PET Bottle Flakes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440370 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

PET Bottle Flakes Market Size

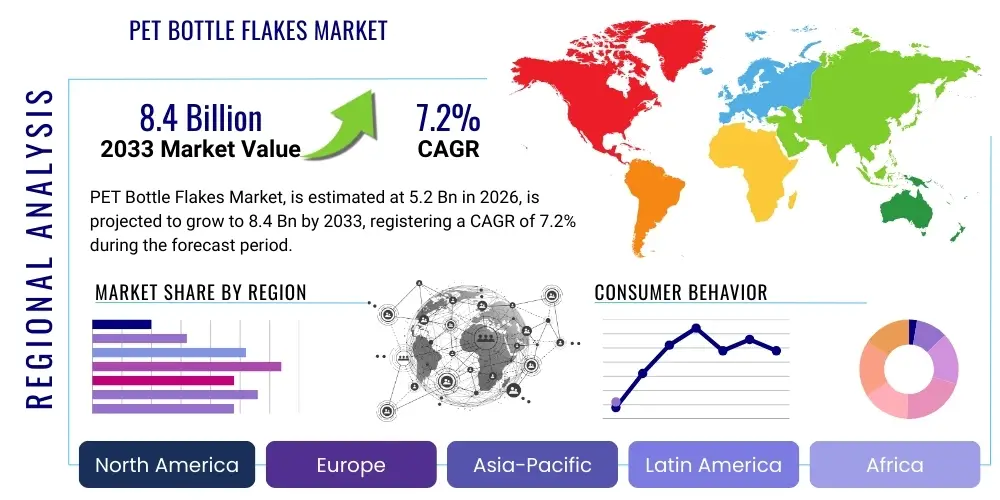

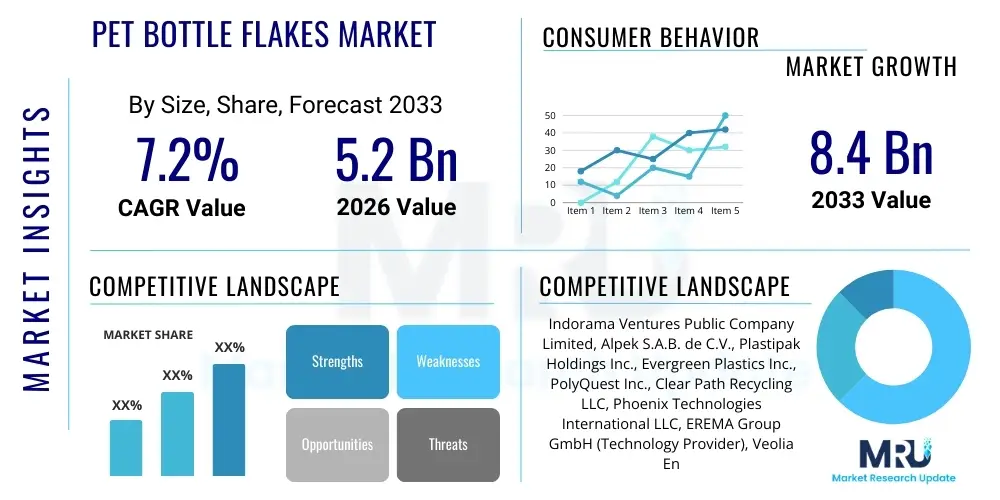

The PET Bottle Flakes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 8.4 Billion by the end of the forecast period in 2033.

PET Bottle Flakes Market introduction

The PET Bottle Flakes Market is an integral component of the global circular economy, primarily driven by the increasing emphasis on plastic waste reduction and resource conservation. PET bottle flakes are recycled polyethylene terephthalate, derived from post-consumer or post-industrial PET bottles, which undergo processes of collection, sorting, washing, and grinding. This product serves as a crucial secondary raw material, offering a sustainable alternative to virgin PET for a multitude of applications. The demand for PET bottle flakes is profoundly influenced by stringent environmental regulations, growing corporate sustainability initiatives, and heightened consumer awareness regarding ecological footprints.

Major applications for these flakes span across various industries, including bottle-to-bottle recycling for new beverage containers, manufacturing of synthetic fibers for textiles and carpets, production of strapping bands, and the creation of sheets and films for packaging. The inherent benefits of using PET bottle flakes are substantial, encompassing a significant reduction in energy consumption and greenhouse gas emissions compared to virgin PET production, conservation of non-renewable resources, and diversion of plastic waste from landfills and oceans. These advantages position PET bottle flakes as a cornerstone in achieving environmental sustainability goals and fostering a more resilient supply chain for plastic-based products. Key driving factors for this market include supportive government policies, technological advancements in sorting and recycling, and expanding end-use applications, all contributing to its robust growth trajectory.

PET Bottle Flakes Market Executive Summary

The PET Bottle Flakes Market is poised for substantial growth, largely propelled by an accelerating global shift towards sustainable manufacturing practices and the circular economy. Business trends indicate a rising investment in advanced recycling infrastructure, including enhanced sorting and cleaning technologies, to meet the escalating demand for high-quality recycled PET (rPET). Major corporations across various sectors, particularly in beverages and consumer goods, are committing to ambitious targets for incorporating recycled content into their products, thereby acting as significant demand drivers. Furthermore, the market is witnessing increasing consolidation among recyclers and strategic partnerships between waste management companies and rPET end-users, aimed at securing consistent supply chains and improving material quality. This collaborative ecosystem is crucial for overcoming challenges related to feedstock availability and quality consistency, ensuring a stable foundation for market expansion.

Regionally, Asia Pacific continues to dominate the market due to its large population base, significant PET consumption, and rapidly developing recycling infrastructure, particularly in countries like China and India. Europe and North America also represent robust markets, characterized by stringent regulatory frameworks, high consumer environmental awareness, and mature recycling systems that prioritize circularity. These regions are investing heavily in innovative recycling technologies to enhance the purity and versatility of PET bottle flakes. In terms of segments, clear PET bottle flakes command the largest share owing to their versatility and suitability for bottle-to-bottle applications, which require higher purity. The fiber segment also holds a significant share, driven by the textile industry's pivot towards sustainable materials. Overall, the market's trajectory is firmly upward, underpinned by a global commitment to environmental stewardship and the economic viability of recycled plastics.

AI Impact Analysis on PET Bottle Flakes Market

The integration of Artificial Intelligence (AI) into the PET Bottle Flakes market addresses several critical challenges and offers significant opportunities for enhanced efficiency, quality, and sustainability. Common user questions revolve around how AI can improve the notoriously difficult and labor-intensive sorting process, reduce contamination, and optimize overall operational costs within recycling facilities. There's also considerable interest in AI's role in supply chain transparency, demand forecasting for rPET, and the development of novel applications for recycled materials. Users expect AI to not only streamline current operations but also to unlock new value from recycled PET by ensuring higher purity grades and facilitating more complex, high-value end-uses, ultimately boosting the market's economic viability and environmental impact.

Users are particularly keen to understand how AI-powered vision systems can precisely identify and separate different types of plastics, colors, and non-PET contaminants at high speeds, minimizing human error and increasing throughput. Concerns also include the initial investment costs for AI integration, the need for specialized technical skills to operate and maintain these systems, and the potential for job displacement in traditional sorting roles. However, the overarching expectation is that AI will be a transformative force, enabling the PET bottle flakes market to scale up its operations, produce consistently high-quality rPET, and respond more agilely to market demands. The summarized key themes include AI's potential for revolutionary advancements in sorting and quality control, its role in supply chain optimization, and its capacity to elevate the overall economic and environmental performance of the PET bottle flakes value chain, despite some anticipated implementation hurdles.

- Enhanced Sorting Accuracy: AI-powered vision systems drastically improve the identification and separation of PET bottles from other plastics and contaminants, leading to higher purity flakes.

- Increased Throughput and Efficiency: Automation driven by AI allows for faster processing speeds and reduced manual labor, optimizing operational efficiency in recycling plants.

- Improved Quality Control: AI algorithms can detect subtle defects and impurities, ensuring consistent, high-quality PET flakes suitable for demanding applications like food-grade packaging.

- Predictive Maintenance: AI monitors equipment performance, predicting potential failures and scheduling maintenance proactively, minimizing downtime and extending machinery lifespan.

- Supply Chain Optimization: AI analyzes data to forecast feedstock availability and demand for rPET, enabling more efficient logistics, inventory management, and market responsiveness.

- New Material Development: AI can assist in simulating and identifying optimal blending ratios or processing parameters for rPET, potentially leading to novel materials with enhanced properties.

- Reduced Operational Costs: By minimizing waste, improving efficiency, and optimizing energy consumption, AI contributes to significant cost savings in the long run.

DRO & Impact Forces Of PET Bottle Flakes Market

The PET Bottle Flakes market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by significant impact forces. A primary driver is the global imperative for sustainability, manifested through escalating environmental regulations and corporate commitments to circular economy principles. Governments worldwide are implementing policies that mandate recycled content in packaging and ban single-use plastics, directly stimulating demand for rPET flakes. Concurrently, a heightened consumer preference for eco-friendly products pushes brands to adopt sustainable packaging solutions, further boosting the market. Technological advancements in sorting, washing, and decontamination processes are continually improving the quality and expanding the applicability of PET flakes, making them more competitive with virgin PET.

However, the market faces considerable restraints. The fluctuating price of virgin PET, which is derived from crude oil, can impact the economic viability of rPET, especially during periods of low oil prices. Issues such as the inconsistent quality and supply of post-consumer PET feedstock, due to varying collection infrastructures and consumer sorting practices across regions, pose significant challenges. High capital investment required for state-of-the-art recycling facilities and the energy-intensive nature of some recycling processes also act as deterrents. Contamination remains a persistent hurdle, necessitating advanced and often costly purification steps to meet stringent quality requirements for food-grade applications.

Despite these challenges, substantial opportunities exist. The expanding applications of rPET beyond traditional uses into sectors like automotive, construction, and electronics present new avenues for growth. The growing demand for food-grade rPET, driven by regulatory support and brand commitments, represents a high-value segment. Emerging economies, with their rapidly expanding consumer bases and nascent but developing recycling infrastructures, offer immense untapped potential for market expansion. Furthermore, continuous innovation in chemical recycling technologies, which can handle more complex and contaminated PET waste, promises to overcome some of the current limitations, ensuring a more robust and circular future for PET bottle flakes. These elements collectively dictate the trajectory and resilience of the PET bottle flakes market.

Segmentation Analysis

The PET Bottle Flakes market is comprehensively segmented to provide a granular understanding of its diverse applications, sources, and product types. This segmentation allows for precise market analysis, enabling stakeholders to identify specific growth areas, understand competitive dynamics, and tailor strategic initiatives. The primary segmentation often revolves around the color of the flakes, as this directly impacts their suitability for various end-use applications, with clear flakes typically commanding a premium due to their versatility. Further critical segmentation includes the end-use industry, distinguishing between applications such as bottle-to-bottle, fiber, and sheet & film, each with unique quality requirements and market dynamics.

Another crucial dimension of segmentation is the source of the PET bottles, differentiating between post-consumer and post-industrial waste, reflecting different collection and processing complexities. This multi-faceted approach to segmentation highlights the diverse value propositions within the market and the varying levels of purity, processing, and cost associated with each category. Understanding these segments is vital for producers, recyclers, and end-users to optimize their operations, meet specific market demands, and navigate the evolving landscape of sustainable plastic solutions. The distinct characteristics of each segment profoundly influence pricing, supply chain configurations, and technological investments, underpinning the market's overall structure and growth potential.

- By Color

- Clear Flakes

- Green Flakes

- Brown Flakes

- Mixed Flakes

- By End-Use Application

- Bottle-to-Bottle

- Fiber (Textiles, Carpets, Non-Woven)

- Strapping

- Sheet & Film (Thermoforming, Blister Packaging)

- Other (e.g., Automotive parts, Construction materials)

- By Source

- Post-Consumer

- Post-Industrial

Value Chain Analysis For PET Bottle Flakes Market

The value chain for PET bottle flakes is a complex network that begins with the collection of discarded PET bottles and culminates in their transformation into valuable raw materials for various industries. The upstream segment involves the collection and initial sorting of post-consumer and post-industrial PET waste. This stage is highly fragmented, encompassing municipal waste collection systems, private recycling centers, and informal waste pickers. Efficiency at this stage is crucial, as the quality and quantity of collected feedstock directly impact downstream processes. Key challenges include contamination levels, logistical complexities in transporting bulky waste, and the need for robust collection infrastructure.

The midstream segment focuses on the transformation of collected PET bottles into flakes. This involves several critical steps: initial sorting (often using automated technologies like NIR spectroscopy), baling, shredding, hot washing to remove labels and contaminants, and then grinding the PET into small flakes. Further purification steps, such as flotation, air classification, and sometimes super-cleaning for food-grade applications, are also undertaken. This stage requires significant capital investment in machinery and adherence to stringent quality control measures to produce high-purity flakes that meet industry specifications. The choice of technology and process efficiency at this stage largely determines the quality and economic viability of the final PET flakes.

The downstream segment involves the distribution and utilization of PET bottle flakes by various manufacturing industries. These flakes are sold as a secondary raw material to producers of new PET bottles (bottle-to-bottle recycling), textile manufacturers for synthetic fibers, packaging companies for strapping and sheets, and other industries for diverse applications. Distribution channels can be direct, where large recyclers supply directly to manufacturers, or indirect, involving brokers and traders who facilitate transactions between smaller recyclers and end-users. The market dynamics in the downstream segment are influenced by demand from end-user industries, pricing of virgin PET, and regulatory requirements for recycled content. Optimizing this entire value chain is essential for enhancing circularity, reducing waste, and maximizing the economic and environmental benefits of PET recycling.

PET Bottle Flakes Market Potential Customers

Potential customers for PET bottle flakes represent a broad spectrum of industries, all seeking sustainable and cost-effective alternatives to virgin PET. The largest and most prominent group includes beverage and food packaging manufacturers who are increasingly mandated or choosing to incorporate recycled content into their new bottles and containers. This demand is driven by stringent regulatory requirements for circularity, ambitious corporate sustainability goals set by global brands, and strong consumer preference for environmentally responsible products. These customers require high-quality, often food-grade, clear PET flakes that can be safely used in direct contact with food and beverages, necessitating advanced purification processes in the upstream value chain. Their purchasing decisions are heavily influenced by consistent supply, price stability, and certified quality.

Another significant customer segment is the textile industry, particularly manufacturers of synthetic fibers for apparel, carpets, and non-woven fabrics. Recycled PET flakes are a primary raw material for producing polyester fibers, offering a sustainable alternative to virgin polyester derived from petrochemicals. This sector values the flakes for their ability to be spun into durable and versatile fibers, contributing to the industry's push towards eco-friendly textiles. The quality requirements here might be less stringent than for food-grade applications, allowing for a wider range of flake colors and purity levels. The demand from this segment is also buoyed by fast fashion's drive for lower costs and the growing market for recycled content in sportswear and outdoor gear.

Beyond these major segments, other key end-users include producers of strapping bands, which are widely used for bundling and packaging in various industries due to their strength and durability. Manufacturers of thermoformed sheets and films for blister packaging, clamshell containers, and other rigid packaging solutions also represent a substantial customer base. Furthermore, the automotive industry utilizes PET flakes in some interior components and insulation, while the construction sector finds applications in geotextiles and building materials. This diverse customer landscape underscores the versatility of PET bottle flakes and their crucial role in enabling a wide array of industries to meet their sustainability objectives and contribute to a more circular economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 8.4 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Indorama Ventures Public Company Limited, Alpek S.A.B. de C.V., Plastipak Holdings Inc., Evergreen Plastics Inc., PolyQuest Inc., Clear Path Recycling LLC, Phoenix Technologies International LLC, EREMA Group GmbH (Technology Provider), Veolia Environnement S.A. (Recycling Services), SUEZ Recycling & Recovery, Zhejiang Anshun Pettechs Fibers Co. Ltd., Nanjing Bausch Advanced Material Co. Ltd., Formosa Taffeta Co. Ltd., Far Eastern New Century Corporation, Thai PET Recycle Group (TPRG), BP Polymers Inc., Avangard Innovative, CarbonLITE Recycling, Verdeco Recycling Inc., Worn Again Technologies (Technology Provider) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Bottle Flakes Market Key Technology Landscape

The PET Bottle Flakes market's technological landscape is characterized by continuous innovation aimed at enhancing efficiency, improving flake quality, and expanding the range of treatable PET waste. At the forefront are advanced sorting technologies, primarily optical sorting systems utilizing Near-Infrared (NIR) spectroscopy, which can rapidly identify and separate different polymer types, colors, and non-PET contaminants. More recently, AI-powered vision systems are being integrated into these sorters, significantly increasing detection accuracy and throughput, thereby minimizing manual intervention and reducing operational costs. These systems are crucial for achieving the high purity levels required for demanding applications like food-grade packaging, making the recycling process more economically viable and environmentally effective.

Following sorting, the washing and decontamination processes are critical. Hot washing systems effectively remove labels, glue, residual product, and other surface contaminants. Chemical washing and super-cleaning technologies are employed to further purify the PET flakes, meeting the stringent standards for direct food contact applications set by regulatory bodies such as the FDA and EFSA. These advanced decontamination methods are essential for closing the loop in bottle-to-bottle recycling, enabling the production of new containers from recycled materials without compromising safety or quality. Innovations in this area focus on reducing water and energy consumption while maximizing impurity removal, enhancing the overall sustainability profile of the recycling operation.

Furthermore, technologies related to grinding, extrusion, and filtration play a vital role in processing the cleaned flakes into a usable form. High-performance grinders ensure uniform flake size, which is critical for subsequent processing steps. Extrusion lines are used to melt and re-pelletize the flakes into rPET pellets, often incorporating melt filtration systems to remove any remaining microscopic impurities. Developments in solid-state polymerization (SSP) technology are also significant, as SSP can increase the intrinsic viscosity (IV) of rPET, making it comparable to virgin PET and suitable for higher-value applications. The continuous evolution of these technologies is not only improving the quality and cost-effectiveness of PET bottle flakes but also broadening their applicability, making them a cornerstone of the sustainable plastics economy.

Regional Highlights

- Asia Pacific (APAC): Dominates the PET bottle flakes market, driven by its large population, rapid industrialization, high consumption of PET bottled products, and increasingly stringent environmental regulations, particularly in China and India. The region is a significant producer and consumer, investing heavily in new recycling facilities.

- Europe: Characterized by strong regulatory frameworks such as the EU Plastics Strategy and high recycling rates, Europe is a mature market focused on achieving circularity and high-quality rPET. Countries like Germany, Italy, and France are leading in collection, sorting technologies, and bottle-to-bottle recycling initiatives.

- North America: Experiencing robust growth due to increasing corporate commitments to recycled content and governmental efforts to improve recycling infrastructure. The demand from beverage and food packaging sectors for high-quality rPET is a key driver, alongside technological advancements in sorting and processing.

- Latin America: Showing promising growth, with countries like Brazil and Mexico enhancing their recycling capabilities amidst rising environmental awareness and economic incentives. Investments in collection infrastructure and recycling plants are increasing to meet local demand and sustainability goals.

- Middle East & Africa (MEA): An emerging market with significant untapped potential. While recycling infrastructure is still developing in many areas, increasing urbanization, rising PET consumption, and growing awareness about plastic pollution are fostering investment in recycling initiatives, particularly in countries like South Africa and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Bottle Flakes Market.- Indorama Ventures Public Company Limited

- Alpek S.A.B. de C.V.

- Plastipak Holdings Inc.

- Evergreen Plastics Inc.

- PolyQuest Inc.

- Clear Path Recycling LLC

- Phoenix Technologies International LLC

- EREMA Group GmbH

- Veolia Environnement S.A.

- SUEZ Recycling & Recovery

- Zhejiang Anshun Pettechs Fibers Co. Ltd.

- Nanjing Bausch Advanced Material Co. Ltd.

- Formosa Taffeta Co. Ltd.

- Far Eastern New Century Corporation

- Thai PET Recycle Group (TPRG)

- BP Polymers Inc.

- Avangard Innovative

- CarbonLITE Recycling

- Verdeco Recycling Inc.

- Worn Again Technologies

Frequently Asked Questions

What are PET bottle flakes and why are they important?

PET bottle flakes are small pieces of recycled polyethylene terephthalate (rPET) derived from post-consumer or post-industrial PET bottles. They are crucial for promoting a circular economy, reducing plastic waste, conserving natural resources, and lowering the carbon footprint associated with virgin plastic production. Their importance stems from their role as a sustainable secondary raw material across various industries.

What are the primary applications of PET bottle flakes?

The primary applications include bottle-to-bottle recycling, where flakes are processed into new PET bottles, and the textile industry for producing synthetic fibers (polyester) for clothing, carpets, and non-woven fabrics. Other significant uses include manufacturing strapping bands, thermoformed sheets and films for packaging, and components in the automotive and construction sectors.

What drives the growth of the PET Bottle Flakes Market?

The market's growth is primarily driven by increasing environmental awareness, stringent government regulations mandating recycled content and restricting single-use plastics, ambitious corporate sustainability goals, and technological advancements in recycling processes. Growing consumer demand for eco-friendly products also plays a significant role in stimulating market expansion.

What challenges does the PET Bottle Flakes Market face?

Key challenges include the inconsistent supply and quality of feedstock (collected PET bottles), contamination issues requiring advanced and costly purification, fluctuating prices of virgin PET (which can make rPET less competitive), and the high capital investment required for modern recycling infrastructure. Overcoming these hurdles is essential for sustained growth.

How does Artificial Intelligence impact the PET Bottle Flakes Market?

AI significantly impacts the market by enhancing sorting accuracy and efficiency through advanced vision systems, improving quality control to meet high purity standards, and optimizing supply chain logistics. AI also enables predictive maintenance for machinery and offers potential for developing new applications for recycled PET, ultimately driving cost reduction and increased market value.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager