PET Stretch Blow Moulding Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432641 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

PET Stretch Blow Moulding Machines Market Size

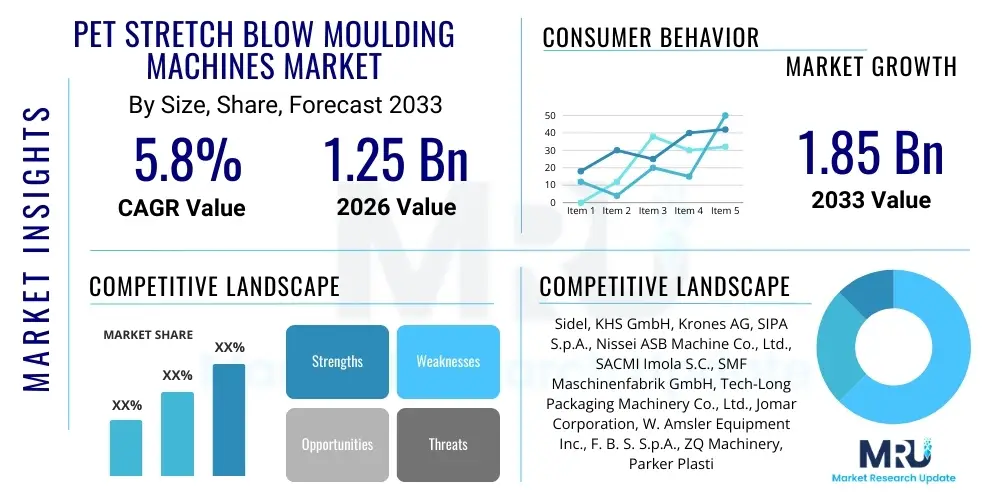

The PET Stretch Blow Moulding Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.85 billion by the end of the forecast period in 2033.

PET Stretch Blow Moulding Machines Market introduction

The PET (Polyethylene Terephthalate) Stretch Blow Moulding Machines Market encompasses specialized industrial equipment designed for the high-volume production of PET bottles and containers. These machines utilize a two-step process: first, injection moulding to create PET preforms, and second, stretch blow moulding where the preforms are heated and then stretched bi-axially while high-pressure air is injected, forming the final container shape. This technology is critical for the beverage, pharmaceutical, and edible oil industries due to PET's superior clarity, lightweight properties, barrier performance, and recyclability. The market is characterized by intense focus on machine efficiency, energy consumption reduction, and the ability to handle complex bottle designs, including lightweighting initiatives mandated by sustainability goals.

Product sophistication in this market is driven by the shift towards fully automated, rotary stretch blow moulding systems that offer exceptional output rates and minimal human intervention. Key benefits derived from modern PET stretch blow moulding technology include enhanced productivity through multi-cavity moulds, consistent container quality assurance, and the flexibility to rapidly switch between different bottle formats and sizes, crucial for diverse product portfolios. Furthermore, advancements in reheating ovens and blowing pressure systems contribute to reduced cycle times, directly impacting operational throughput and reducing overall manufacturing costs, which is highly appealing to large-scale packaging operations.

Major applications span bottled water, carbonated soft drinks (CSD), juices, alcoholic beverages, household cleaning products, and personal care items. The driving factors behind market expansion include the surging global demand for packaged drinking water, particularly in emerging economies, the continuous innovation in packaging aesthetics to differentiate products on shelves, and the growing regulatory push for sustainable packaging materials, where PET plastic excels due to its closed-loop recycling capabilities. The need for faster production lines capable of supporting the high consumption rates of packaged goods globally cements the reliance on advanced blow moulding solutions.

PET Stretch Blow Moulding Machines Market Executive Summary

The PET Stretch Blow Moulding Machines Market is experiencing robust expansion, largely fueled by aggressive capital expenditure in packaging infrastructure across Asia Pacific and Latin America, driven by population growth and increasing disposable incomes leading to higher per capita consumption of packaged beverages. Business trends emphasize the adoption of high-speed rotary machines equipped with advanced heating technology and intelligent controls, prioritizing minimal energy consumption and enhanced operational stability. Sustainability goals are profoundly influencing machine development, with a strong market pull towards equipment capable of processing recycled PET (rPET) materials effectively, ensuring that container properties like strength and clarity are maintained even with high percentages of recycled content. This focus on efficiency and sustainability defines the current investment cycle within the market.

Regional trends indicate that Asia Pacific remains the dominant and fastest-growing region due to massive urbanization and the expansion of the food and beverage industry, particularly in India and China, where bottled water consumption is soaring. North America and Europe, while mature, are focusing heavily on equipment modernization, replacing older hydraulic systems with advanced electric and servo-driven machines to meet stringent energy efficiency standards and reduce Total Cost of Ownership (TCO). These developed regions are pioneers in implementing digital manufacturing principles, integrating their blow moulding operations within wider Industry 4.0 frameworks for real-time monitoring and predictive maintenance.

Segmentation trends highlight the rapid growth of the fully automated machines segment due to their unmatched production capacity and reliability, especially within the CSD and bottled water sectors. Technology segmentation shows a clear preference for rotary stretch blow moulding technology over linear systems for high-output environments, offering superior speed and dimensional precision. Furthermore, the market for aseptic filling lines, often integrated directly with blow moulding machines (Sidel's Combi solutions being a prime example), is expanding, driven by the demand for shelf-stable sensitive beverages such as juices and milk products, necessitating the highest levels of hygienic production processes directly at the point of manufacture.

AI Impact Analysis on PET Stretch Blow Moulding Machines Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) and Machine Learning (ML) on the PET Stretch Blow Moulding Machines Market revolve primarily around optimization, predictive maintenance, and quality control. Users are keen to understand how AI can minimize defects, reduce energy consumption per bottle, and predict component failure, thereby minimizing costly downtime. There is also significant interest in using ML algorithms to fine-tune complex variables like preform temperature, blow pressure, and stretch rod speed automatically in real-time, achieving perfect consistency even when processing varying batches of recycled materials. The consensus indicates a strong expectation that AI integration will fundamentally shift machine operation from reactive monitoring to proactive, self-optimizing manufacturing cells, delivering immediate operational cost savings and improved resource utilization.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast potential failures in heating elements, valves, or stretch rods, scheduling maintenance proactively, and significantly increasing machine uptime (OEE).

- Real-time Quality Optimization: Employing vision systems and ML algorithms to instantly detect micro-defects or dimensional inconsistencies in bottles and automatically adjusting machine parameters during the production run, minimizing scrap rates.

- Energy Consumption Reduction: AI models analyzing production schedules, ambient conditions, and material flow to optimize heating curve profiles and compressor usage, resulting in lower energy usage per thousand bottles produced.

- Process Parameter Self-Tuning: Machine learning systems automatically adjusting complex moulding variables (temperature, pressure, time) based on material characteristics (virgin vs. rPET content) to maintain optimal bottle strength and weight consistency.

- Supply Chain Integration: Using AI to link machine output data directly with inventory management and raw material ordering systems, ensuring just-in-time logistics for preforms and mould parts.

- Enhanced Security and Monitoring: Implementing AI for anomaly detection in operational patterns, identifying potential cyber threats or unauthorized access attempts to proprietary machine control systems.

DRO & Impact Forces Of PET Stretch Blow Moulding Machines Market

The PET Stretch Blow Moulding Machines Market is propelled by robust drivers, primarily the accelerating global consumption of packaged beverages, particularly aseptic and functional drinks, which demand high-quality, reliable packaging. Concurrently, major restraints exist, including the significant initial capital investment required for advanced, high-speed rotary systems, which often poses a barrier to entry for smaller or regional packaging providers. Opportunities are abundant, centered around the integration of Industry 4.0 technologies, the development of machines optimized for 100% rPET usage, and the expansion into niche markets like specialized pharmaceutical packaging. These dynamics create a powerful impact force matrix that dictates market direction, emphasizing efficiency improvements and sustainable design.

Key drivers include rapid urbanization in developing nations, fueling demand for convenient single-serve packaging, and continuous technological advancements in machine design leading to ultra-lightweight containers, which reduce material costs and improve environmental profiles. The necessity for high-speed production lines capable of meeting the demands of global beverage giants further cements market growth. However, this growth is partially constrained by growing environmental concerns regarding plastic waste, potentially leading to increased taxes or regulation on single-use plastics, forcing manufacturers to invest heavily in rPET-compatible machinery, which adds complexity and cost.

The high impact force of sustainability acts as both a driver (pushing innovation in rPET machines) and a restraint (increasing regulatory burden). The opportunities presented by digitalization—specifically the ability to connect blow moulding operations to cloud platforms for performance diagnostics and remote troubleshooting—offer significant competitive advantages. The shift toward specialized barrier packaging (e.g., oxygen scavengers) for sensitive products like beer and fruit juices also mandates investment in highly sophisticated, multi-layer blow moulding solutions, representing a lucrative technological opportunity for machine manufacturers who can provide integrated barrier solutions seamlessly.

Segmentation Analysis

The PET Stretch Blow Moulding Machines market is comprehensively segmented based on technology, operation type, degree of automation, and primary application, providing a granular view of market dynamics and adoption patterns across various end-use industries. Technology segmentation differentiates between rotary and linear systems, where rotary machines dominate high-volume, continuous production lines, offering superior speed and consistency essential for global beverage bottling operations. Linear machines, conversely, appeal to small-to-medium enterprises requiring flexibility for shorter production runs and frequent changeovers.

Segmentation by operation type includes two-step and one-step processes. Two-step moulding, which separates preform production from the blowing stage, currently holds the largest market share due to its flexibility in handling preform logistics and allowing specialized preform injection moulders to supply multiple blowing operations. The automation level distinguishes between automatic and semi-automatic machines, with the overwhelming trend favoring fully automatic, integrated solutions to maximize efficiency, reduce labor costs, and ensure hygienic standards, especially in pharmaceutical and aseptic beverage production environments.

Application analysis segments the market based on the end-user industry, with the beverage segment (covering CSD, water, and juices) being the most dominant consumer of these machines globally. However, the non-food segment, including pharmaceuticals, cosmetics, and household chemicals, is showing accelerated growth due to increasing demand for clear, durable, and chemically resistant packaging formats. These segmentations are crucial for suppliers to tailor machine specifications and features, such as specialized neck finishes or high-barrier capabilities, to meet the specific requirements of distinct industrial sectors.

- By Technology:

- Rotary Stretch Blow Moulding Machines

- Linear Stretch Blow Moulding Machines

- By Operation Type:

- Two-Step Stretch Blow Moulding Machines

- One-Step Stretch Blow Moulding Machines

- By Degree of Automation:

- Automatic Machines

- Semi-Automatic Machines

- By End-Use Application:

- Beverages (Water, CSD, Juices & Nectars, Alcoholic Beverages, Dairy Products)

- Food (Edible Oils, Sauces, Dressings)

- Chemicals & Fertilizers

- Pharmaceuticals & Cosmetics (Personal Care Products)

- Others (Household Goods, Industrial Products)

- By Cavity Type:

- Low Cavity (Up to 6)

- Medium Cavity (8-16)

- High Cavity (18+)

Value Chain Analysis For PET Stretch Blow Moulding Machines Market

The value chain for the PET Stretch Blow Moulding Machines Market begins with upstream activities involving the sourcing of highly specialized raw materials, primarily steel alloys, sophisticated electronic components (PLCs, servo motors), pneumatic and hydraulic systems, and advanced heating elements necessary for machine construction. Key upstream suppliers include steel manufacturers, specialized software providers for control systems, and component manufacturers known for precision engineering. The quality and reliability of these upstream inputs directly influence the final machine's longevity, operational speed, and ability to perform consistently under high-stress, continuous production cycles.

Midstream processes involve the machine manufacturers themselves, who focus on research and development (R&D) to innovate new designs emphasizing energy efficiency, integration capabilities (e.g., integrating blowing and filling), and the ability to handle lightweight and rPET materials. This stage includes precision machining, assembly, software integration, and rigorous testing. Competitive advantage at this stage is often determined by intellectual property related to proprietary blowing processes, rapid changeover systems, and advanced diagnostic software, differentiating top-tier suppliers like Sidel, KHS, and SIPA from smaller competitors.

Downstream activities involve the distribution channel, which utilizes both direct sales (for large-scale, customized rotary systems sold directly to global beverage corporations) and indirect distribution through regional distributors and agents (for standardized linear or medium-speed machines targeting smaller end-users). Direct sales ensure comprehensive after-sales service, installation, and operator training, critical due to the technical complexity of the machinery. Ultimately, the machines are delivered to end-users (bottlers and co-packers) across the beverage, food, and non-food sectors, concluding the value chain with long-term maintenance contracts and spare parts supply, representing a continuous revenue stream for manufacturers.

PET Stretch Blow Moulding Machines Market Potential Customers

The primary potential customers and end-users of PET Stretch Blow Moulding Machines are major beverage and liquid packaging companies that require high-throughput, reliable equipment to meet mass market demand. This includes multinational soft drink and bottled water manufacturers, such as Coca-Cola, PepsiCo, and Nestle, who invest heavily in rotary systems for their massive bottling plants across the globe. These large entities prioritize speed, efficiency, and the integration of blow moulding directly into aseptic filling lines (Combi systems) to minimize costs and maintain hygiene integrity.

A rapidly expanding segment of customers includes co-packers and private label manufacturers. These entities often serve multiple brands and require highly flexible machinery (often linear or medium-speed rotary machines) capable of quick changeovers between different bottle shapes, sizes, and neck finishes to manage diverse client portfolios. Furthermore, specialized customers in the pharmaceutical and cosmetic industries demand machines designed for precision, smaller container volumes, and strict adherence to regulatory standards regarding material contact and sanitation, focusing on cleanroom compatibility and process validation.

Emerging market bottlers and regional dairy and juice producers also constitute significant potential customers, particularly those transitioning from traditional glass or heavy plastic packaging to lightweight PET containers to reduce transportation costs and enhance product shelf life. These buyers often seek cost-effective, durable, and easy-to-maintain automatic machines. The shift towards sustainable packaging also means any company committed to using high percentages of rPET becomes a prime target for manufacturers offering specialized, high-tolerance machinery capable of handling recycled resins without compromising bottle strength or visual appeal.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sidel, KHS GmbH, Krones AG, SIPA S.p.A., Nissei ASB Machine Co., Ltd., SACMI Imola S.C., SMF Maschinenfabrik GmbH, Tech-Long Packaging Machinery Co., Ltd., Jomar Corporation, W. Amsler Equipment Inc., F. B. S. S.p.A., ZQ Machinery, Parker Plastic Machinery, BBM Extrusion Blow Moulding, Haitian International Holdings Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Stretch Blow Moulding Machines Market Key Technology Landscape

The technological landscape of the PET Stretch Blow Moulding Machines market is defined by several advanced innovations aimed at maximizing operational efficiency, minimizing environmental impact, and enabling complex container geometries. A central focus is on servo motor technology, replacing older hydraulic and pneumatic systems, which allows for precise control over the stretching and clamping processes. Servo-driven machines offer significantly lower energy consumption, faster cycle times, and reduced noise levels, making them the preferred choice for new high-speed installations. Furthermore, advancements in infrared heating technology, particularly the use of high-efficiency lamps and refined oven designs, ensure uniform heating of the PET preforms, which is critical for achieving consistent material distribution and optimal bottle mechanical strength during the blowing process, especially with varying rPET content.

Another crucial technological development is the implementation of near-infrared (NIR) and shortwave infrared (SWIR) radiation technology for preform heating. These systems provide faster, more precise temperature control compared to conventional heating methods, enabling rapid heat penetration into thicker preform walls and facilitating faster machine indexing. This precision is vital for successful lightweighting efforts, where minimal material is used, demanding exceptional control to prevent neck distortion or base rupture. Furthermore, the integration of modular tooling systems and rapid mould changeover mechanisms drastically reduces downtime, addressing the industry's need for flexibility in managing diverse product lines and container formats.

The frontier of technology involves integrated blow-fill-cap systems (Combi solutions), which connect the blow moulding process directly to the aseptic filling and capping lines via hygienic transfer systems. This integration eliminates the need for bottle conveying, rinsing, and storage, dramatically reducing the risk of contamination, minimizing floor space requirements, and lowering operational costs. The continuous evolution of these integrated platforms, coupled with sophisticated barrier technologies like plasma coating or multi-layer co-injection systems (for enhanced oxygen or CO2 protection), demonstrates the industry's commitment to supporting highly sensitive and extended shelf-life products in the growing functional beverage and dairy segments.

Regional Highlights

The global PET Stretch Blow Moulding Machines market exhibits distinct growth patterns and adoption trends across major geographic regions, influenced by economic development, consumer behavior, and regulatory frameworks.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, driven by massive consumption of packaged water, soft drinks, and edible oils, particularly in China and India. Rapid industrialization and foreign direct investment into local bottling facilities necessitate the continuous acquisition of high-capacity, automatic rotary machines. The region also acts as a major manufacturing hub for several global machine suppliers.

- North America: Characterized by high technological maturity, this region focuses heavily on machine modernization, replacing older equipment with advanced, energy-efficient servo-driven models. The demand is heavily influenced by strict sustainability targets, driving the requirement for machines optimized for handling high percentages of post-consumer recycled PET (rPET) materials.

- Europe: Europe is defined by stringent environmental regulations and a strong emphasis on the circular economy. This market exhibits strong demand for sophisticated machinery capable of seamless integration into Industry 4.0 environments, featuring advanced energy recovery systems and highly specialized aseptic filling capabilities for niche beverage markets. Germany, Italy, and France are key centers for both demand and technological innovation.

- Latin America (LATAM): Growth in LATAM is robust, fueled by increasing urbanization and the expansion of the beverage industry, especially in Brazil and Mexico. The market is primarily seeking a balance between cost-effectiveness and medium-to-high capacity automatic machinery to handle growing domestic consumption and export demands for goods like fruit juices and mineral water.

- Middle East & Africa (MEA): This region shows steady growth, particularly in the Gulf Cooperation Council (GCC) countries due to high demand for bottled water (necessitated by arid climates) and soft drinks. Investment often focuses on reliable, durable machinery that can operate effectively in extreme heat conditions, prioritizing robustness and consistent cooling systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Stretch Blow Moulding Machines Market.- Sidel

- KHS GmbH

- Krones AG

- SIPA S.p.A.

- Nissei ASB Machine Co., Ltd.

- SACMI Imola S.C.

- SMF Maschinenfabrik GmbH

- Tech-Long Packaging Machinery Co., Ltd.

- Jomar Corporation

- W. Amsler Equipment Inc.

- F. B. S. S.p.A.

- ZQ Machinery

- Parker Plastic Machinery

- BBM Extrusion Blow Moulding

- Haitian International Holdings Ltd.

- Husky Injection Molding Systems Ltd.

- Automa S.p.A.

- Chumpower Machinery Co., Ltd.

- Zhejiang Huangyan Jinbo Machinery Co., Ltd.

- Powerjet Blow Molding Machine Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the PET Stretch Blow Moulding Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for high-speed rotary PET blow moulding machines?

The increasing global consumption of fast-moving consumer goods (FMCG), particularly packaged water, carbonated soft drinks (CSD), and juices, necessitates exceptionally high production throughput. Rotary machines offer continuous, high-speed operation (often exceeding 2,000 bottles per hour per cavity), which is essential for multinational bottlers to meet mass market demand and achieve economies of scale efficiently.

How are sustainability trends influencing the design of modern blow moulding equipment?

Sustainability mandates are forcing manufacturers to prioritize lightweighting (reducing material use per bottle) and optimizing machines to handle high percentages of recycled PET (rPET). Modern equipment features enhanced heating and process controls to maintain bottle quality and mechanical strength even when using complex rPET blends, supporting circular economy initiatives.

What is the key difference between one-step and two-step PET stretch blow moulding processes?

The two-step process separates preform injection moulding from the reheating and blowing stage, allowing preforms to be manufactured centrally and shipped globally, offering logistics flexibility. The one-step process performs both preform creation and bottle blowing on the same machine, offering advantages for highly specialized or highly sensitive containers, such as those in pharmaceutical or cleanroom environments, due to reduced handling.

Which geographical region represents the most significant growth opportunity for this market?

Asia Pacific (APAC), specifically emerging economies like India and China, offers the most significant growth opportunity. This is driven by rapid population growth, increasing disposable incomes, urbanization, and continuous investment in localized food and beverage manufacturing and packaging infrastructure to serve expanding middle-class consumer bases.

What role does Industry 4.0 play in the operation of PET blow moulding equipment?

Industry 4.0 integration, enabled by sophisticated sensors and AI/ML, allows for real-time data collection, remote monitoring, and predictive maintenance. This digitalization optimizes machine performance, reduces unplanned downtime by forecasting component failure, and automatically adjusts complex operating parameters, leading to substantial improvements in Overall Equipment Effectiveness (OEE).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager