Parallel Robots Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437935 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Parallel Robots Market Size

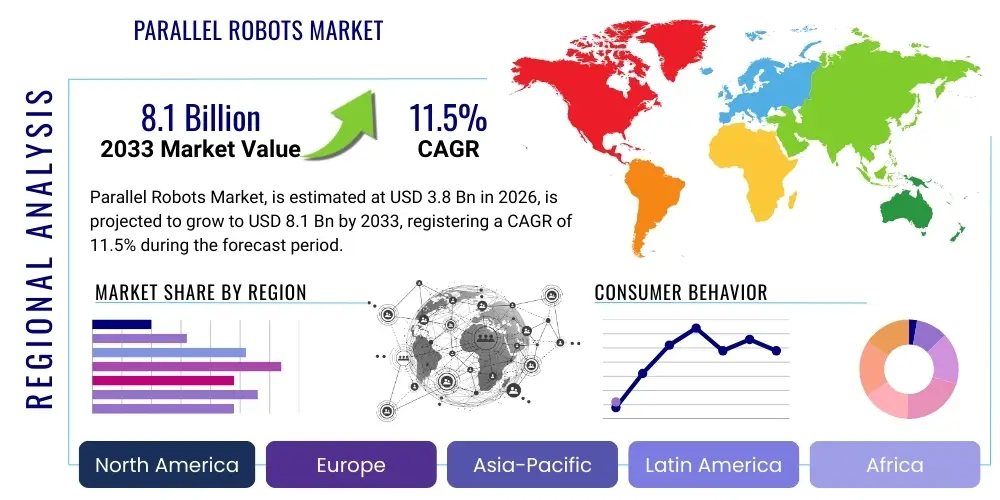

The Parallel Robots Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at $3.8 Billion in 2026 and is projected to reach $8.1 Billion by the end of the forecast period in 2033. This substantial expansion is primarily driven by the increasing demand for high-speed, high-precision automation solutions across various manufacturing sectors, particularly in packaging and assembly lines where cycle time minimization is paramount for operational efficiency and competitive advantage.

Parallel Robots Market introduction

The Parallel Robots Market encompasses highly specialized robotic systems characterized by multiple kinematic chains connecting the base to a single end-effector platform. This architecture, predominantly seen in Delta and sometimes Hexapod configurations, offers significant advantages over traditional serial robots, including superior rigidity, enhanced payload-to-weight ratio, and exceptional speed capabilities, making them indispensable in applications requiring rapid, precise movements over a defined, often smaller, workspace. Key products include various configurations designed for pick-and-place, sorting, handling, and intricate assembly tasks, primarily utilizing lightweight materials like carbon fiber for maximum agility.

Major applications for parallel robots span across highly regulated and high-volume production environments, notably in the food and beverage industry for primary and secondary packaging, pharmaceuticals for sterile handling and inspection, and the electronics sector for micro-assembly and component placement. Their inherent precision minimizes potential damage to delicate items while maximizing throughput. Furthermore, the inherent mechanical design allows for dynamic operations with minimal cumulative positional error, a crucial factor in quality control and continuous process improvement strategies adopted globally.

The primary driving factors propelling market growth include the relentless global push toward industrial automation (Industry 4.0), escalating labor costs in developed economies, and the necessity for superior hygiene standards in sensitive production areas. Parallel robots, often constructed from stainless steel or composite materials compliant with FDA/EHEDG standards, meet these rigorous requirements. The substantial benefits realized by end-users, such as reduced operational expenditure, improved quality consistency, and enhanced production scalability, solidify the strategic investment case for adopting these advanced robotic solutions.

Parallel Robots Market Executive Summary

The global Parallel Robots Market is witnessing robust business trends marked by increased merger and acquisition activities focused on bolstering software capabilities and expanding geographic distribution networks. Key industry trends indicate a strong move toward collaborative parallel robots (cobots), enabling safe human-robot interaction and integration into flexible production layouts without extensive safety caging. Furthermore, manufacturers are focusing heavily on developing vision-integrated systems that utilize sophisticated machine learning algorithms to handle randomly oriented items, thereby increasing application flexibility beyond traditional structured environments and overcoming previous limitations associated with complex part presentation methods.

Regional trends highlight the Asia Pacific (APAC) region as the dominant market driver, fueled by massive investments in factory automation, particularly in China, South Korea, and Japan, which serve as global manufacturing hubs for electronics, automotive components, and consumer goods. North America and Europe, while mature, demonstrate sustained growth driven by the need for reshoring manufacturing operations and adopting advanced robotic solutions to combat labor shortages and maintain high quality standards. Regulatory environments in these regions strongly encourage automation technologies that improve worker safety and compliance with stringent quality metrics.

Segment trends underscore the dominance of the Delta configuration due to its versatility and established track record in high-speed pick-and-place operations. However, the use of custom parallel kinematics, especially Hexapods, is rapidly gaining traction in high-precision, force-feedback applications such as simulation, advanced testing, and micro-manipulation. The segmentation by end-user shows the Food and Beverage sector maintaining the largest share, characterized by high-volume, repetitive tasks, while the Pharmaceuticals and Healthcare sector is projected to exhibit the fastest growth owing to increasing complexity in drug packaging and diagnostics handling requiring ultra-clean, precise automation.

AI Impact Analysis on Parallel Robots Market

User queries regarding the impact of Artificial Intelligence (AI) on the Parallel Robots Market frequently revolve around optimizing complex motion planning, enhancing real-time adaptability, and integrating predictive maintenance capabilities. Users are keen to understand how AI can solve the challenges of kinematic complexity inherent in parallel structures and maximize the efficiency of high-speed trajectories. Key concerns often focus on the computational requirements for implementing advanced reinforcement learning models and the cybersecurity implications of connecting highly autonomous robotic cells to centralized AI platforms. Expectations center on AI dramatically reducing commissioning time, improving error recovery, and unlocking capabilities for handling unstructured, highly variable tasks that traditional programmed robots cannot manage efficiently.

The integration of AI significantly transforms the operational profile of parallel robots, transitioning them from purely programmed deterministic machines to cognitive, adaptive systems. AI algorithms, specifically deep learning models applied to robot vision, allow parallel robots to perform high-speed inspection and quality checks with human-level accuracy, recognizing defects, color variations, or incorrect placements in real-time. This capability is paramount in high-throughput environments where even minor production bottlenecks can lead to substantial losses, enabling immediate process adjustments and minimizing waste materials, thereby enhancing the overall equipment effectiveness (OEE).

Furthermore, AI-driven predictive maintenance utilizes sensor data collected from motor current, temperature, and vibration analysis to forecast component failure in high-wear mechanisms, such as joints and linkages, which are critical in parallel robot architectures due to the constant high-frequency movement. By anticipating maintenance needs, unscheduled downtime is drastically reduced, ensuring continuous operation, which is a key performance indicator in highly automated production lines. AI also facilitates optimal load balancing and trajectory optimization, dynamically adjusting the robot's movement based on real-time feedback to conserve energy and reduce mechanical stress, extending the robot's service life and lowering the total cost of ownership (TCO).

- AI optimizes complex path planning and trajectory generation, crucial for maximizing the speed and precision of Delta robots.

- Machine Vision integrated with AI allows for enhanced sorting of randomly presented objects and superior quality inspection at high velocities.

- Predictive maintenance implemented via AI monitors joint wear and motor performance, significantly reducing unscheduled downtime and improving system reliability.

- Reinforcement learning enables parallel robots to quickly adapt to variances in product geometry or palletizing patterns without extensive reprogramming.

- AI improves energy efficiency by dynamically adjusting acceleration and deceleration profiles based on the current payload and desired cycle time.

DRO & Impact Forces Of Parallel Robots Market

The Parallel Robots Market dynamics are governed by powerful drivers such as the overwhelming global need for high-speed automation solutions and escalating labor costs in industrialized nations, making rapid ROI from robotics increasingly attractive. Opportunities emerge primarily through the development of collaborative parallel robots (cobots) for smaller businesses (SMEs) and the expansion of applications into secondary markets like logistics and specialized healthcare handling. However, the market faces significant restraints, chiefly the complexity associated with integrating these advanced systems, the necessity for specialized programming skills, and the relatively higher initial capital investment compared to standard SCARA or linear robots, particularly for low-payload applications.

Key impact forces shaping the market include technological advancements in control systems and material science. The continuous improvement in servo motor technology and the use of ultra-lightweight carbon composite materials directly enable faster acceleration and higher payload capacity, thereby expanding the applicability of parallel robots into sectors previously reliant on slower, heavier machinery. Furthermore, the standardization of communication protocols, such as OPC-UA and EtherCAT, facilitates seamless integration into existing Industrial Internet of Things (IIoT) frameworks, boosting operational data transparency and process control, which accelerates adoption across large manufacturing enterprises committed to digital transformation.

The strong impetus from regulatory standards, particularly those governing food safety and pharmaceutical traceability (e.g., CFR 21 Part 11 compliance), heavily favors the sterile, contamination-resistant design inherent in many parallel robot architectures. This regulatory pull ensures sustained demand in high-compliance sectors. Conversely, the market’s reliance on specialized integrators for complex implementation acts as a dampening force, creating a bottleneck for widespread adoption in regions lacking adequate technical expertise. Overcoming this restraint through simplified teaching interfaces and standardized application modules presents a significant growth opportunity for leading market participants seeking to democratize access to high-speed automation.

Segmentation Analysis

The Parallel Robots Market segmentation provides a detailed structure for analyzing market trends based on configuration type, application, payload capacity, and end-user industry. This granular analysis is crucial for strategic planning and identifying high-growth pockets within the market landscape. The configuration segment, dominated by Delta robots, reflects the primary demand for rapid pick-and-place tasks, while the growth in Hexapod and custom kinematics demonstrates the increasing necessity for sophisticated multi-axis control and high-precision simulation capabilities. Understanding these segment dynamics helps stakeholders tailor product development and market penetration strategies effectively.

- By Configuration:

- Delta Robots (3-axis, 4-axis, 6-axis variants)

- Hexapod Robots (6-DOF systems)

- Custom Parallel Kinematics Machines (PKMs)

- By Payload Capacity:

- Light (Up to 1 kg)

- Medium (1 kg to 3 kg)

- Heavy (Above 3 kg)

- By Application:

- Pick-and-Place

- Packaging and Palletizing

- Assembly and Dispensing

- Inspection and Quality Control

- Testing and Simulation

- By End-User Industry:

- Food and Beverage

- Pharmaceuticals and Healthcare

- Electronics and Semiconductor

- Automotive and Aerospace

- Logistics and Warehouse Automation

Value Chain Analysis For Parallel Robots Market

The Parallel Robots value chain initiates with the upstream analysis, primarily involving specialized component suppliers providing high-performance materials such as carbon fiber composites for linkages, sophisticated servo motors, precision gearboxes, and advanced sensor technologies (e.g., force sensors, high-resolution cameras). The quality and reliability of these upstream inputs are paramount, as the high acceleration and rapid cycle times inherent to parallel robots place extreme stress on mechanical components. Strategic relationships with niche suppliers who can maintain consistency and innovation in lightweight, durable materials are crucial for robot manufacturers seeking to enhance speed and extend maintenance intervals.

The central segment of the value chain involves the design, manufacturing, and assembly of the parallel robot systems. This phase requires significant expertise in kinematics modeling, control algorithm development, and highly clean assembly processes, especially for units destined for food or pharmaceutical applications. Distribution channels are bifurcated into direct sales for major global manufacturers handling large, complex enterprise projects, and indirect channels relying on a network of certified system integrators (SIs) and distributors. System integrators play a vital role, especially in the downstream market, as they bridge the gap between complex robotic technology and specific end-user application requirements, often customizing end-effectors (grippers, vacuum tools) and programming the vision systems.

Downstream analysis focuses on installation, commissioning, maintenance, and aftermarket services. The complexity of parallel robot systems necessitates specialized training and prompt technical support, driving opportunities for recurring service revenue. Direct and indirect distribution channels both rely heavily on the system integration partners for localized support and maintenance contracts. End-user satisfaction is heavily dependent on the efficiency of this downstream support, emphasizing the strategic importance of building a robust and technically proficient ecosystem of service providers capable of handling intricate mechanical diagnostics and software updates, ensuring maximum uptime for highly automated production environments.

Parallel Robots Market Potential Customers

The primary potential customers for parallel robots are large manufacturing enterprises operating high-volume production lines that require exceptional speed, precision, and consistency for repetitive tasks. Industries such as multinational food processors, global pharmaceutical companies, and major consumer electronics manufacturers constitute the core buyer base. These customers often require automation solutions that adhere to strict regulatory compliance, demanding features like food-grade lubricants, stainless steel construction, and sterile design, making parallel robots an optimal choice due to their enclosed structure and easy cleanability.

Secondary, yet rapidly expanding, customer segments include smaller to mid-sized enterprises (SMEs) that are beginning to adopt automation to compete effectively on quality and cost. While SMEs previously faced barriers due to high capital investment and complex integration, the rise of collaborative parallel robot variants (cobots) that are easier to program and deploy, coupled with flexible financing options, has significantly lowered the entry barrier. These SME customers are typically found in regional packaging hubs or specialized component assembly facilities that require flexible changeovers and minimal footprint utilization on the factory floor.

Moreover, specialized institutions, including research laboratories, advanced testing facilities, and aerospace manufacturers, represent high-value, niche customers. These entities often purchase Hexapod configurations for demanding applications such as flight simulation, vibration testing of critical components, or high-precision tool positioning. In these scenarios, the key buying criteria are less focused on high throughput and more centered on extreme positional accuracy, high degrees of freedom (DOF), and the ability to handle heavy payloads with microscopic precision and repeatability over an extended operational envelope.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $3.8 Billion |

| Market Forecast in 2033 | $8.1 Billion |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., FANUC Corporation, Yaskawa Electric Corporation, KUKA AG, Kawasaki Heavy Industries, Mitsubishi Electric Corporation, Seiko Epson Corporation, COMAU S.p.A., Universal Robots A/S, Schunk GmbH & Co. KG, Staubli International AG, Codian Robotics, Parpas, Omron Corporation, Festo SE & Co. KG, HIWIN Corporation, Wipro Infrastructure Engineering (WIN), Rethink Robotics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Parallel Robots Market Key Technology Landscape

The technological landscape of the Parallel Robots Market is rapidly evolving, driven by advancements in advanced kinematics, material science, and integrated control systems. A primary focus area is the development of next-generation control algorithms that can efficiently handle the complex inverse kinematics calculations required for parallel structures, ensuring smooth, vibration-free motion at extremely high speeds. These algorithms are increasingly incorporating machine learning to predict and compensate for minor mechanical deflections or thermal drift, thereby maintaining sub-millimeter precision over extended operational periods, which is critical for sensitive tasks like semiconductor handling and high-speed bottling.

Another crucial technological advancement involves the pervasive integration of advanced sensor fusion, combining high-definition 3D vision systems with force/torque sensors located at the wrist or end-effector. This fusion enables parallel robots to achieve true flexibility, allowing them to accurately locate, identify, and manipulate objects whose position or orientation may vary, moving beyond the constraints of highly structured conveyor belt systems. Furthermore, the adoption of collaborative robot technologies (cobots) based on parallel architectures requires sophisticated safety-rated control systems and lightweight structural designs that can instantaneously detect human proximity and halt motion, ensuring compliance with ISO/TS 15066 safety standards while maximizing collaborative efficiency.

Material innovation, specifically the use of advanced composites and highly optimized actuator technology, continues to be a cornerstone of competitive advantage. Manufacturers are leveraging ultra-lightweight carbon fiber linkages to significantly reduce the moving mass, allowing for higher acceleration rates and lower power consumption while maintaining exceptional rigidity necessary for precision work. Concurrently, the proliferation of digital twin technology is allowing manufacturers and end-users to simulate the entire robot cell and production sequence virtually before physical deployment, drastically reducing integration time and mitigating risks associated with complex multi-robot coordination and collision avoidance in highly constrained workspaces.

Regional Highlights

Regional dynamics play a crucial role in shaping the Parallel Robots Market, reflecting varying levels of industrial maturity, labor costs, and governmental support for automation technologies. The Asia Pacific (APAC) region stands out as the largest and fastest-growing market, largely due to its status as the global manufacturing powerhouse. Countries like China, driven by policies such as "Made in China 2025," have aggressively invested in advanced robotics to enhance manufacturing capabilities and address rapidly rising domestic labor wages. Japan and South Korea, mature adopters, continue to drive innovation in high-precision electronics and automotive components, maintaining strong demand for high-speed parallel kinematics systems.

North America, characterized by high labor costs and a strategic emphasis on manufacturing quality and resilience (reshoring), represents a significant market. Adoption is particularly strong in the specialized food processing and pharmaceutical sectors, where regulatory compliance and hygiene are top priorities. The U.S. market demands sophisticated, high-throughput solutions capable of managing complex packaging variations and providing extensive data connectivity for traceability and performance monitoring, leveraging high investment capacities to integrate cutting-edge AI and vision technologies.

Europe maintains a leading position in advanced manufacturing and collaborative robotics. Nations such as Germany, Italy, and Switzerland prioritize the integration of highly flexible and safe collaborative parallel robots (cobots) into existing production lines. Driven by stringent EU quality standards and the need for energy-efficient production, European manufacturers invest heavily in highly efficient, low-maintenance parallel systems that can easily comply with complex machinery directives. The adoption rate here is steady, focused on optimizing highly customized and specialized production rather than pure volume growth.

- Asia Pacific (APAC): Dominant market share and fastest growth driven by massive investments in electronics, automotive, and high-volume packaging automation in China and South Korea.

- North America: Strong adoption in regulated industries (Food & Beverage, Pharma); growth fueled by reshoring initiatives and necessity for high-speed, integrated AI vision systems to combat labor shortages.

- Europe: Focus on collaborative parallel robotics (cobots) and high-precision systems for specialized manufacturing and logistics, emphasizing energy efficiency and strict quality compliance (Germany, Italy).

- Latin America: Emerging market with increasing penetration in basic packaging and sorting processes, primarily driven by foreign direct investment in large-scale food and consumer goods production facilities.

- Middle East and Africa (MEA): Nascent growth concentrated in specific large-scale industrial projects, particularly in food production and logistics in the GCC countries, supported by large infrastructural development plans.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Parallel Robots Market.- ABB Ltd.

- FANUC Corporation

- Yaskawa Electric Corporation

- KUKA AG (Midea Group)

- Kawasaki Heavy Industries, Ltd.

- Mitsubishi Electric Corporation

- Seiko Epson Corporation

- COMAU S.p.A.

- Universal Robots A/S (Teradyne)

- Staubli International AG

- Omron Corporation

- Festo SE & Co. KG

- Codian Robotics

- HIWIN Corporation

- Rethink Robotics GmbH

- Bosch Rexroth AG

- I-Robots (Nachi-Fujikoshi Corp.)

- Wipro Infrastructure Engineering (WIN)

Frequently Asked Questions

Analyze common user questions about the Parallel Robots market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a parallel robot and how does it differ from a serial robot?

A parallel robot (e.g., Delta or Hexapod) uses multiple rigid kinematic chains to connect the base to the end-effector. This structure provides superior stiffness, high payload-to-weight ratios, and extreme speed, distinguishing it from serial robots (e.g., articulated arms) which use a single chain, offering larger workspaces but lower rigidity and speed.

Which industries are the primary drivers of demand for high-speed parallel robots?

The highest demand is generated by the Food and Beverage industry for high-speed primary and secondary packaging (pick-and-place), followed closely by the Pharmaceuticals sector requiring sterile handling, and the Electronics industry for micro-assembly tasks requiring high precision and throughput.

What are the main technical limitations of implementing parallel robot systems?

Primary limitations include a significantly smaller working envelope compared to serial robots, complex kinematic modeling requiring specialized control software, and higher initial capital investment. Effective implementation also demands specialized expertise for programming and integration, especially for dynamic trajectory optimization.

How is Artificial Intelligence (AI) enhancing the capabilities of parallel robots?

AI integration enhances parallel robot capabilities primarily through sophisticated machine vision for handling unstructured input, real-time trajectory optimization to maximize cycle speeds, and predictive maintenance algorithms that utilize sensor data to minimize unexpected operational downtime.

What is the projected growth trajectory for collaborative parallel robots (cobots)?

Collaborative parallel robots are projected to be the fastest-growing segment, driven by the increasing need for flexible automation solutions in small and medium enterprises (SMEs). Their compact design, safety features allowing operation alongside human workers, and easier programming facilitate rapid deployment and faster return on investment in varied manufacturing settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Parallel Robots Market Size Report By Type (Double Arms, Multiple Arms, Hexapods, Delta Robots), By Application (Food and Beverages, Medical, Electronics, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Parallel Robots Market Statistics 2025 Analysis By Application (Food Industry, Pharmaceutical Industry, Daily Chemical Industry, 3C Industry), By Type (Multi-Axis, Two-Axis), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager