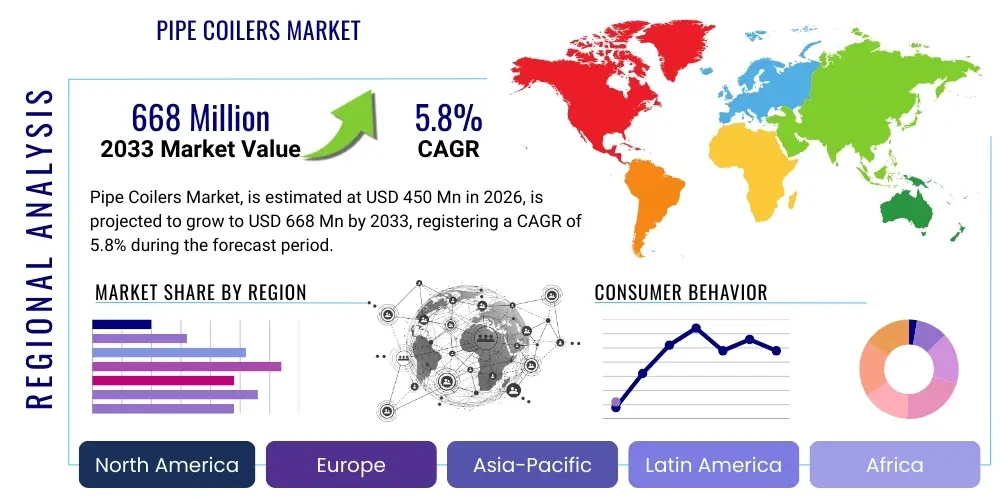

Pipe Coilers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437695 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Pipe Coilers Market Size

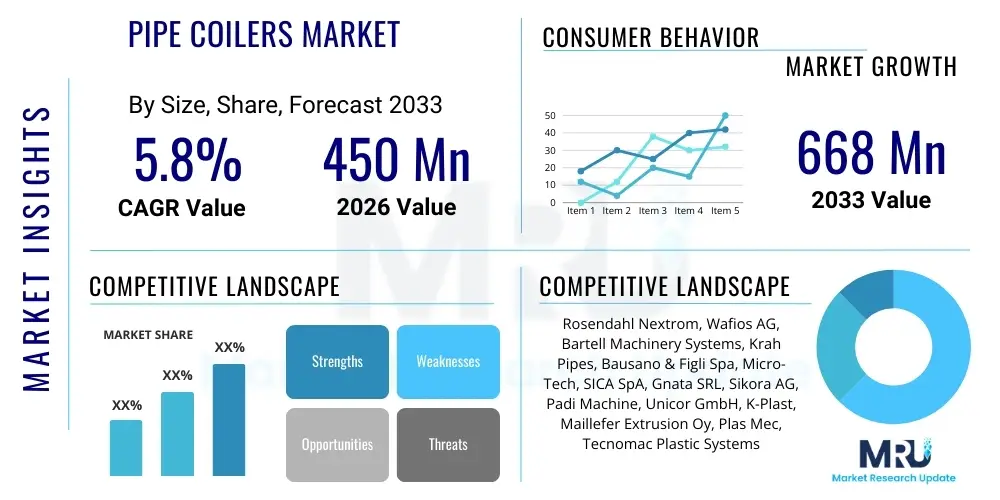

The Pipe Coilers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $450 Million USD in 2026 and is projected to reach $668 Million USD by the end of the forecast period in 2033.

Pipe Coilers Market introduction

The Pipe Coilers Market encompasses the manufacturing, sales, and service of specialized industrial machinery designed to wind continuous lengths of extruded pipes, primarily those made from plastics like HDPE, PVC, and PP, onto spools or coils for efficient storage, transport, and deployment. These coiling systems are indispensable components in modern extrusion lines, ensuring that finished products, often used in infrastructure, plumbing, irrigation, and telecommunications conduits, are handled without damage and conform to standardized packaging requirements. The growing global investment in smart city infrastructure and the replacement of aging metallic piping systems with corrosion-resistant plastic alternatives are key factors driving the widespread adoption of advanced pipe coiling equipment across various geographical regions.

Pipe coiling systems offer significant operational benefits, including increased production throughput due to high winding speeds, reduced manual handling which minimizes labor costs, and improved product integrity by preventing kinking or deformation during packaging. They are primarily utilized in major applications such as water distribution networks, gas pipeline installations, cable protection conduit manufacturing, and agricultural drip irrigation systems. The core benefit derived from modern coilers is their ability to handle large diameter and long length pipes automatically, ensuring efficiency and consistency that manual methods cannot achieve, thereby contributing directly to the profitability of pipe manufacturers globally.

Driving factors propelling this market include stringent global standards mandating continuous pipe lengths for large infrastructure projects, coupled with the rising demand for medium to high-density polyethylene (HDPE) pipes in the utility sector due to their longevity and flexibility. Furthermore, technological advancements introducing servo-driven systems, automatic cutting features, and integrated tension control mechanisms are enhancing the precision and versatility of these machines, making them essential capital expenditures for leading pipe extrusion companies aiming for operational excellence and maximizing output capacity.

Pipe Coilers Market Executive Summary

The Pipe Coilers Market demonstrates robust growth driven by significant global investments in infrastructure, particularly water and sanitation projects and the rollout of high-speed fiber optic networks which require extensive lengths of protective plastic conduit. Business trends indicate a strong shift towards highly automated, dual-coiling systems capable of non-stop operation, minimizing downtime and catering to the increasing demand for larger coil diameters and heavier weights while maintaining precise winding quality. Manufacturers are focusing on modular designs that allow for easy integration into existing extrusion lines and offer enhanced flexibility regarding pipe material and size changeovers, positioning efficiency and adaptability as critical competitive differentiators in the market landscape.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid urbanization, massive government infrastructure spending in China and India, and the widespread adoption of modern irrigation techniques in agricultural economies. North America and Europe maintain a mature but steady market, characterized by demand for sophisticated, energy-efficient, and Industry 4.0 compatible coiling solutions that emphasize data integration and predictive maintenance capabilities. Segment trends highlight the dominance of automatic coilers over semi-automatic and manual versions, reflecting the industry's pervasive focus on maximizing output and ensuring repeatability across high-volume production environments.

Within the segmentation based on material, the HDPE pipe coiler segment accounts for the largest market share due to the ubiquitous use of HDPE pipes in municipal and industrial applications requiring superior chemical resistance and flexibility. Future market expansion will largely be shaped by the convergence of IoT technologies with machinery operation, enabling remote monitoring and optimization of coiling parameters, alongside the rising importance of sustainable manufacturing practices, influencing machine design towards lower energy consumption and waste reduction.

AI Impact Analysis on Pipe Coilers Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Pipe Coilers Market predominantly center on how AI can enhance operational efficiency, minimize material waste, and improve predictive maintenance capabilities. Users frequently ask about the implementation of machine learning algorithms for optimizing winding tension parameters based on real-time pipe characteristics (such as temperature and plasticity), and how AI-driven vision systems can detect subtle pipe defects during the coiling process. The collective expectation is that AI will move the market beyond simple automation towards intelligent, self-optimizing manufacturing environments, significantly reducing manual intervention and boosting overall equipment effectiveness (OEE).

The core concerns revolve around the cost and complexity of integrating sophisticated AI software into legacy coiling machinery and the need for specialized training for operators and maintenance personnel. Users are keen to understand the Return on Investment (ROI) associated with AI-enabled predictive maintenance, specifically its ability to anticipate potential component failure (e.g., motor wear, bearing stress) before catastrophic breakdown occurs, thus maximizing uptime. Furthermore, there is interest in using AI for supply chain integration, optimizing spool inventory levels based on real-time production rates and forthcoming customer orders, driving leaner manufacturing processes across the sector.

AI's influence is thus projected to revolutionize quality control and process optimization within the pipe coiling domain. By analyzing massive datasets collected from sensors on extrusion lines (speed, temperature, pressure) and the coiler itself (tension, winding pattern, cutting frequency), AI systems can dynamically adjust machine settings to maintain consistent product quality even under variable production conditions. This level of granular control is crucial for high-value applications, ensuring compliance with strict industry standards and significantly reducing the frequency of scrap material generation.

- AI-driven Predictive Maintenance: Reduces unplanned downtime by forecasting equipment failures.

- Optimal Tension Control: Machine learning models adjust winding tension instantly based on material plasticity.

- Enhanced Quality Inspection: AI vision systems detect surface defects or anomalies during the coiling cycle.

- Process Parameter Optimization: Algorithms fine-tune speed and cut length for maximum material yield.

- Supply Chain Optimization: AI integrates production output with raw material and spool inventory management.

DRO & Impact Forces Of Pipe Coilers Market

The market for pipe coiling machinery is significantly propelled by infrastructural drivers, constrained by high capital expenditure requirements, yet holds substantial potential through technological innovations and expansion into nascent geographies. Key drivers include accelerating global urbanization leading to massive investments in utility infrastructure, particularly the rapid deployment of plastic piping for water, sewage, and telecommunications conduits, which necessitates efficient continuous coiling solutions. Conversely, a primary restraint is the substantial initial investment required for sophisticated, fully automatic coiling systems, posing a barrier to entry for smaller manufacturers or those operating in developing economies with limited access to capital. The necessity for highly specialized technical support and maintenance personnel also acts as a constraint, particularly in regions where skilled labor is scarce.

Opportunities are predominantly emerging from the transition towards smart manufacturing, specifically the integration of Industry 4.0 principles, including IIoT and advanced robotics, into the coiling process to achieve unmanned operation and real-time remote diagnostics. Furthermore, the increasing global focus on sustainable materials and green construction methods presents an opportunity for manufacturers to develop coilers optimized for innovative bioplastics or recycled polymer pipes. The impact forces are currently skewed towards high demand due to infrastructure requirements, exerting upward pressure on the market. However, global economic volatility and fluctuations in commodity prices, particularly plastic resins, present a moderating impact force on investment cycles for new machinery purchases.

The interaction of these forces suggests a market trajectory favoring advanced, versatile coiling systems. While cost remains a concern, the long-term benefits derived from automation—such as reduced labor dependency and enhanced product quality—override these restraints for major industry players. Successful market penetration will depend on vendors offering flexible financing models and comprehensive service agreements that mitigate the risks associated with high upfront capital expenditures, effectively converting the opportunity for automation into realized growth.

Segmentation Analysis

The Pipe Coilers Market is critically segmented based on operational mode, material compatibility, industry application, and coil capacity, allowing for tailored solutions addressing diverse end-user requirements across the global pipe manufacturing ecosystem. Segmentation provides crucial insights into the technological preferences and investment trends adopted by pipe producers, differentiating between high-volume producers who prioritize fully automatic dual coilers and niche manufacturers who might still utilize semi-automatic or manual systems for specialized pipe materials or smaller batch sizes. The comprehensive segmentation strategy assists market participants in designing targeted marketing strategies and R&D efforts focusing on high-growth areas, such as the increasing demand for large-capacity HDPE coilers required for major municipal projects.

Analyzing the market by operational mode reveals the dominant trend toward automation, driven by the need for speed and repeatable precision in competitive markets. Within the end-use industry segment, the water management and telecommunications sectors are showing accelerated adoption rates, specifically demanding specialized coiling equipment suitable for micro-ducts and large-diameter pressure pipes, respectively. Material compatibility remains a fundamental segmentation criterion, dictating machine specifications such as tension control mechanisms and winding geometry, ensuring that the integrity of delicate materials like flexible PVC or high-stress materials like reinforced HDPE is maintained throughout the coiling cycle.

- By Operational Mode:

- Automatic Pipe Coilers

- Semi-Automatic Pipe Coilers

- Manual Pipe Coilers

- By Pipe Material:

- HDPE Coilers

- PVC Coilers

- PP Coilers

- Other Polymer Coilers

- By Capacity (Coil Diameter/Weight):

- Low Capacity (Up to 100 kg)

- Medium Capacity (100 kg to 500 kg)

- High Capacity (Above 500 kg)

- By End-Use Industry:

- Construction and Infrastructure (Water, Sewage)

- Oil and Gas (Non-pressure conduits, protection)

- Telecommunications and Data (Fiber optic ducts)

- Agriculture (Irrigation and Drainage)

Value Chain Analysis For Pipe Coilers Market

The Value Chain for the Pipe Coilers Market begins with upstream activities focused on the sourcing of critical raw materials and specialized components, predominantly precision-engineered steel, high-performance electronics (PLCs, servo motors, sensors), and robust hydraulic or pneumatic systems. Key upstream suppliers include steel manufacturers, specialized electrical component vendors, and software developers who provide the control systems and human-machine interface (HMI) essential for modern coiling operations. The quality and reliability of these upstream inputs directly influence the final machine performance, lifecycle, and technological sophistication, making strategic supplier relationships vital for machine builders to manage costs and ensure high-quality output.

Midstream activities involve the core manufacturing, assembly, and rigorous testing of the pipe coiling machinery. This stage is dominated by specialized equipment manufacturers who design and assemble the complex winding mechanisms, cutting systems, and automatic strapping devices. Differentiation at this stage relies heavily on engineering expertise, intellectual property regarding patented winding technologies, and adherence to stringent safety and quality standards (e.g., CE, ISO). The integration of automation technologies, such as robotic arms for handling finished coils and sophisticated tension feedback systems, adds significant value during the manufacturing process.

Downstream analysis focuses on the distribution channels, installation, post-sales support, and direct end-user engagement. Distribution primarily occurs through direct sales channels, where coiler manufacturers establish direct relationships with large pipe extrusion companies to offer customized solutions, training, and maintenance contracts. Indirect distribution channels, utilizing local agents or specialized industrial machinery distributors, are often employed in emerging or geographically challenging markets to provide localized sales support and quicker response times. The final stage involves the end-user, the pipe manufacturer, who utilizes the coiler to produce marketable goods, emphasizing that effective after-sales service and spare parts availability are crucial factors influencing long-term customer loyalty and repeat purchases.

Pipe Coilers Market Potential Customers

The primary potential customers and end-users of pipe coiling equipment are large-scale plastic pipe manufacturers specializing in high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP) extrusion. These customers require continuous, high-speed machinery to handle the output of multi-layer or single-layer pipe extrusion lines, catering specifically to municipal water supply, agricultural irrigation, and industrial fluid transfer needs. Given the high capital expenditure involved, potential buyers are typically established corporations or large enterprises undergoing expansion, capacity upgrades, or technological modernization initiatives, often driven by new government infrastructure contracts or regulatory changes favoring flexible piping.

A significant segment of potential customers also includes telecommunication infrastructure providers and specialized manufacturers producing conduits for fiber optic cables and electrical wiring. These companies demand precision coilers capable of handling smaller diameter micro-ducts and ensuring extremely accurate meterage and uniform winding to protect sensitive internal components. The decision-making process for these buyers is heavily influenced by machine reliability, long-term maintenance costs, the coiler's ability to integrate seamlessly with existing extrusion software (SCADA systems), and the availability of localized technical service.

Furthermore, regional pipe manufacturers focusing on the replacement and rehabilitation of aging metallic infrastructure in developed markets represent continuous potential customers. These buyers are increasingly seeking sophisticated, energy-efficient coiling systems that minimize energy usage and enhance sustainability profiles. The agricultural sector, particularly in regions adopting modern drip and micro-irrigation techniques, also constitutes a growing customer base, demanding robust, medium-capacity coilers suitable for use with flexible irrigation tubes and lateral piping.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million USD |

| Market Forecast in 2033 | $668 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rosendahl Nextrom, Wafios AG, Bartell Machinery Systems, Krah Pipes, Bausano & Figli Spa, Micro-Tech, SICA SpA, Gnata SRL, Sikora AG, Padi Machine, Unicor GmbH, K-Plast, Maillefer Extrusion Oy, Plas Mec, Tecnomac Plastic Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pipe Coilers Market Key Technology Landscape

The technological landscape of the Pipe Coilers Market is rapidly evolving, driven primarily by the need for higher production speeds, increased operational safety, and enhanced flexibility to handle varied pipe types and sizes without extensive retooling. A core technological advancement is the widespread adoption of servo-driven coiling systems, which replace traditional hydraulic or mechanical drives. Servo systems offer unparalleled precision in winding tension and speed control, which is crucial for preventing pipe distortion, especially for thin-walled or high-pressure applications. This precision ensures uniform coil dimensions and optimized material usage, thereby increasing overall manufacturing efficiency and reducing the risk of product rejection.

Another significant development is the integration of sophisticated Human-Machine Interfaces (HMI) and Programmable Logic Controllers (PLC) that enable seamless communication and data exchange between the coiler and the preceding extrusion line components. Modern coilers feature complex software algorithms that automatically adjust coiling parameters—including traverse speed, oscillation, and cutting length—in real-time based on input from upstream sensors regarding pipe temperature and material flow rate. Furthermore, dual-head or non-stop coiling systems, which allow continuous production flow by switching the pipe stream from a full spool to an empty one without halting the extrusion process, are becoming standard for high-capacity installations, maximizing operational uptime.

Furthermore, the incorporation of Industrial Internet of Things (IIoT) sensors and cloud connectivity is transforming maintenance practices. Modern pipe coilers are equipped with sensors monitoring vibration, temperature, and current draw on critical components, transmitting this data for remote analysis. This enables advanced predictive maintenance strategies, where potential mechanical failures are anticipated and scheduled repairs are performed before production interruption occurs. The technological shift towards fully automated handling systems, including robotic palletizing and wrapping integrated directly after the coiler, further minimizes labor requirements and enhances end-of-line logistics efficiency.

Regional Highlights

- Asia Pacific (APAC) Dominance: APAC remains the most dynamic region in the Pipe Coilers Market, primarily due to colossal infrastructural investments across China, India, and Southeast Asian nations. Rapid urbanization necessitates extensive upgrades to water supply and sewage systems, driving immense demand for HDPE and PVC piping, thereby fueling the requirement for high-speed automatic coilers. Government initiatives focusing on national broadband rollouts further accelerate the demand for equipment capable of producing specialized telecommunication ducts. The competitive landscape in APAC is characterized by a mix of local manufacturers offering cost-effective solutions and global leaders providing high-end, fully automated systems, leading to intense technological competition and continuous capacity expansion among regional pipe producers. This region is expected to exhibit the highest CAGR during the forecast period due to the scale and pace of ongoing utility projects.

The economic growth of nations like India and Vietnam, accompanied by significant foreign direct investment into their manufacturing sectors, provides a robust foundation for the continued expansion of the pipe extrusion industry. This expansion naturally translates into heightened procurement of advanced coiling machinery. Furthermore, the agricultural sector's transition towards modern irrigation practices, particularly micro-irrigation in drought-prone areas, drives specific demand for smaller-capacity, robust coilers suitable for thin-walled polyethylene tubes. The strong regulatory environment supporting infrastructure development, coupled with favorable manufacturing policies, solidifies APAC's position as the global center for volume production of coiled plastic pipes.

Manufacturers in APAC prioritize machine flexibility and durability, often requiring coilers that can operate reliably under harsh environmental conditions and handle diverse material specifications. The emphasis on localized service and spare parts availability is a key purchasing criterion in this region, influencing vendor selection heavily. The sheer volume of demand and the continuous commissioning of new pipe extrusion plants ensure that APAC will contribute the largest share to the global pipe coiler revenue pool for the foreseeable future, making it the strategic focus area for global machinery suppliers.

- North America Market Maturity: The North American market is characterized by high levels of automation and a focus on premium, energy-efficient machinery. Demand is steady, largely driven by the replacement of aging municipal infrastructure, particularly lead and cast iron pipes, with modern plastic alternatives in line with stringent environmental and health regulations. The market growth here is less about capacity expansion and more focused on technological replacement, with customers upgrading to Industry 4.0 compatible coilers featuring integrated diagnostics and minimal manual intervention.

The telecommunications sector, particularly the ongoing deployment of 5G networks requiring extensive fiber optic cabling and protective conduit, is a vital demand driver in the US and Canada. Pipe manufacturers in this region demand coilers with the highest levels of precision and integration, often requiring machines certified to strict safety and performance standards. High labor costs necessitate investment in fully automatic coil handling and strapping solutions integrated downstream of the coiler, minimizing the need for human operators.

Competition in North America primarily revolves around technological superiority, machine reliability, and comprehensive service packages. Leading manufacturers leverage local assembly and service centers to provide rapid support, differentiating themselves based on lifetime operational cost (TCO) rather than initial purchase price. The preference for large diameter and high-weight coils due to long-distance transport logistics also influences machine design requirements in this highly sophisticated market.

- Europe Market Sophistication: Europe represents a mature market demanding high-specification, technologically advanced, and ecologically compliant pipe coiling systems. The focus is heavily placed on energy efficiency, precision engineering, and the integration of sustainability principles into the manufacturing process. European regulations regarding material traceability and waste reduction push manufacturers to adopt coilers that offer highly accurate cutting and minimal material waste during the winding process.

The market is primarily driven by renewal projects, stringent environmental standards, and specialized applications such as district heating networks utilizing multi-layer or pre-insulated pipes, demanding customized coiling solutions. Western European countries, including Germany and Italy, host significant manufacturing centers for coiling equipment, driving innovation in areas like modular design and rapid changeover capabilities. The demand profile favors highly flexible machines that can handle short runs of specialized products efficiently alongside large volume production.

Eastern Europe is experiencing higher growth rates due to modernization and harmonization with EU infrastructure standards, leading to new plant constructions and subsequent equipment procurement. European customers prioritize long-term reliability and low operational noise, often incorporating features like acoustic dampening into their machinery specifications. Vendor selection is strongly influenced by compliance with CE marking and proven records of machine longevity and performance consistency.

- Latin America (LATAM) Development: The LATAM pipe coilers market is characterized by fluctuating economic stability but possesses significant long-term potential fueled by ongoing urbanization and the expansion of basic utility infrastructure. Countries like Brazil, Mexico, and Chile are making substantial investments in water and sanitation projects, boosting demand for medium-capacity HDPE and PVC pipe coilers. Market procurement is often cost-sensitive, leading to strong competition from suppliers offering robust, yet affordable, semi-automatic and automatic systems.

The challenge in LATAM lies in economic volatility and logistics complexities, which can delay or reduce capital expenditure on machinery. However, the region’s vast agricultural sector provides a consistent source of demand for irrigation piping, driving steady sales of entry- to mid-level coiling equipment. International vendors often partner with local distributors to navigate customs and provide essential on-site installation and maintenance support.

As economies stabilize, there is a gradual shift towards automated solutions to improve efficiency and maintain quality standards necessary for exporting finished pipes. The increasing influence of international construction standards further encourages local pipe producers to invest in reliable coiling technology that ensures precise product specification and documentation, enhancing the overall maturity of the market over the forecast period.

- Middle East and Africa (MEA) Emerging Potential: The MEA market for pipe coilers is experiencing substantial growth, particularly in the Gulf Cooperation Council (GCC) countries due to massive development projects related to oil and gas infrastructure, water desalination, and smart city construction (e.g., NEOM in Saudi Arabia). These projects require vast quantities of large-diameter plastic pipes, driving demand for high-capacity, specialized coilers.

In Africa, the market is emerging, driven by humanitarian and development aid focused on improving water access and sanitation in densely populated areas. This generates demand for durable, often medium-capacity, machinery suitable for operational use in remote locations. The market is fragmented, with localized needs varying significantly between the resource-rich Middle East, focusing on specialized and large-scale coilers, and the developing African nations, focusing on rugged, reliable, and simpler automatic models.

Extreme climate conditions in the Middle East necessitate coilers designed for high-temperature operation, often requiring reinforced cooling systems and robust mechanical components to ensure machine longevity. Key purchasing decisions in the MEA region are heavily influenced by the vendor's ability to provide comprehensive after-sales service and rapid deployment of technical teams, given the complexity of international logistics and customs procedures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pipe Coilers Market.- Rosendahl Nextrom GmbH

- Wafios AG

- Bartell Machinery Systems, LLC

- Krah Pipes GmbH & Co. KG

- Bausano & Figli Spa

- SICA SpA

- Gnata SRL

- Sikora AG

- Micro-Tech

- Padi Machine

- Unicor GmbH

- Maillefer Extrusion Oy

- Plas Mec S.r.l.

- Tecnomac Plastic Systems

- Zoladz Group

- Qingdao Jinfeng Plastic Machinery Co., Ltd.

- Zhejiang Aike Pipe Machine Co., Ltd.

- Battenfeld-Cincinnati Group

- KraussMaffei Technologies GmbH

- Rolf Schlicht GmbH

Frequently Asked Questions

Analyze common user questions about the Pipe Coilers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of automatic pipe coilers over semi-automatic systems?

Automatic pipe coilers offer superior throughput, consistent winding quality, and significantly reduced labor requirements compared to semi-automatic systems. They integrate advanced features like non-stop dual-head operation, automatic cutting, and integrated strapping, minimizing downtime and maximizing overall equipment efficiency (OEE), making them essential for high-volume production lines.

How does pipe material impact the choice of a coiling machine?

Pipe material fundamentally dictates coiler specification, primarily affecting tension control and cooling requirements. HDPE pipes require specialized tension systems due to their flexibility and memory effect, while PVC may require faster cooling before coiling. High-capacity coilers must be robustly designed to handle the weight and rigidity of heavy-duty materials effectively without distortion.

What is the role of Industry 4.0 and IIoT in modern pipe coiling operations?

Industry 4.0 integration enables modern coilers to utilize IIoT sensors for real-time data collection on speed, tension, and component health. This data facilitates cloud-based monitoring, remote diagnostics, and AI-driven predictive maintenance, moving operations towards self-optimizing, unmanned manufacturing environments that drastically reduce operational expenditures and increase uptime.

Which end-use industry drives the highest demand for large-capacity pipe coilers?

The Construction and Infrastructure sector, specifically for municipal water and sewage management projects, drives the highest demand for large-capacity coilers. These applications require large diameter HDPE or PVC pressure pipes that necessitate machinery capable of handling heavy weights (often exceeding 500 kg) and substantial coil dimensions while maintaining precise dimensional stability.

What factors restrain the growth of the Pipe Coilers Market in developing regions?

The primary restraint is the high initial capital investment required for purchasing advanced automatic coiling systems. Furthermore, inadequate technical infrastructure, volatility in local currencies, and a shortage of specialized maintenance personnel capable of servicing complex PLC-driven machinery often pose significant challenges to widespread market adoption in developing regions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager