Piano Hinge Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434281 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Piano Hinge Market Size

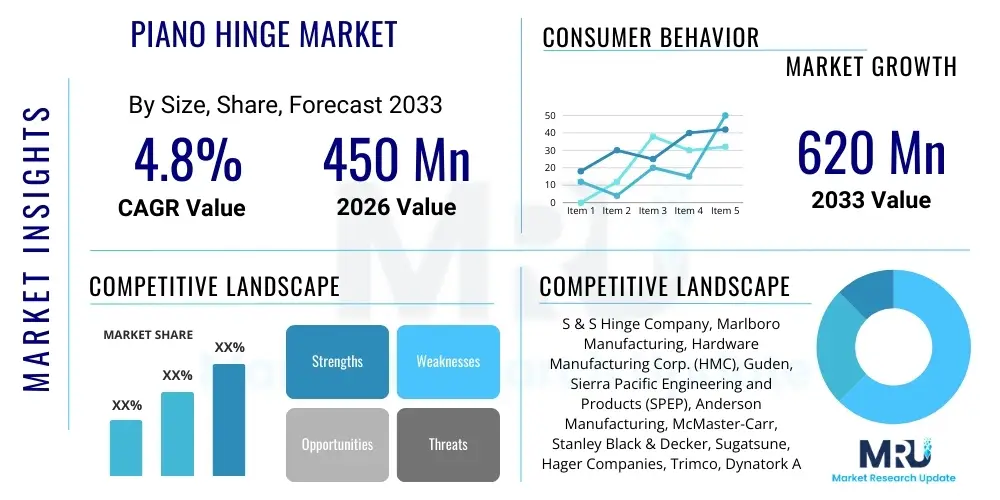

The Piano Hinge Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 620 Million by the end of the forecast period in 2033.

The steady growth trajectory of the piano hinge market is intrinsically linked to robust activity across global construction, woodworking, and specialized industrial sectors. Piano hinges, also known as continuous hinges, are valued for their uniform strength distribution along the entire length of a joint, offering superior stability and load-bearing capacity compared to traditional butt hinges. This inherent durability and versatility make them indispensable components in applications requiring high cycle life and continuous support, such as large industrial enclosures, aircraft interior components, and institutional furniture.

Furthermore, the increasing demand for customized furniture and specialized architectural solutions in emerging economies contributes significantly to market expansion. While standardized continuous hinges dominate volume sales, the premium segment—focusing on specialized materials like marine-grade stainless steel or anodized aluminum for corrosion resistance in harsh environments—commands higher prices and drives value growth. Manufacturers are increasingly focusing on automation in production and utilizing advanced coating techniques to enhance product lifespan and aesthetic appeal, catering to the aesthetic demands of modern interior design and cabinetry.

The market landscape is characterized by the presence of numerous regional and international players, leading to intense competition primarily focused on material quality, precision engineering, and timely supply chain delivery. Key regions, particularly Asia Pacific, are experiencing accelerated urbanization and industrialization, leading to massive infrastructure projects and expanding manufacturing capabilities, which consequently fuel the demand for high-quality continuous hinge solutions across diverse applications, ranging from residential doors to heavy-duty machinery safety guards.

Piano Hinge Market introduction

The Piano Hinge Market encompasses the manufacturing, distribution, and application of continuous hinges, mechanical bearing devices utilized to connect two solid objects, allowing only a limited angle of rotation between them. These hinges derive their common name from their original widespread use on piano lids, spanning the full length of the component they connect. They consist of two elongated leaves and a central pin, providing continuous support and consistent alignment, distinguishing them fundamentally from conventional butt hinges which use intermittent connections. Their primary product description emphasizes their continuous nature, offering uniform strength and rigidity essential for heavy or frequently used panels, doors, and covers.

Major applications of piano hinges span a wide spectrum, including residential and commercial doors, cabinetry and furniture (especially storage units requiring long-term durability), industrial enclosures and machinery access panels, automotive compartments (e.g., trunk lids or specialized vehicle doors), and marine applications where corrosive resistance is paramount. The fundamental benefits driving their adoption include high load distribution, resistance to warping or sagging, enhanced security due to the continuous pin design, and aesthetic integration, as they can be recessed or mounted externally depending on design requirements. The versatility in material composition (steel, stainless steel, aluminum, brass) further allows them to meet specific functional and environmental criteria across these diverse sectors.

Driving factors for the market include the global rebound in construction and infrastructure development, increased complexity in industrial machinery requiring reliable, large access points, and advancements in materials science allowing hinges to be lighter yet stronger (e.g., lightweight aluminum alloys for aerospace or high-strength stainless steel for food processing equipment). Additionally, the robust growth in DIY and home renovation sectors, particularly in North America and Europe, contributes positively, as continuous hinges are favored for custom storage solutions and workbench designs requiring stable, long-lasting linkages. Regulatory emphasis on safety enclosures and machinery guarding also mandates the use of reliable, full-length articulation systems, thereby solidifying the position of piano hinges in industrial safety applications.

Piano Hinge Market Executive Summary

The Piano Hinge Market is positioned for stable growth, fueled primarily by sustained investments in global infrastructure, the booming furniture and cabinetry industry, and the increasing incorporation of specialized hinges in heavy-duty industrial and transportation applications. Current business trends indicate a shift towards highly customized, precision-engineered continuous hinges, particularly those incorporating advanced finishes like powder coating or specialized platings (e.g., zinc or chromium) to enhance corrosion resistance and aesthetic value. Key manufacturers are focusing on optimizing production processes through automation to meet high-volume demands while simultaneously improving material efficiency and reducing lead times, which is crucial for maintaining competitiveness in global supply chains characterized by fragmented sourcing and intense pricing pressures, especially in the steel and aluminum segments.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market due to rapid urbanization, massive housing development projects in countries like China and India, and the expansion of the regional manufacturing base, particularly in the production of consumer electronics enclosures and automotive parts. North America and Europe maintain significant market shares, characterized by a preference for high-quality, specialized hinges (e.g., architectural-grade stainless steel) driven by stringent building codes and higher consumer spending on premium architectural hardware and customized interior design. The Middle East and Africa (MEA) region is showing promising growth linked to large-scale hospitality and commercial construction projects, requiring durable, aesthetically pleasing hardware solutions.

Segment trends underscore the dominance of the Stainless Steel segment by value, attributed to its superior corrosion resistance, making it essential for marine, medical, and demanding exterior applications. By application, the Cabinets & Furniture segment holds the largest volume share, driven by mass production and standardization in residential and office furniture manufacturing. However, the Industrial Equipment and Automotive segments are projected to exhibit higher growth rates, necessitating heavy-duty and specialized material hinges capable of handling extreme temperatures, vibrations, and high operational cycles. The market is also witnessing subtle trends toward environmentally conscious manufacturing, with some buyers prioritizing suppliers who demonstrate sustainable sourcing of raw materials and optimized waste reduction protocols.

AI Impact Analysis on Piano Hinge Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Piano Hinge Market primarily revolve around how automation and predictive maintenance influence traditional manufacturing processes, material optimization, and supply chain logistics. Common questions ask whether AI can design more efficient hinge profiles, if Machine Learning (ML) algorithms can predict component failure in heavy-duty hinges before it occurs, and how AI-driven quality control systems compare to traditional inspection methods. The core themes center on leveraging AI to move beyond incremental mechanical improvements towards systemic efficiency gains, particularly in predicting optimal cutting patterns for raw materials (reducing scrap), automating welding and assembly processes requiring high precision, and enhancing supply chain resilience by dynamically forecasting demand shifts based on global construction indices and macroeconomic indicators.

The immediate and tangible influence of AI is observed predominantly in the manufacturing phase. AI and advanced machine vision systems are revolutionizing quality control by inspecting hinges for microscopic defects, material inconsistencies, and tolerance deviations at speeds and accuracies unattainable by human inspectors, thereby reducing costly recalls and improving overall product reliability. Furthermore, generative design algorithms, while still nascent in standard hinge design, are increasingly being tested to optimize weight-to-strength ratios for specialized, high-performance continuous hinges used in aerospace or medical device enclosures, potentially leading to hinges with novel internal structures that maximize material utilization while maintaining load-bearing specifications.

In the broader operational context, AI-driven analytics are significantly optimizing supply chain management. By processing massive datasets related to raw material prices (steel, aluminum futures), shipping routes, and manufacturing capacity, AI tools provide manufacturers with predictive insights that allow for more proactive procurement decisions, mitigating risks associated with material price volatility and geopolitical disruptions. This shift towards smart manufacturing and proactive supply chain orchestration ensures that even low-margin, high-volume products like piano hinges maintain profitability while meeting the increasing demands for customization and rapid delivery schedules required by major industrial clients.

- AI-enhanced Quality Control: Implementation of machine vision for 100% automated defect detection in plating, drilling, and assembly tolerances.

- Predictive Maintenance (PM): Utilizing sensors and ML models on manufacturing equipment (e.g., stamping machines) to predict maintenance needs, minimizing production downtime.

- Generative Design Optimization: Limited use in complex, specialized hinge designs to optimize material distribution and reduce overall product weight without compromising structural integrity.

- Supply Chain Forecasting: AI algorithms utilized to predict fluctuations in raw material costs (e.g., steel coil prices) and optimize inventory management and procurement timing.

- Automated Production Planning: Scheduling and sequencing production runs based on real-time demand signals and machine availability, maximizing throughput efficiency.

DRO & Impact Forces Of Piano Hinge Market

The dynamics of the Piano Hinge Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively influencing the impact forces on market growth and profitability. Key drivers include sustained global growth in residential and commercial construction, the increasing use of continuous hinges in specialized industrial enclosures requiring high security and accessibility, and the inherent structural advantages these hinges offer over conventional counterparts (superior load distribution and reduced sagging). Furthermore, the aesthetic appeal and customization potential for architectural hardware and high-end cabinetry provide a consistent demand floor, particularly in developed markets where design innovation is a crucial purchasing factor. These factors create strong inertial forces driving market expansion, particularly in high-quality stainless steel and specialized alloy segments.

However, the market faces significant restraints, primarily centered around volatility in raw material prices, particularly steel and aluminum, which directly affects manufacturing costs and final product pricing, sometimes eroding thin profit margins. The availability of substitute products, such as specialized concealed hinges or heavy-duty industrial door systems employing alternative articulation mechanisms, poses a competitive threat, especially in applications where continuous support is not strictly mandatory. Additionally, the relatively long product lifespan of piano hinges means replacement cycles are often extended, limiting recurring revenue from the aftermarket. These restraints exert downward pressure, particularly on manufacturers operating in the highly commoditized standard steel segment, requiring constant focus on cost management and operational efficiency to remain competitive against cheaper, often lower-quality imports.

Opportunities for growth are abundant, particularly in niche high-value sectors. The expansion of the aerospace and defense industries demands lightweight, high-performance continuous hinges made from specialized, high-cost materials (e.g., titanium or advanced aluminum alloys) meeting stringent regulatory standards. The booming e-commerce and logistics sector requires robust, long-lasting hardware for warehouse storage systems and heavy-duty container access points. Moreover, technological integration, such as incorporating smart features (e.g., embedded sensors for hinge usage tracking or remote locking capabilities) into continuous hinges for security applications, presents significant avenues for premium product development and market differentiation, allowing companies to command higher margins in technologically advanced end-use environments.

Segmentation Analysis

The Piano Hinge Market is meticulously segmented based on material, application, and type to address the varying demands across industrial, commercial, and residential sectors. Segmentation allows market players to specialize in areas where they possess competitive advantages, whether in high-volume production of standard steel hinges for furniture or precision manufacturing of corrosion-resistant stainless steel hinges for marine and medical environments. Understanding these segment dynamics is crucial for strategic planning, resource allocation, and targeted marketing efforts, ensuring that product offerings align precisely with the functional requirements and budgetary constraints of specific end-users. The continuous evolution of manufacturing technology and material science constantly refines these segments, enabling the creation of hybrid hinges tailored for complex, multi-functional applications.

The Material segment is arguably the most critical determinant of product performance and pricing, differentiating between high-volume, cost-effective options like standard rolled steel and premium offerings such as architectural bronze or specialized aluminum alloys. Stainless steel dominates the value share due to its requirement in high-demand environments, while aluminum offers the advantage of lightweight and excellent corrosion resistance for applications like RVs, trailers, and outdoor enclosures. The Application segment highlights usage patterns, with Residential/Commercial Furniture demanding large volumes of standard quality hinges, contrasted sharply by the Industrial Machinery and Aerospace sectors, which require hinges meeting rigorous safety, durability, and operational cycle standards, justifying higher price points and demanding stricter compliance with technical specifications.

The Type segmentation, often categorized by dimensions (Narrow, Wide, Heavy Duty), directly relates to the load-bearing requirements and intended use environment. Heavy-duty hinges are exclusively required for large, weighty industrial doors, access hatches, and security vaults, typically made from thicker gauge steel or stainless steel to withstand extreme stresses and frequent usage. Conversely, narrow and wide standard hinges are commonly utilized in light-to-medium-duty applications like cabinetry, toy boxes, and internal doors. The interplay between these three segmentations—Material, Application, and Type—defines the competitive landscape, pushing manufacturers to continuously innovate in material processing and dimensional precision to cater effectively to highly specialized or highly commoditized market niches.

- By Material:

- Stainless Steel (304, 316 Grades)

- Rolled Steel (Plain, Zinc Plated)

- Aluminum (Anodized, Mill Finish)

- Brass and Bronze

- By Application:

- Cabinets & Furniture

- Doors & Windows (Residential & Commercial)

- Industrial Equipment & Enclosures

- Automotive & Transportation (RV, Marine)

- Aerospace & Defense

- Medical Equipment

- By Type:

- Standard Width (Narrow)

- Wide Width

- Heavy Duty/High Load Capacity

- Specialty (Spring-Loaded, Friction Hinges)

Value Chain Analysis For Piano Hinge Market

The value chain for the Piano Hinge Market begins with the upstream suppliers of primary raw materials, predominantly steel (especially cold-rolled steel coils for standard hinges and stainless steel billets), aluminum, and brass. The efficiency and cost-effectiveness of this initial stage are critically dependent on global commodity market stability and robust relationships between hinge manufacturers and large metal suppliers. Manufacturers often engage in processes such as stamping, rolling, punching, and finishing (plating, painting) to convert raw metal stock into the final hinge product. The competitiveness at the manufacturing stage is often determined by economies of scale, precision engineering capabilities, and adherence to quality standards like ISO certification and specific industry standards (e.g., military specifications or fire ratings for doors).

Moving downstream, the distribution channel plays a pivotal role in linking manufacturers to a highly fragmented end-user base. Distribution is typically bifurcated into direct and indirect channels. Direct distribution is favored for large Original Equipment Manufacturers (OEMs), such as major furniture producers, industrial machinery companies, or automotive suppliers, where customized specifications, large volumes, and direct technical support necessitate direct sales relationships. These direct contracts usually involve long-term agreements and specific supply chain integration, ensuring just-in-time delivery and strict adherence to quality assurance protocols outlined in the contract. This streamlined approach minimizes handling costs and optimizes the delivery pipeline for high-volume requirements.

The indirect channel relies on a network of wholesale distributors, specialized architectural hardware suppliers, industrial supply houses (MRO providers), and increasingly, e-commerce platforms. This channel is essential for reaching smaller construction firms, individual contractors, DIY customers, and smaller-scale fabrication shops. Hardware wholesalers often purchase inventory in bulk from multiple manufacturers, managing regional stockholding and offering a range of hinge materials and sizes, providing critical logistical support and localized market access for manufacturers who lack extensive regional sales infrastructure. The rise of sophisticated e-commerce platforms has further democratized access, allowing specialized suppliers to cater directly to niche requirements, often bypassing traditional brick-and-mortar retail outlets and increasing price transparency and competitive pressure across the entire value chain.

Piano Hinge Market Potential Customers

Potential customers for the Piano Hinge Market represent a diverse and extensive base, spanning virtually every sector that requires articulation, access, or closure mechanisms, with the largest volume consumers categorized into the construction/architectural, furniture manufacturing, and specialized industrial sectors. End-users are broadly segmented into large-scale Original Equipment Manufacturers (OEMs) who integrate hinges into their finished products (e.g., office cubicles, heavy machinery enclosures), and Maintenance, Repair, and Operations (MRO) buyers who purchase hinges for replacement, repair, or small-scale fabrication projects. Construction contractors, cabinet makers, and interior designers form a significant block of professional buyers seeking durable and aesthetically suitable hardware for both new installations and renovation projects, typically prioritizing reliability and finish options.

In the industrial sphere, critical end-users include manufacturers of climate control equipment, electrical enclosures, telecommunications cabinets, and medical sterilization units, all requiring high-quality, often sealed or specialized material hinges to meet functional and regulatory demands regarding security, hygiene, and environmental protection (e.g., NEMA ratings). The automotive and marine sectors are also high-value customers, requiring corrosion-resistant materials (e.g., 316 stainless steel) for applications like boat hatches, engine covers, and specialized vehicle compartment doors, where exposure to moisture and extreme temperatures mandates superior performance specifications and robust material quality. These buyers prioritize product certifications, long cycle life testing results, and consistent supply reliability.

Furthermore, specialized segments such as the aerospace industry utilize customized, often lightweight piano hinges for interior aircraft components like luggage bins and cabin dividers, where strict weight constraints and fire safety compliance are non-negotiable purchasing criteria. The DIY and consumer markets, served predominantly through retail hardware stores and online channels, represent a steady consumer base, purchasing standard-gauge steel or aluminum hinges for home improvement projects, toolboxes, and simple storage solutions, where ease of installation and cost-effectiveness are the primary buying determinants, demonstrating the vast breadth of the customer base from highly technical military applications to simple household repairs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 620 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | S & S Hinge Company, Marlboro Manufacturing, Hardware Manufacturing Corp. (HMC), Guden, Sierra Pacific Engineering and Products (SPEP), Anderson Manufacturing, McMaster-Carr, Stanley Black & Decker, Sugatsune, Hager Companies, Trimco, Dynatork Air Motor, Bommer Industries, Blum, Hafele, Tectus, Bossard Group, ASSA ABLOY, Fastenal, Reliance Hinges. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Piano Hinge Market Key Technology Landscape

The manufacturing of piano hinges relies on mature but continually optimizing technologies centered around precision metal forming and finishing. Key technological landscapes involve high-speed progressive die stamping for consistently creating hinge leaves and pins, ensuring tight tolerances for smooth articulation and minimal play, particularly crucial for heavy-duty and specialized hinges. Advanced Computer Numerical Control (CNC) machining is used for customizing hole patterns, end configurations, and secondary operations like countersinking or notching required by specific OEM clients. The utilization of high-precision multi-slide forming machines allows manufacturers to produce complex continuous hinge profiles with high throughput and reduced material waste, enhancing overall production economics and responsiveness to high-volume orders.

A significant technological focus area is surface finishing and material preparation, which is essential for determining the hinge's longevity and suitability for specific environments. Technologies include continuous electroplating lines for zinc or chrome finishes, providing essential corrosion resistance for standard steel hinges, and advanced powder coating systems that offer superior durability and a wide range of aesthetic colors for architectural applications. For stainless steel, passive treatment technologies are critical to maximize the material's inherent corrosion resistance, especially for marine-grade 316 steel used in harsh outdoor or corrosive industrial settings. The mastery of these coating and treatment technologies is a key differentiator in quality and overall product lifespan, especially when dealing with moisture or chemical exposure.

Furthermore, technology is being applied upstream in material management and production flow. Modern facilities integrate sophisticated ERP systems and real-time monitoring of tooling wear and production quality. Laser cutting and welding technologies are increasingly adopted for creating specialized, low-volume hinges or for integrating unique features, offering higher flexibility than traditional stamping methods. The overall trend is towards 'lean manufacturing' principles supported by digital tools, reducing setup times, improving yield rates, and allowing manufacturers to rapidly switch between different hinge materials and specifications to meet dynamic market demand without excessive inventory buildup, maintaining a competitive edge in a highly price-sensitive global market.

Regional Highlights

The global Piano Hinge Market exhibits distinct regional consumption and production patterns, largely dictated by industrial maturity, construction activity levels, and material sourcing capabilities. Asia Pacific (APAC) stands out as the primary engine of market growth and the largest manufacturing hub globally. This dominance is driven by high-volume, cost-competitive production capacities in countries like China and India, serving both massive domestic construction and manufacturing sectors and acting as major exporters of standard and medium-duty hinges worldwide. Rapid infrastructure development, sustained urbanization, and burgeoning automotive manufacturing in Southeast Asia further solidify APAC's leading market position, focusing heavily on zinc-plated steel and standard aluminum hinges.

North America (NA) represents a mature, high-value market characterized by stringent quality demands and a preference for specialized, architectural-grade, and heavy-duty hinges. The demand here is largely driven by commercial and institutional construction (schools, hospitals, government buildings) requiring high-cycle-life products and compliance with local fire and safety codes. Manufacturers in this region often focus on high-margin, custom-engineered products, including stainless steel for specialty applications and large industrial equipment. The extensive home improvement and DIY culture also ensures steady demand for medium-duty, consumer-grade hinges, typically distributed through large retail chains and dedicated hardware distributors.

Europe mirrors North America in its focus on quality and specialization, with strong demand emanating from Germany, the UK, and France. European markets place a premium on aesthetics, precision engineering, and adherence to environmental standards (e.g., REACH regulations). The region is a key consumer of high-quality brass and specialized finishes for the high-end cabinetry and architectural hardware sectors. Latin America and the Middle East & Africa (MEA) are emerging regions, where market growth is highly correlated with fluctuating commodity prices and governmental spending on infrastructure. MEA, in particular, is witnessing substantial demand for durable, often climate-resistant, continuous hinges used in massive hospitality, commercial, and energy sector construction projects, requiring robust corrosion protection and long-term durability in arid or humid environments.

- Asia Pacific (APAC): Dominates manufacturing volume; highest growth driven by China, India, and ASEAN countries; focus on residential construction and high-volume industrial enclosures.

- North America: High-value market; emphasis on heavy-duty, specialty hinges for institutional and commercial applications; strong presence of specialized distributors and OEM suppliers.

- Europe: Focus on architectural quality, aesthetic finishes (brass, bronze), and compliance with strict environmental and building standards; steady demand from luxury furniture and design-led industries.

- Middle East & Africa (MEA): Emerging market characterized by large-scale infrastructure and energy projects; demand for highly corrosion-resistant materials due to environmental factors.

- Latin America: Growth driven by residential construction recovery and localized manufacturing expansion; high price sensitivity impacting procurement decisions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Piano Hinge Market.- S & S Hinge Company

- Marlboro Manufacturing

- Hardware Manufacturing Corp. (HMC)

- Guden

- Sierra Pacific Engineering and Products (SPEP)

- Anderson Manufacturing

- McMaster-Carr

- Stanley Black & Decker

- Sugatsune

- Hager Companies

- Trimco

- Dynatork Air Motor

- Bommer Industries

- Blum

- Hafele

- Tectus

- Bossard Group

- ASSA ABLOY

- Fastenal

- Reliance Hinges

Frequently Asked Questions

Analyze common user questions about the Piano Hinge market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key benefits of using a piano hinge over a standard butt hinge?

Piano hinges (continuous hinges) offer superior load distribution across the entire length of the joint, preventing warping and sagging, especially for heavy or long doors and panels. They provide enhanced stability, greater security (due to the continuous pin), and allow for smooth, consistent articulation with higher cycle life compared to the localized support provided by butt hinges. They are essential for applications demanding structural uniformity.

Which material segment holds the largest value share in the Piano Hinge Market?

The Stainless Steel segment, particularly grades 304 and 316, holds the largest value share. This is driven by its necessity in high-demand, specialized applications such as marine, medical, food processing, and exterior architectural projects where exceptional corrosion resistance, hygiene, and high durability against environmental stress are mandatory purchasing requirements, justifying the higher raw material and manufacturing costs.

How does raw material price volatility impact the profitability of piano hinge manufacturers?

Raw material price volatility, particularly fluctuations in steel and aluminum coil prices, significantly impacts manufacturer profitability because materials constitute a large portion of the total production cost for hinges. Since piano hinges are often a commoditized product with competitive pricing, manufacturers frequently absorb these increases or must constantly adjust pricing, leading to pressure on profit margins and necessitating strong supply chain forecasting to mitigate cost risks.

What is the primary driving factor for the Piano Hinge Market growth in the Asia Pacific region?

The primary driving factor in the Asia Pacific (APAC) region is rapid urbanization and large-scale infrastructure and residential construction projects. The necessity for high-volume, cost-effective hardware for mass-produced furniture, commercial buildings, and standard industrial enclosures fuels immense demand for continuous hinges, positioning APAC as both the largest consumer and the highest-volume manufacturing center globally.

Are piano hinges customizable, and which industries require custom specifications?

Yes, piano hinges are highly customizable in terms of material gauge, length, width (leaf size), hole patterns, pin material, and specialized finishes (e.g., custom powder coatings or specialized plating). Industries requiring stringent custom specifications include Aerospace (for weight and safety), Defense (for military standards), and specialized Industrial Equipment manufacturers (for specific load-bearing or sealing requirements), often necessitating precise CNC machining and rigorous testing protocols.

This concludes the comprehensive, formal, and informative market insights report on the Piano Hinge Market, adhering strictly to the specified structural, formatting, and content requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager