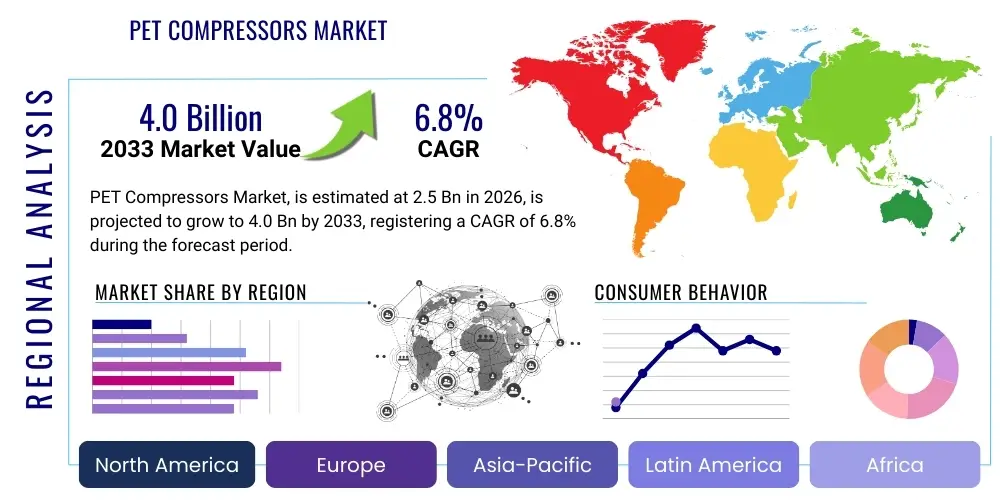

PET Compressors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440359 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

PET Compressors Market Size

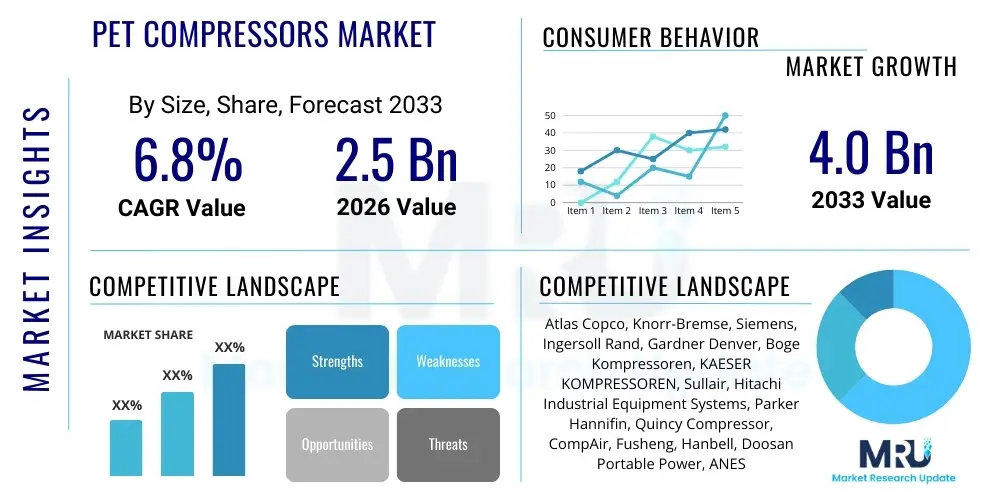

The PET Compressors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.0 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by the incessant global demand for polyethylene terephthalate (PET) packaging across diverse industries, particularly beverages, food, pharmaceuticals, and personal care. The market's expansion is further underpinned by continuous technological advancements aimed at enhancing energy efficiency, reliability, and air purity, which are critical parameters for modern PET blowing operations. Furthermore, the increasing focus on sustainable manufacturing practices and the integration of smart technologies are set to provide significant impetus to market valuation throughout the forecast period.

PET Compressors Market introduction

The PET Compressors Market encompasses the global industry dedicated to the manufacturing, distribution, and servicing of high-pressure air compressors specifically designed for polyethylene terephthalate (PET) bottle blowing applications. These specialized compressors are indispensable components in the production of PET containers, which are widely utilized for packaging beverages, food products, pharmaceuticals, and various consumer goods due to their lightweight, durability, transparency, and recyclability. The market is characterized by a critical need for consistent, oil-free, high-pressure compressed air, typically ranging from 35 to 40 bar, to perfectly form PET preforms into finished bottles via the stretch blow molding process. The integrity of the final product, especially in sensitive sectors like food and pharmaceuticals, directly depends on the purity and reliability of the compressed air supply.

Product descriptions within this market vary, primarily encompassing reciprocating (piston) compressors, rotary screw compressors, and, to a lesser extent, centrifugal compressors, all adapted for high-pressure operation. Oil-free technologies are particularly dominant, driven by stringent industry standards for product contamination prevention and operational efficiency. Key features of these compressors often include multi-stage compression, advanced filtration systems, variable speed drive (VSD) technology for energy optimization, and sophisticated control systems for precise pressure management and operational monitoring. The design focuses on robust construction, extended service intervals, and minimal downtime to support continuous, high-volume production lines characteristic of the PET manufacturing industry. This emphasis on reliability and efficiency makes them a cornerstone technology for modern packaging facilities worldwide.

Major applications for PET compressors span the entire spectrum of PET packaging. The beverage industry, including bottled water, carbonated soft drinks, juices, and alcoholic beverages, represents the largest end-use segment. The food industry utilizes PET containers for edible oils, sauces, condiments, and dairy products. Furthermore, the pharmaceutical sector relies on PET for medicine bottles, while personal care products such as shampoos, lotions, and cosmetics frequently employ PET packaging. The driving factors behind this market's growth are multifaceted, including the burgeoning global population, rising disposable incomes, urbanization, and the increasing demand for convenience packaging. Benefits such as enhanced energy efficiency through VSD technology, reduced operational costs due to robust designs, superior product quality through oil-free air, and compliance with strict food and pharmaceutical safety regulations are pivotal in sustaining and expanding the market for PET compressors globally.

PET Compressors Market Executive Summary

The PET Compressors Market is currently experiencing dynamic shifts driven by a confluence of evolving business trends, significant regional developments, and distinct segmental preferences. From a business perspective, the market is witnessing a strong impetus towards technological innovation, particularly in areas concerning energy efficiency, automation, and predictive maintenance capabilities. Manufacturers are increasingly integrating Industry 4.0 principles, leveraging IoT sensors, advanced analytics, and AI-driven control systems to enhance operational uptime, optimize energy consumption, and provide proactive service. There is also a growing trend towards modular designs, offering greater flexibility and scalability for diverse production needs, alongside an intensifying focus on aftermarket services as a key differentiator and revenue stream. Consolidation among major players and strategic partnerships aimed at expanding global reach and technological portfolios are also prominent business trends.

Regionally, the market presents a diverse landscape. Asia Pacific continues to emerge as the fastest-growing region, propelled by rapid industrialization, burgeoning middle-class populations, and expanding domestic consumption, particularly in countries like China, India, and Southeast Asian nations. This region is a hotbed for new manufacturing capacities for PET packaging. North America and Europe, while mature markets, demonstrate steady demand driven primarily by replacement cycles, stringent environmental regulations necessitating energy-efficient upgrades, and a strong emphasis on automation and smart factory initiatives. Latin America and the Middle East & Africa regions are also showing considerable potential, buoyed by economic development, increasing foreign investment in manufacturing infrastructure, and a rising adoption of packaged consumer goods, albeit with varying levels of technological sophistication and market maturity.

Segmentation trends within the PET Compressors Market highlight a pronounced preference for oil-free compressor technologies due to strict air purity requirements in food, beverage, and pharmaceutical applications, ensuring product integrity and safety. Variable Speed Drive (VSD) compressors are gaining significant traction across all segments, as they offer substantial energy savings by adjusting output to meet fluctuating demand, thereby reducing operational costs and carbon footprint. High-pressure reciprocating compressors remain a cornerstone, especially for high-volume PET blowing, appreciated for their reliability and performance. The beverage sector continues to dominate the end-use market, but segments such as food, personal care, and pharmaceuticals are demonstrating robust growth, driving demand for specialized compressor solutions that cater to their unique operational pressures and hygienic standards. This granular understanding of trends is crucial for strategic market positioning and product development.

AI Impact Analysis on PET Compressors Market

User inquiries regarding AI's influence on the PET Compressors Market primarily center on its potential to revolutionize operational efficiency, enhance predictive maintenance, optimize energy consumption, and improve overall product quality. Users are keen to understand how AI can move compressor systems from reactive troubleshooting to proactive management, minimizing downtime and extending equipment lifespan. Key themes emerging from these questions include the application of machine learning for anomaly detection in real-time performance data, AI-driven algorithms for dynamic pressure and flow optimization, and the integration of AI into smart factory ecosystems to enable seamless communication between compressors and other production line machinery. There is also significant interest in the cost-benefit analysis of AI implementation, scalability challenges, and the security implications of deploying AI in industrial settings, reflecting both excitement about innovation and practical considerations for adoption. The collective expectation is that AI will usher in a new era of highly intelligent, autonomous, and energy-efficient compressor operations.

The implementation of AI in PET compressor systems is poised to significantly elevate operational intelligence and performance across the entire packaging value chain. By continuously analyzing vast streams of operational data—including pressure, temperature, vibration, energy consumption, and air purity levels—AI algorithms can identify subtle patterns indicative of impending failures long before they manifest, enabling true predictive maintenance. This capability dramatically reduces unplanned downtime, optimizing maintenance schedules and inventory management for spare parts. Furthermore, AI can dynamically adjust compressor parameters in real-time, matching air output precisely to the production line's immediate demand, thereby preventing over-compression and significantly reducing energy waste. This level of granular control is crucial in an energy-intensive industry like PET bottle manufacturing, leading to substantial cost savings and a reduced environmental footprint. The integration of AI also facilitates enhanced quality control by monitoring air purity and consistency, ensuring that every PET bottle meets stringent industry standards.

- Predictive Maintenance and Diagnostics: AI algorithms analyze sensor data (vibration, temperature, pressure, current draw) to predict potential component failures, enabling proactive maintenance scheduling and minimizing unplanned downtime, which is critical for continuous PET production lines.

- Energy Optimization and Efficiency: AI-powered control systems can dynamically adjust compressor output and pressure based on real-time demand, minimizing energy consumption by preventing over-compression and optimizing load distribution across multiple units, leading to significant operational cost savings.

- Enhanced Operational Control: Machine learning models can fine-tune compressor parameters (e.g., motor speed, valve timing) for optimal performance under varying production conditions, ensuring consistent air purity and pressure vital for PET bottle quality.

- Quality Assurance and Anomaly Detection: AI can monitor air quality and consistency, immediately flagging any deviations that could compromise the integrity of PET preforms or final bottles, thus preventing defects and reducing waste in sensitive applications like food and pharmaceuticals.

- Integration with Industry 4.0 Ecosystems: AI facilitates seamless communication and data exchange between PET compressors and other smart factory components, enabling holistic production line optimization, automated resource allocation, and centralized control for improved overall efficiency.

- Remote Monitoring and Management: AI-driven platforms allow for sophisticated remote monitoring, providing operators with actionable insights and enabling off-site troubleshooting, reducing the need for on-site personnel and speeding up response times.

- Lifecycle Performance Optimization: AI can learn from historical operational data to suggest optimal running conditions and maintenance intervals, extending the lifespan of compressor components and maximizing the return on investment for the equipment.

- Automated Fault Resolution: In advanced systems, AI can even suggest or initiate automated adjustments to resolve minor operational anomalies without human intervention, ensuring uninterrupted production flow.

- Supply Chain Optimization for Spares: By accurately predicting component lifespan, AI can optimize spare parts inventory, ensuring necessary parts are available when needed without excessive stockholding, reducing capital tied up in inventory.

- Environmental Impact Reduction: Through optimized energy use and extended equipment life, AI indirectly contributes to a lower carbon footprint and reduced industrial waste, aligning with global sustainability goals for PET packaging.

DRO & Impact Forces Of PET Compressors Market

The PET Compressors Market is significantly influenced by a dynamic interplay of Drivers, Restraints, Opportunities, and a variety of Impact Forces that collectively shape its growth trajectory and competitive landscape. A primary driver is the relentless growth in global demand for PET packaging, which continues to expand across a multitude of end-use industries, including beverages (water, carbonated soft drinks, juices), food (edible oils, sauces), pharmaceuticals, and personal care products. This demand is fueled by factors such as increasing global population, urbanization, rising disposable incomes in emerging economies, and the inherent advantages of PET as a packaging material—its lightweight nature, durability, transparency, and high recyclability. Furthermore, the escalating global focus on energy efficiency and sustainability mandates the adoption of advanced compressor technologies, such as Variable Speed Drives (VSD) and oil-free systems, thereby driving replacement demand and new installations. Technological advancements in compressor design, offering higher reliability, lower noise levels, and reduced operational footprint, also serve as significant market accelerators, directly addressing the operational priorities of PET manufacturers aiming for streamlined, cost-effective production.

Conversely, several restraints impede the market's full potential. The high initial capital investment required for sophisticated, high-pressure PET compressors can be a significant barrier, particularly for smaller and medium-sized manufacturers in developing regions. Coupled with substantial maintenance costs and the need for specialized technicians, these factors can impact profitability and deter new market entrants. The intense competitive landscape, characterized by numerous global and regional players, leads to price pressures and compressed profit margins, forcing manufacturers to innovate continuously while maintaining cost-effectiveness. The availability and increasing adoption of alternative packaging materials, such as glass, aluminum cans, and aseptic cartons, pose a potential threat, as these alternatives may offer different perceived benefits in terms of sustainability or premium branding. Moreover, geopolitical uncertainties, fluctuating raw material prices, and disruptions in global supply chains, exemplified by recent events, can impact manufacturing costs and lead times, thereby restraining market growth and operational stability.

Despite these challenges, substantial opportunities exist within the PET Compressors Market. Emerging economies, particularly in Asia Pacific, Latin America, and the Middle East & Africa, represent vast untapped potential, driven by growing industrialization, increasing consumer spending on packaged goods, and nascent but rapidly expanding manufacturing capabilities for PET containers. The integration of Industry 4.0 and IoT technologies, including predictive analytics, remote monitoring, and artificial intelligence, offers manufacturers avenues to enhance operational efficiency, reduce energy consumption, and provide superior aftermarket services, creating significant value propositions. The demand for sustainable compressor solutions, such as those incorporating waste heat recovery systems and eco-friendly lubricants, is also on the rise, aligning with global environmental initiatives and offering a competitive edge. Analyzing the impact forces through a Porter's Five Forces lens reveals high bargaining power of buyers due to standardization and numerous suppliers, but also high bargaining power of suppliers for specialized components. The threat of new entrants is moderate due to high capital requirements and technological expertise, while the threat of substitutes, as noted with alternative packaging, is ever-present. Competitive rivalry is fierce, pushing continuous innovation and differentiation as strategic imperatives for market players.

Segmentation Analysis

Segmentation analysis is a critical exercise for understanding the nuanced dynamics of the PET Compressors Market, allowing for a granular examination of diverse customer needs, technological preferences, and regional variations. By breaking down the total market into distinct categories based on product type, technology, pressure range, drive type, capacity, end-use industry, and sales channel, stakeholders can gain profound insights into specific growth drivers, competitive intensities, and emerging opportunities. This detailed dissection aids in formulating targeted marketing strategies, optimizing product development efforts, and making informed investment decisions, ensuring that product offerings are precisely aligned with market demands. For instance, the purity requirements of the pharmaceutical segment necessitate different compressor specifications compared to general industrial applications, highlighting the importance of tailored solutions across various categories.

The segmentation also reveals how technological advancements are driving shifts within sub-segments. For example, the increasing adoption of Variable Speed Drive (VSD) technology, categorized under 'Drive Type,' underscores the market's strong push towards energy efficiency, impacting all compressor types and capacities. Similarly, the 'By Type' segmentation emphasizes the dominance of oil-free compressors, reflecting the overarching industry demand for contamination-free compressed air critical for product safety and quality in sensitive applications like food and beverages. Understanding these cross-segment influences is essential for anticipating market evolution and positioning products effectively. The analysis further clarifies the distribution landscape, distinguishing between direct sales, which allow for bespoke solutions for large enterprises, and indirect channels, which provide broader market penetration and localized support, particularly for smaller to medium-sized customers.

- By Type:

- Oil-Free Compressors: These compressors are critical for applications where air purity is paramount, such as food, beverage, and pharmaceutical packaging. They prevent contamination of the PET preforms and final products, ensuring safety and compliance with stringent hygiene standards. They typically involve advanced sealing and coating technologies.

- Oil-Lubricated Compressors: While less common for direct PET blowing due to purity concerns, these are sometimes used for utility air or in conjunction with sophisticated air treatment systems where initial cost is a primary consideration, or in less sensitive industrial PET applications.

- By Technology:

- Reciprocating (Piston) Compressors: Predominantly used for high-pressure PET blowing due to their robust design and ability to achieve very high pressures efficiently. Multi-stage reciprocating compressors are common in this segment.

- Rotary Screw Compressors: Often used for lower pressure auxiliary air or in combination with booster compressors for PET applications. Oil-free screw compressors are gaining traction due to their continuous operation capability and energy efficiency for base load air.

- Centrifugal Compressors: Typically employed in very large-scale PET production facilities requiring high volumes of consistent, oil-free air. They offer excellent energy efficiency for constant demand scenarios.

- By Pressure Range:

- High Pressure (above 30 bar): This is the most crucial segment for PET compressors, as the stretch blow molding process specifically requires air pressures ranging from 35 to 40 bar to accurately form PET preforms into bottles.

- Medium Pressure (10-30 bar): Used for some ancillary processes in a PET plant, such as pre-blow air or general utility air, but not for the final high-pressure blowing stage.

- Low Pressure (below 10 bar): Primarily for general plant air, instrument air, or other non-critical applications within a PET manufacturing facility.

- By Drive Type:

- Variable Speed Drive (VSD): Compressors equipped with VSD technology adjust their motor speed to match air demand, leading to significant energy savings, reduced wear and tear, and optimized operational costs, especially in fluctuating demand scenarios.

- Fixed Speed Drive: These compressors run at a constant speed, ideal for applications with consistent and continuous air demand. While simpler in design, they can be less energy-efficient for variable loads.

- By Capacity:

- Small (up to 500 CFM): Suitable for small-scale PET production lines, regional bottlers, or specialized product runs with lower volume requirements.

- Medium (501-2000 CFM): Caters to a broad range of medium-sized PET manufacturers, offering a balance of capacity and energy efficiency for moderate production volumes.

- Large (above 2000 CFM): Designed for high-volume, continuous production lines in large beverage plants or contract packaging facilities, where maximum throughput and uptime are critical.

- By End-Use Industry:

- Beverages: The largest segment, including bottled water, carbonated soft drinks, juices, and dairy products, driving consistent demand for high-purity, high-pressure PET compressors.

- Food: For packaging edible oils, sauces, condiments, and other food items where PET offers protection and transparency.

- Pharmaceutical & Healthcare: Requires the highest standards of air purity for packaging medicines, supplements, and medical devices, driving demand for advanced oil-free solutions.

- Personal Care & Cosmetics: Utilizes PET for shampoos, lotions, creams, and other beauty products due to its aesthetic appeal and barrier properties.

- Industrial: For various non-food/non-pharma industrial applications requiring PET containers, such as automotive fluids, chemicals, and cleaning agents.

- Others: Includes niche applications or emerging uses of PET packaging in different sectors.

- By Sales Channel:

- Direct Sales: Manufacturers sell directly to large-scale end-users, often involving custom solutions, project management, and direct after-sales support.

- Indirect Sales/Distributors: Sales through a network of authorized distributors, dealers, and system integrators, providing broader market reach, local presence, and regional service capabilities, particularly for SMBs.

Value Chain Analysis For PET Compressors Market

The value chain for the PET Compressors Market is a complex ecosystem beginning with the upstream supply of specialized raw materials and components, moving through manufacturing and assembly, and extending downstream to distribution, sales, installation, and critical after-sales services for the end-user. The upstream segment is fundamentally dependent on a global network of suppliers providing high-grade materials such as specialized steels, cast iron, aluminum alloys, and composites that withstand high pressures and continuous operation. Key components like precision-engineered air ends, robust electric motors, sophisticated control systems (PLCs, HMIs), advanced filtration media, high-performance valves, and durable seals are sourced from a specialized group of manufacturers globally. The quality and reliability of these upstream inputs are paramount, as they directly impact the performance, energy efficiency, and lifespan of the final compressor unit, thereby dictating the overall value proposition to the end-user in the PET bottling industry.

Moving downstream, Original Equipment Manufacturers (OEMs) of PET compressors integrate these specialized components, along with their proprietary designs and intellectual property, to assemble complete compressor systems. This stage involves extensive research and development to incorporate innovations like advanced cooling systems, noise reduction technologies, and smart functionalities (IoT integration, predictive maintenance). Once manufactured, these compressors reach the end-users primarily through well-established distribution channels. Direct sales are common for large-scale PET bottling plants or major international beverage companies, where OEMs can offer tailored solutions, direct project management, and comprehensive service contracts. This channel allows for a closer customer relationship and a deeper understanding of specific operational requirements, leading to highly customized and integrated solutions, often with long-term service agreements.

The indirect distribution channel involves a network of authorized distributors, dealers, and system integrators. These partners play a crucial role in providing broader market penetration, especially to small and medium-sized PET manufacturers or those in geographically dispersed regions. Indirect channels often offer localized sales, technical support, installation services, and readily available spare parts, which are vital for ensuring operational continuity and rapid response to service needs. Value is added throughout this chain at every stage: from the precision engineering of raw materials and components, through the innovative design and rigorous manufacturing processes of the OEMs, to the localized support and expertise provided by distributors and service providers. The ultimate value delivery is the reliable, energy-efficient supply of high-purity, high-pressure air that ensures consistent PET bottle quality, minimizes production downtime, and reduces operational costs for the end-user, thereby safeguarding product integrity and maximizing productivity in the highly competitive PET packaging industry.

PET Compressors Market Potential Customers

The primary potential customers and end-users of PET compressors are invariably companies involved in the manufacturing of polyethylene terephthalate (PET) bottles and containers across various industries. This includes a broad spectrum of businesses, from multinational beverage conglomerates operating large-scale, automated bottling lines to regional food processors and specialized pharmaceutical companies. These entities require a consistent and reliable supply of high-pressure, oil-free compressed air, which is fundamental to the stretch blow molding process that transforms PET preforms into finished bottles. Their purchasing decisions are critically influenced by factors such as the compressor's energy efficiency, its ability to maintain high air purity standards (especially for food and pharmaceutical applications), operational reliability to minimize costly downtime, and the overall total cost of ownership, including initial investment and ongoing maintenance expenses. Customization options, service availability, and integration capabilities with existing production infrastructure are also key considerations for these sophisticated industrial buyers.

Specifically, the beverage industry represents the largest segment of potential customers, encompassing producers of bottled water, carbonated soft drinks, fruit juices, and even alcoholic beverages. These companies operate at high volumes and require compressors capable of continuous, heavy-duty performance with uncompromising air quality to prevent any contamination of their products. Similarly, the food industry, which packages items like edible oils, sauces, jams, and condiments in PET containers, constitutes a significant customer base, demanding stringent hygienic standards from their air supply. Pharmaceutical companies, requiring sterile environments and absolute air purity for packaging medicines, medical devices, and health supplements, form a highly specialized but crucial customer segment, often driving demand for the most advanced oil-free and certified compressor technologies.

Beyond food and beverage, the personal care and cosmetics industry is a growing customer segment, utilizing PET bottles for shampoos, lotions, cleansers, and other beauty products, valuing the material's aesthetic versatility and protective qualities. Furthermore, industrial chemical manufacturers, producing containers for cleaning agents, automotive fluids, and lubricants, also form a segment of the potential customer base, albeit with potentially less stringent air purity requirements than food or pharma, but still demanding high reliability and efficiency. Each of these end-user categories possesses distinct operational scales, budget constraints, and regulatory environments, necessitating a diverse range of compressor capacities, technologies, and service packages from PET compressor manufacturers. Understanding these varied needs is paramount for effective market penetration and long-term customer relationship management.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Knorr-Bremse, Siemens, Ingersoll Rand, Gardner Denver, Boge Kompressoren, KAESER KOMPRESSOREN, Sullair, Hitachi Industrial Equipment Systems, Parker Hannifin, Quincy Compressor, CompAir, Fusheng, Hanbell, Doosan Portable Power, ANEST IWATA Corporation, ALMiG Kompressoren GmbH, Bauer Kompressoren GmbH, Sauer Compressors, Corken, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Compressors Market Key Technology Landscape

The technological landscape of the PET Compressors Market is continuously evolving, driven by the critical need for enhanced energy efficiency, uncompromising air purity, increased reliability, and intelligent operational control. Central to this evolution is the pervasive adoption of oil-free compression technology, which is paramount for preventing contamination in sensitive applications such as food, beverages, and pharmaceuticals. This technology utilizes innovative designs, often incorporating dry components, water-injected screws, or magnetic bearings, to eliminate the need for oil in the compression chamber, ensuring the delivered air is 100% free of oil aerosols and vapors. Concurrently, Variable Speed Drive (VSD) technology has become a cornerstone, significantly improving energy efficiency by dynamically adjusting the compressor's motor speed to match the precise demand for compressed air. This capability reduces energy waste during periods of fluctuating demand, leading to substantial operational cost savings and a reduced carbon footprint, making it a crucial differentiator in a market sensitive to energy expenses.

Beyond core compression techniques, the integration of advanced control systems and the Internet of Things (IoT) is fundamentally reshaping how PET compressors operate and are managed. Modern compressors feature sophisticated Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that offer precise control over pressure, flow, and operational parameters, enabling optimized performance and easy diagnostics. IoT sensors embedded within these systems collect vast amounts of real-time data on temperature, pressure, vibration, current, and air quality. This data is then transmitted to cloud-based platforms, enabling remote monitoring, predictive maintenance, and real-time performance analytics. Such capabilities allow manufacturers to anticipate potential failures, schedule maintenance proactively, and even perform remote troubleshooting, thereby maximizing uptime and operational continuity, which are vital for high-volume PET production lines.

Emerging and innovative technologies further enrich this landscape. Energy recovery systems, for instance, capture and repurpose the waste heat generated during compression, often for heating water or facilities, leading to further energy savings and improved sustainability. Modular compressor designs are gaining traction, offering greater flexibility in installation, easier expansion of capacity, and simpler maintenance. Magnetic bearing technology represents a significant advancement, eliminating wear and tear associated with traditional bearings, reducing maintenance, and improving energy efficiency by reducing friction. Furthermore, advancements in air treatment solutions, including highly efficient desiccant dryers and advanced filtration systems, ensure ultra-dry and pure air, critical for maintaining the structural integrity and optical clarity of PET bottles. The ongoing development in noise reduction technologies also contributes to a more conducive and compliant working environment, highlighting the holistic approach to technological enhancement in the PET compressor market.

Regional Highlights

- North America: The North American market for PET compressors is characterized by maturity, stable demand, and a strong emphasis on technological upgrades and efficiency. Key drivers include stringent environmental regulations promoting energy-efficient compressor systems and a robust replacement cycle for aging infrastructure in established beverage and food packaging industries. The region also exhibits a high adoption rate of advanced technologies such as Variable Speed Drive (VSD) and IoT-integrated compressors, driven by the imperative to reduce operational costs and enhance productivity. The United States and Canada are major contributors, with a focus on innovation in smart manufacturing and aftermarket services. Growth is steady, often linked to the expansion of craft beverage industries and increasing demand for customized packaging solutions.

- Europe: Europe represents a significant market for PET compressors, marked by strict environmental standards, a strong drive towards sustainability, and a high level of automation in manufacturing. The demand is heavily influenced by directives aimed at reducing carbon emissions and energy consumption, leading to widespread adoption of oil-free and energy-efficient compressor technologies. Germany, France, Italy, and the UK are key markets, with a focus on high-quality, reliable, and technologically advanced systems. The region is also at the forefront of circular economy initiatives, impacting PET production and, consequently, the demand for compressors that support efficient and sustainable operations. Aftermarket services and long-term support contracts are particularly valued here.

- Asia Pacific (APAC): The Asia Pacific region stands out as the fastest-growing market for PET compressors globally. This rapid expansion is fueled by booming industrialization, increasing urbanization, a burgeoning middle class, and rising disposable incomes that are driving unprecedented demand for packaged food and beverages. Countries like China, India, Indonesia, and Vietnam are at the epicenter of this growth, with significant investments in new PET manufacturing capacities. The market here is characterized by a mix of new installations and a growing demand for cost-effective yet reliable solutions. While initial cost remains a factor, there is an increasing awareness and adoption of energy-efficient and oil-free technologies, particularly in food and pharmaceutical segments, as local regulations and consumer expectations evolve towards higher standards.

- Latin America: The Latin American market for PET compressors is experiencing robust growth, driven by economic development, increasing foreign investments in manufacturing, and a rising consumption of packaged goods across the region. Brazil, Mexico, and Argentina are leading the demand, with significant expansion in their beverage and food processing sectors. The market is characterized by a need for durable, reliable, and easy-to-maintain compressor solutions. While price sensitivity can be a factor, there is a growing recognition of the long-term benefits of energy-efficient and technologically advanced systems. Infrastructure development and a focus on expanding regional production capabilities are key market accelerators, contributing to steady growth over the forecast period.

- Middle East and Africa (MEA): The Middle East and Africa region presents an emerging but promising market for PET compressors. Growth is primarily driven by ongoing infrastructure development, increasing industrialization, and a rising demand for packaged food and beverages due to population growth and changing consumer lifestyles. Countries in the Gulf Cooperation Council (GCC) and South Africa are leading the charge, with investments in new bottling plants and manufacturing facilities. The market is often influenced by global players setting up operations and a strong emphasis on robust, reliable compressors that can withstand demanding environmental conditions. While still in nascent stages compared to other regions, the MEA market is expected to demonstrate significant growth, particularly with continued economic diversification efforts and increased foreign direct investment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Compressors Market.- Atlas Copco

- Knorr-Bremse

- Siemens

- Ingersoll Rand

- Gardner Denver

- Boge Kompressoren

- KAESER KOMPRESSOREN

- Sullair

- Hitachi Industrial Equipment Systems

- Parker Hannifin

- Quincy Compressor

- CompAir

- Fusheng

- Hanbell

- Doosan Portable Power

- ANEST IWATA Corporation

- ALMiG Kompressoren GmbH

- Bauer Kompressoren GmbH

- Sauer Compressors

- Corken, Inc.

Frequently Asked Questions

What is a PET compressor and why is it essential for PET bottle manufacturing?

A PET compressor is a specialized high-pressure air compressor designed to provide the precise, oil-free compressed air required for the stretch blow molding process of PET (polyethylene terephthalate) bottles. It is essential because PET preforms must be inflated with air typically ranging from 35 to 40 bar to form their final bottle shape. The purity and consistency of this air are critical to ensure the structural integrity, clarity, and safety of the final PET product, especially for food, beverage, and pharmaceutical applications, making the compressor an indispensable component of any PET bottling line.

What are the primary factors driving the growth of the PET Compressors Market?

The PET Compressors Market is primarily driven by the escalating global demand for PET packaging across various industries such as beverages, food, pharmaceuticals, and personal care, fueled by population growth, urbanization, and rising disposable incomes. Additionally, stringent regulations and an increasing focus on energy efficiency and sustainability compel manufacturers to adopt advanced compressor technologies like Variable Speed Drives (VSD) and oil-free systems, further stimulating market growth by driving both new installations and replacement demand.

How do oil-free compressors contribute to the PET packaging industry, particularly in sensitive sectors?

Oil-free compressors are crucial in the PET packaging industry, especially for sensitive sectors like food, beverages, and pharmaceuticals, because they deliver compressed air that is 100% free of oil contamination. This prevents any risk of product adulteration, ensuring compliance with strict hygiene and safety regulations (e.g., ISO 8573-1 Class 0 standards). By eliminating oil traces, these compressors safeguard product quality, extend shelf life, and maintain consumer trust, which are paramount for health-conscious and regulated markets.

What impact does artificial intelligence (AI) have on the PET Compressors Market?

AI significantly impacts the PET Compressors Market by enabling advanced predictive maintenance, optimizing energy consumption, and enhancing operational control. AI algorithms analyze real-time data to anticipate potential equipment failures, schedule proactive maintenance, and dynamically adjust compressor parameters for peak efficiency, leading to reduced downtime and substantial energy savings. AI also facilitates seamless integration into Industry 4.0 environments, improving overall production line efficiency and ensuring consistent air quality for superior PET bottle manufacturing.

What are the key technological advancements shaping the PET Compressors Market?

Key technological advancements shaping the PET Compressors Market include the widespread adoption of Variable Speed Drive (VSD) technology for superior energy efficiency, advanced oil-free compression methods ensuring ultra-pure air delivery, and the integration of IoT and AI for real-time monitoring, predictive maintenance, and optimized operational control. Other significant advancements involve modular designs for scalability, energy recovery systems to repurpose waste heat, and sophisticated control systems that enhance reliability and ease of use, collectively driving performance and sustainability in PET production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager