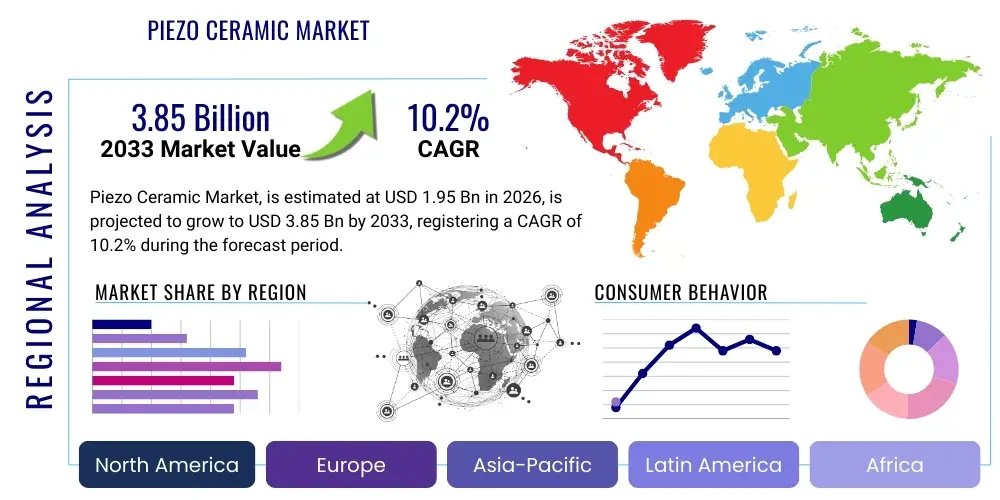

Piezo Ceramic Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435472 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Piezo Ceramic Market Size

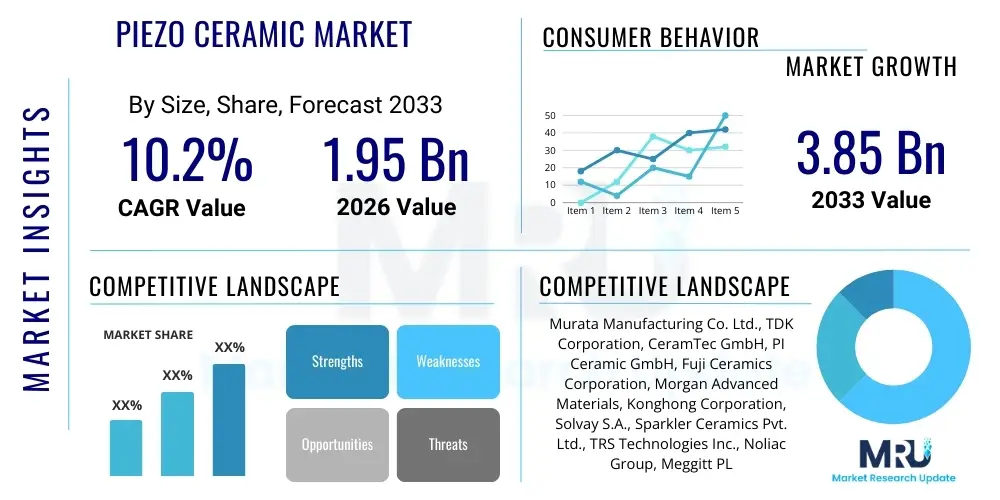

The Piezo Ceramic Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.2% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.85 Billion by the end of the forecast period in 2033.

Piezo Ceramic Market introduction

Piezo ceramics are advanced functional materials that exhibit the piezoelectric effect, converting mechanical energy (stress or vibration) into electrical energy, and vice versa. These synthetic materials, primarily lead zirconate titanate (PZT) and increasingly lead-free alternatives, form the core components in devices requiring precise motion control, sensing capabilities, and efficient energy transduction. Their unique electromechanical coupling properties make them indispensable across highly specialized sectors such as medical imaging, high-frequency ultrasonic cleaning, industrial non-destructive testing, and precision fluid control systems. The inherent versatility of piezo ceramics allows for tailored material compositions to meet demanding operational parameters, including high temperature stability, increased sensitivity, or high power generation.

Major applications of piezo ceramic technology span across actuators, sensors, and transducers. Piezoelectric actuators are critical in micro-positioning stages, fuel injection systems, and active vibration damping, offering sub-nanometer resolution essential for semiconductor manufacturing and advanced optical systems. Sensors utilize piezo ceramics to detect pressure, acceleration, and flow rate with exceptional responsiveness, dominating automotive safety systems (knock sensors) and healthcare diagnostics (ultrasound). Transducers, central to applications like sonar and medical therapeutic devices, leverage these materials for efficient transmission and reception of acoustic waves. The seamless integration of these materials into complex electronic systems underlines their critical role in modern engineering.

The market growth is fundamentally driven by the escalating demand for advanced automation in industrial processes and the continuous innovation in the healthcare sector, specifically in high-resolution medical imaging and minimally invasive surgical tools. Furthermore, the global push towards energy efficiency and the development of intelligent transportation systems mandate high-precision control elements, bolstering the adoption of piezo ceramic actuators. Key benefits include reliability, high responsiveness, compact size, and low power consumption for sensing applications. However, challenges related to the toxicity of lead-based materials (PZT) are simultaneously driving significant investment into lead-free alternatives, ensuring long-term sustainability and compliance with stringent environmental regulations.

Piezo Ceramic Market Executive Summary

The Piezo Ceramic Market is currently experiencing robust growth, propelled by the digitization of industrial manufacturing and the proliferation of IoT devices that require highly reliable sensing capabilities. Business trends indicate a strategic pivot by major manufacturers toward developing highly specialized, customized components tailored for specific industrial needs, such as high-temperature or high-pressure applications in oil and gas and aerospace. There is a discernible trend of vertical integration, with key players focusing on controlling the entire value chain, from raw material processing (powder synthesis) to final device integration, ensuring quality control and proprietary technological advantage. Moreover, sustainability concerns are mandating research and development efforts to commercialize high-performance, lead-free (LFN, BNT, BZT) piezo ceramic formulations, which represent a significant future revenue stream and competitive differentiator in environmentally sensitive markets like Europe.

Regional trends highlight Asia Pacific (APAC) as the dominant and fastest-growing market, primarily fueled by massive manufacturing bases in China, Japan, and South Korea, which are heavy consumers of piezo ceramics in consumer electronics, automotive components, and industrial automation equipment. North America and Europe maintain strong market positions due to established medical technology sectors and significant R&D spending on advanced defense and aerospace applications that demand high-reliability sensors and actuators. Regulatory frameworks, such as the EU's Restriction of Hazardous Substances (RoHS) directive, continue to shape technological advancements, pushing European manufacturers to lead the transition towards sustainable, lead-free solutions faster than other regions, thus influencing global materials research direction.

Analysis of market segments reveals that the Actuators segment is poised for the highest growth rate, driven by their critical role in sophisticated systems like adaptive optics, micro-dosing pumps, and precision motion control necessary for automation and robotics. The Sensors segment maintains the largest market share, underpinned by ubiquitous applications in automotive (parking assist, fuel injection, safety features) and consumer electronics (haptic feedback). In terms of material, PZT remains the primary choice due to its superior piezoelectric coefficient, but the strategic emphasis is rapidly shifting towards lead-free ceramics, particularly those based on Barium Titanate (BT) and Bismuth Sodium Titanate (BNT), which are expected to gain considerable traction in consumer and regulated medical device applications by the end of the forecast period.

AI Impact Analysis on Piezo Ceramic Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Piezo Ceramic market frequently revolve around questions of predictive maintenance optimization, enhanced sensor data interpretation, and AI-driven materials discovery. Users are primarily concerned with how AI can elevate the performance and reliability of piezo ceramic components—specifically, utilizing machine learning algorithms to filter noise from sensor data, enabling more accurate diagnostics in complex environments (e.g., machinery vibration analysis), and potentially extending the lifespan of actuators through optimized usage patterns. Key expectations include AI algorithms assisting in the design phase, simulating novel ceramic compositions to identify materials with superior dielectric and piezoelectric properties faster than traditional trial-and-error methods, thereby accelerating the commercialization of next-generation, lead-free piezo ceramics.

- AI-Powered Predictive Maintenance: Utilizing ML algorithms to analyze real-time vibration and acoustic data collected by piezo sensors, allowing for early detection of mechanical failure in industrial machinery, minimizing downtime.

- Enhanced Data Interpretation: Deploying sophisticated neural networks to process high-frequency and multi-channel sensor inputs, improving signal-to-noise ratio and extracting nuanced information in medical ultrasound and non-destructive testing (NDT).

- Accelerated Materials Discovery: AI and computational simulation tools expedite the development and optimization of new lead-free piezo ceramic formulations by predicting stability, Curie temperature, and electromechanical coupling factors.

- Optimized Actuator Control: Implementation of AI-based feedback loops for piezo actuators in precision positioning systems, achieving higher accuracy, reduced hysteresis, and faster response times in robotics and optical alignment.

- Smart Manufacturing and Quality Control: Integration of AI vision systems and piezo acoustic sensing in manufacturing lines for real-time monitoring of ceramic sintering and bonding processes, ensuring defect reduction and material consistency.

DRO & Impact Forces Of Piezo Ceramic Market

The dynamics of the Piezo Ceramic Market are shaped by a complex interplay of internal and external forces. Key drivers include the exponential growth in demand for miniaturized and high-resolution medical imaging devices, where piezo ceramics are essential for generating high-frequency ultrasound waves, and the pervasive need for precise fluid control in industries like automotive fuel injection systems and inkjet printing technology. Simultaneously, the market faces significant restraints, primarily the ongoing regulatory scrutiny and material toxicity concerns associated with the dominant PZT (lead zirconate titanate) materials. This regulatory pressure, particularly in Europe and parts of Asia, necessitates costly and time-consuming research into viable lead-free alternatives. These dynamics create a powerful impact force, driving rapid technological evolution within the materials science domain.

Opportunities for market expansion are abundant, particularly in emerging high-growth fields such as energy harvesting and advanced defense applications. Piezoelectric energy harvesting systems, which convert ambient vibrations or mechanical movement into usable electrical power, offer a sustainable solution for powering wireless sensor networks (WSNs) and low-power IoT devices, providing a robust pathway for long-term growth. Furthermore, the development of specialized materials capable of operating efficiently at extreme temperatures is opening new markets in aerospace engines and deep-sea exploration equipment. Strategic mergers and acquisitions among material suppliers and application device manufacturers are accelerating innovation and optimizing supply chain efficiencies, transforming niche technologies into commercial realities.

The collective impact forces demonstrate a strong market momentum favoring innovation. While the restraint of lead toxicity imposes initial R&D costs, it simultaneously acts as a powerful driver for sustainable material innovation, offering a substantial competitive advantage to early adopters of lead-free technologies. The rapid adoption of Industry 4.0 principles, necessitating greater sensor density and precision control, solidifies the foundational demand for piezo ceramic components. The market balance is thus determined by the ability of manufacturers to transition effectively from established PZT technology to high-performance, compliant lead-free substitutes while maintaining cost-effectiveness and scalability, particularly for high-volume automotive and consumer applications.

Segmentation Analysis

The Piezo Ceramic Market is comprehensively segmented based on material composition, functional application, and diverse end-use industries, providing a granular view of demand trends and technological preferences across various sectors. Material segmentation distinguishes between traditional PZT-based ceramics and emerging, regulatory-compliant lead-free options, reflecting the industry's shift toward sustainability. Application segmentation clearly delineates the end function of the component, primarily categorizing products into actuators, sensors, and transducers, each serving distinct high-precision roles. End-use analysis provides insight into where the technology is commercialized, revealing the dominance of the automotive sector, followed closely by the fast-growing healthcare and industrial automation sectors, guiding strategic investment decisions in manufacturing capacity and R&D focus.

- Material Type:

- Lead Zirconate Titanate (PZT): Dominant material due to high piezoelectric constants and superior performance, utilized widely across industrial and automotive sectors.

- Lead-free Piezo Ceramics: Includes Barium Titanate (BT), Bismuth Sodium Titanate (BNT), and Potassium Sodium Niobate (KNN); growing rapidly due to environmental compliance and targeting consumer electronics and medical devices.

- Application:

- Actuators: Used for micro-positioning, motor control, precision dispensing (e.g., fuel injectors, micro-pumps), offering high force and fast response.

- Sensors: Employed for measuring pressure, acceleration, vibration, and strain (e.g., automotive knock sensors, pressure monitors, flow sensors).

- Transducers: Key components in medical ultrasound, sonar systems, non-destructive testing (NDT), and high-power ultrasonic cleaning systems.

- End-Use Industry:

- Automotive: Critical for fuel injection, parking assistance, air bag sensors, and engine management systems, driven by strict emission standards and safety mandates.

- Healthcare: Essential for diagnostic ultrasound imaging, therapeutic high-intensity focused ultrasound (HIFU), and surgical instruments.

- Industrial & Manufacturing: Utilized in precision robotics, flow meters, industrial ultrasonic processing, and advanced quality control systems.

- Aerospace & Defense: Applications in sonar, gyroscope sensors, advanced surveillance, and high-reliability systems requiring extreme operating conditions.

- Consumer Electronics: Used in haptic feedback devices (smartphones, wearables), buzzers, and specialized microphones.

Value Chain Analysis For Piezo Ceramic Market

The Piezo Ceramic Value Chain begins with the upstream segment, focusing intensely on the sourcing and processing of raw materials, primarily metallic oxides such as lead oxide, titanium oxide, and zirconium oxide for PZT, and increasingly, barium, bismuth, and sodium compounds for lead-free alternatives. This stage is highly critical as the purity and precise stoichiometric mixture of these powders fundamentally determine the final ceramic’s piezoelectric properties, Curie temperature, and stability. Key upstream activities involve advanced synthesis techniques like co-precipitation or solid-state reactions to produce highly homogeneous ceramic powders, followed by milling and calcination. Control over this initial process directly impacts the cost and performance of the finished component, making proprietary powder formulation a significant competitive barrier.

Midstream activities encompass the actual fabrication of the ceramic components. This involves various forming techniques such as pressing (dry or isostatic), extrusion, and tape casting, followed by high-temperature sintering (firing) to achieve the required density and microstructure. The subsequent process, known as polarization or poling, where the ceramic material is subjected to a high DC electric field, is essential to aligning the internal domains and activating the piezoelectric effect. Manufacturers invest heavily in optimizing these thermal and electrical processes to ensure maximum electromechanical coupling and consistency across batches. The efficiency and yield rates at this stage are crucial for maintaining profitability, especially in high-volume applications like sensors and actuators for the automotive sector.

The downstream segment involves product finishing, device assembly, and distribution channels. Finished piezo ceramics are machined, electroded (coated with conductive material), and integrated into final products like sensors (e.g., strain gauges, accelerometers), actuators (e.g., multi-layer actuators), or transducers (e.g., ultrasound probes). Distribution predominantly relies on specialized direct sales channels for B2B transactions, particularly when dealing with complex industrial or medical integrators who require specific technical support and customization. Indirect channels, involving distributors or agents, are common for standard components sold into the high-volume consumer electronics and lower-tier automotive markets. Strong collaborative partnerships with Original Equipment Manufacturers (OEMs) are essential for achieving deep market penetration and influencing next-generation device design.

Piezo Ceramic Market Potential Customers

Potential customers for piezo ceramic components are highly diverse, spanning major industries that require ultra-precise motion control, accurate fluid handling, and reliable sensing capabilities under demanding operational conditions. The primary segment comprises manufacturers of high-specification machinery and systems, including automotive Tier 1 suppliers who integrate piezo components into crucial engine management (fuel injection), stability control, and safety systems. These customers demand extreme reliability, tolerance to temperature fluctuations, and compliance with stringent quality standards like ISO/TS 16949. Their purchasing decisions are driven by long-term supply contracts, technical support, and component lifespan, making them high-value, long-cycle clients.

Another rapidly expanding customer base resides within the medical device manufacturing sector. Companies specializing in diagnostic ultrasound equipment (MRI, CT, and portable scanners) are critical buyers, requiring high-frequency, fine-pitch transducer arrays for enhanced image resolution and minimally invasive surgery tools (HIFU). These customers prioritize biocompatibility, exceptional acoustic performance, and regulatory approval (e.g., FDA clearance). The trend toward portable and handheld medical devices further increases demand for smaller, more efficient piezo components, driving innovation in miniaturized multi-layer ceramics tailored for high-frequency acoustic applications.

Furthermore, industrial automation and robotics companies represent a significant and growing end-user segment. These customers utilize piezo actuators for precision wafer handling in semiconductor manufacturing, optical alignment, and high-speed sorting mechanisms. The demand here is centered on high-throughput capabilities, nanometer-level precision, and long operational life, supporting the global push toward fully automated factories (Industry 4.0). Defense and aerospace contractors also remain core customers, purchasing specialized piezo materials for critical applications such as naval sonar, high-reliability igniters, and robust structural health monitoring (SHM) sensors designed to withstand extreme environments, valuing proprietary technology and secure supply chains above all else.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.85 Billion |

| Growth Rate | 10.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Murata Manufacturing Co. Ltd., TDK Corporation, CeramTec GmbH, PI Ceramic GmbH, Fuji Ceramics Corporation, Morgan Advanced Materials, Konghong Corporation, Solvay S.A., Sparkler Ceramics Pvt. Ltd., TRS Technologies Inc., Noliac Group, Meggitt PLC (Parker Hannifin), APC International, Ltd., Exide Technologies, KEMET (Yageo), CTS Corporation, Taiyo Yuden Co., Ltd., Boston Piezo-Optics, Sensor Technology Ltd., Piezo Kinetics Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Piezo Ceramic Market Key Technology Landscape

The technology landscape of the Piezo Ceramic Market is characterized by intense material science innovation aimed at replacing PZT with high-performance, environmentally compliant alternatives. A central technological focus is the optimization of lead-free materials, primarily based on Bismuth Sodium Titanate (BNT) and Potassium Sodium Niobate (KNN) systems, to achieve piezoelectric coefficients and Curie temperatures comparable to PZT. Current technological advancements involve alloying these materials with small amounts of rare earth elements or developing complex crystalline structures to enhance their electromechanical coupling factor and thermal stability. The successful commercialization of these next-generation ceramics is dependent on developing cost-effective, scalable production methods that ensure homogeneous material quality during large-scale sintering processes, which remains a significant engineering hurdle.

Another crucial technological development involves the fabrication of multi-layer piezo ceramic components. Multi-layer technology allows for the stacking of thin ceramic layers and internal electrodes, which significantly reduces the driving voltage required while increasing the displacement (for actuators) or sensitivity (for sensors). This technology is fundamental to miniaturization trends in consumer electronics and medical devices, enabling smaller, faster, and more energy-efficient components. Advancements in high-precision tape casting and cofiring techniques are essential for producing these thin layers with nanometer accuracy and maintaining structural integrity under high mechanical stress, making manufacturing precision a key competitive differentiator in the actuator segment.

Furthermore, smart integration and packaging technologies are rapidly evolving. The trend moves beyond selling simple ceramic elements towards providing fully integrated, packaged modules that include drive electronics, feedback systems, and microprocessors. This technological shift is crucial for high-end applications like active vibration cancellation and adaptive optics, where the piezo component must interface seamlessly with digital control systems. This integration leverages advancements in microelectronics and MEMS (Micro-Electro-Mechanical Systems) technology, enabling the development of "smart sensors" and "smart actuators" that can perform self-diagnosis and communicate wirelessly, aligning the piezo market directly with the demands of the Industrial Internet of Things (IIoT).

Regional Highlights

- Asia Pacific (APAC): APAC commands the largest market share and exhibits the fastest growth due to the presence of large-scale manufacturing hubs for automotive components, consumer electronics, and industrial machinery, particularly in China, Japan, and South Korea. Japan remains a pioneer in high-quality ceramic material technology and piezoelectric applications in robotics and medical imaging. Significant investment in infrastructure and the push towards domestic high-tech production in China further solidify APAC's dominance, driving volume demand for both PZT and emerging lead-free materials in consumer electronics and electric vehicle components.

- North America: North America represents a mature, high-value market driven primarily by the aerospace, defense, and healthcare sectors. The demand here is focused on highly specialized, high-reliability piezo ceramics for military sonar, missile guidance systems, and advanced diagnostic equipment (MRI, ultrasound). Investment is heavily concentrated on R&D for high-performance materials capable of extreme temperature operation and long-term stability, ensuring the region maintains its technological edge in sophisticated, low-volume applications.

- Europe: Europe is characterized by stringent environmental regulations, particularly the RoHS directive, which makes it the global leader in the development and adoption of lead-free piezo ceramics. The region’s strong automotive sector (especially high-end, precision-engineered vehicles) and advanced industrial automation sector drive demand for actuators used in precision fuel injection and high-speed manufacturing processes. German manufacturers, in particular, lead innovation in high-precision piezo positioning systems and sophisticated industrial sensors.

- Latin America (LATAM): The LATAM market is nascent but growing, primarily driven by investments in healthcare infrastructure and automotive manufacturing, particularly in Brazil and Mexico. Demand focuses on standard PZT components for automotive safety systems and basic medical diagnostic transducers. Market growth is contingent upon industrialization rates and foreign direct investment in manufacturing capabilities, providing an opportunity for established global players seeking new assembly locations.

- Middle East and Africa (MEA): Growth in MEA is largely fueled by the energy sector, specifically the demand for robust pressure and acoustic sensors used in oil and gas exploration, drilling, and pipeline monitoring systems. Defense spending also contributes significantly to the market. The high-temperature, high-pressure environments inherent in energy exploration necessitate specialized, resilient piezo ceramic formulations, making reliability and durability key purchasing criteria.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Piezo Ceramic Market.- Murata Manufacturing Co. Ltd.

- TDK Corporation

- CeramTec GmbH

- PI Ceramic GmbH

- Fuji Ceramics Corporation

- Morgan Advanced Materials

- Konghong Corporation

- Solvay S.A.

- Sparkler Ceramics Pvt. Ltd.

- TRS Technologies Inc.

- Noliac Group

- Meggitt PLC (Parker Hannifin)

- APC International, Ltd.

- KEMET (Yageo)

- CTS Corporation

- Taiyo Yuden Co., Ltd.

- Boston Piezo-Optics

- Sensor Technology Ltd.

- Piezo Kinetics Inc.

- Channel Technologies Group (CTG)

Frequently Asked Questions

Analyze common user questions about the Piezo Ceramic market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between PZT and lead-free piezo ceramics?

PZT (Lead Zirconate Titanate) offers superior electromechanical performance (higher piezoelectric coefficient) and thermal stability, making it the industry standard. However, lead-free ceramics (like BNT or KNN) are critical alternatives developed to meet environmental regulations, particularly in Europe, despite often having slightly lower performance metrics in specific applications.

How is the automotive industry leveraging piezo ceramic technology?

The automotive industry utilizes piezo ceramics extensively in precision fuel injection systems for improved efficiency and lower emissions, knock sensors for engine monitoring, and ultrasonic sensors for parking assistance and autonomous driving features, demanding high temperature stability and robust reliability.

What role do piezo ceramic actuators play in micro-positioning systems?

Piezo ceramic actuators provide ultra-fine, sub-nanometer resolution movement due to the direct and precise electromechanical conversion. This capability is essential for critical applications in semiconductor manufacturing, adaptive optics, and micro-fluidics where positional accuracy is paramount.

Which region currently dominates the global Piezo Ceramic Market?

The Asia Pacific (APAC) region dominates the market due to its extensive manufacturing base for consumer electronics, automotive components, and industrial automation equipment, driven primarily by high-volume production in countries like China, Japan, and South Korea.

Is the market experiencing a shift towards energy harvesting applications?

Yes, piezoelectric energy harvesting is an emerging and high-growth opportunity. Piezo ceramics convert ambient mechanical vibrations (from traffic, machinery, or human movement) into electrical energy, enabling self-powered, sustainable solutions for wireless sensor networks (WSNs) and low-power IoT devices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Piezo Ceramic Technology Market Size Report By Type (Lead zinc titanates (PZT), Lead titanate (PT), Lead magnesium niobate (PMN)), By Application (Industrial &Manufacturing, Automotive, Information & Telecommunication, Medical Devices, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Piezo Ceramic Element Market Statistics 2025 Analysis By Application (Automotive Electronics, Home Appliances, Other), By Type (Direct Radiation Type, Indirect Radiation Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Piezo Ceramic Market Statistics 2025 Analysis By Application (Industrial &Manufacturing, Automotive, Information & Telecommunication, Medical Devices), By Type (Lead zinc titanates (PZT), Lead titanate (PT), Lead magnesium niobate (PMN)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager