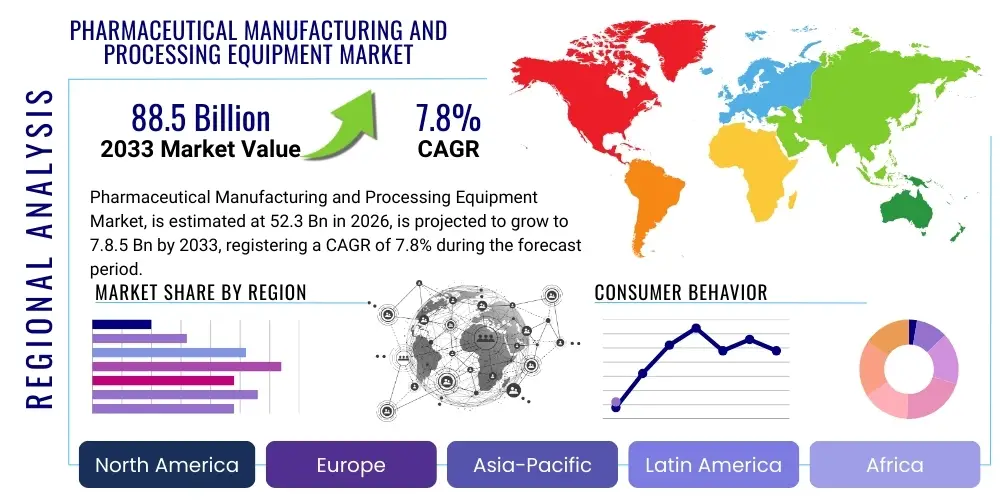

Pharmaceutical Manufacturing and Processing Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440302 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Pharmaceutical Manufacturing and Processing Equipment Market Size

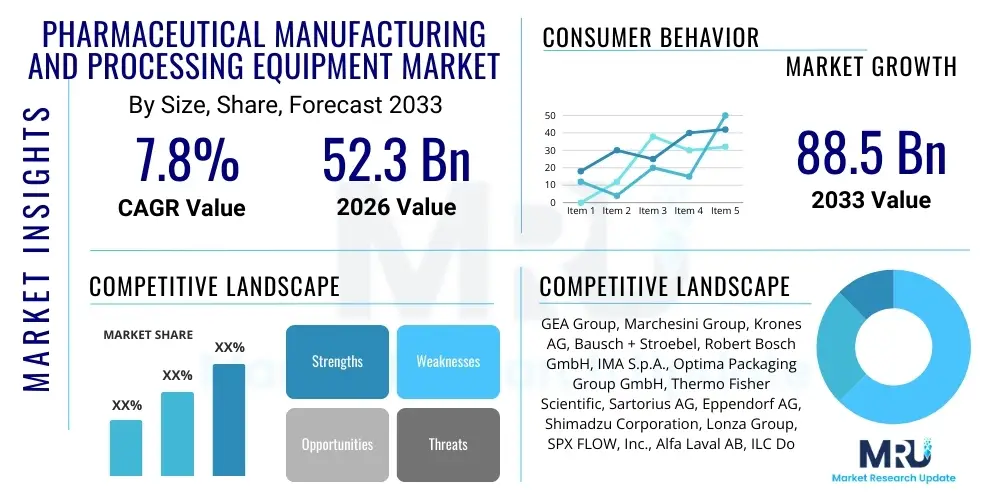

The Pharmaceutical Manufacturing and Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 52.3 billion in 2026 and is projected to reach USD 88.5 billion by the end of the forecast period in 2033. This robust growth trajectory is underpinned by the increasing global demand for pharmaceutical products, a surge in research and development activities, and the continuous innovation in drug manufacturing technologies aimed at enhancing efficiency, safety, and compliance with evolving regulatory standards. The market's expansion is also significantly influenced by the rising prevalence of chronic diseases and the growing biopharmaceutical sector, which necessitates specialized and sophisticated equipment for drug development and production.

Pharmaceutical Manufacturing and Processing Equipment Market introduction

The Pharmaceutical Manufacturing and Processing Equipment Market encompasses a wide array of machinery and systems essential for the production of pharmaceutical drugs, from raw material handling to final product packaging. This sophisticated equipment is crucial for ensuring product quality, safety, and efficacy, adhering to stringent global regulatory requirements such as Good Manufacturing Practices (GMP). Key product categories include processing equipment like reactors, mixers, granulators, tablet presses, and encapsulators, as well as specialized packaging equipment such as blister machines, bottling lines, and labeling systems. Major applications span the entire pharmaceutical value chain, including the production of solid, liquid, and semi-solid formulations, biologics, and active pharmaceutical ingredients (APIs).

The benefits derived from advanced pharmaceutical equipment are multifaceted, ranging from enhanced production efficiency and reduced operational costs to improved product consistency and accelerated time-to-market for new drugs. Modern equipment incorporates automation and precision controls, minimizing human error and ensuring optimal manufacturing conditions. Driving factors for market growth include the escalating global demand for both generic and branded drugs, significant investments in pharmaceutical research and development, particularly in biotechnology and personalized medicine, and the imperative for pharmaceutical companies to comply with increasingly rigorous quality and safety standards imposed by regulatory bodies worldwide. Furthermore, the expansion of contract manufacturing organizations (CMOs) and the strategic shift towards continuous manufacturing processes are further propelling the adoption of advanced equipment.

Pharmaceutical Manufacturing and Processing Equipment Market Executive Summary

The Pharmaceutical Manufacturing and Processing Equipment Market is experiencing substantial growth, driven by dynamic business trends such as the outsourcing of manufacturing activities to CMOs, the globalization of pharmaceutical production, and the increasing focus on advanced manufacturing techniques like continuous processing and Industry 4.0 integration. Companies are investing heavily in automation, robotics, and digital technologies to enhance operational efficiency, reduce costs, and improve data integrity across their production lines. This strategic shift is aimed at optimizing resource utilization and achieving higher throughput while maintaining the highest levels of quality control. The competitive landscape is characterized by a mix of established global players and niche technology providers, all striving to offer innovative solutions that address the complex needs of pharmaceutical manufacturers.

Regionally, the market exhibits varied growth patterns, with established markets like North America and Europe demonstrating consistent demand for upgrades and technologically advanced equipment, driven by strict regulatory environments and a focus on high-value biopharmaceuticals. The Asia Pacific region, particularly China and India, is emerging as a significant growth hub due to expanding domestic pharmaceutical industries, increasing healthcare expenditure, and a growing presence of global pharmaceutical companies establishing manufacturing facilities. Latin America and the Middle East & Africa are also showing promising growth, fueled by rising healthcare access and government initiatives to bolster local pharmaceutical production capabilities. Segment-wise, processing equipment continues to hold a dominant share, but packaging equipment is rapidly gaining traction as companies prioritize efficient and secure drug delivery systems. The biopharmaceutical segment is a key driver, demanding specialized fermentation, purification, and sterile filling equipment, underscoring the market's evolution towards more complex and precise manufacturing solutions.

AI Impact Analysis on Pharmaceutical Manufacturing and Processing Equipment Market

User inquiries regarding Artificial Intelligence (AI) in the Pharmaceutical Manufacturing and Processing Equipment Market frequently revolve around its potential to revolutionize operational efficiency, enhance predictive maintenance, optimize process control, and accelerate drug development timelines. Key concerns include the initial investment costs, the complexity of integration with legacy systems, data security implications, and the need for a skilled workforce to manage AI-driven systems. Users are keenly interested in how AI can minimize human error, reduce waste, improve product quality consistency, and ultimately contribute to faster regulatory approvals. There is also significant curiosity about AI's role in real-time monitoring, intelligent automation of complex tasks, and the potential for personalized medicine manufacturing, indicating a strong expectation for AI to drive transformative change across the entire pharmaceutical production lifecycle.

- AI enhances predictive maintenance by analyzing equipment data, forecasting failures, and scheduling preventative repairs, thereby minimizing downtime and extending machinery lifespan.

- Optimized process control through AI algorithms allows for real-time adjustments to manufacturing parameters, ensuring consistent product quality and maximizing yield.

- AI-driven automation in tasks like quality inspection, material handling, and sterile filling reduces human error, increases throughput, and improves safety in sensitive environments.

- Accelerated drug development and formulation through AI by simulating experiments, predicting optimal excipient combinations, and identifying potential manufacturing challenges early.

- Improved supply chain efficiency and inventory management using AI to forecast demand, optimize logistics, and prevent stockouts or overstocking of critical components.

- Enhanced data integrity and compliance by utilizing AI for robust data analysis, anomaly detection, and automated reporting, facilitating easier adherence to regulatory standards.

- Facilitates personalized medicine manufacturing through AI-driven flexible production lines capable of adapting to smaller batch sizes and customized drug formulations.

- Reduces energy consumption and operational costs by optimizing equipment performance and identifying inefficiencies in the manufacturing process through AI analytics.

- Enables intelligent robotic systems for precise and repetitive tasks, reducing labor intensity and improving the overall accuracy of pharmaceutical manufacturing operations.

- Supports advanced analytics for process optimization, providing deep insights into manufacturing bottlenecks and areas for continuous improvement.

- AI-powered vision systems are used for high-speed, accurate defect detection in tablets, capsules, and packaging, ensuring higher product quality before market release.

DRO & Impact Forces Of Pharmaceutical Manufacturing and Processing Equipment Market

The Pharmaceutical Manufacturing and Processing Equipment Market is significantly shaped by a confluence of Drivers, Restraints, and Opportunities, collectively forming the key impact forces. Major drivers include the persistently increasing global demand for pharmaceuticals, propelled by an aging population, rising prevalence of chronic diseases, and greater access to healthcare in emerging economies. Concurrent with this, substantial investments in pharmaceutical research and development, particularly in complex biopharmaceuticals and gene therapies, necessitate advanced and highly specialized manufacturing equipment. The continuous evolution of manufacturing technologies, focusing on automation, digitalization, and the adoption of Industry 4.0 principles, further stimulates market growth by offering improved efficiency, cost-effectiveness, and quality control. Moreover, the increasingly stringent global regulatory landscape, demanding higher standards of quality, safety, and traceability, compels pharmaceutical companies to invest in compliant, state-of-the-art equipment to avoid penalties and ensure market access.

Conversely, several restraints impede the market's expansion. The most notable is the substantial capital investment required for purchasing and installing sophisticated pharmaceutical manufacturing equipment, which can be a significant barrier for smaller companies or those in developing regions. The complex and time-consuming regulatory approval processes for new equipment and facilities also add to the cost and timeline of market entry or expansion. Furthermore, a persistent shortage of skilled labor proficient in operating, maintaining, and troubleshooting advanced pharmaceutical machinery poses operational challenges for manufacturers. Economic downturns and geopolitical uncertainties can also impact investment decisions, leading to deferred purchases and project delays. Despite these restraints, considerable opportunities exist for market growth. The emergence of continuous manufacturing paradigms offers the promise of higher efficiency and reduced footprint, driving demand for specialized, integrated systems. The rapid adoption of Industry 4.0 technologies, including AI, IoT, and big data analytics, presents avenues for optimizing production, enhancing predictive maintenance, and improving overall operational intelligence. The expansion into untapped and emerging markets, coupled with the growing trend of personalized medicine, which requires flexible and scalable manufacturing solutions, further fuels the market's long-term potential.

Segmentation Analysis

The Pharmaceutical Manufacturing and Processing Equipment Market is comprehensively segmented across various dimensions, including product type, application, and end-user, providing a granular view of market dynamics and opportunities. This detailed segmentation enables a thorough understanding of demand patterns, technological preferences, and growth areas within the diverse pharmaceutical industry landscape. Each segment represents distinct needs and investment priorities, from the specific machinery required for different drug formulations to the varied operational requirements of pharmaceutical companies versus contract manufacturers or biotechnology firms. Analyzing these segments helps in identifying niche markets, tailoring product offerings, and formulating effective market entry strategies.

- By Product Type

- Processing Equipment

- Reactors

- Mixers and Blenders

- Granulators

- Tablet Presses

- Encapsulators

- Filtration Equipment

- Sterilization Equipment

- Fermenters and Bioreactors

- Lyophilizers (Freeze Dryers)

- Coating Machines

- Milling Equipment

- Homogenizers

- Heat Exchangers

- Packaging Equipment

- Blister Packaging Machines

- Strip Packaging Machines

- Bottle Filling & Capping Machines

- Labelling Machines

- Cartoning Machines

- Inspection Machines

- Form-Fill-Seal Machines

- Sachet and Pouch Packaging Machines

- Syringe Filling Machines

- Tube Filling Machines

- Utilities & Services

- Cleanroom Equipment

- HVAC Systems

- Water Purification Systems (WFI, Purified Water)

- Waste Treatment Systems

- Automation & Control Systems (SCADA, MES)

- Calibration Services

- Maintenance Services

- Validation Services

- Process Analytical Technology (PAT) Systems

- Processing Equipment

- By Application

- Pharmaceutical Formulations (Solids, Liquids, Semi-Solids)

- Biopharmaceuticals (Vaccines, Monoclonal Antibodies, Recombinant Proteins, Cell & Gene Therapies)

- Active Pharmaceutical Ingredients (API) Manufacturing

- Nutraceuticals Production

- Cosmetics & Personal Care Products

- By End-User

- Pharmaceutical Companies

- Biotechnology Companies

- Contract Manufacturing Organizations (CMOs)

- Contract Research Organizations (CROs)

- Academic & Research Institutions

- Compounding Pharmacies

Value Chain Analysis For Pharmaceutical Manufacturing and Processing Equipment Market

The value chain for the Pharmaceutical Manufacturing and Processing Equipment Market is intricate, involving multiple stages from raw material sourcing to the end-use of the equipment in pharmaceutical production. Upstream analysis focuses on the suppliers of components, raw materials (e.g., specialized metals, polymers, electronic components), and sophisticated sub-systems that are crucial for equipment manufacturing. These suppliers play a vital role in determining the quality, reliability, and cost-effectiveness of the final machinery. Equipment manufacturers often engage in rigorous qualification processes for their upstream partners to ensure compliance with industry standards and maintain the integrity of their products. Collaboration with technology providers for advanced control systems, software, and automation components is also a key upstream activity.

Downstream analysis delves into the distribution channels and the ultimate end-users. Equipment typically reaches pharmaceutical manufacturers, biotechnology companies, and CMOs through direct sales teams for large, complex installations or via a network of distributors and agents for more standardized or smaller machinery. Direct channels facilitate closer customer relationships, customization, and comprehensive after-sales support, which is critical for complex capital equipment. Indirect channels, through distributors, offer broader market reach, particularly in diverse regional markets, and often provide localized service and support. The effectiveness of these distribution channels significantly influences market penetration and customer satisfaction. After-sales services, including installation, validation, calibration, maintenance, and training, form a critical part of the downstream value chain, ensuring optimal equipment performance and customer loyalty.

Pharmaceutical Manufacturing and Processing Equipment Market Potential Customers

The primary potential customers and end-users of pharmaceutical manufacturing and processing equipment are diverse entities within the life sciences and healthcare sectors, all requiring specialized machinery to produce high-quality, compliant pharmaceutical products. Pharmaceutical companies, ranging from large multinational corporations to small and medium-sized enterprises, represent the largest customer segment. These companies require equipment across their entire production spectrum, from active pharmaceutical ingredient (API) synthesis to final dosage form manufacturing and packaging for both branded and generic drugs. Their demand is driven by the need for new drug development, capacity expansion, and modernization of existing facilities to meet evolving regulatory standards and market demands.

Biotechnology companies constitute another significant customer base, especially with the surging growth in biologics, vaccines, and cell and gene therapies. These firms require highly specialized equipment such as bioreactors, fermentation systems, purification equipment, and sterile filling lines that can handle sensitive biological materials while maintaining aseptic conditions. Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs) are rapidly expanding their equipment investments as pharmaceutical companies increasingly outsource their manufacturing processes. CMOs serve multiple clients, necessitating flexible, scalable, and versatile equipment capable of producing a wide range of products for various therapeutic areas. Additionally, academic and research institutions, although typically requiring smaller-scale equipment for laboratory and pilot plant applications, also contribute to market demand for R&D purposes. These institutions drive innovation and often serve as early adopters of novel manufacturing technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 52.3 billion |

| Market Forecast in 2033 | USD 88.5 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, Marchesini Group, Krones AG, Bausch + Stroebel, Robert Bosch GmbH, IMA S.p.A., Optima Packaging Group GmbH, Thermo Fisher Scientific, Sartorius AG, Eppendorf AG, Shimadzu Corporation, Lonza Group, SPX FLOW, Inc., Alfa Laval AB, ILC Dover, ACG Group, Romaco Pharmatechnik GmbH, Körber AG (Medipak Systems), Truking Technology Ltd., Fette Compacting GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pharmaceutical Manufacturing and Processing Equipment Market Key Technology Landscape

The Pharmaceutical Manufacturing and Processing Equipment Market is characterized by a rapidly evolving technological landscape, driven by the imperative for enhanced efficiency, precision, quality, and regulatory compliance. One of the most significant shifts is towards automation and robotics, which are increasingly integrated across the entire production line, from raw material handling to final packaging. This includes robotic arms for sterile filling, automated guided vehicles (AGVs) for material transport, and sophisticated control systems that minimize human intervention, thereby reducing contamination risks and improving process repeatability. Process Analytical Technology (PAT) is another pivotal technology, involving real-time measurement and control of critical quality and performance attributes of raw materials, in-process materials, and processes. PAT systems, including spectroscopic techniques (NIR, Raman), chromatography, and particle size analysis, enable proactive adjustments to ensure consistent product quality and accelerate release testing.

The adoption of Industry 4.0 concepts, encompassing the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data analytics, is fundamentally transforming pharmaceutical manufacturing. IoT sensors embedded in equipment collect vast amounts of data on machine performance, environmental conditions, and product quality, which is then analyzed by AI algorithms to enable predictive maintenance, optimize process parameters, and identify potential bottlenecks. This data-driven approach facilitates greater operational visibility and decision-making. Continuous manufacturing, moving away from traditional batch processes, is gaining traction due to its benefits in terms of reduced footprint, lower operational costs, and improved product quality control. This requires highly integrated, modular, and flexible equipment designed for uninterrupted production flows. Advanced aseptic processing technologies, including isolators and restricted access barrier systems (RABS), are also critical, particularly for biopharmaceuticals and sterile injectable drugs, ensuring product sterility and operator safety. Furthermore, single-use technologies, such as disposable bioreactors and mixing bags, are becoming prevalent in biopharmaceutical manufacturing, offering advantages in terms of reduced cleaning validation, faster changeovers, and lower capital expenditure.

Regional Highlights

- North America: This region, particularly the United States, represents a mature but highly innovative market. It is characterized by significant R&D investments, a robust biopharmaceutical sector, and stringent regulatory frameworks (e.g., FDA), driving demand for advanced, high-precision, and compliant manufacturing and processing equipment. The focus on personalized medicine and sophisticated drug delivery systems also contributes to continuous equipment upgrades and innovation.

- Europe: Europe is another major market for pharmaceutical manufacturing equipment, propelled by a strong presence of leading pharmaceutical companies, significant research funding, and a well-established regulatory environment (e.g., EMA). Countries like Germany, Switzerland, and France are key players, known for their technological advancements in machinery, automation, and aseptic processing solutions. The emphasis on sustainable manufacturing and Industry 4.0 integration further stimulates market growth.

- Asia Pacific (APAC): The APAC region is the fastest-growing market, driven by expanding pharmaceutical industries in countries such as China, India, Japan, and South Korea. Factors contributing to this growth include increasing healthcare expenditure, a large patient pool, growing prevalence of chronic diseases, government initiatives to boost local manufacturing, and the rising number of contract manufacturing organizations. There is a strong demand for both cost-effective and technologically advanced equipment to meet increasing production volumes and quality standards.

- Latin America: This region presents a promising growth outlook, with countries like Brazil and Mexico leading the market. Factors such as increasing access to healthcare, rising investments by multinational pharmaceutical companies, and government efforts to develop domestic pharmaceutical capabilities are driving the demand for modern manufacturing and processing equipment. The region often seeks solutions that balance cost-effectiveness with compliance.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, primarily fueled by rising healthcare infrastructure development, government initiatives to reduce reliance on imported drugs, and increasing investments in local pharmaceutical production facilities, particularly in countries like Saudi Arabia, UAE, and South Africa. The market is developing, with a focus on establishing basic to moderately advanced manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pharmaceutical Manufacturing and Processing Equipment Market.- GEA Group

- Marchesini Group

- Krones AG

- Bausch + Stroebel

- Robert Bosch GmbH

- IMA S.p.A.

- Optima Packaging Group GmbH

- Thermo Fisher Scientific

- Sartorius AG

- Eppendorf AG

- Shimadzu Corporation

- Lonza Group

- SPX FLOW, Inc.

- Alfa Laval AB

- ILC Dover

- ACG Group

- Romaco Pharmatechnik GmbH

- Körber AG (Medipak Systems)

- Truking Technology Ltd.

- Fette Compacting GmbH

Frequently Asked Questions

What are the key drivers for growth in the Pharmaceutical Manufacturing and Processing Equipment Market?

Key drivers include the rising global demand for pharmaceuticals, increasing investments in R&D, continuous advancements in manufacturing technologies, stringent regulatory requirements, and the rapid expansion of the biopharmaceutical sector, all pushing for more efficient and compliant production solutions.

How is AI impacting pharmaceutical manufacturing equipment?

AI is transforming the market by enabling predictive maintenance, optimizing process controls, enhancing quality inspection, automating complex tasks, and accelerating drug development, leading to improved efficiency, reduced costs, and higher product consistency.

Which geographical region is expected to show the most significant growth?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth, driven by expanding pharmaceutical industries, rising healthcare expenditures, a large patient population, and government initiatives promoting local drug manufacturing capabilities in countries like China and India.

What types of equipment are included in the processing segment?

The processing segment includes a broad range of machinery such as reactors, mixers, granulators, tablet presses, encapsulators, filtration equipment, sterilization equipment, fermenters, lyophilizers, and coating machines, essential for various stages of drug formulation.

What are the primary challenges faced by this market?

Primary challenges include the high capital investment required for advanced equipment, complex and lengthy regulatory approval processes, a persistent shortage of skilled personnel, and the need for seamless integration of new technologies with existing infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager