PET Felt Panels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431953 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

PET Felt Panels Market Size

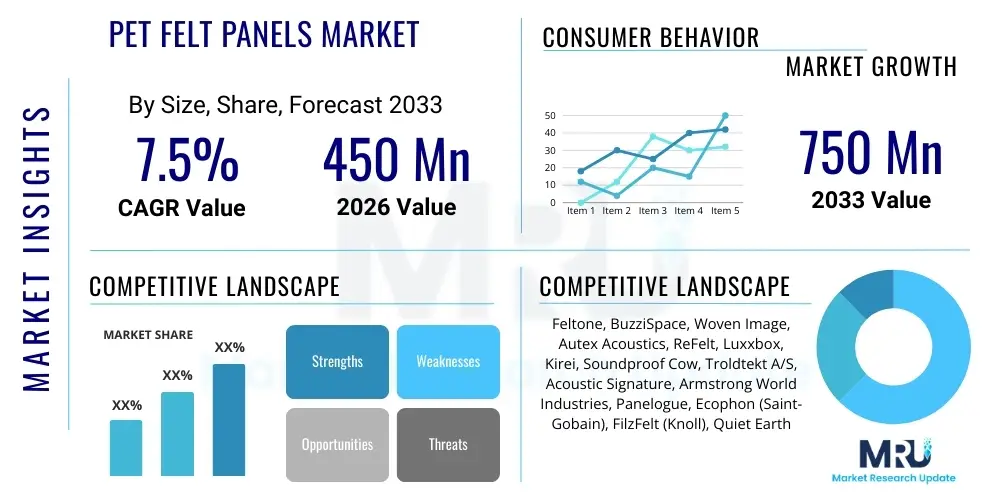

The PET Felt Panels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 750 Million by the end of the forecast period in 2033.

PET Felt Panels Market introduction

The PET Felt Panels market encompasses the production and distribution of acoustic panels derived primarily from recycled polyethylene terephthalate (PET) plastic bottles. This product category is fundamentally positioned within the sustainable building and interior design sectors, offering dual benefits of superior sound absorption and environmental responsibility. PET felt is manufactured through a process involving washing, shredding, melting, and forming the recycled plastic into non-woven polyester fibers, which are then compressed and thermally bonded into rigid or flexible panel formats. These panels are increasingly utilized across commercial, institutional, and residential environments where noise reduction and aesthetic appeal are critical design requirements, reflecting a growing global emphasis on occupant well-being and green certifications in construction projects.

Major applications of PET felt panels span across corporate offices, educational facilities, healthcare settings, retail spaces, and specialized environments like recording studios and home theaters. In corporate settings, they are essential for mitigating noise pollution in open-plan layouts, enhancing speech privacy, and improving overall cognitive function among employees. The inherent material benefits, such as lightweight structure, durability, fire resistance, and mold resistance, make them a favored alternative to traditional acoustic treatments. Furthermore, the material’s versatility allows for extensive customization in terms of color, thickness, texture, and shape, enabling architects and interior designers to integrate acoustic solutions seamlessly into complex architectural visions without compromising aesthetic standards.

The primary driving factors propelling the expansion of this market include stringent governmental regulations promoting sustainable building practices, such as LEED and BREEAM certifications, which favor materials with high recycled content. Concurrently, the increasing recognition of the health and productivity benefits associated with optimal acoustic environments is stimulating demand. The global push toward circular economy principles further reinforces the market, positioning PET felt panels as a key innovation in tackling plastic waste while addressing sophisticated acoustic challenges in modern construction. Continuous technological advancements in manufacturing processes are also leading to more cost-effective production methods and enhanced product performance, broadening the market’s accessibility across various price points and application areas globally.

PET Felt Panels Market Executive Summary

The global PET Felt Panels market is experiencing robust growth driven by accelerating global sustainability mandates and the paradigm shift toward human-centric office and educational design. Business trends indicate a strong move toward vertical integration among key manufacturers, aiming to secure reliable sources of high-quality recycled PET (rPET) flake supply and achieve greater control over the production lifecycle, enhancing profitability and ensuring compliance with green claims. Furthermore, there is a visible trend toward offering comprehensive acoustic solutions, where panels are integrated with lighting systems or modular furniture, moving beyond simple wall treatments to holistic interior solutions. Customization capabilities, facilitated by advanced cutting and printing technologies, are unlocking premium market segments that demand unique and highly personalized interior aesthetics for high-end commercial projects.

Regional trends reveal that Asia Pacific (APAC) is emerging as the fastest-growing market, primarily fueled by massive infrastructure development, rapid urbanization, and increased adoption of international building standards in commercial real estate across countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, maintain dominance in terms of technological innovation and market valuation, largely due to stringent environmental policies, high awareness regarding acoustic quality, and the widespread refurbishment of existing commercial buildings to meet modern sustainability targets. The Middle East and Africa (MEA) region show burgeoning potential, particularly within high-profile hospitality and institutional projects where striking architectural design and acoustic performance are paramount requirements.

Segment trends underscore the dominance of the commercial application segment, driven by persistent demand for acoustic privacy in modern workspaces. Within product types, ceiling panels and baffles are witnessing significant uptake, offering effective overhead sound control solutions that are particularly suitable for large, reverberant spaces. The material thickness segment shows increasing traction for 12mm and 24mm panels, balancing acoustic efficacy with cost and ease of installation. Segmentation analysis also highlights the expanding role of distributors and specialized acoustic consultants in the sales channel, reflecting the technical nature of product specification and installation required in sophisticated architectural projects. Overall, the market remains highly competitive, prioritizing innovation in material aesthetics, acoustic performance metrics, and verified sustainable sourcing credentials.

AI Impact Analysis on PET Felt Panels Market

Common user questions regarding AI's influence on the PET Felt Panels market typically center on efficiency gains in manufacturing, the personalization of design, and the integration of acoustic elements into smart building ecosystems. Users are keen to understand how Artificial Intelligence can optimize the complex production processes involving recycled materials, specifically concerning defect detection, material density control, and waste minimization during cutting and molding. Furthermore, there is significant interest in AI-driven acoustic modeling software that can accurately predict required panel placement and density based on room geometry and intended function, moving beyond traditional calculation methods. Expectations include using AI to analyze real-time acoustic data in occupied buildings, adjusting or recommending maintenance schedules for panels, or providing dynamic design suggestions tailored to fluctuating occupant needs, thereby enhancing the functional lifespan and efficacy of PET felt installations in smart environments.

- AI-driven optimization of manufacturing processes, including predictive maintenance for thermal bonding equipment and precise control over fiber alignment, significantly reducing material waste and improving overall product consistency and performance metrics.

- Integration of AI algorithms into architectural design software (BIM tools) to instantly simulate complex acoustic scenarios, recommending optimal panel layouts, thickness variations, and geometric patterns to achieve predefined Noise Reduction Coefficients (NRC) goals.

- Enhanced supply chain efficiency through machine learning models that forecast demand fluctuations for specific panel designs, colors, and thicknesses, enabling just-in-time inventory management of rPET raw materials and finished goods, lowering operational costs.

- Development of personalized acoustic environments using AI sensors and actuators within smart buildings, allowing PET felt panels to be dynamically utilized (e.g., through motorized or adjustable systems) based on real-time noise mapping and occupancy data, maximizing occupant comfort.

- Quality control improvement via computer vision systems that scan finished panels for minute imperfections, color variances, or structural defects at high speeds, ensuring only premium-grade products enter the market and upholding brand reputation for excellence in acoustic solutions.

DRO & Impact Forces Of PET Felt Panels Market

The PET Felt Panels market is currently shaped by a powerful confluence of drivers, restraints, and opportunities that dictate its trajectory and competitive landscape. Key drivers primarily revolve around the strong global impetus toward sustainability and the increasing regulatory environment favoring circular economy materials. The demonstrable benefits of PET felt in enhancing indoor environmental quality (IEQ), particularly through effective noise reduction, directly contribute to improved occupant productivity and well-being, which is a major purchasing criterion for commercial developers. These factors create robust, sustained demand, especially in high-density urban areas where noise pollution is a chronic issue, pushing architects to specify high-performance, aesthetically pleasing acoustic materials derived from recycled sources. The versatility of design and customization capabilities further solidifies its position as a preferred modern building material.

However, the market faces significant restraints that temper its growth rate and market penetration. The relatively high initial cost of PET felt panels compared to conventional gypsum or mineral fiber acoustic boards remains a barrier for budget-constrained projects, particularly in developing economies, despite the long-term cost benefits associated with durability and environmental compliance. Furthermore, the reliance on a stable supply chain of post-consumer PET bottles introduces volatility; fluctuations in recycling rates and competition from other industries utilizing rPET (e.g., textiles, packaging) can impact raw material prices and availability. Finally, achieving consumer and designer awareness regarding the distinct performance and sustainability attributes of PET felt, often requiring detailed technical specification support, poses a perpetual marketing challenge that requires significant investment in educational content.

Opportunities for market acceleration are abundant, primarily focused on technological innovation and market expansion. The development of advanced manufacturing techniques that allow for even higher recycled content (approaching 100%) or novel material blends to enhance fire resistance and durability represents a lucrative avenue. Geographically, untapped potential lies in residential retrofit markets, driven by increasing consumer expenditure on home office upgrades and interior design enhancements, moving beyond the traditional commercial focus. Moreover, the integration of PET felt with smart technology, such as embedded sensors or integrated heating/cooling elements, opens up premium niche markets requiring multi-functional, sophisticated building solutions. These forces collectively create a dynamic market environment where innovation and verified sustainability credentials are essential for sustained competitive advantage.

Segmentation Analysis

The PET Felt Panels market is segmented comprehensively based on several critical parameters including Type, Application, End-use, and Thickness, allowing for targeted analysis of consumer preferences and market needs across various sectors. Analyzing these segments provides strategic insights into which product configurations are gaining traction and which end-user industries are driving the most significant volume and value growth. This detailed categorization helps manufacturers tailor their product portfolios, pricing strategies, and distribution channels to maximize market reach and responsiveness. Key segmentation highlights the shift toward customized solutions and high-density panels necessary for meeting stringent acoustic requirements in commercial environments.

- By Type:

- Acoustic Wall Panels

- Acoustic Ceiling Panels (Baffles, Clouds)

- Desk Screens and Partitions

- Custom Molded Shapes

- By Thickness:

- 9mm

- 12mm

- 24mm and Above

- By Application:

- Sound Absorption

- Noise Diffusion

- Aesthetic/Design

- By End-Use Industry:

- Commercial (Offices, Retail, Hospitality)

- Institutional (Education, Healthcare)

- Industrial

- Residential

- By Manufacturing Process:

- Needle Punching

- Thermal Bonding

Value Chain Analysis For PET Felt Panels Market

The value chain for the PET Felt Panels market begins fundamentally at the upstream stage with the sourcing and preparation of raw materials, which primarily involves the collection, sorting, washing, and flaking of post-consumer PET bottles to produce high-quality recycled PET (rPET) flakes or pellets. This segment is highly sensitive to global recycling infrastructure efficiency and commodity pricing volatility, meaning securing long-term, stable contracts with reliable recycling partners is critical for cost management and ensuring the sustainability claims of the final product. The processing stage then transforms the rPET into non-woven felt through advanced manufacturing techniques like needle punching and thermal bonding, which requires specialized, energy-intensive machinery. Efficiency at this stage, focusing on minimizing energy use and maximizing yield, directly impacts the final product's competitive pricing and environmental footprint.

The midstream of the value chain involves the fabrication and customization processes, where large sheets of PET felt are cut, shaped, printed, and sometimes laminated or backed with specialized adhesives to meet specific architectural requirements. This customization is often facilitated by advanced technologies such as CNC cutting, laser etching, and high-resolution digital printing, adding significant value and differentiating premium products. Following fabrication, the distribution channel plays a pivotal role in market penetration. Sales are typically managed through a mix of direct and indirect channels. Direct sales are common for large-scale commercial contracts, involving close collaboration between manufacturers and architecture/design firms (A&D). Indirect channels utilize specialized acoustic distributors, building material wholesalers, and increasingly, e-commerce platforms targeting smaller residential or DIY markets, requiring robust logistics and warehousing capabilities to handle varying product sizes and complex installation guides.

The downstream segment encompasses the end-users—architects, interior designers, commercial developers, and facility managers—who specify and install the panels. The success in the downstream market relies heavily on providing comprehensive technical support, including acoustic performance data (NRC ratings), fire safety certifications, and aesthetic samples, effectively bridging the gap between technical material properties and architectural vision. Installation services, whether provided directly by the manufacturer or through certified contractors, finalize the value chain, ensuring the panels function optimally in the intended environment. The circularity of the product is also a growing consideration, with some manufacturers initiating take-back programs to recycle the panels at the end of their useful life, thereby closing the loop and enhancing the product’s long-term environmental value proposition.

PET Felt Panels Market Potential Customers

The primary end-users and buyers of PET felt panels are highly segmented across the commercial, institutional, and residential construction ecosystems, with purchasing decisions heavily influenced by specifications set by architects and interior designers. Commercial real estate developers constitute a major customer base, particularly those undertaking large-scale office park developments, high-rise buildings, and mixed-use facilities where employee well-being and green building certifications (e.g., LEED Platinum, WELL Building Standard) are non-negotiable requirements. These customers prioritize high Noise Reduction Coefficient (NRC) performance, fire safety compliance, and verifiable documentation of recycled content to meet their corporate sustainability mandates and enhance property valuations in a competitive market. Furthermore, the hospitality sector, including hotels, resorts, and high-end restaurants, is increasingly adopting these panels for subtle noise control that complements luxurious and modern design aesthetics.

Institutional customers, encompassing the educational sector (universities, K-12 schools) and healthcare facilities (hospitals, clinics), represent another critical customer segment. In schools, effective acoustic management is directly linked to improved learning outcomes and speech intelligibility in classrooms and auditoriums, driving sustained demand for durable, non-toxic, and easy-to-clean acoustic solutions like PET felt. Healthcare environments utilize these panels to reduce stress-inducing ambient noise, contributing to patient recovery and staff concentration, making material specifications highly focused on hygiene, low Volatile Organic Compounds (VOCs), and stringent fire ratings. Facility management companies that oversee the refurbishment and maintenance of existing building stock are also key purchasers, focusing on panels that offer quick installation and long-term durability to minimize disruption during operational periods.

Indirectly, but critically influential, are the independent architecture and interior design firms (A&D community). They act as the gatekeepers, specifying the materials used in almost all major construction projects. Manufacturers dedicate significant sales and marketing efforts toward educating this community about the technical and aesthetic advantages of PET felt, including its customizable features, color palettes, and structural versatility. The residential market, while smaller in volume, is growing rapidly, driven by homeowners investing in dedicated home offices, media rooms, and aesthetic acoustic solutions to improve quality of life and enhance remote work environments, typically sourcing materials through specialized retail distributors or professional home improvement contractors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 750 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Feltone, BuzziSpace, Woven Image, Autex Acoustics, ReFelt, Luxxbox, Kirei, Soundproof Cow, Troldtekt A/S, Acoustic Signature, Armstrong World Industries, Panelogue, Ecophon (Saint-Gobain), FilzFelt (Knoll), Quiet Earth |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Felt Panels Market Key Technology Landscape

The technology landscape governing the PET Felt Panels market is constantly evolving, focusing intensely on improving material purity, manufacturing efficiency, and aesthetic versatility. A foundational technology is the advanced recycling process used to convert post-consumer PET into high-quality fiber, specifically chemical recycling techniques which promise higher purity and potentially infinite recycling cycles compared to traditional mechanical recycling. This technological advancement ensures a steady supply of high-grade raw material that meets stringent requirements for color consistency and structural integrity necessary for premium acoustic panels. Furthermore, manufacturers are investing in highly automated, continuous production lines that utilize sophisticated needle punching and thermal bonding technologies, allowing for the creation of panels with customized densities and consistent acoustic performance across large batches, significantly reducing production lead times and labor costs.

In the fabrication phase, precision cutting and customization technologies are paramount to market differentiation. High-speed Computer Numerical Control (CNC) routers and advanced laser cutting systems enable manufacturers to produce complex geometric patterns and custom three-dimensional shapes with exacting precision, offering architects unparalleled freedom in design execution. Complementing this is the emergence of digital printing technology specifically optimized for porous polyester felt surfaces. This allows for high-resolution graphics, wood grain patterns, or photographic images to be printed directly onto the acoustic panels without compromising their sound-absorbing properties, transforming the panels from mere functional elements into primary design features within an interior space. These advancements in digital fabrication are crucial for targeting niche markets demanding bespoke architectural acoustic solutions.

Beyond material processing, innovative product technologies are emerging that integrate additional functionality into the felt panels. This includes the development of multi-functional panels that incorporate lighting elements (LED strips), modular attachment systems (magnetic or interlocking mechanisms for easy reconfigurability), or specialized coatings that enhance fire resistance (Class A certification) or improve hygiene characteristics. Furthermore, there is growing exploration into incorporating Phase Change Materials (PCMs) within the panel structure to offer passive temperature regulation alongside acoustic benefits, moving the product beyond simple sound absorption toward integrated interior climate management solutions. These technological integrations underscore the market's trajectory toward highly engineered, multi-utility building components essential for future smart and sustainable construction projects.

Regional Highlights

- North America: This region holds a significant market share, characterized by high corporate awareness of employee wellness and productivity, translating into robust demand for IEQ-enhancing materials. The U.S. and Canada benefit from widespread adoption of green building standards (LEED, WELL), driving specifications for high-recycled content products. Major consumption is concentrated in the commercial office sector, higher education facility construction, and the booming tech industry, requiring sophisticated acoustic solutions for open-plan workspaces. Regulatory incentives and a mature recycling infrastructure support the sustained growth of the PET felt market here.

- Europe: Europe is a leader in market penetration due to some of the world's most stringent environmental regulations and a strong cultural emphasis on architectural design quality and sustainability. Countries like Germany, the Netherlands, and Scandinavia show high per capita consumption, driven by mandates for energy efficiency and the circular economy framework. The market here is highly competitive, emphasizing premium aesthetics, superior fire safety ratings (Euroclass certification), and highly transparent sourcing documentation for the recycled content used in the panels.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR during the forecast period, powered by rapid urbanization and massive investment in commercial and public infrastructure projects, particularly in China, India, and Southeast Asia. While initial adoption was slower, the increasing penetration of global architectural firms and the necessity for modern soundproofing in densely populated urban centers are accelerating demand. The key challenges involve developing consistent rPET supply chains and increasing awareness among local developers regarding the long-term benefits of premium acoustic materials over cheaper, traditional alternatives.

- Latin America (LATAM): This region represents an emerging market, with growth primarily concentrated in Brazil and Mexico, driven by foreign direct investment in commercial properties and luxury residential projects. Market growth is contingent on improving local recycling infrastructure and increasing developer focus on sustainable certifications. The hospitality sector, aiming to attract international tourism, is a key early adopter of PET felt panels for enhancing guest experience and minimizing noise transfer between rooms.

- Middle East and Africa (MEA): Growth in MEA is highly project-specific, fueled by ambitious mega-projects in the UAE, Saudi Arabia, and Qatar (e.g., NEOM, Expo 2030 projects). These regions prioritize high-end, iconic architectural statements where customized, visually striking acoustic solutions are necessary to complement complex designs. While sustainability is a growing focus, the demand often centers on superior thermal and acoustic performance suitable for extreme climate conditions, requiring panels with high durability and customized fire ratings.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Felt Panels Market.- Feltone

- BuzziSpace

- Woven Image

- Autex Acoustics

- ReFelt

- Luxxbox

- Kirei

- Soundproof Cow

- Troldtekt A/S (though primarily wood wool, they compete in acoustic panels)

- Acoustic Signature

- Armstrong World Industries (via relevant acoustic lines)

- Panelogue

- Ecophon (Saint-Gobain)

- FilzFelt (Knoll)

- Quiet Earth

- Inspec Group

- Tarkett (Desso)

- Offecct

- AcousPanel

- Recycelt Acoustics

Frequently Asked Questions

Analyze common user questions about the PET Felt Panels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material composition of PET Felt Panels and why is it considered sustainable?

PET Felt Panels are primarily composed of recycled polyethylene terephthalate (rPET) fibers, derived from post-consumer plastic bottles. This use of recycled content significantly reduces landfill waste and the reliance on virgin petroleum-based resources, positioning the panels as a highly sustainable and circular economy building material widely favored for LEED and WELL certified projects globally.

How effective are PET Felt Panels at reducing noise, and what NRC rating can typically be achieved?

PET Felt Panels are highly effective sound absorbers due to their porous, non-woven fiber structure, which traps sound waves and reduces reverberation. Depending on thickness and density (e.g., 9mm, 12mm, or 24mm), these panels typically achieve a Noise Reduction Coefficient (NRC) ranging from 0.45 up to 0.90, making them suitable for mitigating mid- to high-frequency noise in commercial and institutional settings.

What are the primary applications driving market growth for PET Felt Panels globally?

The primary growth applications are commercial offices, where they address noise challenges in open-plan environments, and institutional facilities, such as schools and hospitals, where optimal acoustics are essential for learning and patient recovery. The global emphasis on improving Indoor Environmental Quality (IEQ) and stringent green building mandates are the core demand drivers.

What are the key technical constraints or challenges facing the PET Felt Panels industry?

Key challenges include the high initial cost compared to traditional non-sustainable acoustic materials and volatility in the supply chain of high-quality recycled PET (rPET) flakes. Furthermore, competitive pressures require continuous investment in advanced technologies to enhance aesthetic customization and ensure compliance with stringent fire safety standards across different regions.

Which geographical region is expected to show the fastest market expansion for PET Felt Panels?

The Asia Pacific (APAC) region, specifically emerging economies within Southeast Asia, China, and India, is forecast to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is attributed to rapid urbanization, massive infrastructure development, and increasing adoption of international commercial building standards that prioritize sustainable and acoustically sound construction materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager