Pintle Hook Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440214 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Pintle Hook Market Size

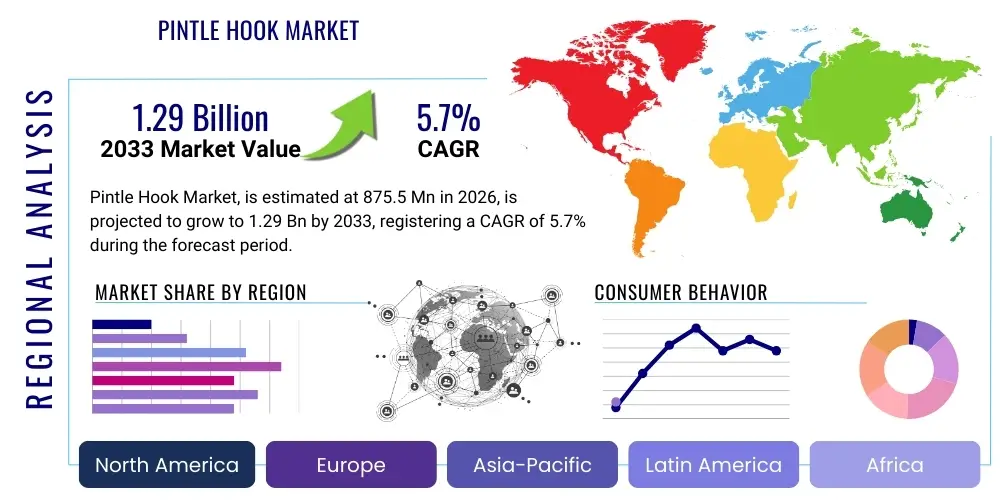

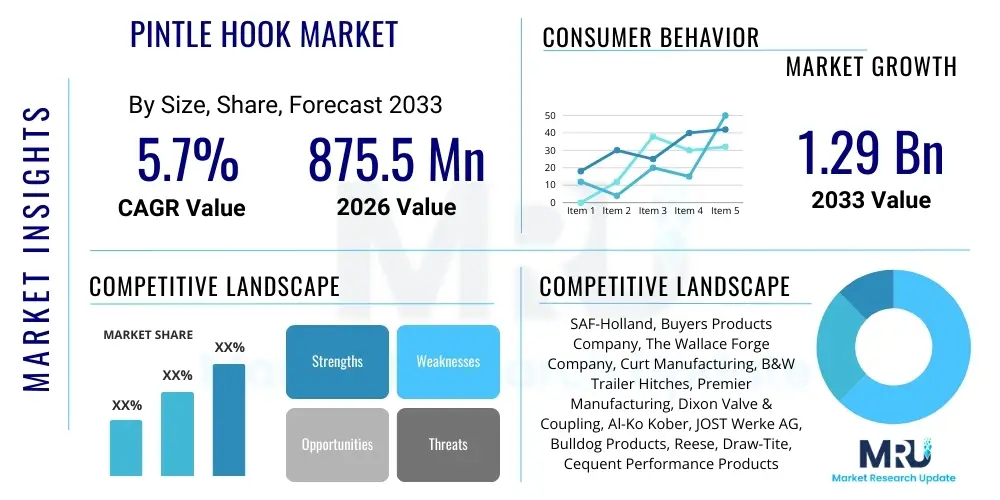

The Pintle Hook Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2026 and 2033. The market is estimated at USD 875.5 Million in 2026 and is projected to reach USD 1.29 Billion by the end of the forecast period in 2033.

Pintle Hook Market introduction

The Pintle Hook Market encompasses the global trade and utilization of heavy-duty coupling devices primarily designed for securely connecting trailers, typically those carrying substantial loads, to towing vehicles. These robust mechanical linkages are critical components in a wide array of heavy-duty applications, ensuring safe and reliable transport across challenging terrains and demanding operational environments. The product's fundamental design emphasizes strength, durability, and a secure connection mechanism, enabling the towing of equipment such as construction trailers, agricultural implements, military vehicles, and various types of industrial and commercial trailers.

Major applications for pintle hooks span sectors including construction, agriculture, defense, mining, logistics, and heavy haulage. In construction, they facilitate the movement of excavators, bulldozers, and material hauling trailers, while in agriculture, they are vital for connecting large planters, harvesters, and irrigation equipment. The primary benefit of pintle hooks lies in their exceptional towing capacity and their ability to operate effectively over uneven terrain, offering a more robust and forgiving connection compared to standard ball hitches, particularly under dynamic load conditions. This inherent ruggedness minimizes wear and tear on the towing mechanism and provides enhanced stability for heavy loads.

Driving factors for the pintle hook market include ongoing global infrastructure development projects, which necessitate the extensive use of heavy machinery and associated transport trailers. The expansion of the logistics and transportation sector, fueled by increasing e-commerce and global trade, also contributes significantly to demand. Furthermore, modernization efforts in military and agricultural sectors, coupled with a steady demand for heavy equipment in mining and industrial applications, continually underscore the importance and growth of the pintle hook market. Their proven reliability and compliance with stringent safety standards for heavy towing operations make them an indispensable component in these critical industries, ensuring the efficient and secure movement of vital assets.

Pintle Hook Market Executive Summary

The executive summary highlights key business trends, regional dynamics, and segment performance shaping the Pintle Hook Market. Business trends indicate a robust demand driven by expanding global infrastructure and logistics sectors, prompting manufacturers to innovate in material science and design for enhanced durability and capacity. Strategic collaborations and mergers among key players are observed as companies seek to consolidate market share and leverage technological advancements, particularly in integrating smart features for improved operational safety and efficiency.

Regional trends reveal strong growth in emerging economies, notably across Asia Pacific, Latin America, and the Middle East & Africa, propelled by rapid urbanization, industrialization, and significant government investments in transportation networks. North America and Europe, while mature markets, maintain substantial demand due to continuous fleet upgrades, stringent safety regulations necessitating high-quality components, and persistent activity in construction, agriculture, and defense sectors. These regions are also at the forefront of adopting advanced manufacturing processes and sustainable material sourcing.

In terms of segment trends, heavy-duty pintle hooks continue to dominate due to their indispensable role in large-scale industrial and commercial applications. The aftermarket segment is experiencing steady growth, driven by replacement cycles and the need for upgraded towing solutions for existing fleets. Innovation in material composition, focusing on lightweight yet high-strength alloys, is a notable trend across all segments, aiming to improve fuel efficiency and load-bearing capabilities. Furthermore, the rise of combination pintle/ball hitches addresses the versatility requirements of diverse end-users, catering to both heavy and lighter towing needs with a single integrated solution.

AI Impact Analysis on Pintle Hook Market

Common user questions regarding AI's impact on the Pintle Hook Market primarily revolve around automation in manufacturing, predictive maintenance for towing systems, and the potential for smart integration in future heavy-duty vehicles. Users are interested in how AI can streamline the production process, reduce costs, and improve the quality and consistency of pintle hooks. There is also significant curiosity about whether AI-driven analytics could forecast equipment failure, optimize maintenance schedules for towing components, and enhance overall operational safety and efficiency in heavy transport, thereby indirectly impacting the demand and specifications for pintle hooks. Concerns often include the initial investment costs of AI implementation and the need for specialized skills to manage such advanced systems within the traditional manufacturing and logistics environments.

Another area of user inquiry focuses on the integration of pintle hooks within broader smart towing systems. Questions arise about how AI might facilitate real-time load monitoring, optimize trailer coupling and uncoupling processes, or even contribute to autonomous heavy-duty vehicle operations where precise and reliable mechanical connections are paramount. While pintle hooks themselves are passive mechanical devices, the ecosystem in which they operate is increasingly digitalized. Therefore, users anticipate AI playing a role in the intelligent management of fleets, optimizing routes, and ensuring compliance with dynamic load regulations, all of which indirectly influence the performance expectations and operational contexts of pintle hooks. This foresight indicates a growing expectation for components to be part of a larger, interconnected smart transportation framework, even if they remain fundamentally mechanical.

- AI-driven predictive maintenance systems can monitor stress, wear, and usage patterns of towing components, including pintle hooks, to anticipate failures and optimize replacement cycles, enhancing safety and extending equipment lifespan.

- Manufacturing processes for pintle hooks can leverage AI for quality control, robotic assembly, and material optimization, leading to higher precision, reduced waste, and increased production efficiency.

- AI in logistics and fleet management can optimize routes and load distribution, reducing stress on towing equipment and influencing demand for specific capacities or designs of pintle hooks based on operational analytics.

- Smart towing systems, potentially enabled by AI, may integrate sensors with pintle hooks to provide real-time feedback on connection status, load stability, and coupling integrity, improving driver awareness and operational safety.

- Demand forecasting for pintle hooks in the aftermarket and OEM segments can be significantly improved by AI algorithms analyzing market trends, economic indicators, and vehicle production data, leading to more efficient inventory management.

DRO & Impact Forces Of Pintle Hook Market

The Pintle Hook Market is significantly influenced by a confluence of drivers, restraints, and opportunities, each contributing to its dynamic landscape. Key drivers include robust growth in global infrastructure development, particularly in emerging economies, which necessitates extensive heavy equipment transport. The expansion of the logistics and transportation industry, fueled by e-commerce proliferation and growing international trade volumes, creates a continuous demand for reliable heavy-duty towing solutions. Furthermore, modernization initiatives in agriculture and military sectors, coupled with sustained activities in mining and construction, solidify the market's foundation. These factors collectively push for higher capacity, more durable, and increasingly safe pintle hook designs, driving innovation in material science and engineering. The inherent reliability of pintle hooks over varied terrain and under extreme load conditions remains a critical advantage, reinforcing their adoption across diverse heavy-duty applications.

However, the market also faces considerable restraints. Economic slowdowns and geopolitical instabilities can directly impact construction, manufacturing, and transportation sectors, leading to reduced capital expenditures on new vehicles and towing equipment. Stringent safety regulations and evolving certification standards, while beneficial for overall product quality, can increase manufacturing costs and complexity, posing challenges for smaller manufacturers. Competition from alternative coupling solutions, such as fifth wheels for specific heavy haulage and ball hitches for lighter applications, can limit market penetration in certain segments. Additionally, fluctuations in raw material prices, particularly for steel and alloy metals, directly influence production costs and profit margins, creating pressure on manufacturers to manage supply chains efficiently without compromising product quality or pricing competitiveness. These restraints necessitate continuous adaptation and strategic planning from market players to maintain growth trajectories.

Opportunities within the Pintle Hook Market are primarily driven by technological advancements and evolving industry needs. The shift towards electric heavy-duty vehicles presents an opportunity for developing pintle hooks optimized for these new platforms, potentially incorporating smart sensing capabilities for enhanced vehicle integration and safety. Innovation in lightweight, high-strength materials offers avenues for improving fuel efficiency and increasing payload capacity without compromising durability. The growing demand for customized towing solutions for specialized applications, alongside the robust expansion of the aftermarket for replacement and upgrade components, provides significant growth potential. Furthermore, advancements in manufacturing processes, such as additive manufacturing and automated quality control, can lead to more efficient production and superior product performance, opening new markets and enhancing competitive advantages. The ongoing focus on safety and compliance also creates opportunities for manufacturers who can offer products that exceed regulatory requirements and provide superior operational reliability.

Segmentation Analysis

The Pintle Hook Market is comprehensively segmented based on various attributes, including type, capacity, material, application, and end-use. This segmentation allows for a detailed analysis of market dynamics, identifying specific growth drivers and challenges within each category. The differing requirements across industries and applications necessitate a diverse range of pintle hook designs and specifications, from lighter-duty options for utility trailers to super heavy-duty systems capable of managing immense loads in extreme industrial environments. Understanding these segments is crucial for manufacturers to tailor their product offerings, optimize marketing strategies, and allocate resources effectively, addressing the distinct needs of each market niche. The continuous evolution of towing technology and industry standards also influences how these segments develop, pushing for innovations in design, materials, and safety features.

- By Type

- Rigid Pintle Hooks

- Swivel Pintle Hooks

- Combination Pintle/Ball Hitches

- By Capacity

- Light-Duty (Up to 10,000 lbs)

- Medium-Duty (10,001 to 25,000 lbs)

- Heavy-Duty (25,001 to 60,000 lbs)

- Super Heavy-Duty (Above 60,000 lbs)

- By Material

- Forged Steel

- Cast Iron

- Alloy Steel

- Other Advanced Materials

- By Application

- Construction

- Agriculture

- Military & Defense

- Mining

- Logistics & Transportation

- Industrial & Manufacturing

- By End-Use

- Original Equipment Manufacturers (OEMs)

- Aftermarket

Value Chain Analysis For Pintle Hook Market

The value chain for the Pintle Hook Market begins with extensive upstream analysis, focusing on the sourcing and procurement of raw materials. This stage is critical as the performance and durability of pintle hooks are heavily reliant on the quality of inputs, primarily high-grade steel, various alloy metals, and specialized components like springs and bolts. Suppliers of these raw materials, including major steel mills and specialized component manufacturers, form the foundational layer, dictating initial costs and influencing the overall quality of the final product. Relationships with these upstream suppliers are often long-term, built on trust and consistent quality control, as any compromise at this stage can have significant implications for the safety and reliability of the pintle hook. Material innovation, such as the development of lighter, stronger, and more corrosion-resistant alloys, also originates in this upstream segment, driving product improvements throughout the chain.

The midstream segment involves the core manufacturing processes, encompassing design, forging or casting, machining, heat treatment, assembly, and rigorous quality assurance. Manufacturers employ advanced engineering techniques, including CAD/CAM and finite element analysis (FEA), to optimize designs for specific load capacities and application environments. Precision forging and casting operations ensure the structural integrity of the hook body, followed by meticulous machining to achieve tight tolerances for pin and latch mechanisms. Heat treatment processes enhance material hardness and fatigue resistance, crucial for the extreme conditions pintle hooks endure. Assembly involves integrating various components, and comprehensive quality control checks, including stress testing and dimensional verification, are performed to ensure compliance with industry standards and safety regulations. These manufacturing processes are highly capital-intensive and require specialized expertise to produce durable and reliable towing components.

Downstream analysis focuses on the distribution channels through which pintle hooks reach end-users. These channels can be broadly categorized into direct and indirect methods. Direct channels typically involve Original Equipment Manufacturers (OEMs) selling directly to heavy vehicle manufacturers, trailer producers, or defense contractors who integrate the pintle hooks into their complete assemblies. This often involves large volume contracts and customized specifications. Indirect channels, on the other hand, leverage a network of distributors, wholesalers, and retailers to serve the aftermarket segment and smaller OEM clients. This includes specialized automotive parts distributors, heavy equipment dealers, industrial supply stores, and increasingly, online e-commerce platforms. These indirect channels provide broader market reach, inventory management, and technical support to a diverse customer base, from fleet operators needing replacement parts to individual users seeking specific towing solutions. The effectiveness of these distribution networks is vital for market penetration and customer satisfaction, ensuring product availability and timely delivery across various geographical regions.

Pintle Hook Market Potential Customers

The Pintle Hook Market primarily serves a broad spectrum of end-users and buyers who require robust and reliable towing solutions for heavy and specialized loads. These customers operate in industries where the safe and efficient transport of equipment, materials, and machinery is paramount for their core operations. The demand for pintle hooks is intrinsically linked to capital expenditures in these sectors, driven by factors such as infrastructure development, industrial expansion, and ongoing fleet maintenance and upgrades. Understanding the specific needs and procurement cycles of these potential customers is essential for manufacturers and distributors to effectively tailor product offerings, develop targeted marketing strategies, and build lasting customer relationships.

Key potential customers include Original Equipment Manufacturers (OEMs) that integrate pintle hooks into their heavy-duty vehicles and trailers. This encompasses manufacturers of heavy trucks, semi-trailers, construction equipment (e.g., dump trucks, specialized transport trailers), agricultural machinery (tractors, harvesting equipment), and military vehicles. These OEMs demand high-quality, high-capacity, and often customized pintle hooks that meet specific design, performance, and regulatory standards for their integrated systems. Their procurement decisions are influenced by long-term supply agreements, product reliability, competitive pricing, and technical support. The aftermarket segment constitutes another significant customer base, comprising fleet operators, logistics companies, mining corporations, construction firms, government agencies, and individual heavy truck owners who require pintle hooks for replacement, repair, or upgrade purposes for their existing vehicle fleets. These customers prioritize durability, ease of installation, availability, and cost-effectiveness, seeking solutions that minimize downtime and enhance operational efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 875.5 Million |

| Market Forecast in 2033 | USD 1.29 Billion |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SAF-Holland, Buyers Products Company, The Wallace Forge Company, Curt Manufacturing, B&W Trailer Hitches, Premier Manufacturing, Dixon Valve & Coupling, Al-Ko Kober, JOST Werke AG, Bulldog Products, Reese, Draw-Tite, Cequent Performance Products, Fulton, Fastway Trailer Products, Weigh Safe, Pro Series, MAX-Bilt, Gen-Y Hitch |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pintle Hook Market Key Technology Landscape

The key technology landscape for the Pintle Hook Market is characterized by continuous advancements aimed at enhancing durability, safety, and performance under extreme conditions. Material science plays a pivotal role, with ongoing research and development in high-strength alloy steels, specialized cast irons, and advanced forging techniques. These innovations focus on improving tensile strength, fatigue resistance, and corrosion properties, crucial for extending the lifespan of pintle hooks and ensuring their reliability in harsh operating environments. Furthermore, manufacturers are exploring lightweight composite materials where appropriate, to reduce overall vehicle weight and improve fuel efficiency, without compromising the structural integrity required for heavy towing applications. Surface treatment technologies, such as specialized coatings and heat treatments, are also continuously refined to provide enhanced wear resistance and protection against environmental degradation, contributing significantly to product longevity and reducing maintenance frequency for end-users.

Precision manufacturing techniques form another critical aspect of the technological landscape. Computer Numerical Control (CNC) machining allows for highly accurate production of complex components, ensuring tight tolerances and optimal fitment for the pintle hook's various parts, including the pin, latch, and body. Robotic welding and automation in assembly lines enhance consistency, efficiency, and safety in the manufacturing process, reducing human error and increasing throughput. These advanced manufacturing methods enable the production of pintle hooks that not only meet but often exceed stringent industry standards and regulatory requirements for heavy-duty towing. The application of Finite Element Analysis (FEA) and other simulation software during the design phase allows engineers to virtually test prototypes under various load conditions, identifying potential stress points and optimizing designs before physical production, thereby accelerating product development cycles and minimizing costly reworks.

While pintle hooks are primarily mechanical, the integration of smart technologies is emerging as an important trend within the broader towing ecosystem. Sensor technology, though not directly integrated into the hook itself in all cases, is increasingly being incorporated into towing systems to monitor real-time load conditions, hitch connection status, and trailer stability. These sensors can provide critical data to the towing vehicle's onboard computer systems, offering insights into operational performance and potential safety issues. The development of advanced testing methodologies, including non-destructive testing (NDT) techniques like ultrasonic inspection and magnetic particle inspection, ensures the integrity of finished products without compromising their structure. Furthermore, adherence to and innovation in international safety standards and certifications, such as SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization) guidelines, underscores a commitment to quality and technological leadership, pushing manufacturers to continuously improve their product designs and manufacturing processes to meet global benchmarks for performance and reliability in heavy-duty towing.

Regional Highlights

- North America: This region represents a mature and significant market for pintle hooks, driven by robust activity in the construction, agriculture, and logistics sectors. The presence of major heavy truck and trailer manufacturers, coupled with substantial military and defense spending, ensures sustained demand. Stringent safety regulations and a strong aftermarket culture further bolster market growth.

- Europe: Characterized by advanced manufacturing capabilities and strict regulatory frameworks, Europe shows steady demand for high-quality pintle hooks. Growth is influenced by infrastructure modernization, a developed logistics network, and substantial agricultural operations. Emphasis on environmental standards and vehicle safety drives innovation in material science and design.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to rapid industrialization, urbanization, and massive infrastructure development projects, particularly in countries like China, India, and Southeast Asian nations. Expanding logistics networks, booming construction, and increasing mechanization in agriculture fuel substantial demand for heavy-duty towing equipment.

- Latin America: This region exhibits growing demand driven by increasing investments in mining, agriculture, and public infrastructure projects. Economic growth in key countries like Brazil and Mexico contributes to the expansion of heavy transportation fleets and the need for reliable pintle hook solutions for resource extraction and agricultural development.

- Middle East and Africa (MEA): The MEA market is experiencing growth largely due to significant investments in oil & gas infrastructure, construction projects (especially in the GCC countries), and ongoing urbanization initiatives. Military and defense sectors also contribute to demand for robust towing equipment, though market size can be influenced by geopolitical stability and commodity prices.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pintle Hook Market.- SAF-Holland

- Buyers Products Company

- The Wallace Forge Company

- Curt Manufacturing

- B&W Trailer Hitches

- Premier Manufacturing

- Dixon Valve & Coupling

- Al-Ko Kober SE

- JOST Werke AG

- Bulldog Products

- Reese

- Draw-Tite

- Cequent Performance Products

- Fulton

- Fastway Trailer Products

- Weigh Safe

- Pro Series

- MAX-Bilt

- Gen-Y Hitch

- Holland Hitch (part of SAF-Holland)

Frequently Asked Questions

What is a pintle hook and what are its primary uses?

A pintle hook is a heavy-duty mechanical coupling device used to connect a trailer or towed implement to a towing vehicle. Its primary uses are in applications requiring robust connections for heavy loads over rough terrain, commonly found in construction, agriculture, military, mining, and commercial logistics to tow equipment like excavators, large agricultural machinery, and freight trailers.

How do I choose the right pintle hook for my towing needs?

Choosing the right pintle hook involves considering the Gross Trailer Weight (GTW) and Tongue Weight (TW) of your load, ensuring the hook's capacity exceeds these values. You should also consider the application type, terrain, and regulatory requirements. Factors like rigid vs. swivel type, material (forged steel, cast iron), and ease of installation are also critical for optimal performance and safety.

What are the key differences between a pintle hook and a ball hitch?

The key differences lie in design and application. A pintle hook uses a simple loop (lunette ring) and a pintle hook with a latch, offering greater articulation and robustness for off-road or heavy-duty industrial towing. A ball hitch uses a ball-shaped coupling and a socket-style coupler, typically suited for lighter loads and on-road applications, offering smoother towing but with less inherent strength and articulation.

What safety considerations are crucial when using pintle hooks?

Crucial safety considerations include ensuring the pintle hook's capacity matches or exceeds the trailer's weight, proper inspection for wear or damage before each use, correct coupling of the lunette ring and secure latching. Always use safety chains or cables as a secondary connection, adhere to manufacturer guidelines for installation and maintenance, and ensure the towing vehicle is appropriately rated for the combined load.

How do technological advancements impact the pintle hook market?

Technological advancements impact the pintle hook market through the development of high-strength, lightweight materials, advanced manufacturing processes for improved durability and precision, and integrated sensor technologies within broader towing systems for enhanced safety and monitoring. These innovations aim to extend product lifespan, increase towing efficiency, and ensure compliance with evolving industry standards, even for these fundamentally mechanical components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager