Parallel Photoreactors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437404 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Parallel Photoreactors Market Size

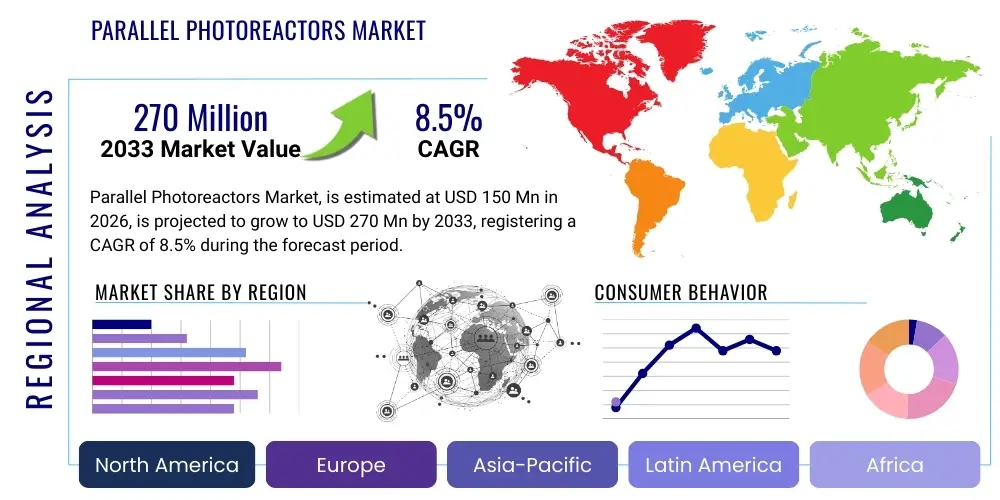

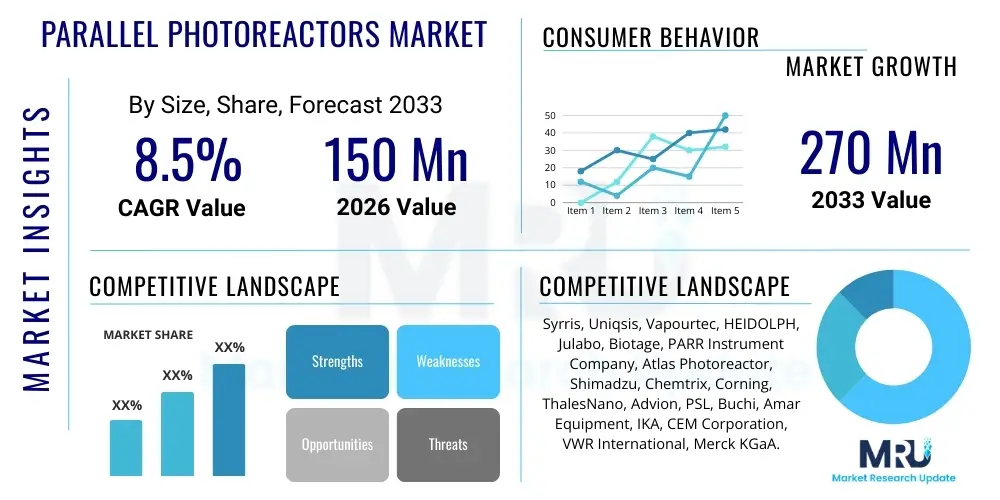

The Parallel Photoreactors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 150 Million in 2026 and is projected to reach USD 270 Million by the end of the forecast period in 2033.

Parallel Photoreactors Market introduction

The Parallel Photoreactors Market encompasses specialized laboratory equipment designed to conduct multiple photochemical reactions simultaneously under controlled conditions. These reactors are crucial tools in high-throughput screening and optimization of synthetic procedures, leveraging light energy to drive chemical transformations that are often difficult or impossible to achieve using traditional thermal methods. The primary product involves integrated systems featuring multiple reaction vessels, precise temperature control, and homogeneous light delivery mechanisms, ranging from UV to visible light sources like LEDs and high-pressure lamps. These systems significantly accelerate research and development cycles, particularly in medicinal chemistry and materials science, where rapid exploration of reaction parameters is essential.

Major applications of parallel photoreactors span across several high-value sectors, including drug discovery, specialty chemical synthesis, and academic research into novel photochemical pathways. In pharmaceutical development, they are indispensable for late-stage functionalization and the production of complex APIs (Active Pharmaceutical Ingredients) using sustainable and efficient processes. The inherent ability of these systems to manage parameters such as light intensity, spectrum, atmosphere, and temperature independently for each reactor vessel provides unparalleled efficiency and reproducibility, directly addressing the industry demand for faster and greener chemical methodologies.

Driving factors for market growth include the increasing global emphasis on sustainable chemistry (Green Chemistry), the rising demand for complex molecules in drug discovery pipelines, and technological advancements leading to highly customizable and automated reactor systems. Furthermore, the shift towards continuous flow photochemistry, often integrated or complemented by parallel static reactor setups, enhances safety and scalability, propelling adoption across industrial and large-scale synthesis environments. The core benefit remains the substantial reduction in time and resources required to identify optimal photochemical conditions, positioning parallel photoreactors as critical infrastructure in modern chemical laboratories.

Parallel Photoreactors Market Executive Summary

The Parallel Photoreactors Market is experiencing robust growth driven primarily by advancements in LED technology and the pervasive adoption of green chemistry principles across pharmaceutical and fine chemical industries. Business trends indicate a strong focus on automation and integration, with manufacturers developing modular systems compatible with robotics and existing high-throughput screening platforms, thereby streamlining workflows and enhancing data generation capabilities. The competitive landscape is characterized by innovation in light delivery systems and miniaturization, catering to demand for high-density screening applications. Geographically, North America and Europe maintain dominance due to high R&D expenditure and strong pharmaceutical sectors, though the Asia Pacific region is emerging rapidly, fueled by increasing investment in contract research organizations (CROs) and growing academic research infrastructure, particularly in China and India. Segmentation trends highlight the increasing preference for Visible Light LED Photoreactors over traditional UV sources due to lower energy consumption, longer lifespan, and enhanced safety profile, while the Drug Discovery application segment remains the largest consumer, seeking faster optimization of novel synthetic routes.

AI Impact Analysis on Parallel Photoreactors Market

Common user inquiries regarding AI in the Parallel Photoreactors Market center on how artificial intelligence can accelerate reaction optimization, predict reaction outcomes, and manage the vast datasets generated by parallel experimentation. Users are keenly interested in predictive modeling capabilities that can minimize the number of physical experiments required, focusing on key themes such as automated data processing, AI-driven parameter selection (e.g., wavelength, solvent, temperature), and integration of machine learning algorithms to map structure-reactivity relationships in photochemistry. Concerns often revolve around the initial investment costs of AI-enabled software and the requirement for robust, standardized data inputs, while expectations include significant reductions in R&D timeframes and the discovery of entirely new, non-intuitive photochemical transformations facilitated by intelligent algorithms. The impact is moving beyond simple data logging towards true autonomous experimentation, where AI dictates the next experimental iteration in real-time, drastically optimizing efficiency.

- AI optimizes experimental design by recommending specific combinations of light source, catalyst, solvent, and temperature, minimizing wasteful trials.

- Machine learning models process high-throughput parallel screening data to predict reaction yields and selectivity with high accuracy.

- Automated data processing and analysis reduce human error and time spent interpreting complex kinetic and spectroscopic data generated by the reactors.

- Integration of AI systems enables autonomous self-optimization loops, where the photoreactor system modifies reaction parameters based on real-time feedback.

- Predictive modeling accelerates drug discovery pipelines by rapidly identifying viable photochemical synthetic routes for complex target molecules.

DRO & Impact Forces Of Parallel Photoreactors Market

The market dynamics for Parallel Photoreactors are shaped by a confluence of accelerating drivers and constraining factors, balanced by compelling future opportunities. A key driver is the fundamental scientific shift towards photochemistry as a cornerstone of sustainable synthesis, offering high atom economy and reduced reliance on harsh reagents and extreme temperatures. Restraints often center on the high capital cost of advanced, automated parallel systems and the specialized expertise required to operate and interpret photochemical reaction data. Opportunities arise from the burgeoning field of photoredox catalysis and the growing application in environmental analysis, such as pollutant degradation studies, coupled with continuous technological refinement leading to more affordable and user-friendly systems. The interplay of these forces defines the market trajectory, leaning towards accelerated adoption in high-budget sectors like pharmaceuticals, while requiring cost-effective solutions for broader academic accessibility.

Drivers are primarily technological and regulatory. The widespread availability of highly efficient, monochromatic LED light sources has revolutionized photoreactor design, allowing precise control over reaction energetics and specificity. Furthermore, stringent environmental regulations pushing the chemical industry towards safer, solvent-free, and energy-efficient processes strongly favor photochemical methods, thus increasing the demand for parallel screening tools to quickly validate green routes. The competitive pressure within the pharmaceutical industry to shorten drug development timelines further necessitates high-throughput technologies capable of rapid optimization, directly boosting the uptake of parallel photoreactors.

However, significant restraints exist, notably the perceived complexity of scaling up optimized parallel reactions to industrial volumes, which requires substantial specialized engineering. Additionally, issues related to light penetration depth in large-volume reactors and potential photodegradation of products remain technical hurdles that necessitate sophisticated engineering solutions and specialized materials, increasing the overall equipment cost. The market is also subject to the cyclical nature of R&D investment, where economic downturns can lead to delayed purchasing decisions for high-cost analytical instruments, impacting short-term growth rates, particularly among smaller research labs and start-ups.

Segmentation Analysis

The Parallel Photoreactors Market segmentation provides a granular view of diverse product offerings, application usage patterns, and end-user behavior. The market is primarily segmented based on the core technology deployed (Reactor Type and Light Source), the area of research utilization (Application), and the purchasing entity (End-User). Analyzing these segments reveals shifting preferences; for instance, the dominance of Glass Photoreactors remains strong due to inertness and visibility, but Micro Photoreactors are rapidly gaining traction for ultra-high-throughput screening and minimal reagent consumption. Similarly, the market is pivoting away from high-energy UV sources towards energy-efficient and specific Visible Light LEDs, which offer superior selectivity in modern photoredox catalysis applications, driving substantial growth in the Chemical Synthesis and Drug Discovery segments.

- By Reactor Type:

- Glass Photoreactors (Standard and Jacketed)

- Stainless Steel Photoreactors

- Micro Photoreactors (Microfluidic Systems)

- By Light Source:

- UV Lamps (Mercury, Xenon)

- Visible Light LEDs (Blue, Green, White)

- Halogen Lamps and Fiber Optic Systems

- By Application:

- Drug Discovery and Development

- Chemical Synthesis (Fine Chemicals, Polymers)

- Material Science Research

- Environmental Testing and Water Treatment Research

- By End-User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Chemical and Petrochemical Industry

- Contract Research Organizations (CROs)

Value Chain Analysis For Parallel Photoreactors Market

The value chain for the Parallel Photoreactors Market begins with the upstream suppliers providing highly specialized components, including precision optics (LEDs, UV lamps, fiber optics), high-grade reaction vessel materials (borosilicate glass, PTFE liners), and advanced temperature control systems (Peltier elements, chillers). These upstream activities are crucial as the performance and longevity of the final reactor heavily depend on the quality and specificity of these components, particularly the homogeneity and stability of the light source. Due to the technical nature of these inputs, supplier power is moderately high, necessitating strong relationships between reactor manufacturers and specialized component providers, especially those supplying high-power LEDs optimized for specific photochemical wavelengths.

The core segment involves the manufacturing and assembly of the parallel photoreactor units. Key activities here include integrating fluid handling, automation capabilities, sophisticated cooling systems, and robust software interfaces necessary for high-throughput operation and data logging. Manufacturers often invest heavily in R&D to enhance system modularity, user safety (e.g., UV containment), and software connectivity for regulatory compliance and data integrity. This stage adds the most significant value, transforming specialized components into integrated, high-precision laboratory instruments ready for complex chemical operations.

Downstream analysis focuses on distribution and end-user adoption. Products are typically distributed through direct sales channels for major pharmaceutical clients requiring customization or via specialized third-party distributors and scientific equipment resellers for academic and smaller industrial labs. Direct sales channels are preferred for high-value, bespoke parallel reactor systems, enabling better post-sales support, installation, and operator training. Indirect channels, while offering broader market reach, require distributors to possess strong technical knowledge regarding photochemical applications. End-user engagement is driven by technical support and ongoing software updates to integrate new photochemical methodologies and compliance features.

Parallel Photoreactors Market Potential Customers

Potential customers for Parallel Photoreactors represent entities heavily invested in chemical innovation, optimization of synthetic processes, and scientific discovery. The primary and most lucrative customer base resides within the Pharmaceutical and Biotechnology sector, encompassing both large multinational drug developers and specialized biotech startups. These entities utilize parallel photoreactors extensively for lead optimization, exploring novel chemical entities (NCEs), and establishing efficient, scalable, and patentable synthetic routes for Active Pharmaceutical Ingredients (APIs), often leveraging advanced photoredox catalysis techniques to access complex molecular scaffolds quickly.

Another significant customer cohort includes Academic and Governmental Research Institutions. Universities and national laboratories frequently employ these reactors for fundamental research in organic chemistry, materials science, and physical chemistry. Their purchasing decisions are often driven by grant availability and the need for state-of-the-art equipment to train future scientists and publish high-impact research on sustainable synthetic methods and novel catalytic systems. While budget constraints might limit purchases of the most high-end automated systems, the demand for versatile, multi-channel research units remains consistently high.

Finally, the Chemical Industry, including manufacturers of fine chemicals, agrochemicals, and specialized polymers, constitutes a growing customer segment. These industrial users focus on process optimization and manufacturing efficiency, seeking parallel photoreactors to screen and optimize conditions for large-scale production, ensuring high yield, purity, and cost-effectiveness. Furthermore, Contract Research Organizations (CROs) act as key intermediaries, purchasing advanced parallel systems to offer high-throughput screening services to pharmaceutical and chemical clients, making them essential buyers focused on maximizing throughput and versatility.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150 Million |

| Market Forecast in 2033 | USD 270 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Syrris, Uniqsis, Vapourtec, HEIDOLPH, Julabo, Biotage, PARR Instrument Company, Atlas Photoreactor, Shimadzu, Chemtrix, Corning, ThalesNano, Advion, PSL, Buchi, Amar Equipment, IKA, CEM Corporation, VWR International, Merck KGaA. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Parallel Photoreactors Market Key Technology Landscape

The technological landscape of the Parallel Photoreactors Market is rapidly evolving, driven primarily by the integration of advanced automation and sophisticated light management systems. A cornerstone technology is the widespread deployment of High-Intensity Light Emitting Diodes (LEDs). Unlike traditional broad-spectrum UV or halogen lamps, LEDs offer narrow bandwidth emission, allowing researchers to precisely tune the light wavelength to match the absorption spectrum of the photocatalyst or reactant. This specificity significantly enhances reaction selectivity, minimizes unwanted side reactions, and dramatically improves energy efficiency. Modern photoreactors utilize large, robust LED arrays coupled with advanced thermal management systems (like Peltier cooling) to maintain stable reaction temperatures, crucial for reproducibility in heat-sensitive photochemical processes.

Another crucial technological development involves the miniaturization and integration of microfluidic technology into parallel photoreactor designs, giving rise to Micro Photoreactors. These systems utilize extremely small reaction volumes, enabling ultra-high-throughput screening while requiring minimal amounts of expensive or rare reagents. Microfluidic channels provide exceptionally high surface area-to-volume ratios, which is critical for efficient light penetration and mass transfer, overcoming traditional limitations associated with scaling light exposure in bulk reactions. This trend towards miniaturization is supported by sophisticated robotic fluid handling systems that automate dosing and sampling across tens or hundreds of parallel reaction chambers simultaneously, greatly accelerating the pace of method development and optimization within drug discovery campaigns.

Furthermore, the technology landscape is being redefined by the push for integrated software and smart laboratory connectivity. Contemporary parallel photoreactors are equipped with intuitive touch screen interfaces and robust data logging capabilities that adhere to strict regulatory standards (e.g., FDA 21 CFR Part 11). They often include integrated sensors for real-time monitoring of key parameters such as pH, dissolved oxygen, and conversion rates via spectroscopy (e.g., in-situ Raman or IR probes). This high level of integration facilitates seamless transfer of experimental data to Laboratory Information Management Systems (LIMS) or AI-driven platforms, enabling autonomous optimization and enhancing the overall efficiency and traceability of photochemical R&D workflows, signifying a major leap towards fully digitalized chemical synthesis laboratories.

Regional Highlights

- North America (NA): Dominates the global market due to the concentration of major pharmaceutical companies, high investment in R&D, and the presence of leading academic institutions focused on chemical innovation. The region leads in adopting advanced, automated parallel systems for drug discovery, driven by competitive pressures to accelerate pipelines and leverage cutting-edge photoredox catalysis research originating from US universities.

- Europe: Represents the second largest market, characterized by strong regulatory support for sustainable and green chemistry initiatives, particularly in countries like Germany and Switzerland. European researchers and manufacturers are quick to adopt high-efficiency LED-based reactors, positioning themselves as leaders in specialized fine chemical synthesis and process optimization using photochemical routes.

- Asia Pacific (APAC): Exhibits the highest growth trajectory, primarily fueled by massive government and private investment in biotechnology and chemical manufacturing across China, India, and South Korea. The rapid expansion of contract research and manufacturing organizations (CRO/CMOs) in this region creates substantial demand for cost-effective, high-throughput parallel screening tools.

- Latin America (LATAM): Growth is steady but moderate, concentrated in educational and governmental research centers in Brazil and Mexico. Market penetration is generally focused on essential research applications, with increasing interest in adopting parallel systems to improve the efficiency of local pharmaceutical and petrochemical research.

- Middle East and Africa (MEA): Currently holds the smallest market share, though growth potential exists in sophisticated research hubs, particularly in Saudi Arabia and the UAE, driven by diversification efforts aimed at establishing world-class scientific infrastructure and boosting pharmaceutical local production capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Parallel Photoreactors Market.- Syrris

- Uniqsis

- Vapourtec

- HEIDOLPH

- Julabo

- Biotage

- PARR Instrument Company

- Atlas Photoreactor

- Shimadzu

- Chemtrix

- Corning Incorporated

- ThalesNano

- Advion, Inc.

- PSL (Process Systems Enterprise)

- Buchi Labortechnik AG

- Amar Equipment

- IKA Werke GmbH & Co. KG

- CEM Corporation

- VWR International (Avantor)

- Merck KGaA (MilliporeSigma)

Frequently Asked Questions

Analyze common user questions about the Parallel Photoreactors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of Visible Light LED Photoreactors over UV-based systems?

Visible Light LED Photoreactors offer precise, monochromatic light control, significantly enhancing reaction selectivity and minimizing byproduct formation compared to broad-spectrum UV systems. LEDs also boast superior energy efficiency, longer operational lifetimes, and significantly improved safety due to reduced exposure to high-energy radiation, aligning with modern green chemistry objectives.

How do Parallel Photoreactors contribute to Green Chemistry initiatives in the chemical industry?

Parallel Photoreactors facilitate Green Chemistry by enabling solvent-free or reduced-solvent reactions, operating at ambient temperatures, and utilizing light as a clean, renewable reagent. Their high-throughput capability allows rapid screening for efficient catalytic systems, thereby reducing waste, energy consumption, and the reliance on harsh, toxic thermal reagents.

Which end-user segment drives the highest demand for advanced automated parallel photoreactor systems?

The Pharmaceutical and Biotechnology sector drives the highest demand. These companies require advanced, automated parallel systems for high-throughput screening and optimization of novel chemical synthesis routes, particularly leveraging photoredox catalysis to accelerate the discovery and development of Active Pharmaceutical Ingredients (APIs).

What major challenges currently restrain the wider adoption of parallel photoreactors in academic settings?

The primary restraints in academic adoption are the high initial capital cost of fully automated, integrated parallel systems and the specialized technical expertise required for optimal operation, maintenance, and complex data interpretation associated with advanced photochemical experimentation.

How is AI specifically integrated into the modern parallel photoreactor workflow to enhance efficiency?

AI is integrated to manage the data generated from parallel experiments and drive autonomous optimization. Machine learning algorithms analyze reaction parameters (light intensity, time, catalyst loading) to predict optimal conditions, drastically reducing the number of physical experiments needed and accelerating the translation of laboratory discoveries into scalable processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager