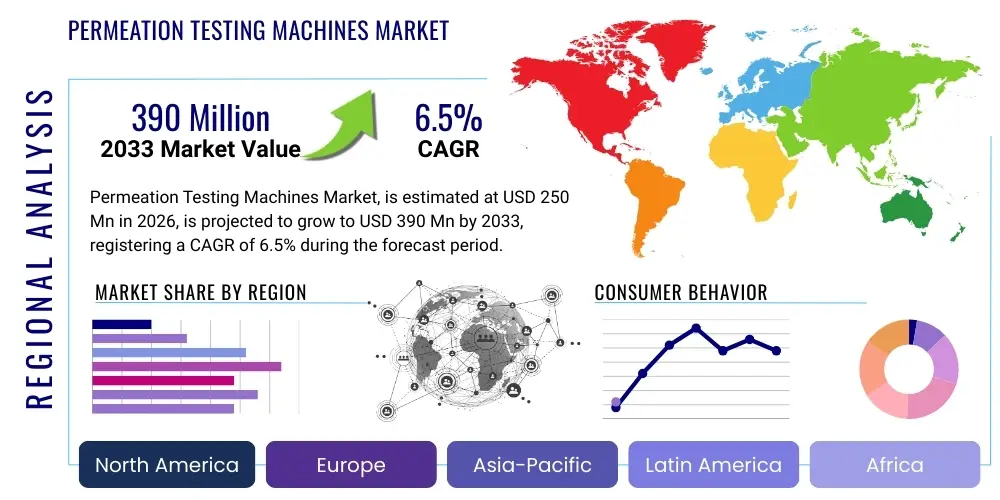

Permeation Testing Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436878 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Permeation Testing Machines Market Size

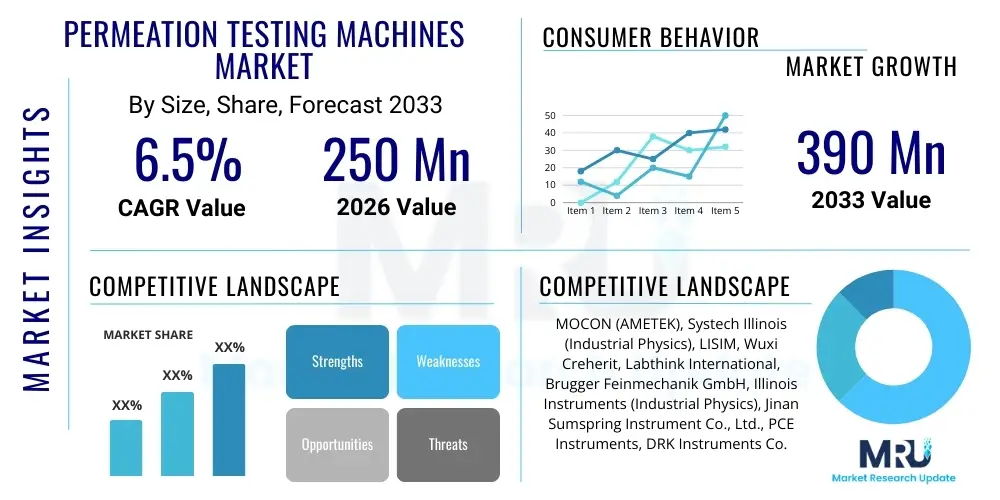

The Permeation Testing Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $250 Million in 2026 and is projected to reach $390 Million by the end of the forecast period in 2033.

Permeation Testing Machines Market introduction

The Permeation Testing Machines Market encompasses specialized laboratory equipment designed to measure the rate at which gases (such as oxygen, water vapor, nitrogen, or carbon dioxide) or liquids pass through barrier materials. These machines are critical for quality control, research and development, and material certification across numerous industries, particularly packaging, pharmaceuticals, food and beverage, and electronics. The fundamental principle involves creating a differential pressure or concentration gradient across a film or material sample, allowing precise measurement of the permeability coefficient. Accurate permeation data is essential for determining shelf life, product integrity, and compliance with strict regulatory standards concerning product packaging and material specifications. The need for precise moisture and oxygen transmission rates (MVTR and OTR) drives continuous innovation in sensor technology and machine automation.

The primary applications of these testing machines span flexible packaging, where films must prevent spoilage and maintain freshness, to the pharmaceutical sector, where barrier materials protect sensitive drugs from degradation due to moisture or gas ingress. Furthermore, the growing use of high-barrier films in solar panels and OLED displays necessitates stringent barrier testing to ensure long-term device performance and reliability. Key benefits derived from utilizing these systems include enhanced product safety, optimized material usage, reduced operational costs associated with product recall, and the acceleration of R&D cycles for new barrier polymers. Manufacturers are increasingly integrating features like multi-cell testing, automated temperature control, and high-sensitivity detection methods to improve efficiency and measurement accuracy.

Market driving factors include the global shift towards sustainable and high-performance packaging solutions, which require novel barrier films with verifiable permeation characteristics. Regulatory frameworks, such as those imposed by the FDA and other international bodies, mandate specific barrier performance levels for food contact materials and medical devices, thereby boosting demand for certified testing equipment. Moreover, the increasing complexity of materials, including multilayer structures and bio-based plastics, demands sophisticated testing apparatus capable of handling diverse sample types and environmental conditions. The ongoing miniaturization of electronics and the expanding cold chain logistics industry further underline the indispensable role of precise permeation testing in maintaining product quality globally.

Permeation Testing Machines Market Executive Summary

The Permeation Testing Machines Market is witnessing robust growth, primarily propelled by escalating demand for quality assurance in food, pharmaceutical, and specialty chemical packaging. Business trends indicate a strong move toward fully automated, high-throughput testing solutions that minimize manual intervention and maximize data accuracy, catering to large-scale manufacturing environments. Key industry players are focusing on developing hybrid systems capable of simultaneously measuring both Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR), improving laboratory efficiency and reducing the total cost of ownership. Strategic partnerships between equipment manufacturers and material science companies are accelerating the adoption of new testing standards for advanced barrier materials, particularly those required for sensitive electronics and next-generation medical implants.

Geographically, Asia Pacific remains the dominant and fastest-growing region, fueled by rapid industrialization, expansion of the food processing sector, and massive investment in pharmaceutical manufacturing, particularly in China and India. North America and Europe maintain significant market shares, characterized by stringent regulatory environments that necessitate high-precision testing and a strong focus on advanced material research and sustainability goals. Regional trends highlight increasing regulatory harmonization efforts, pushing equipment manufacturers to ensure their machines comply with global standards like ASTM and ISO, thus facilitating international trade and adoption.

Segment trends reveal that the Water Vapor Permeation Testing segment holds the largest market share due to the ubiquitous requirement for moisture protection across almost all packaged goods. However, the Multi-Gas Permeation Testing segment is projected to exhibit the highest CAGR, driven by the need to understand complex gas interactions in modified atmosphere packaging (MAP). Technology-wise, the sensors and instruments employing coulometric (for OTR) and infrared detection (for WVTR) techniques dominate, offering unparalleled sensitivity and measurement precision critical for ultra-high barrier applications. End-user segmentation shows that the packaging industry remains the primary consumer, but pharmaceutical and materials research laboratories are expanding their procurement significantly to support novel drug delivery systems and sustainable material development.

AI Impact Analysis on Permeation Testing Machines Market

Common user inquiries concerning AI in the Permeation Testing Machines Market revolve around data handling, predictive maintenance, and calibration accuracy. Users frequently ask how AI can automate the interpretation of complex, noisy measurement data and whether machine learning algorithms can predict material performance degradation over time based on initial permeation characteristics. There is significant interest in using AI for optimizing testing protocols, reducing the number of physical tests required, and flagging anomalies or calibration drifts automatically. Users are seeking assurances that AI integration will lead to higher reproducibility and faster R&D cycles, rather than introducing new layers of complexity or increasing reliance on specialized data science personnel. The summarized theme is that users expect AI to transition permeation testing from a reactive measurement process to a proactive, predictive material science tool.

- AI-driven Data Analysis: Automated processing of large datasets generated by multi-cell testing, minimizing human error in interpreting complex permeation curves.

- Predictive Maintenance: Utilization of machine learning to monitor sensor health and predict necessary calibration or component replacement, ensuring maximum uptime and data reliability.

- Optimized Testing Protocols: Algorithms suggest the optimal temperature, humidity, and test duration for specific material types, reducing test cycle time.

- Material Performance Prediction: AI models correlate permeation data with material structure and external conditions (e.g., storage environment) to accurately forecast shelf life and barrier longevity.

- Anomaly Detection: Real-time identification of inconsistent test results caused by sample defects or environmental fluctuations, enhancing quality control robustness.

DRO & Impact Forces Of Permeation Testing Machines Market

The Permeation Testing Machines Market is primarily driven by the expansion of regulated industries requiring verifiable barrier properties and the ongoing innovation in advanced material science. Restraints include the high initial cost of high-precision testing equipment and the technical complexity involved in setting up and operating highly sensitive detection systems, particularly for ultra-low permeation rate measurements. Opportunities abound in emerging economies adopting global packaging standards and the increasing global focus on developing fully biodegradable and compostable barrier materials, which require new standardized testing methodologies. The competitive forces within this market are shaped by technological differentiation and the need for global service and calibration support, making proprietary sensor technology a significant barrier to entry for new competitors.

Drivers: Strict regulatory requirements regarding food safety and pharmaceutical integrity mandate precise barrier testing. The rapid growth of the global flexible packaging market, coupled with the rising consumer demand for extended shelf life and reduced preservatives, necessitates high-performance barrier films, driving the need for sophisticated OTR and WVTR machines. Additionally, the proliferation of sensitive electronic components, such as OLEDs and photovoltaics, requires ultra-high barrier testing capabilities to prevent catastrophic failure from moisture ingress over time.

Restraints: The capital investment required for acquiring high-end, multi-gas permeation testing systems can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, maintaining the required calibration standards and skilled personnel to operate and interpret results from highly sensitive testing equipment poses a constant challenge. Market penetration in specific regions is also hampered by the lack of standardized testing protocols for novel or experimental barrier coatings, leading to uncertainty among potential buyers.

Opportunities: The growing market for sustainable packaging materials, including bio-plastics and recycled content polymers, presents substantial opportunities for equipment manufacturers to develop specialized testing protocols and machines optimized for these new substrates. Expansion into new application areas such as automotive components (e.g., fuel cell membranes) and advanced medical textiles (e.g., wound dressings) offers diversification. The rise of centralized testing laboratories serving multiple clients further represents an opportunity for adopting high-throughput, automated testing platforms.

Impact Forces: The bargaining power of buyers is moderate, influenced by the high specialization of the equipment; however, the availability of comprehensive service contracts is often a deciding factor. The threat of substitutes is low, as physical permeation testing remains indispensable for certification and quality control, although predictive modeling (leveraging AI) may eventually reduce the volume of routine testing. Supplier power is high for manufacturers specializing in proprietary, high-sensitivity sensor components (e.g., coulometric sensors). Competitive rivalry is high among the few dominant global players who continuously compete on accuracy, automation features, and compliance with emerging global standards.

Segmentation Analysis

The Permeation Testing Machines market is comprehensively segmented based on the type of permeant measured, the detection technology utilized, the automation level, and the end-use industry. This structure allows for precise market sizing and strategic targeting. The Water Vapor Permeation Testing segment is currently the most mature and largest, driven by universal moisture sensitivity across food and chemical industries. Conversely, the technology segmentation highlights the dominance of high-precision methods like Coulometric (for OTR) and Infrared (for WVTR), although faster, less sensitive methods like differential pressure are used for high-permeability screening. Geographic segmentation underscores the intense growth expected from emerging Asian economies prioritizing product quality and regulatory compliance.

- By Permeant Type:

- Oxygen Permeation Testing (OTR) Machines

- Water Vapor Permeation Testing (WVTR) Machines

- Carbon Dioxide Permeation Testing Machines

- Multi-Gas Permeation Testing Machines (e.g., Nitrogen, Helium)

- By Technology:

- Coulometric Sensors (ASTM D3985)

- Infrared Sensors (ASTM F1249)

- Differential Pressure Sensors

- Electrochemical Sensors

- Manometric Method

- By Automation Level:

- Manual/Semi-Automatic Systems

- Fully Automatic/High-Throughput Systems

- By End-User Industry:

- Packaging (Flexible and Rigid)

- Pharmaceuticals and Medical Devices

- Food and Beverage

- Material Science Research

- Chemical and Petrochemical

- Electronics (OLED, Photovoltaics)

- By Geographical Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East and Africa (MEA)

Value Chain Analysis For Permeation Testing Machines Market

The value chain for permeation testing machines begins with the upstream sourcing of highly specialized components, primarily high-precision sensors (e.g., electrolytic, infrared), specialized flow control systems, temperature and humidity control units, and robust data acquisition hardware/software. Key upstream dependencies include the semiconductor industry for sensor manufacturing and specialized material fabricators for creating the necessary high-integrity testing cells. Manufacturer profitability relies heavily on securing reliable, high-quality component suppliers and maintaining intellectual property protection over proprietary detection algorithms and cell designs. The complexity of these components means that supplier bargaining power, particularly for proprietary sensors, is relatively high, necessitating strong long-term relationships and stringent quality control at the manufacturing level.

The manufacturing stage involves the precision assembly, rigorous calibration, and quality assurance testing of the complex integrated systems. Manufacturers invest heavily in R&D to enhance detection limits (to ppb levels), improve automation features, and ensure compliance with international standards (ISO, ASTM). Distribution channels are critical, often combining direct sales for high-value contracts with technical expertise requirements, alongside indirect channels utilizing specialized regional distributors or laboratory equipment suppliers. These indirect partners provide local service support, installation, and essential application training, especially in geographically dispersed or emerging markets, optimizing market penetration and reducing manufacturer logistics overheads.

Downstream activities center on post-sale services, including installation, extensive application training, routine calibration (a mandatory regulatory requirement), and preventative maintenance contracts. For customers in the highly regulated pharmaceutical and electronics sectors, reliable, traceable calibration services are non-negotiable, providing a sustainable revenue stream for manufacturers. Direct distribution, characterized by manufacturer sales engineers interacting directly with large corporate R&D centers and quality labs, ensures expert consultation and tailored solutions. Indirect channels, typically through lab equipment dealers, are effective for standard models targeting universities or smaller contract testing facilities, leveraging the dealer's existing client base and logistical infrastructure. The efficiency of the service network directly impacts customer satisfaction and repeat business, making it a critical competitive differentiator.

Permeation Testing Machines Market Potential Customers

Potential customers for permeation testing machines are organizations whose product quality, safety, and shelf life are intrinsically linked to the barrier properties of the packaging or material used. The packaging conversion industry, which produces flexible films, rigid containers, and laminates, represents the largest customer base, using these machines for raw material quality control and final product certification before distribution. Pharmaceutical companies and contract research organizations (CROs) constitute another vital segment, employing these systems to assess packaging integrity for sensitive drugs, sterile medical devices, and moisture-sensitive powders, ensuring compliance with stability testing guidelines.

The food and beverage sector utilizes these machines extensively, particularly in the production of modified atmosphere packaging (MAP) and aseptic packaging, to guarantee long-term freshness, prevent oxidation, and reduce food waste. Furthermore, academic institutions, government research laboratories, and material science departments of chemical companies are significant buyers, focusing on R&D for next-generation barrier polymers, sustainable materials, and advanced coating technologies. These end-users demand versatility and high-resolution measurement capabilities to accurately characterize novel materials often operating under diverse temperature and humidity conditions, driving demand for specialized and flexible laboratory systems.

A rapidly emerging customer segment includes manufacturers in the advanced electronics industry, specifically those producing Organic Light Emitting Diodes (OLEDs), flexible displays, and photovoltaic (solar) cells. These products require ultra-high barrier films (often measured in 10-6 g/m²·day), demanding the most sophisticated and sensitive testing equipment available, such as those employing specialized calcium tests or high-sensitivity coulometric sensors. The need for absolute reliability and verifiable performance in these high-value devices makes these customers prioritize accuracy and traceability over cost, favoring premium, automated systems from established market leaders.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $250 Million |

| Market Forecast in 2033 | $390 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MOCON (AMETEK), Systech Illinois (Industrial Physics), LISIM, Wuxi Creherit, Labthink International, Brugger Feinmechanik GmbH, Illinois Instruments (Industrial Physics), Jinan Sumspring Instrument Co., Ltd., PCE Instruments, DRK Instruments Co., Ltd., Precise Testing Machines, Shenzhen Neopak Co., Ltd., Nü-Tec GmbH, Meishuo Instruments, C.W. Brabender Instruments, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Permeation Testing Machines Market Key Technology Landscape

The technological landscape of the Permeation Testing Machines Market is defined by the pursuit of enhanced sensitivity, speed, and automation necessary to handle increasingly sophisticated barrier materials. Key technological advancements center around optimizing detection methods. For Oxygen Transmission Rate (OTR) measurement, the Coulometric Sensor (or highly sensitive electrolytic detection) remains the gold standard, offering the highest sensitivity (down to 0.005 cc/(m²·day)) required for ultra-barrier films used in electronics. Recent innovations focus on reducing the purge time and enhancing the stability of these sensors under varying humidity conditions, thereby increasing throughput without sacrificing precision. The integration of advanced microfluidic controls allows for highly stable and precise regulation of carrier gases and testing environments.

For Water Vapor Transmission Rate (WVTR) measurement, the Infrared Sensor technique, often coupled with differential pressure methods, dominates the high-precision market. Modern infrared technology has improved stability and reduced baseline drift, enabling rapid and accurate measurements down to very low levels. A crucial technological trend is the development of modular and multi-cell testing systems. These systems allow laboratories to simultaneously test multiple samples under different conditions (temperature, humidity), dramatically accelerating the material characterization process. Furthermore, manufacturers are incorporating advanced software interfaces that comply with regulatory requirements such as FDA 21 CFR Part 11, ensuring data integrity, audit trails, and secure electronic records, which are vital for pharmaceutical applications.

Emerging technologies include fluorescence-based sensors and advanced optical methods that offer non-destructive testing capabilities, potentially reducing sample preparation time and complexity. There is also a significant push towards integrating advanced temperature and humidity mapping within the testing cells, providing a more realistic simulation of actual end-use storage conditions, which is particularly relevant for MAP and pharmaceutical packaging integrity studies. The convergence of software and hardware, allowing for remote diagnostics, automated calibration reminders, and cloud-based data storage and retrieval, is becoming standard, catering to the globalization of R&D and quality control operations across multinational corporations.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by massive consumption growth in food and beverage and the establishment of global manufacturing hubs for pharmaceuticals and electronics (China, India, South Korea). The region benefits from lower manufacturing costs and increasing local adoption of international quality standards (ISO/ASTM), fueling demand for high-volume, reliable testing equipment.

- North America: North America holds a substantial market share, characterized by high adoption rates of premium, automated systems, driven by stringent FDA regulations in the pharmaceutical and medical device sectors. Significant investment in advanced material science R&D, particularly concerning sustainable packaging and high-performance military applications, ensures steady demand for state-of-the-art permeation testers.

- Europe: Europe is a mature market focusing heavily on sustainability and compliance with environmental directives. High demand exists for testing machines capable of characterizing bio-based and recycled barrier materials. Germany, France, and the UK are key markets due to their strong presence in advanced chemical manufacturing, pharmaceutical R&D, and premium food packaging industries.

- Latin America (LATAM): Growth in LATAM is moderate but steady, largely influenced by the expansion of the regional food processing and export sectors (e.g., Brazil, Argentina). Increasing awareness of shelf-life extension and quality control drives the acquisition of standard-model OTR and WVTR machines to meet international export requirements.

- Middle East and Africa (MEA): MEA is an emerging market, primarily driven by investments in domestic pharmaceutical production and the need to protect imported goods, especially in harsh climatic conditions (high temperature/humidity). Demand is focused on robust, easy-to-maintain equipment suitable for challenging environmental installations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Permeation Testing Machines Market.- MOCON (AMETEK)

- Systech Illinois (Industrial Physics)

- Labthink International, Inc.

- Wuxi Creherit Technology Co., Ltd.

- Jinan Sumspring Instrument Co., Ltd.

- Brugger Feinmechanik GmbH

- LISIM (Suzhou) Testing Equipment Co., Ltd.

- Illinois Instruments (Industrial Physics)

- PCE Instruments

- DRK Instruments Co., Ltd.

- Precise Testing Machines Pvt. Ltd.

- Shenzhen Neopak Co., Ltd.

- Nü-Tec GmbH

- Meishuo Instruments

- C.W. Brabender Instruments, Inc.

- Koehler Instrument Company, Inc.

- Toray Engineering Co., Ltd.

- Thwing-Albert Instrument Company

- Bostwick Consistometer (Industrial Physics)

- Aalborg Instruments and Controls, Inc.

Frequently Asked Questions

Analyze common user questions about the Permeation Testing Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between OTR and WVTR testing machines?

OTR (Oxygen Transmission Rate) machines measure the rate at which oxygen gas permeates through a barrier material, often using high-sensitivity coulometric sensors. WVTR (Water Vapor Transmission Rate) machines measure moisture ingress, typically utilizing infrared or gravimetric detection methods. Both are critical for determining product shelf life and barrier material effectiveness.

Which technology is considered the most accurate for ultra-high barrier film testing?

For ultra-high barrier films, particularly those used in OLEDs and flexible electronics, the Coulometric detection method (for OTR) and high-precision modulated infrared sensors (for WVTR) offer the required sensitivity, often measuring permeation rates down to 0.005 cc/(m²·day) or lower.

How do regulatory standards influence the demand for permeation testing equipment?

Strict regulatory bodies like the FDA, EMA, and ISO mandate specific barrier performance requirements for food, pharmaceuticals, and medical devices. Compliance with these standards (e.g., ASTM D3985, F1249) necessitates the use of certified and traceable permeation testing machines, directly driving market demand, especially for automated and compliant systems.

What role does automation play in modern permeation testing?

Automation, including multi-cell testing, automated temperature and humidity control, and software integration, significantly reduces testing time, minimizes human operational variance, and improves throughput. This is vital for large packaging manufacturers and contract testing labs needing high-volume, reliable data generation.

Which end-user segment drives the highest growth rate for multi-gas permeation machines?

The Pharmaceutical and Electronics industries drive the highest demand for multi-gas permeation machines. Pharmaceuticals require testing for gases like CO2 and nitrogen related to stability testing, while electronics manufacturers require comprehensive testing against multiple corrosive gases for long-term device integrity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager