoT platforms to enable holistic process control. The expectation is that AI will transform reactive maintenance into predictive scheduling, thereby significantly lowering operational expenses and extending equipment lifespan.

The immediate impact of AI integration centers on enhancing the efficiency and sustainability of paper bed filters. By leveraging machine learning models trained on historical operating data, AI systems can accurately determine the optimal filter media advancement rate, ensuring media is used to its maximum capacity before disposal. This predictive capability directly addresses a major operational cost—media consumption—and contributes substantially to waste reduction. Furthermore, AI-powered diagnostics can swiftly identify anomalies in fluid condition or mechanical faults within the filter system, allowing for proactive maintenance before catastrophic failure or significant dips in coolant quality occur. This shift towards smart filtration is critical for high-volume, high-precision manufacturing environments.

Looking ahead, AI will facilitate the integration of paper bed filters into broader Smart Factory ecosystems. Advanced analytics will allow filtration parameters to be dynamically linked to production schedules; for instance, filtration rates could be automatically boosted during periods of high throughput or adjusted based on the specific type of material being machined. This level of optimization, enabled solely by AI, moves the paper bed filter from a passive waste management tool to an active, intelligent component of the production process, contributing directly to higher quality output and greater resource efficiency, thereby increasing the intrinsic value proposition of advanced filtration equipment.

- Predictive maintenance scheduling for pumps, conveyors, and indexing mechanisms.

- Optimization of filter media advancement using real-time contamination load analysis.

- Automated fault detection and remote diagnostic capabilities, reducing downtime.

- Integration with Manufacturing Execution Systems (MES) and Industrial IoT platforms (IIoT).

- Enhanced coolant life monitoring and chemical stability control through pattern recognition.

- Development of self-calibrating and self-adjusting filtration parameters based on operational feedback.

DRO & Impact Forces Of Paper Bed Filter Market

The Paper Bed Filter Market is influenced by strong drivers such as escalating global manufacturing output and the critical need for high-quality coolant management in precision industries. Restraints include the recurring operational cost associated with filter media replacement and the potential emergence of more sophisticated, media-less filtration technologies (like centrifugal separators or ultrafiltration systems) in niche high-cost applications. Opportunities are abundant in developing biodegradable filter media, expanding into emerging markets with rapidly industrializing economies, and integrating smart sensors and IoT capabilities for data-driven filtration optimization. The primary impact forces are regulatory pressure favoring reduced industrial waste and the continuous technological push towards higher filtration efficiencies required by advanced machine tools.

Drivers primarily stem from the global increase in high-precision metalworking. Modern Computer Numerical Control (CNC) machining centers operate at higher speeds and tighter tolerances, requiring extremely clean coolants to prevent thermal distortion and ensure optimal surface finish. The ubiquity and cost-effectiveness of paper bed filters make them the default choice for bulk solids removal in these applications. Moreover, the increasing adoption of difficult-to-machine materials like aerospace alloys and specialized steels results in unique particulate matter that traditional separation methods struggle with, thereby solidifying the demand for versatile paper media filters. Furthermore, global coolant and lubricant consumption is rising, directly correlating with the need for systems that extend fluid longevity.

Conversely, significant restraints exist, notably the ongoing expense of consumables. While paper bed filters offer low initial capital expenditure, the continuous purchasing and disposal of filter media rolls constitute a long-term operating cost that can become substantial, especially for large facilities. This operational expenditure pressure drives interest in technologies that minimize or eliminate consumables. Another restraint is the environmental concern linked to the disposal of spent, coolant-soaked media. Although manufacturers are addressing this with eco-friendly media, the sheer volume of waste generated poses logistical and regulatory challenges in many regions, potentially slowing adoption where alternative, non-consumable systems are viable.

Opportunities for market expansion are centered on sustainability and digital transformation. The development of next-generation, compostable, or highly recyclable paper filter media presents a significant avenue for market differentiation, appealing strongly to environmentally conscious manufacturers. Geographically, underserved industrial sectors in Southeast Asia and Latin America represent substantial untapped potential. Technological opportunities focus on incorporating advanced sensor technologies (e.g., optical particle counters) to provide real-time fluid cleanliness feedback, coupled with IoT platforms that allow remote diagnostics and predictive maintenance, transforming the product offering into a highly efficient, data-generating asset.

Segmentation Analysis

The Paper Bed Filter Market is systematically segmented based on Type, Flow Rate, Application, and End-User Industry, allowing for precise market evaluation and strategic planning. The Type segmentation distinguishes between Gravity-fed Filters, which are the most common due to their simplicity and reliability, and Vacuum Filters, which offer enhanced filtration efficiency for finer particulate removal and higher fluid volumes. The flow rate categorization—Low, Medium, and High—directly reflects the capacity requirements of industrial operations, ranging from single machine applications to centralized facility-wide coolant management systems. Analysis across these segments reveals a growing preference for automated, high-capacity systems capable of supporting modern, 24/7 manufacturing operations with stringent cleanliness standards.

The Application segmentation categorizes the market based on the specific industrial processes where these filters are utilized, primarily encompassing grinding operations, honing, lapping, and general machining (e.g., milling and turning). Grinding applications typically demand the highest level of cleanliness due to the fine, abrasive nature of the swarf produced, making high-efficiency paper bed filters indispensable. Furthermore, the End-User Industry segmentation provides insight into the major revenue streams, with the Automotive and Aerospace sectors consistently leading demand due to their high production volumes and strict component quality mandates, requiring reliable removal of metal fines from process fluids.

Strategic analysis of these segments indicates that the Vacuum Filter segment, despite being more costly, is projected to witness the fastest growth rate, driven by the increasing complexity of materials being machined (e.g., composites and specialty alloys) which generate ultra-fine particles. Similarly, the High Flow Rate segment is expanding rapidly as large manufacturers consolidate individual coolant systems into central purification plants to achieve economies of scale and centralized quality control. Geographic segmentation remains crucial, with localized industrial infrastructure dictating the preferred product types—for example, simpler gravity filters dominate small to medium enterprises (SMEs), while sophisticated, automated systems are standard in large multinational corporations.

- Type:

- Gravity Filters (Standard Paper Bed Filters)

- Vacuum Filters (High-Efficiency Vacuum Paper Filters)

- Automatic Indexing Filters

- Magnetic Separators Combined Filters

- Flow Rate:

- Low Flow Rate (Up to 100 LPM)

- Medium Flow Rate (100–500 LPM)

- High Flow Rate (Above 500 LPM)

- Application:

- Grinding Operations (Surface, Cylindrical, Centerless)

- Honing and Lapping

- Machining (Milling, Turning, Drilling)

- Washing and Degreasing Systems

- End-User Industry:

- Automotive and Transportation

- Aerospace and Defense

- Heavy Machinery and Equipment

- General Manufacturing and Job Shops

- Metal Processing and Fabrication

Value Chain Analysis For Paper Bed Filter Market

The value chain for the Paper Bed Filter Market begins with upstream activities focused on raw material sourcing and media production. Upstream analysis involves suppliers of non-woven fabrics, specialized paper pulp, and various synthetic fibers used in the manufacturing of the filter media rolls. Key considerations at this stage include the cost volatility of raw materials, the development of sustainable/biodegradable media, and maintaining consistent material specifications critical for filtration performance. Concurrently, the upstream segment includes manufacturers of core system components such as conveyor mechanisms, fluid pumps, electrical control panels, and automation sensors, which are essential for building the physical filter unit.

Midstream activities encompass the manufacturing, assembly, and testing of the complete paper bed filter systems. Filter manufacturers integrate the sourced components and media rolls, applying proprietary designs for flow distribution and indexing mechanisms to maximize efficiency and longevity. Quality control in manufacturing is paramount, ensuring leak-proof construction and reliable automation. Distribution channels play a critical role, segmenting into direct sales models, often utilized for large, customized, or integrated projects with major automotive or aerospace clients, and indirect channels relying heavily on regional industrial distributors, maintenance, repair, and operations (MRO) suppliers, and specialized fluid management integrators who serve smaller and medium-sized enterprises (SMEs).

Downstream analysis focuses on installation, after-sales service, and the crucial management of consumables. After the sale, ongoing revenue streams are generated through the supply of replacement filter media, spare parts for pumps and conveyors, and maintenance contracts. Direct engagement allows manufacturers to provide specialized technical support and customized solutions, while indirect channels leverage the distributor network for immediate local service and media stocking. The efficiency of the downstream segment, particularly the reliable supply of consumables and responsive technical support, significantly influences customer satisfaction and retention in this maintenance-intensive equipment market.

Paper Bed Filter Market Potential Customers

The primary potential customers for Paper Bed Filters are businesses operating within the metalworking and precision manufacturing sectors that utilize water-soluble coolants or cutting oils in their production processes. The largest end-users include major automotive manufacturers (OEMs) and their Tier 1 and Tier 2 suppliers, who rely on continuous, high-volume machining for engine blocks, transmissions, brake components, and chassis parts. These customers require centralized, high-capacity filtration systems to manage large coolant reservoirs and maintain stringent fluid cleanliness standards to comply with quality mandates like ISO/TS 16949, minimizing defects and rework.

Another critical customer segment is the aerospace and defense industry. While their volume is generally lower than automotive, the extremely high precision and zero-tolerance requirements for components made from exotic alloys (titanium, nickel-based superalloys) necessitate superior filtration performance. Customers in this sector demand highly efficient vacuum paper filters and integrated systems that can remove extremely fine particulate matter generated during complex grinding and milling operations, directly influencing component safety and performance. The stringent quality assurance demands in aerospace make them willing to invest in premium filtration technologies that guarantee fluid integrity.

Beyond the core transportation industries, potential customers include heavy machinery and equipment manufacturers (e.g., construction and mining equipment), general metal fabrication job shops, and specialized manufacturers involved in bearing production, tool and die making, and medical device manufacturing. These diverse end-users require customized solutions ranging from small, standalone gravity filters for individual machines to modular systems capable of being scaled up as operations expand. The universal need for maximizing the lifespan of expensive coolants and protecting capital-intensive machine tools positions virtually any enterprise engaged in continuous metal removal processes as a viable potential customer.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Donaldson Company, Inc., Alfa Laval AB, Barnes International, Inc., CLARCOR Industrial Air (Parker Hannifin), Filtration Group, Mayfran International, PRAB, Inc., Losma SpA, Eriez Manufacturing Co., Hydro-Flow Filtration Systems, KMT Filtration, Micropure Filtration Inc., Flow Pro Products, Inc., Monlan Group, S.P.P. Engineering Private Limited, Transor Filter, Inc., Fluid Systems, Industrial Filter Manufacturers, Inc., Oberlin Filter Company, LAKOS Filtration. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Paper Bed Filter Market Key Technology Landscape

The technology landscape of the Paper Bed Filter Market is characterized by continuous refinement aimed at maximizing filtration efficiency, minimizing media consumption, and enhancing automation and connectivity. Core technological advancements revolve around the filter media itself. Manufacturers are increasingly utilizing composite non-woven fabrics that combine natural cellulose fibers with synthetic materials (like polypropylene or rayon) to achieve superior tensile strength when wet, high permeability, and optimal pore size distribution, leading to finer particle separation without sacrificing flow rate. The development of advanced polymer fibers and multilayer media structures allows for effective filtration down to 5–10 micron levels, catering to the exacting demands of modern machining processes. Furthermore, there is a push towards creating specialized, application-specific media designed to handle fluids with high levels of tramp oil or specific chemical compositions.

System architecture innovations focus heavily on automation and optimizing the indexing mechanism. Modern paper bed filters feature sensor-based control systems that accurately measure the static fluid head or differential pressure across the media, ensuring that the filter fabric is advanced only when necessary, thus significantly reducing media wastage. Technologies such as electronically controlled indexing motors, pneumatic clamping systems, and integrated sludge removal mechanisms (e.g., magnetic pre-separators or drag conveyors) are now standard. These technological enhancements ensure that the filtration process is continuous, highly reliable, and requires minimal operator intervention, aligning with industry trends toward unmanned operation in large industrial facilities.

The most transformative recent technology involves the integration of IoT and digital monitoring capabilities. High-end paper bed filters are now equipped with communication interfaces (e.g., OPC UA, Ethernet/IP) that allow real-time monitoring of performance metrics such as flow rate, pressure, temperature, and media roll inventory. This connectivity enables remote diagnostics, performance benchmarking, and integration with factory-wide SCADA or MES systems. Future technological focus is on embedding AI and machine learning algorithms to predict maintenance needs, dynamically adjust filtration cycles based on instantaneous process load changes, and provide prescriptive operational recommendations, fundamentally improving the total cost of ownership (TCO) for end-users.

Regional Highlights

The global market for Paper Bed Filters exhibits distinct regional dynamics, primarily driven by the concentration of manufacturing industries, regulatory frameworks, and technological adoption rates. Asia Pacific (APAC), led by China, India, Japan, and South Korea, constitutes the largest market share and is projected to experience the highest growth rate during the forecast period. This dominance is attributed to massive investments in automotive production, heavy machinery manufacturing, and the rapid expansion of general metalworking and component fabrication operations. Low manufacturing costs and supportive government policies in countries like China and India have spurred the proliferation of facilities requiring effective coolant management solutions, leading to high volume demand for both standard gravity filters and advanced vacuum systems.

North America and Europe represent mature markets characterized by stringent quality standards and high levels of automation. In North America, demand is stable, driven primarily by replacement needs and technological upgrades in the aerospace, defense, and high-end automotive sectors. The emphasis here is on integrating smart filtration solutions, leveraging IoT capabilities, and meeting increasingly strict environmental regulations regarding industrial effluent discharge. European demand is robust, especially in Germany and Italy, home to major machine tool builders and precision engineering firms. European adoption is fueled by strict occupational health and safety (OHS) mandates, necessitating cleaner workplace environments and highly efficient filtration to minimize the exposure to mists and contaminated fluids.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging markets for paper bed filters. Growth in LATAM is concentrated in key industrial nations like Brazil and Mexico, driven by localized automotive assembly and mining equipment maintenance, requiring basic to medium-complexity filtration solutions. The MEA region, particularly the UAE and Saudi Arabia, shows incremental growth linked to diversification away from oil economies, focusing on building domestic manufacturing capabilities and infrastructure projects. While these regions currently adopt simpler, cost-effective filtration technologies, increasing industrial maturity and rising quality demands are expected to spur greater investment in automated paper bed filtration systems over the forecast period.

- Asia Pacific (APAC): Dominates the market due to high volume manufacturing, especially in China and India, focusing on automotive and general fabrication sectors.

- North America: Mature market focused on technological sophistication, integrating IoT, and serving the high-precision aerospace and defense industries.

- Europe: Driven by strict environmental and safety regulations; strong demand from specialized machine tool and high-precision engineering firms (Germany, Italy).

- Latin America (LATAM): Growing industrial base, particularly in automotive assembly and resource extraction equipment maintenance in Brazil and Mexico.

- Middle East and Africa (MEA): Emerging market growth linked to industrial diversification efforts and large-scale infrastructure projects requiring local manufacturing support.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Paper Bed Filter Market.- Donaldson Company, Inc.

- Alfa Laval AB

- Barnes International, Inc.

- CLARCOR Industrial Air (Parker Hannifin)

- Filtration Group

- Mayfran International

- PRAB, Inc.

- Losma SpA

- Eriez Manufacturing Co.

- Hydro-Flow Filtration Systems

- KMT Filtration

- Micropure Filtration Inc.

- Flow Pro Products, Inc.

- Monlan Group

- S.P.P. Engineering Private Limited

- Transor Filter, Inc.

- Fluid Systems

- Industrial Filter Manufacturers, Inc.

- Oberlin Filter Company

- LAKOS Filtration

Frequently Asked Questions

Analyze common user questions about the Paper Bed Filter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function and operating mechanism of a paper bed filter?

A paper bed filter is an industrial liquid filtration system that uses gravity or vacuum pressure to push contaminated coolant or oil through a disposable, non-woven filter media (the "paper bed"). It separates solid particulates (swarf, fines) from the fluid. When the media becomes saturated with solids, the liquid level rises, triggering an automatic indexing mechanism to advance fresh filter media, ensuring continuous operation and clean fluid return to the machine.

How do Gravity Filters differ from Vacuum Paper Bed Filters, and which is more efficient?

Gravity filters rely solely on gravity and fluid head pressure for filtration, making them simple and cost-effective, typically used for lower flow rates and coarser particles. Vacuum filters use a vacuum pump to actively draw the fluid through the media, resulting in higher flow rates and significantly finer micron filtration capability (higher efficiency), often required for precision grinding applications.

What major industries drive the demand for paper bed filters?

The demand is primarily driven by industries requiring high-precision metal removal and efficient coolant management. Key sectors include the Automotive industry (engine and transmission component machining), Aerospace and Defense (working with specialized alloys), and Heavy Machinery manufacturing. These industries utilize paper bed filters to protect expensive machine tools and maintain high component quality standards.

What is the most significant operational challenge associated with paper bed filtration?

The most significant operational challenge is the recurring cost and environmental disposal of the spent filter media. Since the media is a consumable item soaked in industrial fluid, managing its procurement, storage, and compliant disposal constitutes a major part of the filter system's Total Cost of Ownership (TCO). Manufacturers are addressing this through predictive indexing technology and developing sustainable, eco-friendly media materials.

How is AI and IoT impacting the future design and performance of paper bed filters?

AI and IoT enable the transformation of paper bed filters into smart, connected devices. This technology allows for predictive maintenance, optimizing media consumption by accurately forecasting when indexing is required, and integrating filtration performance data into centralized factory management systems (IIoT). This enhances efficiency, reduces waste, and minimizes unplanned downtime in manufacturing environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager