Piling Sheet, Anchoring Equipment and Trench Shoring System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439913 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Piling Sheet, Anchoring Equipment and Trench Shoring System Market Size

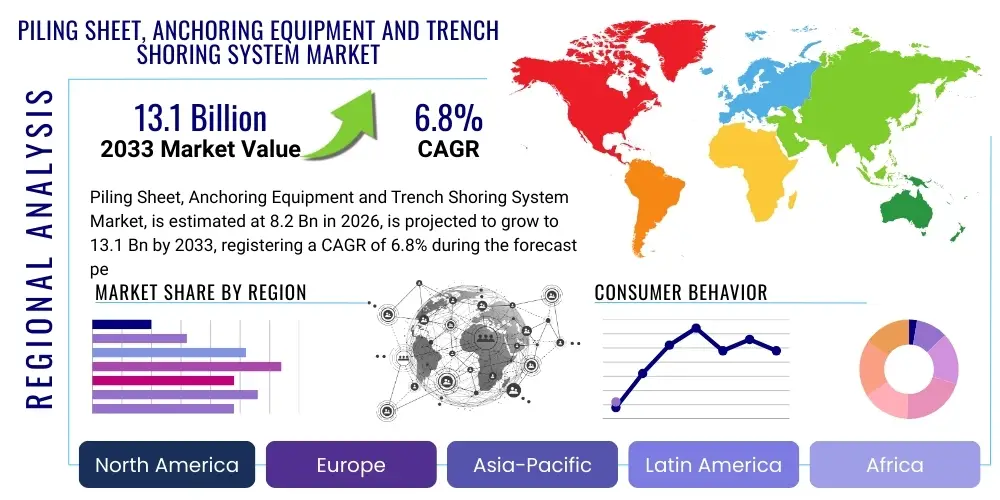

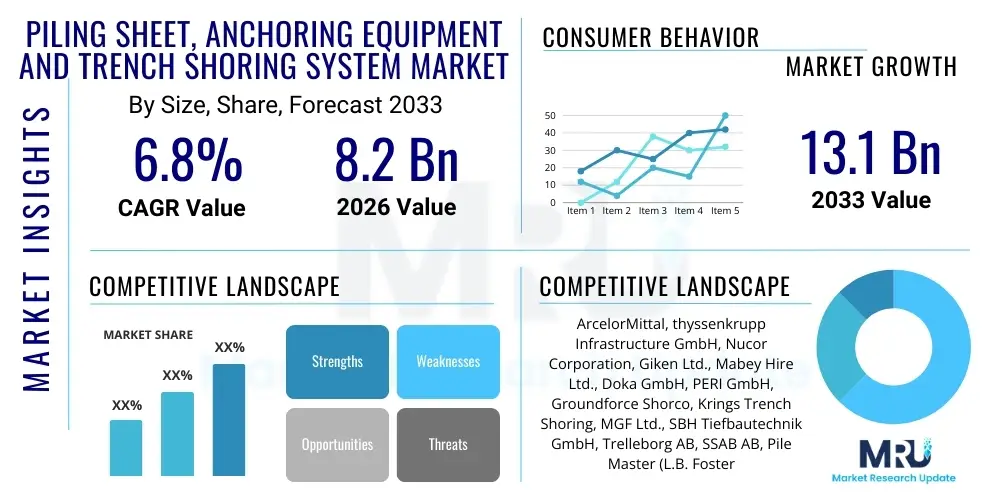

The Piling Sheet, Anchoring Equipment and Trench Shoring System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 8.2 Billion in 2026 and is projected to reach USD 13.1 Billion by the end of the forecast period in 2033.

Piling Sheet, Anchoring Equipment and Trench Shoring System Market introduction

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market encompasses a critical segment of the construction and civil engineering industry, providing essential solutions for ground support, excavation stability, and structural foundation. Piling sheets, often made of steel or concrete, are driven into the ground to create retaining walls, cofferdams, or foundations, preventing soil collapse and managing groundwater. Anchoring equipment, including ground anchors, rock bolts, and tie-backs, provides lateral support to retaining structures and slopes, enhancing overall stability and safety in demanding environments. Trench shoring systems, comprising hydraulic bracing, timber, or aluminum shoring, are designed to prevent the collapse of trench walls during excavation, safeguarding workers and maintaining the integrity of adjacent structures.

These systems are fundamental across a wide array of major applications, from large-scale infrastructure projects like bridge construction, highway expansions, and tunneling, to urban development projects such as building foundations, underground parking, and utility installations. They are also indispensable in marine engineering for port construction, quay walls, and dredging operations, as well as in mining for excavation support. The primary benefits derived from the deployment of these solutions include significantly enhanced site safety, prevention of costly collapses, protection of adjacent property, and enabling efficient work in challenging ground conditions. Furthermore, they contribute to project timelines by creating stable work environments, reducing potential delays and rework, and ultimately ensuring the successful execution of complex construction endeavors with a strong emphasis on structural integrity and worker well-being.

The market is primarily driven by escalating global investments in infrastructure development, fueled by rapid urbanization and industrialization, particularly in emerging economies. There is a continuous demand for robust and reliable ground support solutions to facilitate the construction of complex structures and deep excavations, alongside the maintenance and repair of aging existing infrastructure in developed nations. Additionally, stringent safety regulations and environmental protection mandates from government bodies worldwide compel contractors to adopt advanced shoring and piling techniques to mitigate risks and ensure worker safety, thereby increasing compliance costs but also fostering higher quality solutions. Technological advancements, such as the development of lightweight, high-strength materials and integrated digital design tools like Building Information Modeling (BIM), further contribute to market growth by improving efficiency, reducing installation times, and enhancing the overall precision of ground engineering projects. The increasing awareness regarding occupational hazards in construction also plays a pivotal role, driving the adoption of safer, more efficient, and technologically advanced shoring and anchoring methods across the industry.

Piling Sheet, Anchoring Equipment and Trench Shoring System Market Executive Summary

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market is experiencing dynamic shifts, driven by a confluence of global business trends, evolving regional demands, and segment-specific innovations. A major business trend is the growing emphasis on rental models, which allow construction companies to access specialized and often expensive equipment without the burden of significant upfront capital investment, offering flexibility and cost efficiency, particularly for projects of varying scales and durations. Sustainability is another crucial trend, with increasing adoption of recyclable materials like steel, and the development of more environmentally friendly installation methods, such as vibratory piling and silent piling techniques, to reduce noise and vibration pollution in urban areas. Digitalization, including the integration of Building Information Modeling (BIM) for design and planning, and IoT-enabled monitoring systems for real-time performance tracking, is enhancing design precision, operational efficiency, and real-time safety management across project lifecycles, driving intelligent construction practices.

Regionally, the Asia Pacific (APAC) market continues to be a primary growth engine, propelled by massive infrastructure projects in countries like China, India, and Southeast Asian nations, driven by rapid urbanization, industrial expansion, and significant government investments in transportation networks, utilities, and commercial real estate. North America and Europe, while mature markets, demonstrate consistent demand, primarily driven by maintenance, repair, and upgrade of aging infrastructure, coupled with strict safety regulations that necessitate advanced shoring and anchoring solutions for renovation and new construction. Latin America, the Middle East, and Africa are showing significant potential, with increasing foreign direct investment in construction and energy sectors, alongside ambitious national development visions. These regions are gradually adopting more sophisticated shoring and piling techniques as their construction industries mature and become more regulated, pushing demand for robust and efficient systems that adhere to international safety and quality benchmarks.

Segment-wise, the market is seeing a notable trend towards modular and versatile shoring systems, which can be easily adapted to various trench sizes, depths, and ground conditions, thereby increasing their utility and reducing operational complexities and setup times on diverse construction sites. In piling sheets, the demand for high-strength steel sheets remains dominant due to their exceptional durability, load-bearing capacity, and reusability, but composite materials are gaining traction for niche applications requiring superior corrosion resistance, lighter weight, or specific environmental properties, such as in marine or chemical environments. Anchoring equipment is evolving with smart sensors for real-time load monitoring and improved installation techniques that minimize environmental disturbance and enhance long-term stability. The integration of advanced materials, such as high-performance concrete and polymers, and automation in manufacturing processes is leading to more robust, lighter, and easier-to-install components, ultimately enhancing worker safety, project efficiency, and overall asset longevity across all three core segments of piling sheets, anchoring equipment, and trench shoring systems, ensuring the industry continues to meet the increasing demands of modern construction.

AI Impact Analysis on Piling Sheet, Anchoring Equipment and Trench Shoring System Market

Common user questions regarding AI's impact on the Piling Sheet, Anchoring Equipment, and Trench Shoring System Market often revolve around how artificial intelligence can enhance safety protocols, optimize design processes, improve operational efficiency on site, and contribute to predictive maintenance strategies for equipment. Users frequently inquire about AI's potential role in mitigating inherent risks associated with deep excavation and ground instability, its capacity to automate complex calculations for shoring designs, and how it can be used to monitor dynamic ground conditions in real-time. There is also significant interest in AI's capacity to streamline supply chain logistics for heavy equipment and specialized materials, manage intricate project schedules more effectively, and offer actionable insights into equipment performance and longevity, leading to better asset utilization. The overarching themes consistently emerging from these inquiries include leveraging AI for smarter, safer, more precise, and ultimately more cost-effective ground engineering solutions that reduce human error and maximize project success.

AI's influence is anticipated to be transformative, moving beyond basic data analytics to truly intelligent systems that can learn from vast datasets, predict potential failures, recommend optimal solutions, and even guide autonomous machinery in specific tasks. This shift is crucial for an industry where safety margins are tight and precision is paramount. By analyzing vast datasets derived from historical project performance, geological surveys, environmental monitoring, and real-time sensor inputs, AI algorithms can identify subtle patterns and anomalies that human operators might overlook. This capability leads to proactive interventions rather than reactive responses to critical situations, significantly enhancing worker safety and preventing costly structural failures. Furthermore, AI can aid in the highly customized design of shoring and piling solutions, matching specific site requirements, soil mechanics, and structural loads with the most appropriate and cost-effective designs, thereby minimizing material waste, optimizing resource utilization, and accelerating the design phase of complex projects.

The integration of AI will also significantly impact the entire project lifecycle, from initial planning and comprehensive risk assessment to meticulous execution and post-completion monitoring. In the planning phase, AI-powered design tools can rapidly simulate various shoring and piling configurations under diverse load conditions, optimizing material use, ensuring compliance with stringent engineering standards, and predicting potential challenges. During execution, AI can process and interpret continuous data streams from IoT sensors embedded within shoring structures and anchoring systems, providing real-time alerts about stress levels, minute ground movements, or potential instabilities, enabling immediate corrective action to prevent incidents. Post-completion, AI can contribute to the long-term monitoring of installed infrastructure, predicting maintenance needs, assessing structural health, and extending the operational lifespan of installed systems, thereby maximizing their return on investment. This continuous learning, adaptive capability, and predictive power position AI as a pivotal technology for driving unprecedented levels of innovation, safety, and efficiency within the piling, anchoring, and trench shoring market, pushing the boundaries of what is possible in ground engineering.

- Enhanced Safety Monitoring: AI-powered sensors and cameras can continuously monitor ground movement, assess the structural integrity of shoring systems, and detect worker proximity to hazardous zones, providing real-time alerts and preventing accidents on site.

- Optimized Design and Engineering: AI algorithms can analyze complex geological data, project-specific requirements, and historical performance metrics to generate highly optimized piling and shoring designs, minimizing material use, ensuring maximum structural stability, and adhering to strict engineering codes.

- Predictive Maintenance: AI can predict potential equipment failures by analyzing extensive operational data from machinery, scheduling maintenance proactively to reduce unscheduled downtime, minimize repair costs, and significantly extend asset lifespan.

- Automated Project Management: AI-driven platforms can intelligently manage complex project schedules, optimize resource allocation, and streamline logistics for equipment and materials, improving overall project efficiency, reducing delays, and lowering operational costs.

- Advanced Risk Assessment and Mitigation: AI can assess site-specific risks by integrating real-time data from various sources (weather patterns, seismic activity, comprehensive soil reports) to provide dynamic risk assessments and recommend appropriate, adaptive safety measures.

- Intelligent Site Logistics: AI can optimize the precise movement and strategic placement of piling sheets and shoring components on congested construction sites, improving material flow, reducing operational bottlenecks, and enhancing overall site organization.

- Automated Quality Control and Inspection: AI-powered vision systems and drones can conduct automated, high-precision inspections of installed piling and shoring elements, ensuring meticulous compliance with design specifications and rigorous quality standards, and detecting anomalies early.

- Virtual Training and Simulation: AI can create realistic virtual training environments for equipment operators and construction workers, simulating various hazardous scenarios to enhance practical skills, improve decision-making under pressure, and promote safety awareness without real-world risks.

- Material Optimization and Selection: AI can identify optimal opportunities for using sustainable, recycled, or novel high-performance materials by analyzing their performance characteristics, cost-effectiveness, and suitability for specific ground conditions and environmental impacts.

- Data-Driven Decision Making: AI provides unparalleled actionable insights from vast and complex datasets, empowering engineers and project managers to make informed, strategic decisions for the most challenging and complex ground engineering situations, leading to superior project outcomes.

DRO & Impact Forces Of Piling Sheet, Anchoring Equipment and Trench Shoring System Market

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that collectively influence its growth trajectory and competitive landscape. Key drivers include robust global infrastructure development initiatives, particularly in rapidly urbanizing regions such as Asia Pacific, which demand extensive ground stabilization and excavation support for new construction projects and the upgrading of existing infrastructure. The increasing emphasis on worker safety and environmental protection, leading to more stringent regulatory frameworks and higher compliance standards from government bodies worldwide, compels construction companies to adopt advanced and certified shoring and piling solutions. Furthermore, continuous technological advancements, such as the introduction of lighter yet stronger materials, integrated digital design tools like BIM, and real-time monitoring systems, significantly enhance efficiency, reduce installation times, and improve operational safety, thereby stimulating market demand for innovative solutions. These factors collectively create a strong impetus for sustained market expansion and technological evolution within the industry.

However, the market also faces significant restraints that could impede its growth and widespread adoption. High initial capital investment required for specialized equipment and advanced shoring systems can be a substantial barrier for smaller contractors or those operating in developing regions with limited access to financing. The scarcity of skilled labor, particularly for operating complex machinery, designing intricate ground engineering solutions, and executing precise installation tasks, poses a persistent challenge to project timelines, quality, and overall efficiency across many markets. Economic downturns, geopolitical instability, or sudden shifts in government spending priorities can lead to deferment or cancellation of large-scale construction projects, directly impacting market demand and revenue streams. Moreover, volatility in raw material prices, especially for essential components like steel and aluminum, can significantly increase production costs, erode profit margins, and affect the predictability of project budgeting for manufacturers and contractors alike. These restraints necessitate innovative business models, such as expanded rental services, and continuous investment in training programs to mitigate their adverse effects and ensure market resilience.

Despite the challenges, numerous opportunities exist for market participants to capitalize on, fostering growth and innovation. The expanding focus on smart city development, coupled with extensive renewable energy infrastructure projects like offshore wind farms and solar installations, presents new avenues for specialized piling and anchoring solutions. The growing global emphasis on sustainable construction practices, including the use of recycled materials, modular designs for reusability, and energy-efficient installation methods, offers a significant competitive edge and aligns with global environmental goals. Furthermore, the expansion of the equipment rental market provides a flexible and cost-effective option for contractors, broadening the customer base and reducing barriers to entry for smaller players, while also promoting the adoption of newer technologies. Emerging markets in Africa, Latin America, and parts of Asia, with their nascent but rapidly developing infrastructure sectors and increasing foreign direct investment, represent significant untapped potential for market expansion and technology transfer. The market is also subject to various impact forces, including the bargaining power of buyers who consistently demand cost-effective, efficient, and safe solutions, and the bargaining power of suppliers, particularly for specialized raw materials or advanced proprietary components. The threat of new entrants, while mitigated by high capital requirements, technical expertise, and regulatory hurdles, exists for niche solutions or disruptive technologies. The threat of substitutes, such as alternative foundation methods (e.g., raft foundations, deep soil mixing) or less conventional shoring techniques, also influences strategic decisions and drives continuous innovation. Finally, intense industry rivalry among established players and new entrants fosters innovation, drives competitive pricing, and enhances service offerings, creating a dynamic and evolving market environment.

Segmentation Analysis

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market is meticulously segmented to provide a granular understanding of its diverse components, applications, and regional dynamics. This comprehensive segmentation allows for a detailed analysis of specific market niches, identifying nuanced growth drivers, competitive landscapes, and emerging trends within each category. Such an in-depth breakdown is crucial for stakeholders to develop highly targeted strategies, optimize product portfolios, and make informed investment decisions in this highly specialized and technologically advancing construction support sector. The market's inherent complexity necessitates a multi-faceted approach to market intelligence, enabling a clear view of where demand originates, how it is fulfilled across different industry verticals, and how geographical factors influence adoption. By dissecting the market into its core constituents, we can uncover specific opportunities for innovation and differentiation, ensuring that market players remain competitive and responsive to evolving client needs.

Understanding these segments is paramount for strategic planning, as each category is influenced by unique drivers, regulatory frameworks, and technological advancements. For instance, the demand for steel sheet piles might be tied to large-scale marine infrastructure projects, while hydraulic shoring systems are critical for urban utility excavations. Material segments, such as steel or aluminum, are impacted by raw material costs, supply chain resilience, and the drive for lighter, more durable solutions. Application segments like civil construction versus marine and offshore have distinct requirements in terms of product specifications, engineering complexity, and project scale. The end-use segmentation, particularly the growth of the rental market, reveals shifts in business models and procurement preferences among contractors. By analyzing these interdependencies, market participants can tailor their offerings, allocate resources effectively, and anticipate future market shifts, positioning themselves for sustainable growth in a dynamic global construction environment. This structured approach to market analysis ensures that all critical aspects are considered, providing a holistic and actionable understanding of the Piling Sheet, Anchoring Equipment, and Trench Shoring System Market.

- By Product Type:

- Piling Sheets:

- Steel Sheet Piles (U-Type, Z-Type, Flat-Type, Box Piles)

- Vinyl Sheet Piles

- Composite Sheet Piles (Fiberglass Reinforced Polymer)

- Timber Sheet Piles

- Precast Concrete Sheet Piles

- CFA Piles (Continuous Flight Auger Piles)

- Driven Piles (Precast, Timber, Steel)

- Anchoring Equipment:

- Ground Anchors (Permanent, Temporary, Self-Drilling Anchors)

- Rock Bolts (Mechanical, Resin, Grouted)

- Soil Nails (Drill and Grout, Driven)

- Tie-Back Systems (Strands, Bars)

- Micropiles (High-Capacity, Mini Piles)

- Anchor Blocks and Plates

- Trench Shoring Systems:

- Hydraulic Shoring Systems (Aluminum Hydraulic Shores, Steel Hydraulic Shores, Vertical Shores, Walers)

- Trench Boxes/Shields (Steel Trench Boxes, Aluminum Trench Boxes, Modular Trench Boxes)

- Slide Rail Systems (Two-Sided, Three-Sided, Four-Sided, Pit Shoring)

- Beam and Plate Systems (Sheeting and Bracing)

- Maneuverable Shoring Systems (Drag Boxes)

- Timber Shoring (Traditional, for lighter loads)

- Road Plate Systems

- Piling Sheets:

- By Material:

- Steel (High-Strength Steel, Recycled Steel)

- Aluminum (Lightweight Aluminum Alloys)

- Composite (Fiberglass, Polymer Blends)

- Timber (Hardwood, Treated Lumber)

- Concrete (Precast, Reinforced Concrete)

- Vinyl/PVC

- By Application:

- Civil Construction (Roads, Bridges, Tunnels, Railways, Metro Systems, Canals, Flood Defenses)

- Commercial Construction (Buildings, High-Rises, Commercial Complexes, Office Parks, Retail Centers)

- Infrastructure Development (Utilities - Water, Sewer, Gas, Electric Pipelines; Telecommunication, Data Centers, Water Treatment Plants)

- Industrial Construction (Factories, Power Plants, Petrochemical Facilities, Warehouses, Logistics Hubs)

- Marine & Offshore (Ports, Harbors, Quay Walls, Piers, Breakwaters, Dry Docks, Offshore Platforms)

- Mining (Open-Pit Support, Underground Tunneling, Shaft Excavation)

- Environmental Remediation (Containment Walls, Landfill Cells, Contaminated Site Stabilization)

- Residential Construction (Basement Excavations, Foundation Support)

- By End-Use:

- Rental (Short-term, Long-term Rentals)

- Sales (Direct Purchase by Contractors, Government Entities)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, ASEAN Countries, Australia & New Zealand, Rest of APAC)

- Latin America (Brazil, Argentina, Colombia, Rest of Latin America)

- Middle East and Africa (UAE, Saudi Arabia, South Africa, Turkey, Rest of MEA)

Value Chain Analysis For Piling Sheet, Anchoring Equipment and Trench Shoring System Market

The value chain for the Piling Sheet, Anchoring Equipment, and Trench Shoring System Market is a complex network involving multiple stages, beginning from raw material sourcing and extending to end-use application on construction sites. Upstream analysis focuses on the initial stages of production, primarily involving the procurement and processing of fundamental raw materials and components. This includes major steel manufacturers who supply high-grade steel plates, sections, and coils used for sheet piles and trench boxes, as well as aluminum producers for lightweight shoring components, and suppliers of specialized composites or sustainably sourced treated timber. These raw material providers form the bedrock of the industry, with their pricing, quality, and supply consistency significantly impacting the subsequent stages of the value chain. Furthermore, specialized manufacturers of anchoring components, such as high-strength steel bars, galvanized cables, synthetic fibers, and various grout materials, also play a crucial role in the upstream segment, ensuring the availability of essential elements for ground stabilization. Their capacity for innovation in materials science directly influences the performance, durability, and cost-effectiveness of the final ground support products. The efficiency, ethical sourcing, and reliability of these upstream suppliers are paramount for maintaining a smooth production flow and ensuring the overall quality and sustainability of market offerings.

Midstream activities involve the intricate processes of fabrication, manufacturing, and precision assembly of piling sheets, anchoring equipment, and trench shoring systems. This stage includes specialized engineering firms that design custom shoring solutions tailored to specific project requirements, advanced manufacturing facilities that cut, bend, weld, and assemble components using automated processes, and rigorous quality control departments that ensure all products meet stringent safety and performance standards, often mandated by international certifications. Many prominent companies in this segment are vertically integrated, controlling aspects from initial design and material procurement to final manufacturing and even distribution, which allows for greater control over product quality, innovation cycles, and cost efficiencies. The adoption of advanced manufacturing techniques, such as robotic welding, precision laser cutting, and modular assembly, contributes to higher product quality, reduced production costs, and faster turnaround times. Furthermore, extensive research and development activities are concentrated in this midstream segment, driving the innovation of new materials, more efficient designs, and enhanced system functionalities to meet evolving construction needs, adhere to stricter regulatory requirements, and address specific geotechnical challenges. The midstream segment is characterized by significant capital investment in machinery, skilled labor, and intellectual property, emphasizing efficiency, adherence to strict engineering specifications, and continuous improvement.

Downstream analysis focuses on the distribution, sales, rental, and final application of these specialized ground support systems. The distribution channel is multifaceted, comprising both direct and indirect approaches to reach a diverse customer base. Direct sales involve manufacturers selling directly to large-scale construction companies, governmental agencies undertaking major infrastructure projects, or major infrastructure developers, often requiring highly customized solutions, extensive technical support, and long-term partnerships. This channel is crucial for high-value, complex projects where direct consultation and in-depth engineering expertise from the manufacturer are paramount. Indirect sales involve a robust network of authorized distributors, wholesalers, and specialized equipment rental companies who purchase products from manufacturers and then supply them to a broader range of smaller contractors, civil engineering firms, and diverse construction projects. Rental services have become a particularly dominant distribution model, especially for trench shoring systems and temporary piling, as they offer unparalleled flexibility, significantly reduce capital expenditure for contractors, and provide access to a diverse and regularly updated fleet of equipment. These rental companies often provide additional value-added services such as logistics, on-site installation support, engineering consultation, and routine maintenance, further enhancing the value proposition for their clients. The end-users, primarily civil engineering contractors, general construction firms, infrastructure developers, utility companies, and specialized shoring contractors, are at the very end of this value chain, utilizing these systems to ensure safe, efficient, and stable excavation and foundation work. Their continuous feedback loop is critical for manufacturers to understand real-world market needs, drive continuous product improvement, and foster ongoing innovation.

Piling Sheet, Anchoring Equipment and Trench Shoring System Market Potential Customers

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market caters to a diverse range of potential customers, primarily end-users and buyers engaged in various facets of construction, civil engineering, and infrastructure development globally. The largest segment of potential customers includes large-scale civil engineering and general construction contractors who undertake major infrastructure projects such as roads, bridges, tunnels, railways, and public utilities. These prominent firms require robust, reliable, and highly efficient ground support systems to ensure project safety, maintain structural stability, and guarantee timely completion, often operating under tight schedules and complex geological conditions. Their demand is primarily driven by the scale and complexity of their projects, stringent regulatory compliance mandates, and the critical need for efficient resource management. They often seek advanced, high-performance systems that can withstand challenging environmental factors, offer significant reusability, and integrate seamlessly with other construction technologies, ultimately minimizing overall project costs and maximizing operational output.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.2 Billion |

| Market Forecast in 2033 | USD 13.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ArcelorMittal, thyssenkrupp Infrastructure GmbH, Nucor Corporation, Giken Ltd., Mabey Hire Ltd., Doka GmbH, PERI GmbH, Groundforce Shorco, Krings Trench Shoring, MGF Ltd., SBH Tiefbautechnik GmbH, Trelleborg AB, SSAB AB, Pile Master (L.B. Foster Company), PVE (Piling & Vibro Equipment), CEMEX S.A.B. de C.V., Atlas Copco (Dynapac), Bauer AG, Keller Group plc, Franki Foundations |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Piling Sheet, Anchoring Equipment and Trench Shoring System Market Key Technology Landscape

The Piling Sheet, Anchoring Equipment, and Trench Shoring System Market is continuously evolving, driven by significant advancements in technology aimed at improving safety, operational efficiency, and environmental sustainability across construction and civil engineering projects. A key technological development is the widespread adoption of advanced hydraulic systems in trench shoring, which offer rapid installation and removal, precise control, and significantly enhanced safety for workers by reducing the need for manual entry into unsupported excavations. These systems are often integrated with smart sensors and telemetry that continuously monitor hydraulic pressure, ground movement, and structural stability in real-time, providing immediate data feedback to operators and ensuring optimal performance and proactive risk management. Furthermore, the development and increasing utilization of high-strength, lightweight materials, such as advanced steel alloys and innovative composite materials, are transforming the design and performance of piling sheets and trench boxes, allowing for greater load-bearing capacities while simultaneously reducing transportation costs, installation effort, and overall carbon footprint. These modern materials also offer improved durability, enhanced corrosion resistance, and extended operational lifespan, thereby increasing the reusability of equipment, which is crucial for sustainable construction practices and long-term cost efficiency.

Regional Highlights

- North America: This region represents a mature yet robust market, characterized by stringent safety regulations and a strong, ongoing focus on infrastructure maintenance, repair, and upgrade. The United States and Canada are leading markets, with significant government and private investments directed towards renewing aging infrastructure such as bridges, highways, public transportation networks, and utility systems. Demand is also consistently driven by commercial and residential construction, particularly in expanding urban centers, which necessitates deep excavations and stable foundations for high-rise buildings and complex structures. The paramount emphasis on worker safety, reinforced by regulations from OSHA (Occupational Safety and Health Administration), drives the widespread adoption of advanced hydraulic shoring systems and well-engineered piling solutions. The strong presence of major construction and rental equipment companies, coupled with continuous technological innovation in materials and digital integration (e.g., BIM, IoT), further contributes to the region's steady growth. The market here benefits from a high degree of automation, a skilled workforce, and advanced engineering capabilities, enabling the deployment of sophisticated ground engineering techniques. Furthermore, there's a growing trend towards rental services, providing exceptional flexibility and cost-efficiency for contractors of all sizes, making access to cutting-edge equipment more feasible.

- Europe: Europe is another well-established market, prominently defined by a strong regulatory environment focused on both environmental protection and occupational safety, often leading to the adoption of the highest global standards. Countries like Germany, the UK, France, Scandinavia, and the Benelux nations are at the forefront of adopting innovative and sustainable ground support solutions. The market is significantly propelled by ongoing investments in high-speed rail networks, extensive urban regeneration projects, the development of critical renewable energy infrastructure (e.g., vast offshore wind farms requiring specialized marine piling), and comprehensive flood defense systems. There is a pronounced emphasis on engineered solutions that minimize environmental impact, such as low-noise and low-vibration piling methods suitable for densely populated areas. Extensive research and development in lightweight, high-strength materials, advanced monitoring systems, and modular shoring solutions are key drivers of innovation. The rental market is highly developed and sophisticated, offering a wide array of specialized equipment and comprehensive services, including technical consultation and logistical support. The region also benefits from a long-standing engineering tradition, a focus on precision in construction, and a strong commitment to quality, leading to the deployment of highly reliable and efficient shoring and piling systems.

- Asia Pacific (APAC): The APAC region stands as the dominant and fastest-growing market globally, driven by unprecedented rates of urbanization, rapid industrialization, and massive government-led infrastructure development projects. Countries such as China, India, and rapidly developing Southeast Asian nations like Indonesia, Vietnam, and the Philippines are experiencing exponential economic growth, fueling immense demand for new residential buildings, expansive commercial complexes, modern transportation networks (roads, railways, metro systems), and critical industrial facilities. The sheer scale and complexity of construction activity, coupled with diverse and often challenging geological conditions (e.g., seismic zones, soft soils), creates immense demand for robust piling sheets, sophisticated anchoring equipment, and versatile trench shoring systems. While initial cost-effectiveness remains a key factor in procurement decisions, there is an increasing shift towards higher quality, safer, and technologically advanced solutions, heavily influenced by international standards, growing environmental awareness, and local regulatory improvements. Foreign direct investment in infrastructure projects also plays a crucial role in enhancing the adoption of advanced technologies, best practices, and expertise from developed markets. The region offers significant opportunities for both established global players and agile local manufacturers to innovate, expand market share, and address specific regional demands, particularly in mega-cities and new economic zones.

- Latin America: This region presents an emerging market with substantial growth potential, primarily driven by increasing investments in critical infrastructure upgrades, accelerating urban development, and robust natural resource extraction projects. Countries like Brazil, Mexico, Chile, Colombia, and Peru are seeing increased construction activity across various sectors, although economic and political stability can sometimes influence project timelines and investment confidence. The demand for piling, anchoring, and shoring systems is closely tied to government spending on public works projects (e.g., roads, sanitation, energy infrastructure) and significant private sector investments in mining, oil and gas, and renewable energy sectors. There is a growing awareness of and adherence to international safety standards, leading to a gradual but definite shift from traditional, often less secure, construction methods to more engineered, robust, and certified ground support solutions. International collaborations, technology transfers, and the increasing presence of global construction firms are playing a significant role in introducing advanced equipment and modern engineering practices into the region. As economies stabilize, urbanization continues, and regulatory frameworks strengthen, the adoption of modern, efficient, and safe ground support systems is expected to accelerate significantly, opening new avenues for market expansion.

- Middle East and Africa (MEA): The MEA region is characterized by significant and ambitious infrastructure investments, particularly in the Middle East, driven by concerted economic diversification efforts away from oil and gas revenues, and the hosting of major international events (e.g., World Expos, FIFA World Cups). Countries like Saudi Arabia, UAE, and Qatar are undertaking colossal construction projects, including new smart cities (e.g., NEOM), commercial hubs, and expansive transportation networks, creating exceptionally high demand for advanced piling and shoring solutions. In Africa, while still nascent in terms of large-scale modern infrastructure compared to other regions, rapid population growth, accelerating urbanization, and increasing foreign investment are driving increased spending on residential, commercial, and basic infrastructure projects across many nations. The market here often relies heavily on imported equipment, expertise, and established technologies from developed regions due to limited local manufacturing capabilities for specialized systems. Key challenges include varying regulatory environments, complexities in project financing, and the critical need for tailored solutions to address diverse geological conditions and extreme climates (e.g., desert environments, coastal areas). However, the long-term growth prospects remain strong as economies continue to develop and industrialize, with a growing focus on sustainable, resilient, and technologically advanced construction practices to support future growth and economic stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Piling Sheet, Anchoring Equipment and Trench Shoring System Market.- ArcelorMittal

- thyssenkrupp Infrastructure GmbH

- Nucor Corporation

- Giken Ltd.

- Mabey Hire Ltd.

- Doka GmbH

- PERI GmbH

- Groundforce Shorco

- Krings Trench Shoring

- MGF Ltd.

- SBH Tiefbautechnik GmbH

- Trelleborg AB

- SSAB AB

- Pile Master (L.B. Foster Company)

- PVE (Piling & Vibro Equipment)

- CEMEX S.A.B. de C.V.

- Atlas Copco (Dynapac)

- Bauer AG

- Keller Group plc

- Franki Foundations

- Aarsleff Piling

- Contech Engineered Solutions LLC

- EUROFOR Group

- Ischebeck TITAN

- Williams Form Engineering Corp.

Frequently Asked Questions

What are the primary benefits of using advanced trench shoring systems?

Advanced trench shoring systems primarily offer enhanced worker safety by preventing dangerous trench collapses, improved operational efficiency through rapid deployment and removal processes, and significant cost savings by reducing the risk of accidents, project delays, and potential legal liabilities. They also ensure structural stability for adjacent properties and infrastructure, and enable efficient work in challenging ground conditions. Modern systems often incorporate lightweight materials and hydraulic mechanisms, making them exceptionally versatile and adaptable to various excavation sizes, depths, and soil types, thereby streamlining construction processes and ensuring adherence to stringent safety regulations and project timelines.

How do environmental regulations influence the Piling Sheet, Anchoring Equipment, and Trench Shoring System Market?

Environmental regulations significantly influence the market by driving demand for more sustainable and eco-friendly ground support solutions. This includes promoting the extensive use of recyclable materials like steel, encouraging the adoption of low-noise and low-vibration piling methods to minimize disturbance to surrounding urban or sensitive areas, and mandating proper waste management and recycling practices on construction sites. Regulations also push for continuous innovations in design and installation techniques that minimize soil disturbance, protect groundwater quality, and reduce the overall carbon footprint of projects. Compliance with these increasingly strict regulations often requires additional investment in technology and advanced methods, but it simultaneously creates significant market opportunities for companies offering green solutions and contributes to long-term market growth by promoting responsible and sustainable construction practices globally.

What is the role of technology, such as BIM and IoT, in modern ground support projects?

Technology like BIM (Building Information Modeling) and IoT (Internet of Things) plays a transformative role in modern ground support projects. BIM enables precise 3D modeling and comprehensive simulation of piling and shoring designs, optimizing material use, identifying potential clashes with existing infrastructure, and significantly improving overall project planning and collaborative efforts. IoT sensors provide real-time data on ground movement, shoring loads, anchor performance, and environmental conditions, allowing for continuous monitoring, predictive maintenance, and immediate risk mitigation strategies. These technologies collectively enhance safety, operational efficiency, and cost-effectiveness by providing data-driven insights and enabling proactive, informed decision-making throughout the entire project lifecycle, leading to more robust, reliable, and intelligently managed ground engineering solutions.

Why is the rental market for shoring and piling equipment experiencing significant growth?

The rental market for shoring and piling equipment is experiencing significant growth primarily due to the exceptional financial flexibility and operational benefits it offers to construction companies. Renting allows contractors to avoid large upfront capital expenditures, effectively manage project-specific demands without long-term asset commitments, and gain access to a wider range of specialized and continually updated equipment without the burden of ownership. It also transfers the responsibilities of maintenance, storage, transportation, and depreciation to the rental provider. This model is particularly appealing for smaller firms or those undertaking projects with fluctuating equipment needs, contributing to improved cash flow, enhanced operational agility, and ensuring access to the latest and safest ground support technologies without heavy investment.

What are the key factors driving demand for piling sheets in infrastructure development?

Key factors driving demand for piling sheets in infrastructure development include rapid global urbanization and substantial population growth, which necessitate new and expanded foundations for high-rise buildings, bridges, tunnels, and extensive underground structures. Increased government and private sector spending on large-scale infrastructure projects like new roads, railways, marine facilities, and flood defenses requires robust and durable ground stabilization. Additionally, stringent geotechnical requirements for complex ground conditions, such as soft soils, high water tables, or seismic activity, mandate the use of effective piling solutions to ensure structural integrity and long-term stability of critical assets. The inherent durability, reusability, and ability of piling sheets to form strong, impermeable retaining walls make them indispensable for these critical applications, directly supporting the longevity, safety, and resilience of modern infrastructure worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager