Peroxide Crosslinkable Cable Compounding Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432083 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Peroxide Crosslinkable Cable Compounding Market Size

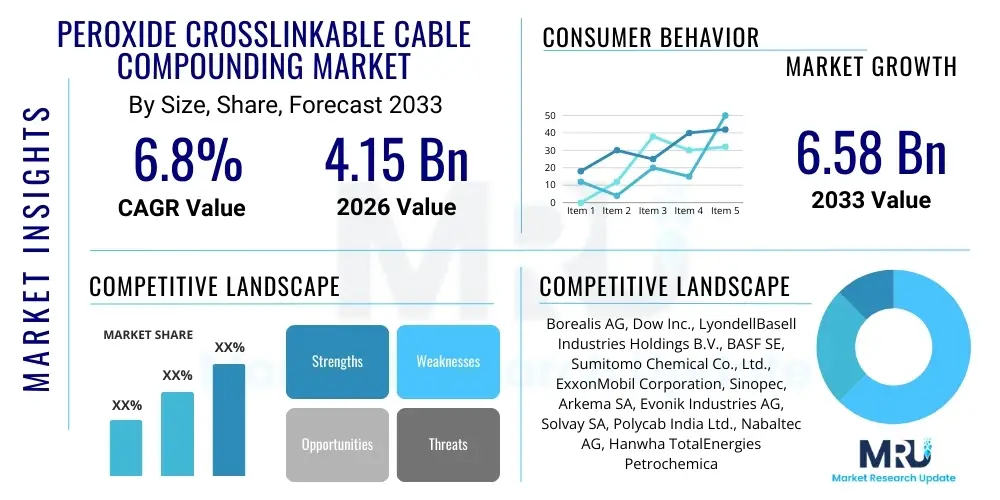

The Peroxide Crosslinkable Cable Compounding Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.15 Billion in 2026 and is projected to reach USD 6.58 Billion by the end of the forecast period in 2033.

Peroxide Crosslinkable Cable Compounding Market introduction

The Peroxide Crosslinkable Cable Compounding Market encompasses specialized polymeric materials designed for the insulation and jacketing of electrical cables, primarily utilized in medium and high-voltage transmission and distribution systems. These compounds, often based on polyethylene (XLPE) or various elastomers, undergo a chemical crosslinking process initiated by organic peroxides. This curing process fundamentally transforms the thermoplastic polymer structure into a thermoset network, imparting superior performance characteristics such as enhanced thermal resistance, mechanical strength, reduced creep under load, and improved chemical resistance compared to conventional non-crosslinked materials. The primary function of these compounds is to ensure long-term reliability and safety of critical power infrastructure.

Major applications driving demand for peroxide crosslinkable compounds include underground and submarine power cables, overhead distribution lines, specialized industrial wiring, and critical applications within renewable energy installations such as wind and solar farms. The shift towards higher voltage transmission necessitated by increasing energy consumption and the integration of decentralized generation sources mandates materials with high dielectric strength and operational stability at elevated temperatures, positioning XLPE compounds as the material of choice globally. Furthermore, the stringent safety and performance standards within the construction and automotive sectors contribute significantly to the consistent growth trajectory of this specialized chemical market segment.

The primary benefit derived from the use of peroxide crosslinkable compounds is the longevity and reliability they offer to electrical infrastructure. Key driving factors include rapid global urbanization leading to extensive power grid modernization and expansion, particularly in developing economies in the Asia Pacific region. Additionally, the global emphasis on renewable energy deployment—which requires specialized, durable cables for energy harvesting and transmission—provides a sustained impetus for market expansion. Regulatory mandates promoting fire safety and environmental compliance further necessitate the adoption of high-performance, low-smoke, halogen-free (LSHF) crosslinked compounds.

Peroxide Crosslinkable Cable Compounding Market Executive Summary

The Peroxide Crosslinkable Cable Compounding Market is characterized by robust growth driven by infrastructural developments and global energy transitions. Business trends indicate a strong focus on material innovation, particularly the development of super clean XLPE grades suitable for extra-high voltage (EHV) applications, minimizing impurities that could compromise dielectric integrity. Leading manufacturers are investing heavily in capacity expansion and backward integration to secure critical raw materials, primarily specialized grades of polyethylene resins and organic peroxides. Consolidation activities and strategic partnerships are prevalent as companies seek to expand their geographical footprint and diversify their product portfolios to include specialized compounds like tree-retardant XLPE (TR-XLPE) and chemically crosslinked compounds optimized for submarine cables.

Regional trends highlight the Asia Pacific (APAC) as the undisputed leader in both consumption and production capacity, propelled by massive governmental investments in smart grid projects and extensive transmission line construction in China and India. North America and Europe maintain stable demand, primarily driven by the replacement of aging infrastructure and the substantial integration of offshore wind power, requiring high-specification, reliable cable compounds. Segmentation analysis reveals that the high-voltage (HV) and extra-high voltage (EHV) segments exhibit the highest growth rate, reflecting the global trend toward efficient long-distance power transmission. Low and medium voltage (LVMV) cables, while constituting a large volume share, demonstrate more stable, steady growth linked to residential and commercial construction activities.

Segment trends underscore the dominance of High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) derived XLPE in terms of material type, offering the best balance of cost and performance for most applications. However, specialty compounds based on rubber and elastomeric materials are carving out niche markets, particularly where high flexibility and extreme temperature resistance are paramount, such as in marine or specialized industrial robotics applications. Overall, the market remains highly dependent on macro-economic factors, specifically capital expenditure cycles in the utility and construction sectors, making governmental infrastructure policy a critical determinant of short-term market fluctuations.

AI Impact Analysis on Peroxide Crosslinkable Cable Compounding Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the complex manufacturing process of peroxide crosslinkable compounds, particularly regarding quality control, material formulation optimization, and predictive maintenance of high-throughput extrusion lines. The key themes revolve around leveraging AI to analyze extensive sensor data generated during compounding to minimize defects (such as voids or contaminants) that critically affect the dielectric strength of XLPE cables. Users express concerns regarding the consistency and purity requirements for EHV compounds and expect AI to provide real-time adjustments to mixer temperatures, pressure profiles, and additive dosing (peroxide injection) to ensure batch consistency, significantly reducing material wastage and maximizing compliance with stringent specifications. Furthermore, expectations are high for AI-driven predictive modeling to optimize the supply chain, anticipating demand shifts in key end-user sectors like utility infrastructure and managing volatile raw material procurement.

- AI-driven optimization of compound formulation parameters to achieve precise crosslinking density and minimize defects.

- Predictive quality control systems utilizing machine vision and deep learning to identify microscopic contaminants in EHV compounds instantaneously.

- Enhanced process efficiency through AI modeling of extruder performance, predicting wear and scheduling preventative maintenance before material properties are compromised.

- Optimization of supply chain logistics, forecasting demand for specific XLPE grades based on regional infrastructure project timelines.

- AI-assisted material discovery and simulation for developing novel, high-performance crosslinkable materials with improved thermal and electrical properties.

DRO & Impact Forces Of Peroxide Crosslinkable Cable Compounding Market

The Peroxide Crosslinkable Cable Compounding Market is propelled by powerful drivers centered on energy infrastructure modernization, constrained by stringent processing requirements, and offers vast opportunities through renewable energy integration. The primary driver remains the global investment in power transmission and distribution (T&D) networks, essential for supporting growing electricity demand and replacing outdated oil-filled cables. However, the market faces significant restraints, notably the highly sensitive nature of the crosslinking process; peroxide additives have limited shelf life and require precise, clean handling during compounding and extrusion to prevent scorch or premature crosslinking, demanding high capital expenditure for state-of-the-art manufacturing facilities. Opportunities are abundant, specifically in the development of specialized compounds tailored for DC transmission lines (HVDC) and offshore wind farms, which demand exceptionally reliable and durable materials capable of operating in challenging environments.

Impact forces acting on this market include the fluctuation in prices of key raw materials, primarily crude oil derivatives used in polymer manufacturing, which directly influences production costs and market pricing strategies. Environmental regulations represent a significant impact force, pushing manufacturers towards developing sustainable, recyclable XLPE alternatives and low-smoke, non-halogenated formulations, especially for indoor and public infrastructure applications. Technological advancements, such as the introduction of electron-beam crosslinking as an alternative curing method in niche applications, pose a subtle but persistent competitive threat to the traditional peroxide method. Nevertheless, the unparalleled reliability and proven performance history of peroxide-crosslinked compounds in HV and EHV systems ensure its continued market dominance.

The market dynamics are further shaped by the cyclical nature of utility spending and governmental regulatory environments. Policy changes regarding power grid resilience, grid interconnection standards, and renewable energy mandates directly translate into immediate demand spikes for high-performance cable compounds. The shift towards smart grids, demanding high-data capacity cables integrated with power lines, also fuels innovation in co-extrusion and composite material development, maintaining a highly competitive and technically demanding market landscape characterized by continuous refinement of material science for electrical applications.

Segmentation Analysis

The Peroxide Crosslinkable Cable Compounding Market is primarily segmented based on material type, voltage application, and end-user industry. The fundamental segmentation is driven by the performance characteristics required for different voltage levels, with specialized polyethylene compounds dominating the high and extra-high voltage segments due to their superior dielectric strength and thermal stability. Material segmentation is crucial as it dictates the processing conditions and final application performance, encompassing various polyethylene variants, rubber, and elastomeric compounds. The end-user analysis provides insight into demand drivers, linking compound consumption directly to global infrastructure, construction, and manufacturing activities.

- By Material Type:

- Polyethylene (PE) Based Compounds

- Low-Density Polyethylene (LDPE)

- High-Density Polyethylene (HDPE)

- Linear Low-Density Polyethylene (LLDPE)

- Tree-Retardant XLPE (TR-XLPE)

- Elastomer and Rubber Based Compounds (e.g., EPR, Silicone)

- Polyethylene (PE) Based Compounds

- By Voltage Application:

- Low Voltage (LV) (Up to 1 kV)

- Medium Voltage (MV) (1 kV to 35 kV)

- High Voltage (HV) (35 kV to 230 kV)

- Extra High Voltage (EHV) (Above 230 kV)

- By End-User Industry:

- Utilities and Power Transmission

- Construction (Residential and Commercial)

- Oil and Gas

- Mining

- Automotive

- Renewable Energy (Wind and Solar)

Value Chain Analysis For Peroxide Crosslinkable Cable Compounding Market

The value chain for the Peroxide Crosslinkable Cable Compounding Market starts with the upstream procurement of essential feedstocks: specialized polymer resins (primarily ethylene derivatives) and organic peroxides. Upstream activities are dominated by major petrochemical producers and specialized chemical manufacturers who provide high-purity, often catalyst-residue-free, base resins critical for maintaining the dielectric performance of the final compound. Quality control at this stage is paramount, as impurities significantly degrade the cable’s longevity and performance. The stability and pricing volatility of these raw materials exert substantial influence over the final product cost and profitability across the entire chain. Strategic collaborations between compounders and resin suppliers are increasingly common to ensure the consistent availability of 'super clean' grades required for EHV cables.

The core midstream activity involves the compounding process, where manufacturers mix base polymers with peroxides, stabilizers, antioxidants, and fillers using high-precision extrusion and kneading machinery. This stage requires rigorous process control to achieve uniform dispersion without initiating premature crosslinking (scorching). Distribution channels for the final compound are typically direct to major cable manufacturers globally, who operate specialized CCV (Catenary Continuous Vulcanization) or VCV (Vertical Continuous Vulcanization) lines. Due to the limited shelf life and required precise handling conditions (temperature and humidity control) of the peroxide-containing compounds, long, complex indirect distribution networks are often avoided, favoring specialized logistics managed by the compound manufacturer itself.

Downstream analysis focuses on the large-scale cable manufacturers and the ultimate end-users, primarily utility companies and construction firms. Cable manufacturers purchase the compound in pellet form and process it into finished cables. The indirect channel involves sales through specialized electrical equipment distributors for smaller construction or industrial projects. The final consumption is dictated by large infrastructure projects—power grid upgrades, renewable energy installations, and large commercial developments. The demand is inelastic in the short term, tied heavily to long-term government infrastructure planning and utility capital expenditure cycles, placing significant pressure on compounders to meet demanding delivery schedules and stringent quality specifications.

Peroxide Crosslinkable Cable Compounding Market Potential Customers

The primary customers for peroxide crosslinkable cable compounds are integrated cable and wire manufacturers who specialize in producing power, control, and instrumentation cables, especially those catering to medium, high, and extra-high voltage applications. These manufacturers require substantial volumes of highly consistent, performance-validated compounds to feed their continuous vulcanization processes. The ultimate purchasers and decision-makers, however, are major national and regional utility companies (T&D operators) who specify the material type and quality standards based on expected operational lifetime, environmental conditions, and regulatory compliance, directly influencing the procurement decisions of their supplying cable firms.

Secondary potential customers include specialized industrial manufacturers, particularly in the oil and gas (petrochemical refineries and offshore platforms) and mining sectors, which require robust, heat-resistant, and chemically stable cables for harsh operating environments. Furthermore, the burgeoning renewable energy sector, encompassing turbine manufacturers and solar farm developers, represents a rapidly expanding customer base. These entities demand specialized XLPE compounds for interconnection cables and collector cables, prioritizing reliability over decades of exposure to temperature fluctuations and moisture. The purchasing criteria for all these customers revolve around dielectric performance, thermal stability, resistance to environmental stress cracking, and proven longevity of the material.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.15 Billion |

| Market Forecast in 2033 | USD 6.58 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Borealis AG, Dow Inc., LyondellBasell Industries Holdings B.V., BASF SE, Sumitomo Chemical Co., Ltd., ExxonMobil Corporation, Sinopec, Arkema SA, Evonik Industries AG, Solvay SA, Polycab India Ltd., Nabaltec AG, Hanwha TotalEnergies Petrochemical Co., Ltd., SCG Chemicals, Trelleborg AB, Momentive Performance Materials Inc., Mexichem (Orbia), Jiangyin Changshun Chemical Fiber Co., Ltd., JNC Corporation, Mitsubishi Chemical Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Peroxide Crosslinkable Cable Compounding Market Key Technology Landscape

The core technological landscape for peroxide crosslinkable cable compounding revolves around achieving extremely high levels of polymer purity, precise additive dispersion, and sophisticated manufacturing processes to prevent premature crosslinking. The leading technological focus is on 'Super Clean' XLPE technology, particularly essential for Extra High Voltage (EHV) cables (230 kV and above). This technology necessitates advanced filtration systems during polymerization and compounding to remove microscopic contaminants, catalyst residues, and impurities that could create stress points under high electrical fields, leading to premature cable failure (electrical treeing). Continuous development in antioxidant packages and stabilizer systems is also crucial to ensure the long-term thermal aging stability of the final compound, extending the operational life of the cable infrastructure.

Processing technology advancements center on the continuous compounding process using specialized twin-screw extruders designed to handle high-viscosity polymers and volatile peroxide liquids safely and accurately. Manufacturers utilize advanced melt homogeneity systems and degassing zones to remove trace moisture and volatile organic compounds before packaging. Furthermore, significant research effort is directed towards developing Tree-Retardant XLPE (TR-XLPE) compounds. These materials incorporate chemical additives that mitigate the effects of moisture and electrical stress, significantly enhancing the durability of cables used in humid or submerged environments, thus offering a substantial lifespan increase over standard XLPE, crucial for underground distribution networks.

An emerging technological area involves the development of specialized compounds for High-Voltage Direct Current (HVDC) applications. Unlike traditional AC cables, HVDC transmission imposes unique stress distributions related to space charge accumulation, requiring compounds with tailored electrical conductivity profiles and high volume resistivity. Research focuses on nanodielectrics and the incorporation of controlled quantities of conductive nanoparticles to manage space charge effects, optimizing the material specifically for efficient and stable long-distance DC power transmission, a necessity for linking remote renewable energy sources to established grids. While peroxide crosslinking remains the dominant curing methodology, process control and material science refinements are the key technological differentiators in this mature but evolving market.

In addition to material formulation and processing excellence, automation and data analytics play a pivotal role in maintaining product consistency across vast production batches. Advanced sensors integrated into the compounding equipment monitor critical parameters such as melt temperature, torque, and pressure in real-time. This real-time data collection facilitates statistical process control (SPC) and predictive maintenance models, ensuring that any deviation from the rigorous quality specifications is immediately flagged and corrected. The investment in advanced control systems minimizes batch-to-batch variation, a non-negotiable requirement when supplying critical infrastructure components where failure rates must be minimized to virtually zero. This technological requirement favors large, vertically integrated chemical producers capable of high capital expenditure.

Another technological frontier addresses sustainability and environmental compliance. There is growing demand for Low-Smoke, Halogen-Free (LSHF) crosslinkable compounds, particularly in applications governed by strict fire safety standards, such as tunnels, metros, and data centers. Developing LSHF XLPE alternatives that maintain the electrical and mechanical performance of standard crosslinked polyethylene requires sophisticated material engineering, often involving metal hydroxide fillers that act as flame retardants and smoke suppressants without compromising the dielectric properties. The successful integration of these flame-retardant technologies while ensuring the crosslinking efficiency of the peroxide system represents a significant challenge and a current focus area for R&D departments across the industry.

The development of compounds optimized for robotic cable applications, where extreme flexibility, abrasion resistance, and torsion capability are needed, also drives niche technological refinement. These applications often utilize specialized elastomeric compounds (like EPR or EPDM) that are peroxide crosslinked to enhance their mechanical toughness and temperature tolerance. The R&D effort here focuses on selecting co-monomers and crosslinking agents that yield a flexible yet robust thermoset structure, distinguishing these products from standard XLPE used primarily for static power transmission lines. This continuous refinement across niche segments ensures that the overall market for peroxide crosslinkable compounds remains at the forefront of polymer performance engineering.

Regional Highlights

The global Peroxide Crosslinkable Cable Compounding market exhibits distinct regional dynamics heavily correlated with infrastructure spending and population density. Asia Pacific (APAC) stands as the dominant market, driven by unparalleled levels of new construction and rapid expansion of power transmission grids, particularly in China and India. These nations are undergoing massive urbanization and industrialization, necessitating high-capacity, reliable underground and overhead power distribution systems. APAC is also a major manufacturing hub, housing both large international compounders and local players, leading to intense competition and a massive scale of production. The high demand extends to both EHV applications for regional grid integration and MV/LV cables for municipal distribution.

Europe and North America represent mature markets characterized primarily by replacement and modernization activities, rather than new grid build-out. Demand in these regions is stable and highly concentrated in high-specification products. Europe, particularly Scandinavian countries and the UK, shows strong demand for subsea and submarine XLPE compounds to support the burgeoning offshore wind energy sector and cross-border grid interconnectors. North America's growth is tied to investments in grid resilience, smart grid deployment, and the replacement of aging infrastructure prone to failures, focusing heavily on Tree-Retardant XLPE (TR-XLPE) for subterranean distribution lines to combat electrical treeing.

Latin America and the Middle East & Africa (MEA) are emerging growth regions. Latin America's market growth is sporadic but significant, driven by specific large-scale hydroelectric and oil infrastructure projects requiring durable, high-voltage cables. The MEA region is witnessing consistent investment in power infrastructure, particularly in the Gulf Cooperation Council (GCC) states, where massive construction projects and the need for reliable high-temperature operation drive demand for premium XLPE grades. However, market adoption in MEA and Latin America can be sensitive to economic fluctuations and political stability, differentiating their growth profile from the steady trajectory seen in APAC.

- Asia Pacific (APAC): Highest growth and volume share; driven by urbanization, massive grid expansion, and renewable energy integration in China and India. Focus on all voltage segments, particularly MV and EHV.

- Europe: Stable, high-value market driven by grid modernization, offshore wind farms, and stringent environmental regulations favoring LSHF compounds. Strong focus on subsea cable compounds.

- North America: Steady demand fueled by infrastructure replacement, grid resilience projects, and specialized requirements for TR-XLPE in aging distribution networks. Focus on high-quality and high-reliability compounds.

- Middle East & Africa (MEA): Emerging market driven by substantial construction investments in the GCC and urbanization in South Africa and Nigeria. Demand is often dictated by climate extremes (high temperature operation).

- Latin America: Growth tied to specific resource extraction projects (mining, oil & gas) and inter-regional transmission line development, highly sensitive to commodity cycles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Peroxide Crosslinkable Cable Compounding Market.- Borealis AG

- Dow Inc.

- LyondellBasell Industries Holdings B.V.

- BASF SE

- Sumitomo Chemical Co., Ltd.

- ExxonMobil Corporation

- Sinopec

- Arkema SA

- Evonik Industries AG

- Solvay SA

- Polycab India Ltd.

- Nabaltec AG

- Hanwha TotalEnergies Petrochemical Co., Ltd.

- SCG Chemicals

- Trelleborg AB

- Momentive Performance Materials Inc.

- Mexichem (Orbia)

- Jiangyin Changshun Chemical Fiber Co., Ltd.

- JNC Corporation

- Mitsubishi Chemical Group

Frequently Asked Questions

Analyze common user questions about the Peroxide Crosslinkable Cable Compounding market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is peroxide crosslinkable cable compounding and why is it preferred for high-voltage cables?

Peroxide crosslinkable compounding involves adding organic peroxides to polymer resins (like polyethylene) during mixing. This chemical addition creates permanent thermoset bonds during cable manufacturing, significantly enhancing the material's thermal stability, mechanical strength, and dielectric integrity, making it indispensable for reliable operation in High Voltage (HV) and Extra High Voltage (EHV) applications.

How does the quality of XLPE compounds impact the longevity of power cables?

The purity and cleanliness of XLPE compounds are crucial for cable longevity. Impurities, voids, or contaminants can create localized electrical stress concentrations, leading to phenomena like "electrical treeing" and premature dielectric breakdown. High-quality, super-clean XLPE minimizes these defects, ensuring a projected service life of 40 to 60 years for critical infrastructure.

Which regional market holds the largest share for peroxide crosslinkable compounds, and what are its key drivers?

The Asia Pacific (APAC) region currently holds the largest market share, predominantly driven by rapid urbanization, massive government investment in smart grid infrastructure, and extensive expansion of both distribution and high-capacity transmission networks, particularly across China and India.

What are the primary differences between standard XLPE and Tree-Retardant XLPE (TR-XLPE)?

Standard XLPE is sufficient for many applications, but TR-XLPE incorporates specialized chemical additives that actively mitigate the initiation and growth of water and electrical trees. TR-XLPE is specifically used in underground Medium Voltage (MV) distribution cables where exposure to moisture is inevitable, significantly extending the cable's lifespan in harsh environments.

What are the major challenges facing manufacturers in the Peroxide Crosslinkable Cable Compounding Market?

Key challenges include maintaining the extreme purity required for EHV compounds, managing the short shelf life and volatile nature of peroxide additives, and navigating the significant price fluctuations of crude oil-derived polymer feedstocks. Additionally, manufacturers must continuously invest in process control technology to prevent material scorching during high-speed production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager